8

IMPORTANT!

Mix only enough fuel for your immediate

needs! If fuel must be stored longer than 30

days and Swisher E4 Engine Oil with fuel

stabilizer is not used, it should rst be treated

with a fuel stabilizer such as STA-BIL™.

Mixing Fuel

1.

Place the trimmer on a flat, level surface.

2. Clear any dirt or other debris from

around the fuel filler cap.

3. Remove the fuel cap, and fill the tank

with clean, fresh fuel.

4. Reinstall the fuel filler cap and tighten

firmly.

Filling the Fuel Tank

CAUTION!

This engine is designed to operate on

a 50:1 mixture consisting of unleaded

gasoline and ISO-L-EGD or JASO FC

class 2-cycle mixing oil only. Use of

non-approved mixing oils can lead to

excessive carbon deposits.

CAUTION!

Never use any type of gasoline con-

taining more than 10% alcohol by vol-

ume! Some types of gasoline contain

alcohol as an oxygenate. Oxygenated

gasoline may cause increased operat-

ing temperatures. Under certain con-

ditions, alcohol-based gasoline may

also reduce the lubricating qualities of

some 2-cycle mixing oils. Generic oils

and some outboard oils may not be

intended for use in high-performance

engines, and should never be used in

your Swisher engine.

nUse only fresh, clean unleaded gasoline

with a pump octane of 87 or higher.

nMix all fuel with a 2-cycle air-cooled mix-

ing oil that meets or exceeds ISO-L-EGD

and/or JASO FC classified oils at 50:1

gasoline/oil ratio.

Examples of 50:1 mixing quantities

n

1 gallon of gasoline to 2.6 oz. mixing oil

n

5 liters of gasoline to 100 ml. mixing oil

Swisher E4 Engine Oil is a registered JASO

FC classified oil and also meets or exceeds

ISO-L-EGD performance requirements.

Swisher E4 engine oil is recommended for

use in all Swisher low emissions engines and

also includes a fuel stabilizer.

WARNING!

Minimize the Risk of Fire

NEVER smoke or light res near the

engine.

ALWAYS stop the engine and allow

it to cool before refueling. Avoid over-

lling and wipe off any fuel that may

have spilled.

ALWAYS inspect the unit for fuel

leaks before each use. During each

rell, check that no fuel leaks from

around the fuel cap and/or fuel tank.

If fuel leaks are evident, stop using the

unit immediately. Fuel leaks must be

repaired before using the unit.

ALWAYS move the unit at least 10

feet (3 meters) away from a fuel stor-

age area or other readily ammable

materials before starting the engine.

NEVER place ammable material

close to the engine mufer.

NEVER operate the engine without

the mufer and spark arrester screen

in place.

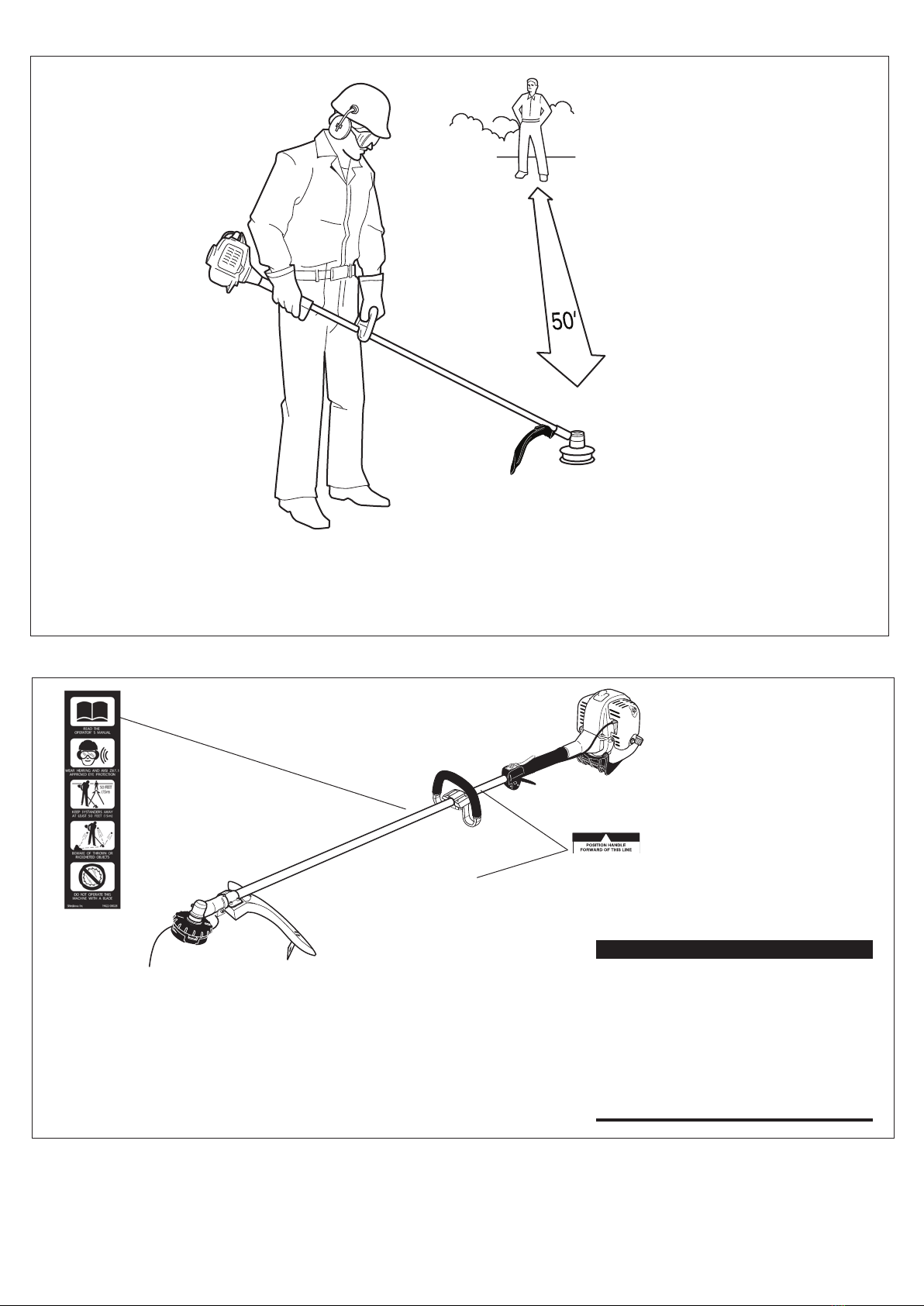

1. Turn the trimmer over so that the gearcase

output shaft faces UP. See Figure 5.

2. Remove and discard the plastic retain-

ing plug.

3. Position the tool holder as shown, and

slide the holder onto the output shaft.

See Figure 5.

4. Rotate the tool holder and shaft until the

notch in the holder aligns with the notch

on the gearcase flange, and use the long

end of the hex wrench to lock the output

shaft in position. See Figure 6.

5. While holding the hex wrench, thread

the trimmer head onto the output shaft,

turning counter-clockwise.

WARNING!

A standard grass trimmer

machine should NEVER be oper-

ated with blade-type attachments.

IMPORTANT!

The trimmer head has a left-hand thread.

Turn the trimmer head counter-clockwise

to install.

6. Using hand pressure only, tighten the

trimmer head firmly on the gearshaft.

See Figure 6.

7. Remove the hex wrench.

Output shaft

Tool holder

Position

attachment

so that the

gearcase

output shaft

faces UP

Figure 5

Hex wrench

Turn trimmer head

COUNTERCLOCKWISE to tighten

Figure 6

Install the Trimmer Head