A A

B

C

D E

G

I

F H

IMPORTANT SAFEG UARD S

When using electrical appliances, basic safety precautions should

always be followed, including the followings:

Re ad al l i nstru cti on s .

To protect against risk of electric shock, do not immerse cord,

plug or base in water or other liquid.

Close supervision is necessary when any appliance is used by or near children.

Never leave an appliance unattended when in use.

Unplug as not in use, before putting on or taking off parts, and before cleaning.

To unplug, grasp plug and pull straight out from outlet. Never pull cord.

Avoid contacting moving parts. Keep fingers or objects other than food out of the Chute.

Do not operate any appliance with a damaged cord or plug or after the appliance malfunctions

or is dropped or damaged in any manner. Return appliance to the nearest authorized service

facility for examination, repair, or adjustment.

The use of attachments not recommended or sold by the appliance manufacturer may cause fire,

electric shock, or injury.

Do not operate or place any part of this appliance on or near any hot surfaces

(such as gas or electric burner or in a heated oven.)

Do not let cord hang over edge of table or counter, or touch hot surfaces.

Be sure to turn switch to the OFF position after each use.

Make sure the motor stops completely before disassembling.

Do not operate this appliance in the presence of explosive and or flammable fumes.

Do not use any accessories or parts from other manufacturers or NOT by Xin Yu Proposal

accessories or parts. The warranty will expire, if you use such accessories or parts.

SA F ETY AND I NST R UCT IONS

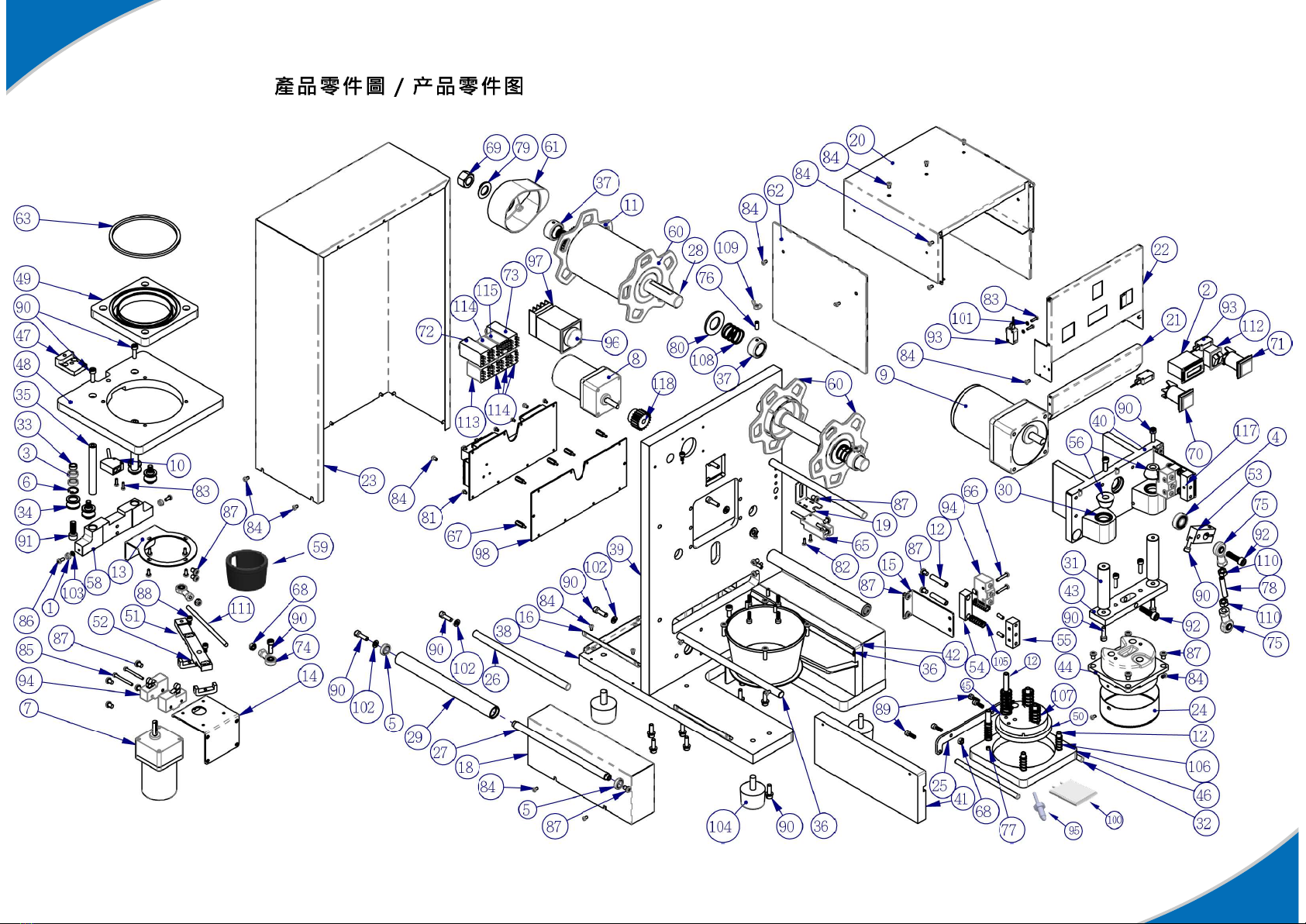

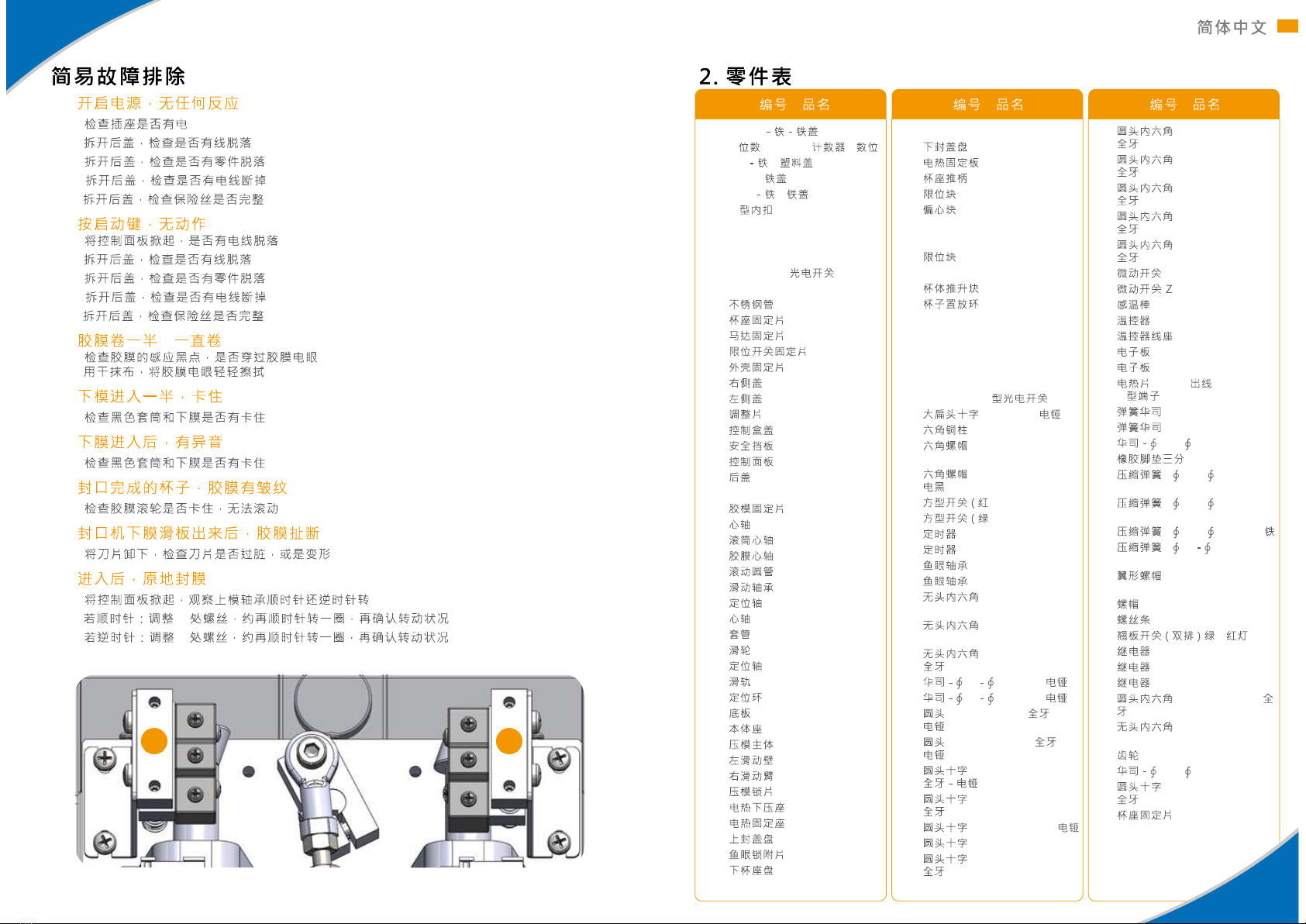

PARTS DESCR IPT ION:

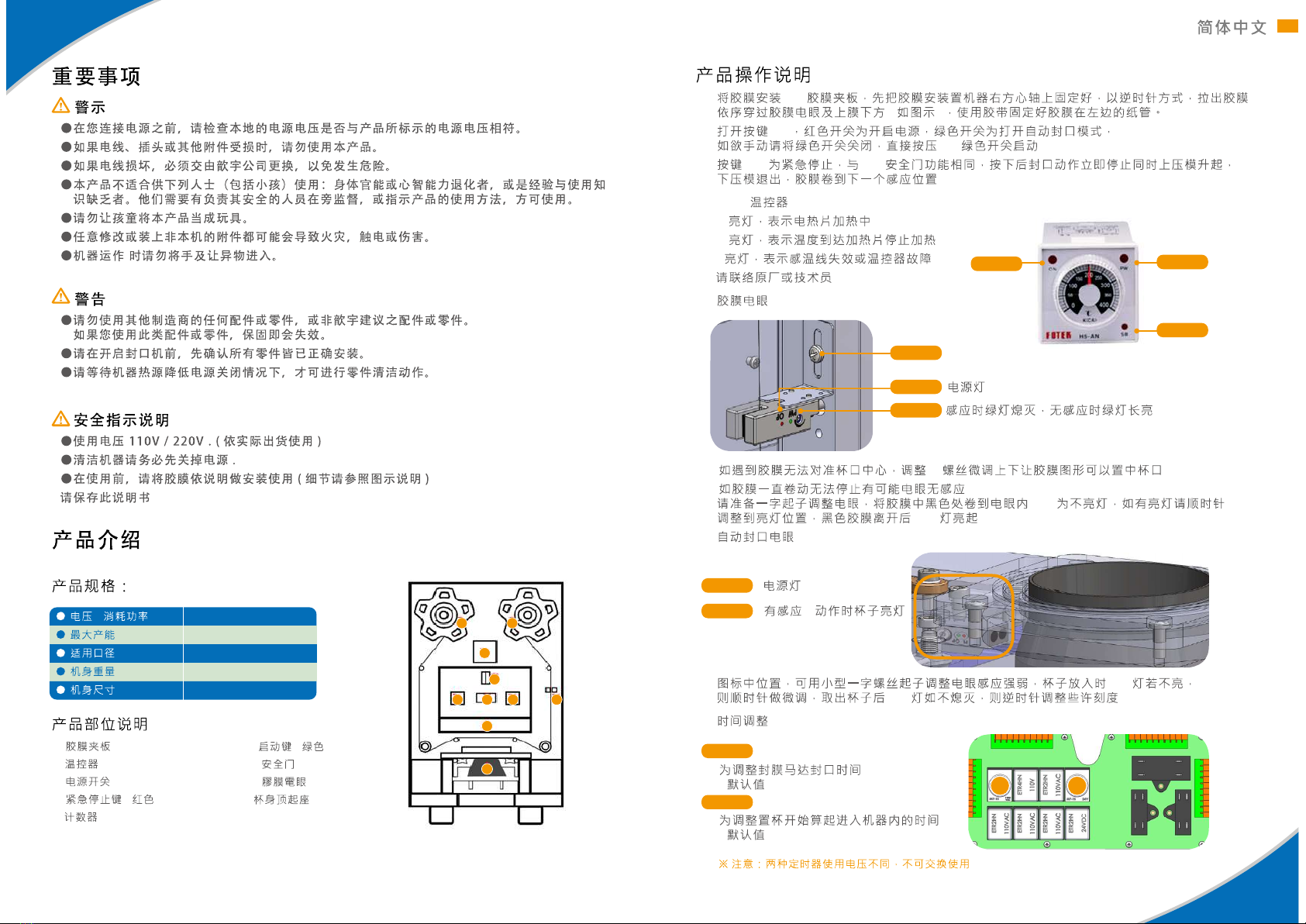

SP ECIFIC AT IONS:

F. Start button (green)

G. Safety Door

H. Film electronic eyes controller

I. Raise the cup base

A. Film clip

B. Temperature controller

C. Power Switch

D. Emergency stop button (red)

E. Counter

Power

Production capacity

Max cup size

Net weight

Product size

110V/ 220V, 220W

600 cups / hr

95 mm ~ 142 mm

35 kgs

320 x 420 x 600 mm

OP E RATI ON:

1. Film installation (A) film clip, please insert film at right side of A, and fixed it by counterclockwise,

after then please pull out the film thought H film electronic eyes controller to left side of A, and

fixed it. Please follow up instruction by drawing of parts description.

2. Turn on button (C), the red button is power switch, the green button is change to automatic

sealing mode, if you like to have manual control, please turn off the green button.

3. Button (D) is an emergency stop, and (G) is also emergency stop function.

4. Temperature control

ON - Turn on, machine is heating

PW - Turn on, stop to operation.

SB - Turn on, error code, please contact us.

5. Film electronic eyes controller

a. If film cannot be aligned with the center of the cup, please adjust A screw.

b. If the film can’t stop the operation. It might be film controller without sensor.

Please use "flat-blade" screwdriver, please have PW no light,

when film black point is meet film controller. If PW is light, please adjust to light on.

6. Cup film electronic eyes controller

Please use "flat-blade" screwdriver to adjust sensor, if there is no light on when cup put in,

please adjust sensor, by clockwise, when OP no light on, or counterclockwise,

when OP light on without turn off.

7. Time adjustment

Note: These two kinds of timer use different voltages, it cannot interchangeable.

OP Power on

PW When the green light sensor is off,

green light without sensor

A

PW

ON

SB

OP Power on

PL When light up,

it senses the cup

or machine operation.

A

Is adjust time when sealing motor operation.

(preset is 0.7 seconds)

B

Is adjust time when cup into the machine.

(preset is 0.7 seconds)

A B