GB.COOLDX.SI.G.190603

We reserve the right to alter specifications.

4 www.swegon.com

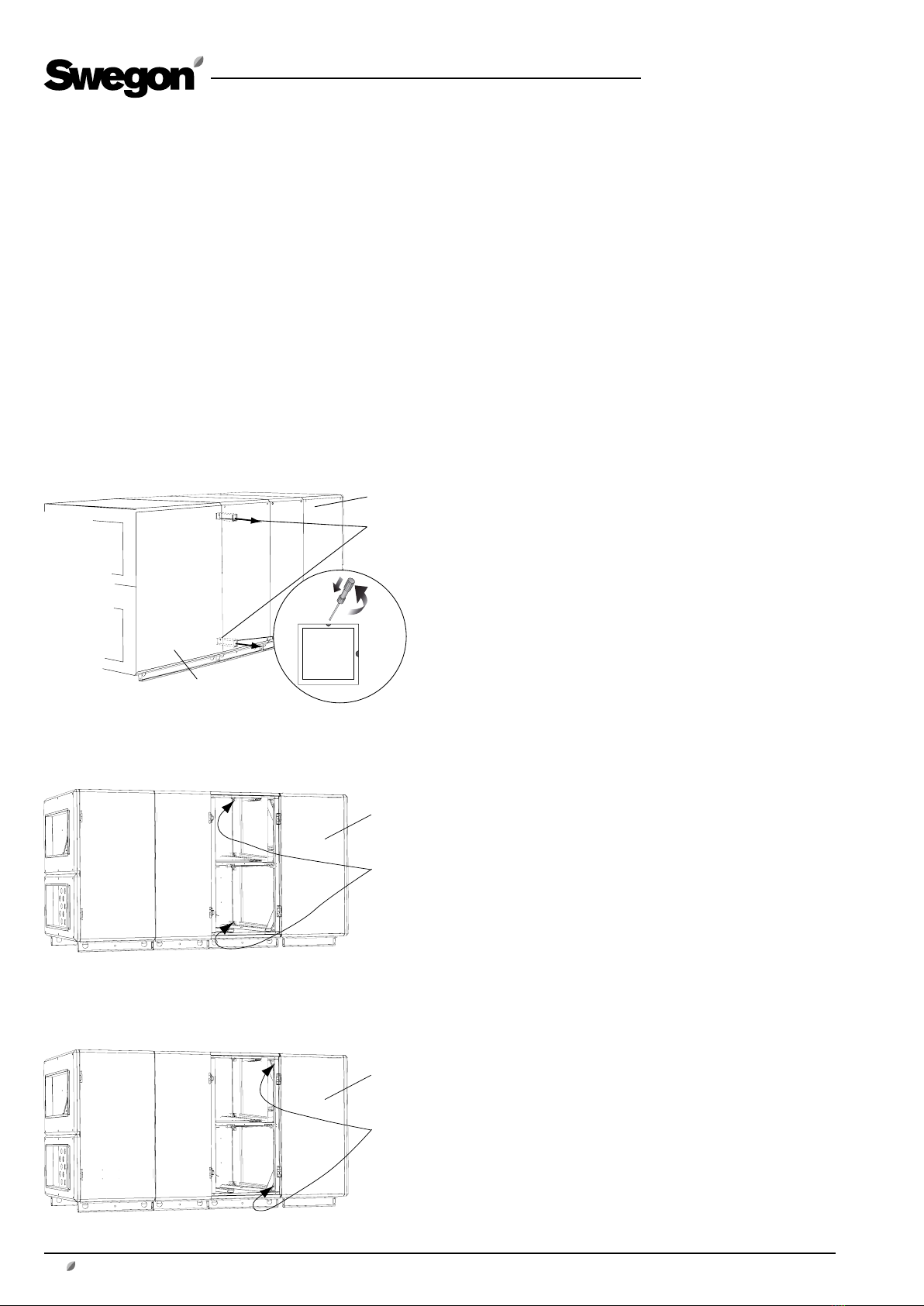

Function

There are two refrigerant circuits in the chiller. The circuits

are separated from one another.

Each circuit is equipped with its own finned condenser,

finned evaporator and compressor.

The two compressors are of different capacity, which

makes it possible to regulate the capacity in 3 steps.

COND

VSH2

M1 M2

EVAP

VET1VET2

IPL1IPL2

FD1FD2

COND Condenser

VSH1 Overpressure protection

VSH2 Overpressure protection

B1-1 High pressure sensor

B2-1 Low pressure switch

B1-2 High pressure sensor

B2-2 Low pressure switch

BP1-2 High pressure switch, alarming

BP2-2 High pressure switch, alarming

M1 Compressor

M2 Compressor

M3 Compressor (size 80, cap. var. 3)

EVAP Evaporator

VET1 Expansion valve with thermostat

VET2 Expansion valve with thermostat

IPL1 Sight glass, cooling medium circuit 1

IPL2 Sight glass, cooling medium circuit 2

FD1 Filter dryer

FD2 Filter dryer

B2-2

HP

The gaseous refrigerant is compressed by cooling com-

pressors M1 and M2 and from there flows to condenser

COND, where it is cooled by the extract air and is con-

densed to liquid form.

The gaseous refrigerant flows through expansion valve

VET1 and VET2, where the pressure and the temperature

decrease.

From the expansion valves, the refrigerant advances to

evaporator EVAP, where the refrigerant evaporates and

cools down the outdoor air.

The evaporated refrigerant flows from evaporator EVAP

further to the suction side by the compressors to once

again be compressed.

Regulation

The cooling capacity is regulated in three binary steps by

having one or two compressors in operation.

COOL DX is controlled via a signal, 0 – 10 V.

Step 1: When cooling is needed, Compressor M1 is start-

ed.

Step 2: If more cooling is needed, Compressor M2 starts

and at the same time Compressor M1 stops. An adjust-

able time delay (a step duration of 250 seconds) ensures

that Compressor M2 will not start until Compressor M1 is

operating at full capacity.

Step 3: If even more cooling is needed, Compressor M1 is

restarted and is run at the same time as Compressor M2.

This third cooling step is also delayed by a preset time de-

lay setting. In addition, the restarting time (300 seconds)

for Compressor M1 shall have expired.

If less cooling is needed and the compressors are subse-

quently switched out step-by-step, there will be no delay

between compressors. The restarting time (300 seconds)

for Compressor M1 shall have expired to enable it to start

again in Step 1 after it has been operated in Step 3.

If any compressor is stopped, the restarting time must

expire before a restart can take place. The restart time is

calculated from one start to the next start.

If the pressure in the cooling circuit becomes too low, or

if the pressure in the condenser circuit becomes too high,

the compressor is stopped.

When the restart time has expired, the compressors will try

to restart.

If the pressure increases more, high pressure switches BP1-

2 and BP2-2 will trip and stop the chiller.

Alarms are shown on the hand-held terminal, see separate

instructions for IC208CX control.

Pressure switches BP1-2 and BP2-2 can be manually reset

by pressing a button under each protective sock on the

upper side of the pressure switch. This can be done with-

out removing the protective sock.

1.2 Basic function diagram

B1-2

LP

HP

B2-1

HP

B1-1

LP

HP

BP2-2BP1-2

VSH1

M3