EN

Table of Contents

1USER INFORMATION ......................................................................................................................4

1.1 SYMBOLS USED .............................................................................................................................. 4

1.2 SCOPE OF SUPPLY .......................................................................................................................... 4

1.3 IMPORTANT INFORMATION........................................................................................................... 4

1.4 INTENDED USE ............................................................................................................................... 4

2INTERFACE SETTINGS .....................................................................................................................5

3UART ZDC COMMANDS..................................................................................................................5

4GENERAL INFORMATION................................................................................................................5

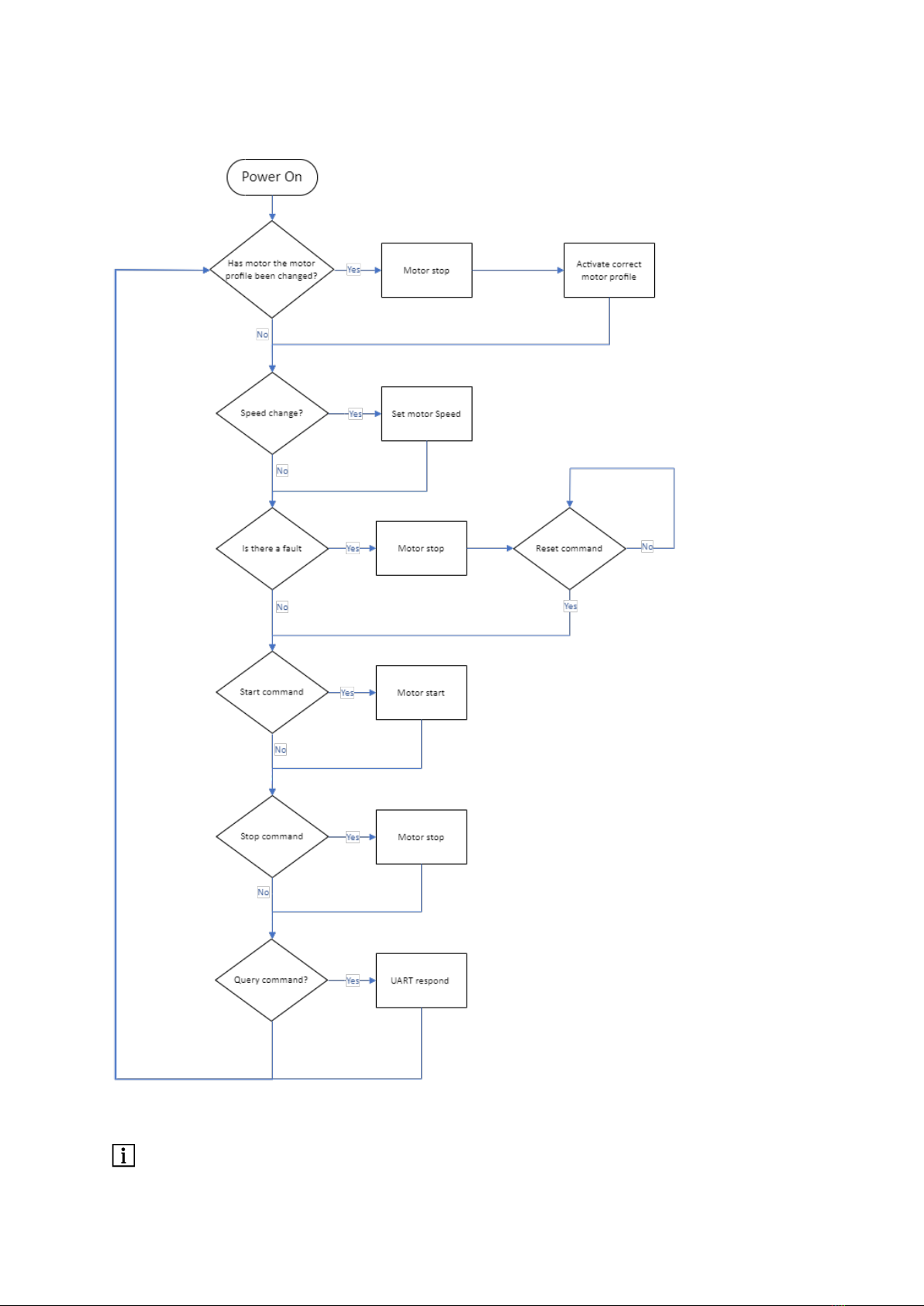

5STATE MACHINE.............................................................................................................................6

6QUERY FIRMWARE/HARDWARE VERSION .....................................................................................7

7QUERY HARDWARE IDENTIFIER......................................................................................................8

8START MOTOR ...............................................................................................................................8

9STOP MOTOR .................................................................................................................................9

10 SET SPEED ......................................................................................................................................9

11 CHANGE MOTOR PROFILE ............................................................................................................10

12 RESET INVERTER...........................................................................................................................10

13 QUERY SPEED...............................................................................................................................11

14 QUERY STATUS.............................................................................................................................12

15 QUERY INTERNAL STATUS............................................................................................................13

16 QUERY POWER.............................................................................................................................14

17 QUERY BUS VOLTAGE...................................................................................................................15

18 QUERY CURRENT..........................................................................................................................16

19 QUERY MOTOR TEMPERATURE....................................................................................................17

20 QUERY INVERTER TEMPERATURE.................................................................................................18

21 QUERY NAME...............................................................................................................................19

WARRANTY CONDITIONS.....................................................................................................................20