Before You Start

·WARNING: Please read these instructions through carefully before you start the

installation. Incorrect product installation may result in serious product failure in use.

Always follow the instructions and retain them for future use.

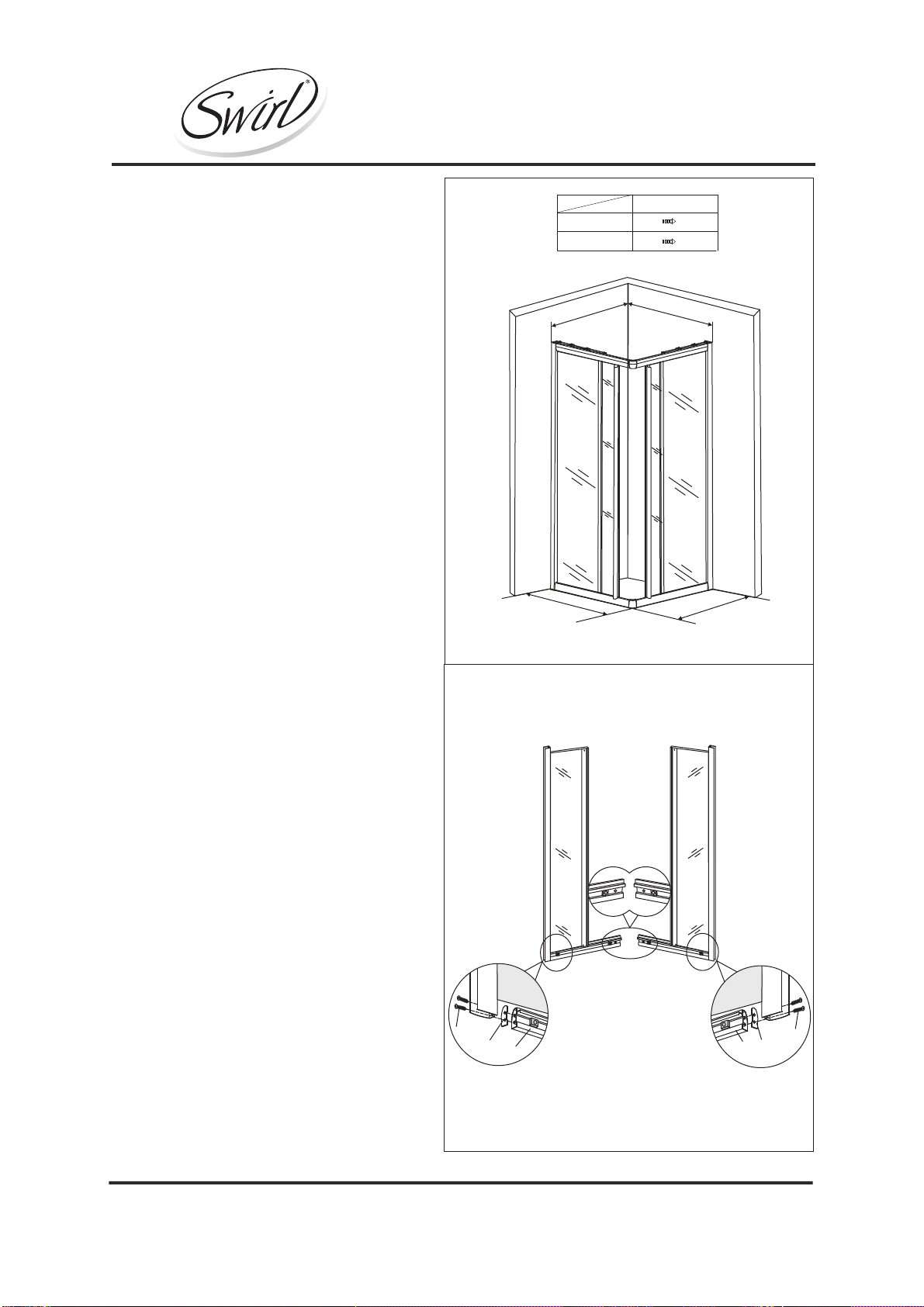

·The enclosure is designed to allow for 20mm adjustment when fitted to "out of true

walls".

· The thickness of the tiles used will affect the overall position of the enclosure on the

tray.

·When you are ready to start, make sure you have the right tools to hand,

plenty of space and a clean dry area for assembly.

·Two people are required for assembly. Please note that although these

instructions are comprehensive, it is always recommended that a technically

competent installer should undertake installation.

·Ensure that the enclosure is fitted to a level tray or floor and vertical walls.

·Please note: The wall plugs included with this product are suitable for solid walls

only. Plasterboard or stud walls may require specialized fixings which are not

provided. (Always ensure that the wall plugs or fittings are correct for the wall type.)

·Caution: Please handle all glass with care. Any damage to the edges, or

scratches to the surface that occur during assembly or normal use can cause

the glass to break suddenly. Tempered glass will shatter into very small pieces

that will still have sharp edges.

·Caution: Care should be taken when drilling into walls to avoid hidden pipes or

electrical cables.

·When working near a tray or bath, ensure that the waste is covered so that small

parts do not fall down it.