We’re pleased to welcome you to a global family of athletes embracing more comfortable, more effective time trailing positions. Sync

Ergonomics strongly recommends the installation of your Sync components to be undertaken by a qualified bicycle mechanic,

experienced with time trial and triathlon bicycles. Irrespective of your level of mechanical experience, please read the following guide

as it contains information vital for correct setup and use.

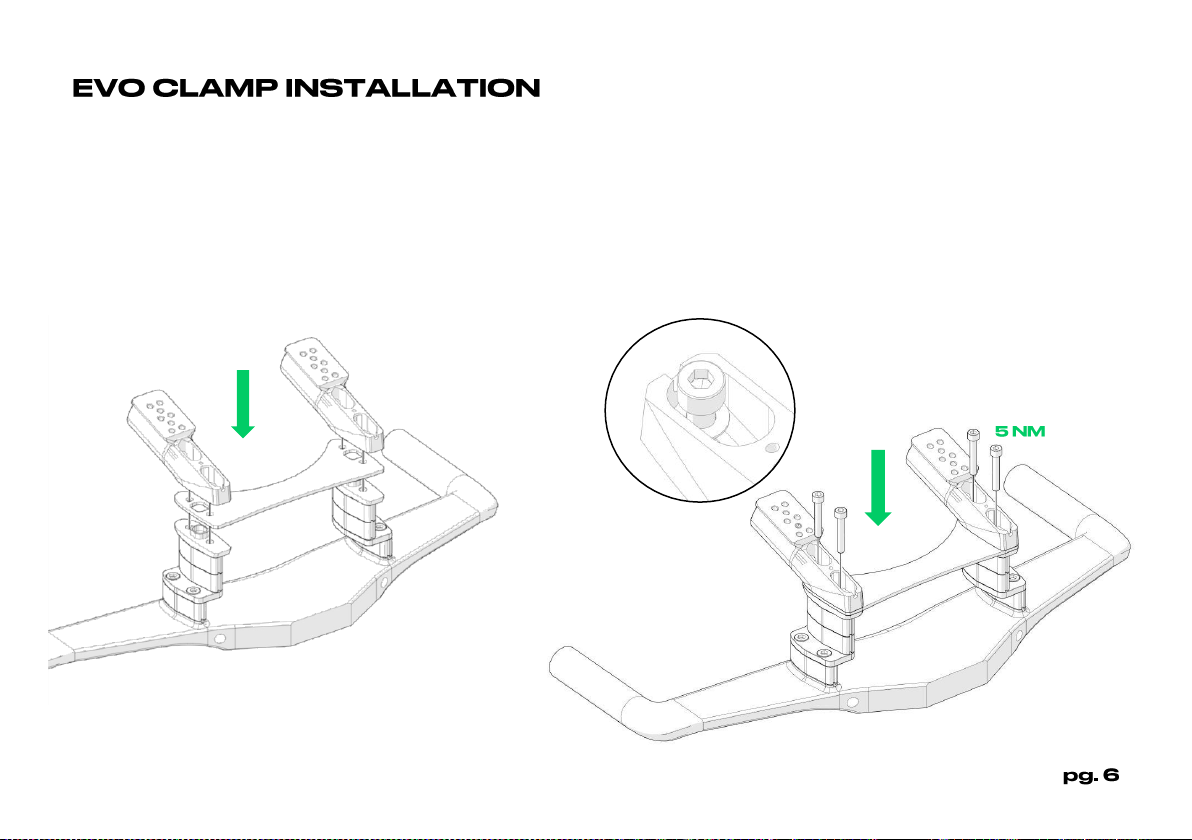

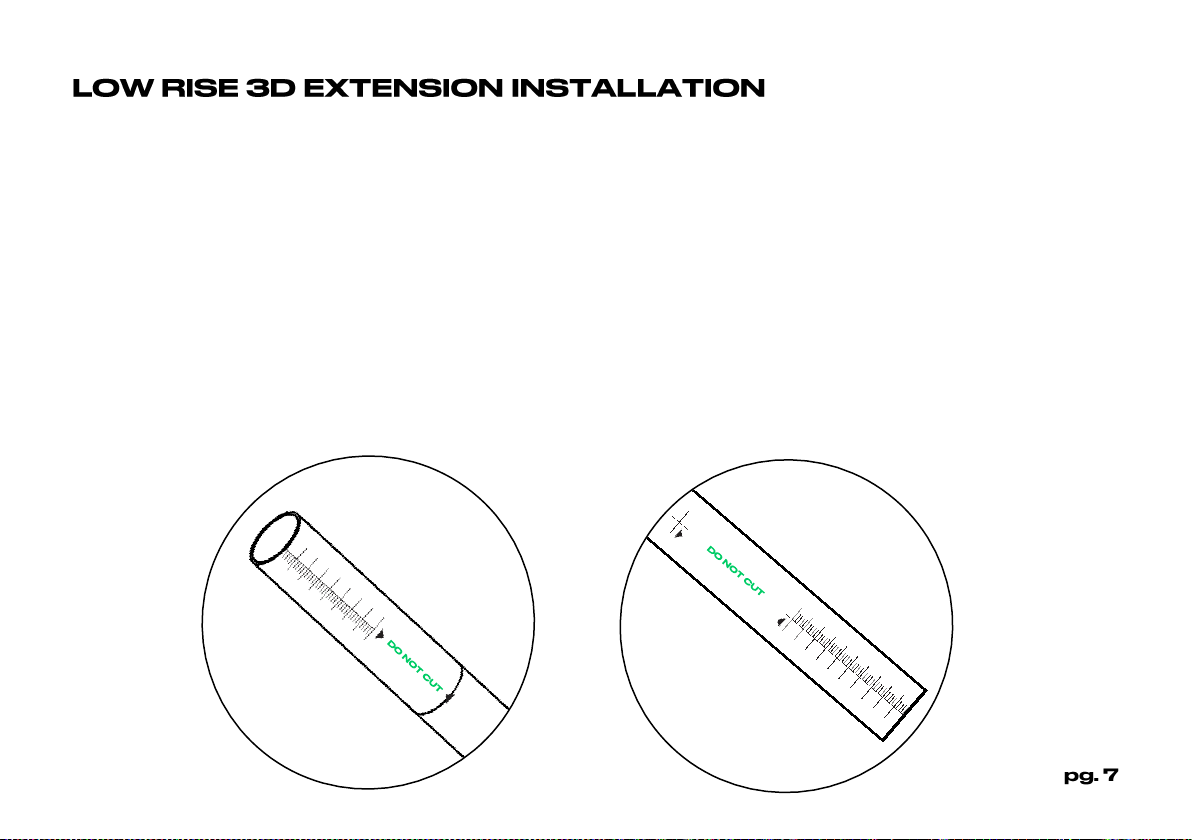

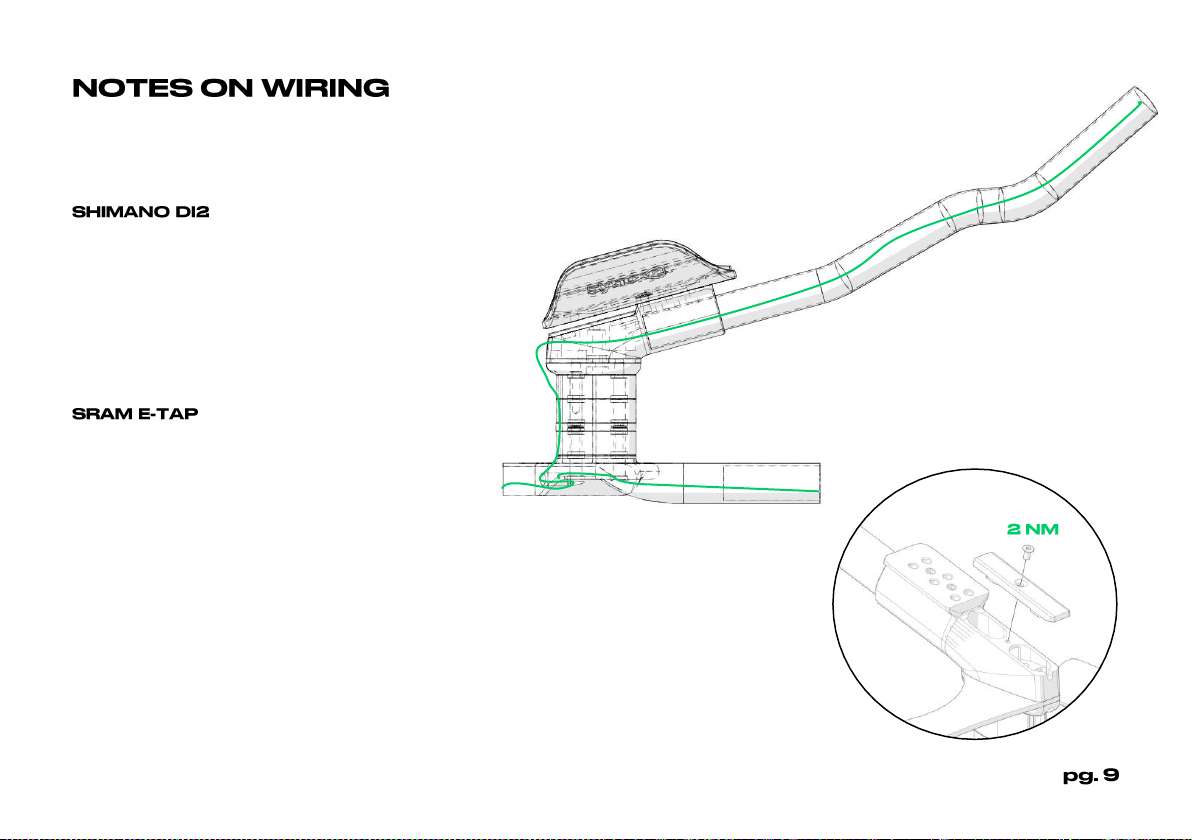

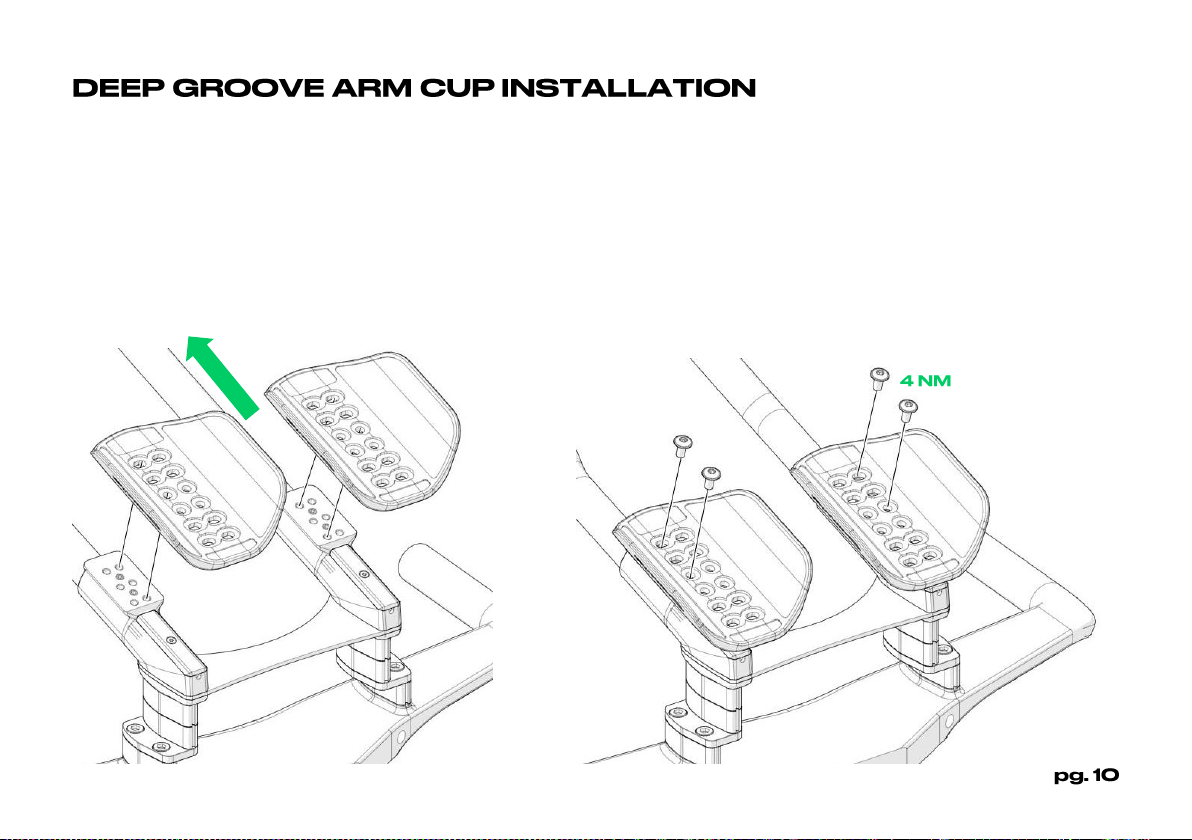

This document has been prepared to guide you through the assembly of your Project 0.2 EVO (EVO) ecosystem. Care must be taken

during the installation process to ensure proper function and ongoing maintenance must be performed to ensure longevity of your Sync

Ergonomics components.

WARNING: In order to be installed correctly the components of Project 0.2 EVO require specialised knowledge of a time trial bicycle. It is recommended that

installation should be performed by a qualified bicycle mechanic. Improper assembly of any of the components of EVO could cause damage to the

product(s) and/or bicycle, may lead to loss of control of the bicycle, and may lead to personal injury, or in severe cases even death. Sync Ergonomics

assumes no responsibility for improper assembly and installation of the product(s).

WARNING: Please have your bicycle and Sync Ergonomics products regularly inspected for possible damage from use, especially from instances such as

accidents, crashes, and/or impact that occurs with travel. In the event of an accident, crash and/or impact in travel, it is strongly recommended you stop

using your bicycle immediately and take your bicycle to a professional bicycle mechanic for inspection to ensure proper function and safety. In the case

of damage, replace affected parts immediately. Even when no damage is visible, there may be internal damage to the integrity of a component. Failure

to replace damaged parts could result in loss of control, and may lead to personal injury, or in severe cases even death. Sync Ergonomics assumes no

responsibility for improper maintenance and inspection of the product(s).

Sync Ergonomics components are free from materials and manufacturing defects for a period of 12 months starting from the original

purchase date, unless otherwise stated in our warranty policy, detailed on our website at www.syncergonomics.com. This warranty is

non-transferable and only applicable to the original customer who purchased this product and this product only. Any modifications to

the product, other than for its original intended use, such as drilling, will effectively and immediately void the warranty.

For more information on our warranty policy and instructions for completing a warranty claim, please visit our website for full details at

www.syncergonomics.com.