4

RDH 760 L / RDH 760 Z

Dok: 101513D-GB 2020

Never smoke while relling the fuel tank or when

working with the machine or servicing it.

Only store fuel in a container that is specially

constructed and approved for that purpose.

Consumed fuel and oil containers must be taken

care of and returned to the retailer.

Never use your ngers to check for uid leakages.

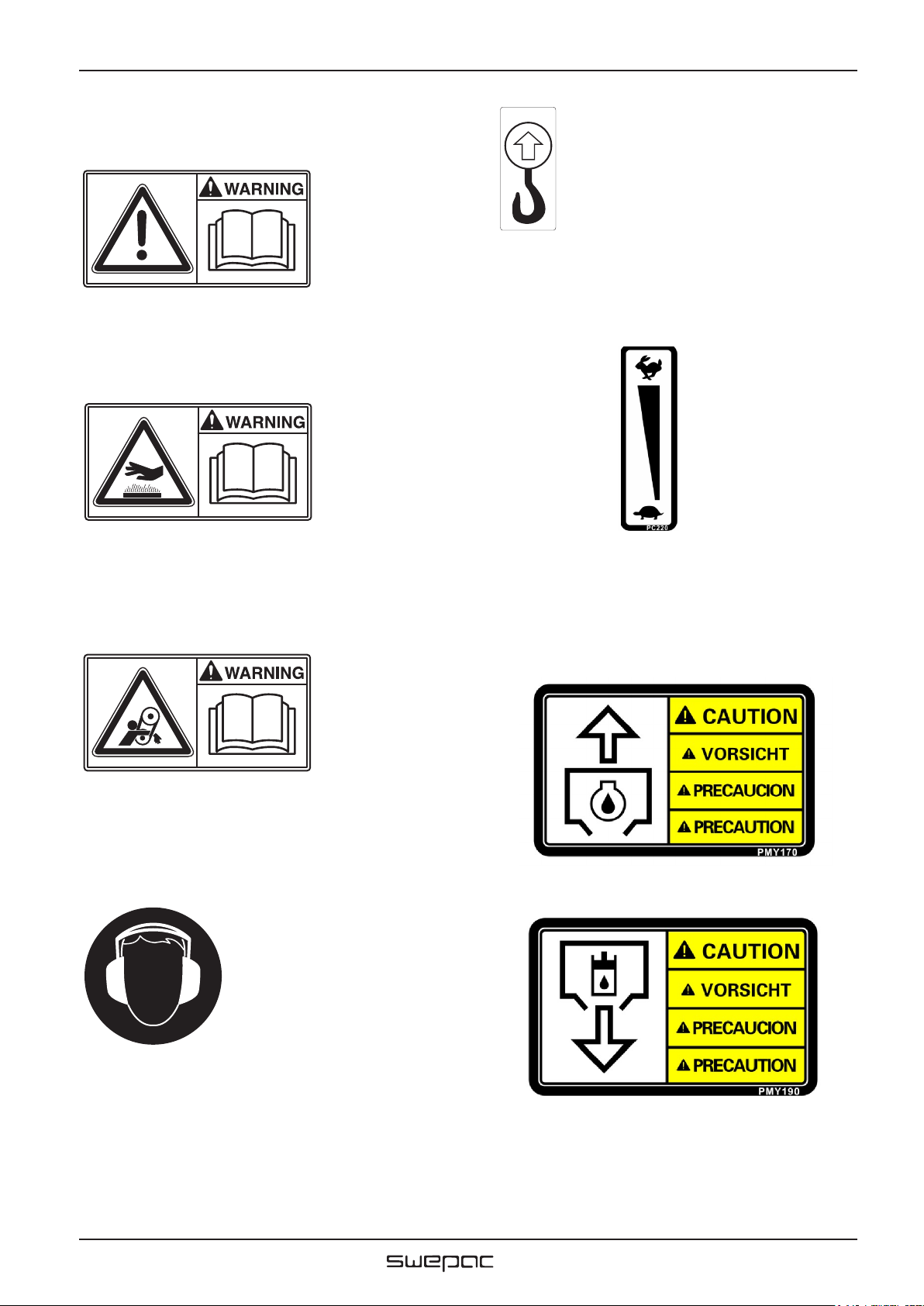

WARNING Unexpected movements

The machine is exposed to heavy strains during

operation. If the machine breaks or gets stuck,

there might be a sudden and unexpected move-

ment that can cause injuries.

Always inspect the machine prior to use. Never

use the machine if you suspect that it is damaged.

Make sure that the handle is clean and free of

grease and oil.

Keep your feet away from the machine. Never sit

on the machine.

Never strike or abuse the machine.

Pay attention and look at what you are doing.

WARNING Dust and fume hazard

Dusts and /or fumes generated or dispersed when

using the machine may cause serious and perma-

nent respiratory disease, illness, or other bodily

injury. Some dusts and fumes created by compac-

tion work contains substances known to cause

respiratory diseases, cancer, birth defects, or other

reproductive problems.

Dust and fumes in the air can be invisible to the

naked eye, so do not rely on eye sight to determine

if there is dust or fumes are the air.

To reduce the risk of exposure to dust and fumes, do

all of the following:

Perform site-specic risk assessment. The risk as-

sessment should include dust and fumes created by

the use of the machine and the potential for distur-

bing existing dust.

Wear, maintain and correctly use respiratory

protection as instructed by your employer and as

required by occupational health and safety regula-

tions. The respiratory protection must be eective

for the type of substance dust contains (if applica-

ble, approved by relevant governmental authority).

Work in a well-ventilated area.

If the machine has an exhaust, direct the exhaust so as to

reduce disturbance of dust in a dust lled environment.

Operate and maintain the machine as recommended in the

operating and safety instructions.

Wear washable or disposable protective clothes at the

worksite. Have a shower and change with clean clothes

before leaving the work site to

reduce exposure of dust and fumes to yourself and others

in the vehicle, at home or other areas.

Avoid eating, drinking, and using tobacco products in

areas where there is dust or fumes.

Wash your hands and face thoroughly as soon as possible

upon leaving the site, and always before eating, drinking,

using tobacco products, or making contact with other per-

sons.

Including the “Occupational Health & Safety Regula-

tions”, comply with all applicable laws and regulations of

the local country.

Participate in air monitoring, medical examination pro-

grams, and health and safety training programs provided

by your employer or trade organizations and in accor-

dance with occupational health and safety regulations and

recommendations. Consult with physicians experienced

in relevant occupational medicine.

Work with your employer and trade organization to reduce

dust and fume exposure at the work site and to reduce the

risks. Eective health and safety programs, policies and

procedures for protecting

workers and others against harmful exposure to dust and

fumes should be established and implemented based on

advice from health and safety experts.

Consult with experts.

DANGER Exhaust gas hazard

The exhaust gas from the machine’s combustion engine

contains carbon monoxide which is poisonous and have

chemicals which may cause cancer, birth defects, or other

reproductive problems. Inhalation of exhaust fumes can

cause serious injury, illness, or death.

Never inhale exhaust fumes.

Ensure good ventilation (extraction of air by fan if

necessary).