2

Field of application

The connectionCenter 3228 All-in-one is used as the basis

for refillable cartridges.

It supplies either softened, fully demineralised or deminera-

lised water with pH value stabilisation for heating systems

in accordance with VDI Guideline 2035 Part 1 and protects

heating systems against lime deposits.

It is also used to automate the filling process in hot water

heating systems.

The built-in BA backflow preventer according to DIN EN 1717

prevents the heating water from flowing back into the drin-

king water pipe.

In this combination, the direct fixed connection of drinking

water to the heating system is approved according to DIN

EN 1717.

The integrated pressure reducer ensures the correct and

constant pressure of the system.

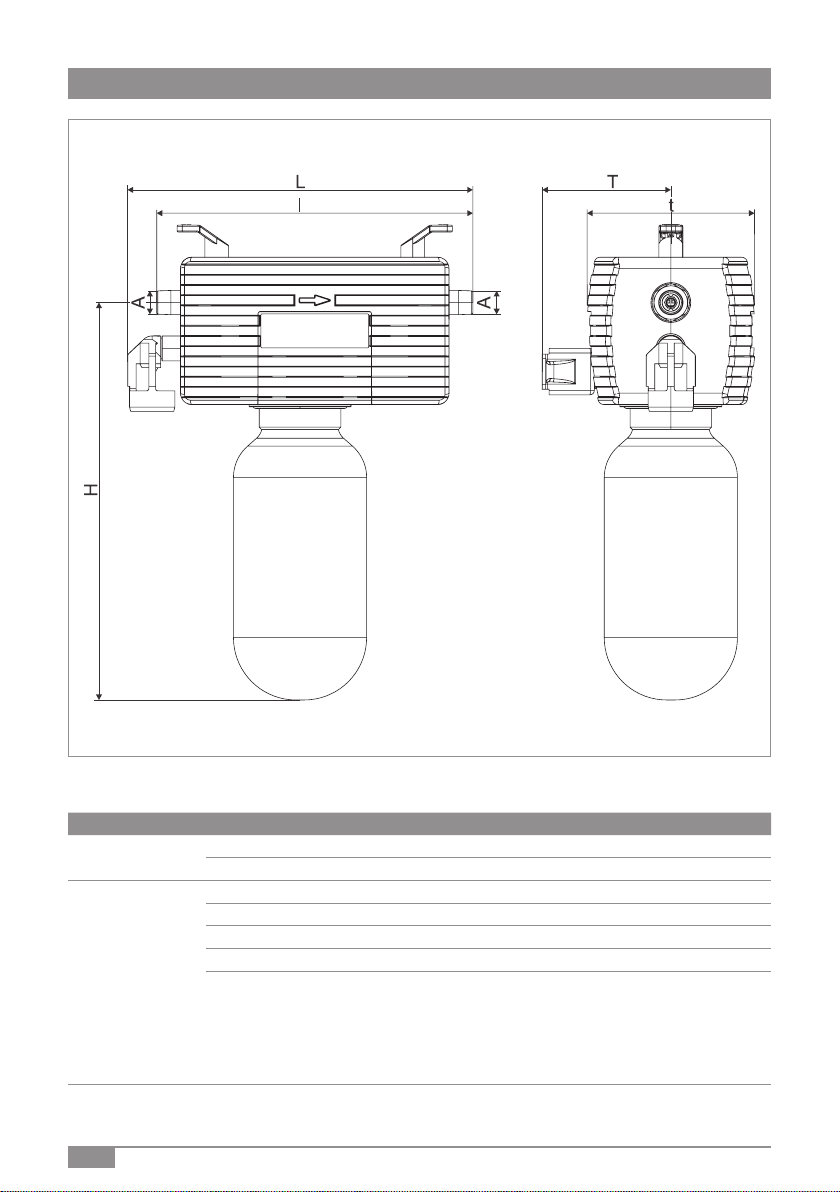

Design

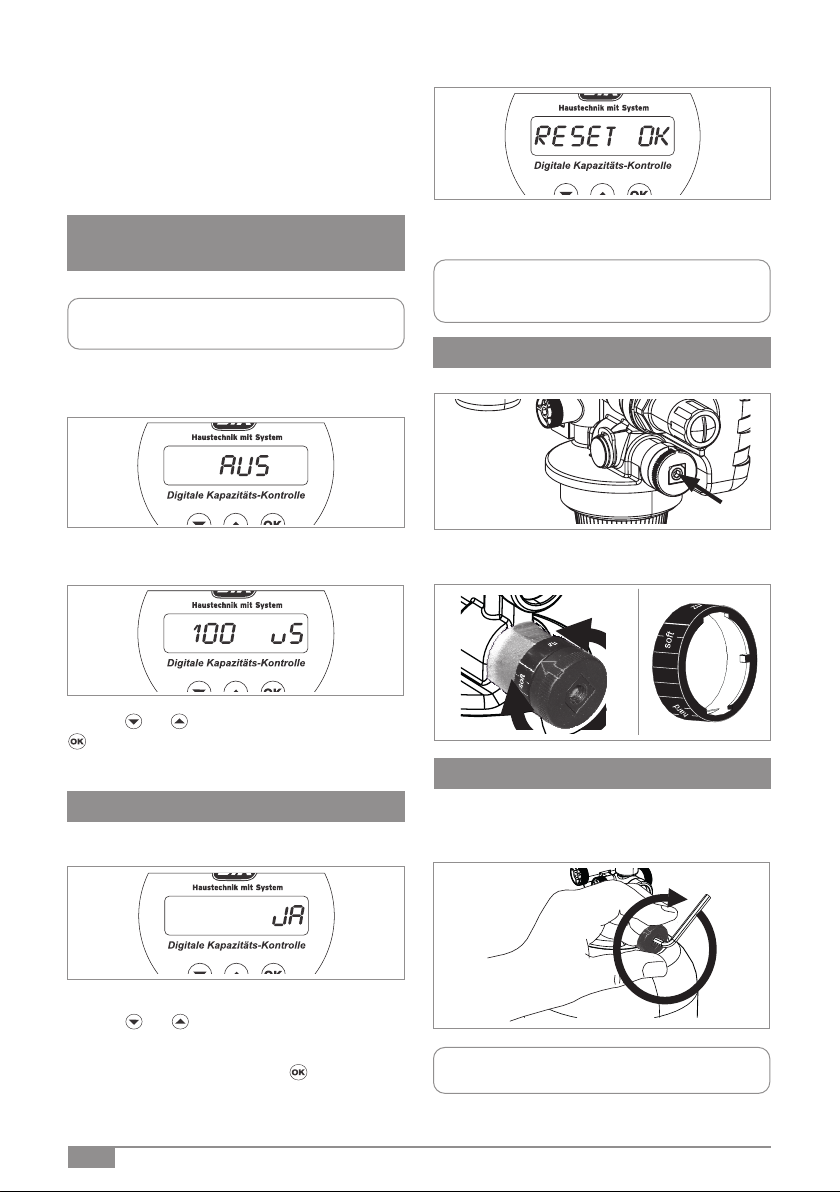

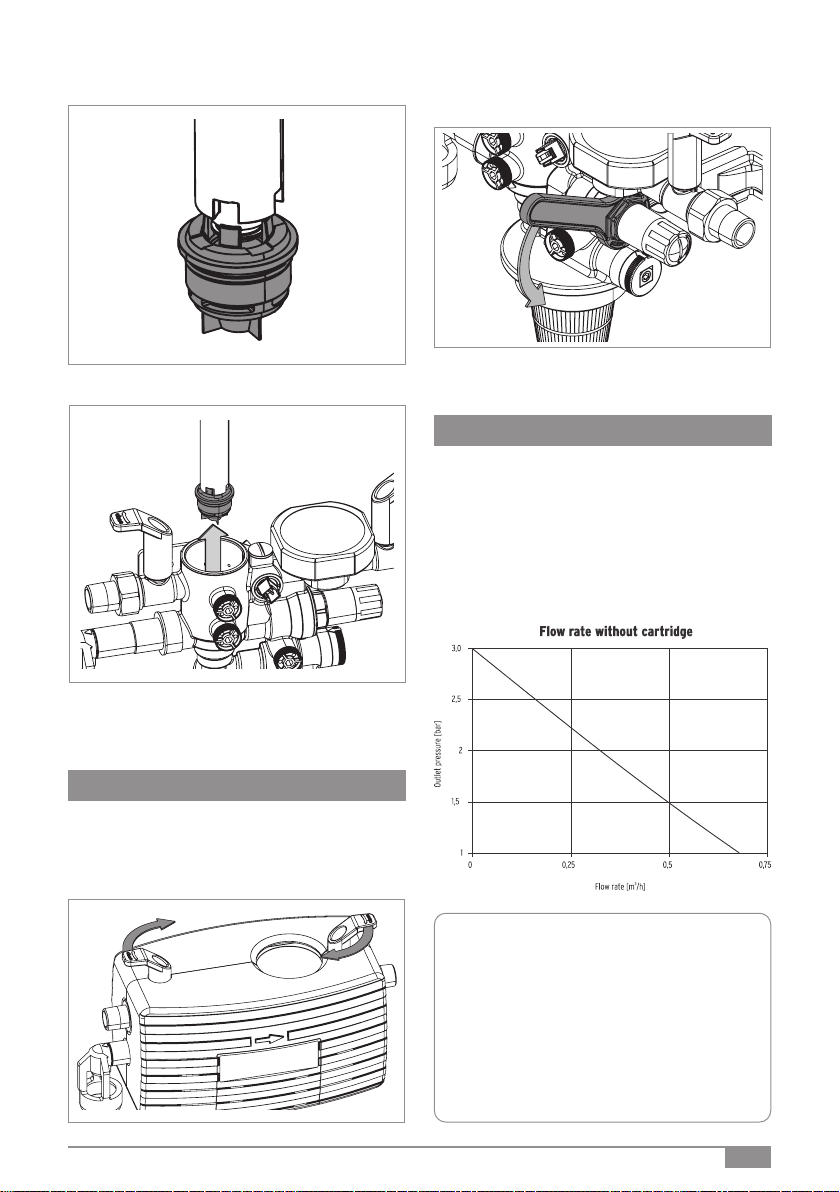

The Connection Center All-in-one contains a digital capacity

control, a shut-off valve on the inlet and outlet side, a sam-

pling connection for soft water, a hardness measuring set, a

wall bracket for installation, a BA backflow preventer accor-

ding to DIN EN 1717, tundish, testing devices and a pressure

reducer. Setting range of the pressure reducer between 1

and 5 bar. Screw connections on both sides.

Please order the already filled cartridges, which are availa-

ble in 2.5, 4, 7, 14 and 30 litre versions for HWE (heating

water softening) HVE (heating demineralisation) and HVE

Plus (pH value stabilisation) and can be refilled with the

corresponding granulate.

A conductivity sensor and pressure sensors are already in-

tegrated in the digital capacity control.

The built-in pressure reducer ensures a constant set output

pressure so that the heating system is protected against

unwanted overpressure during the filling process.

Housing made of pressed brass. Internal parts and tundish

made of high-quality plastic and NBR.

The plastic parts and elastomers in contact with the drin-

king water comply with the KTW guideline of the Federal

Environment Agency.

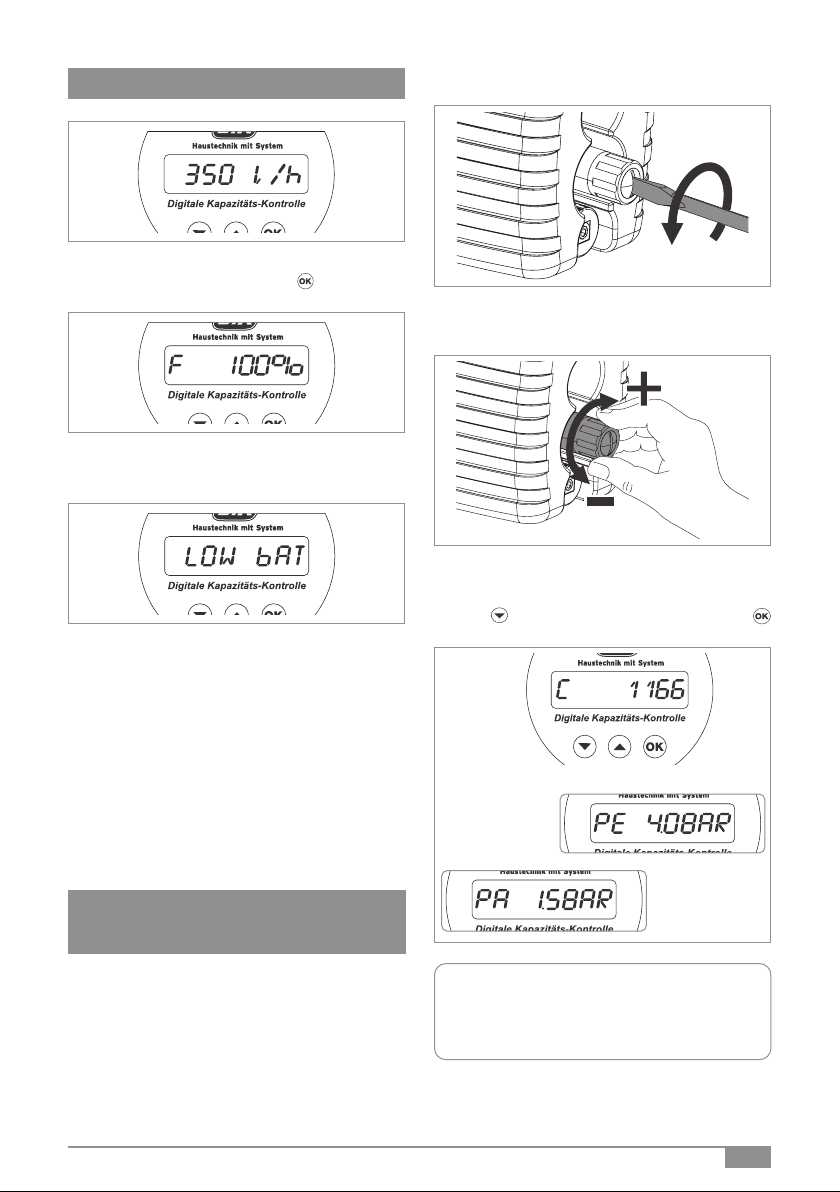

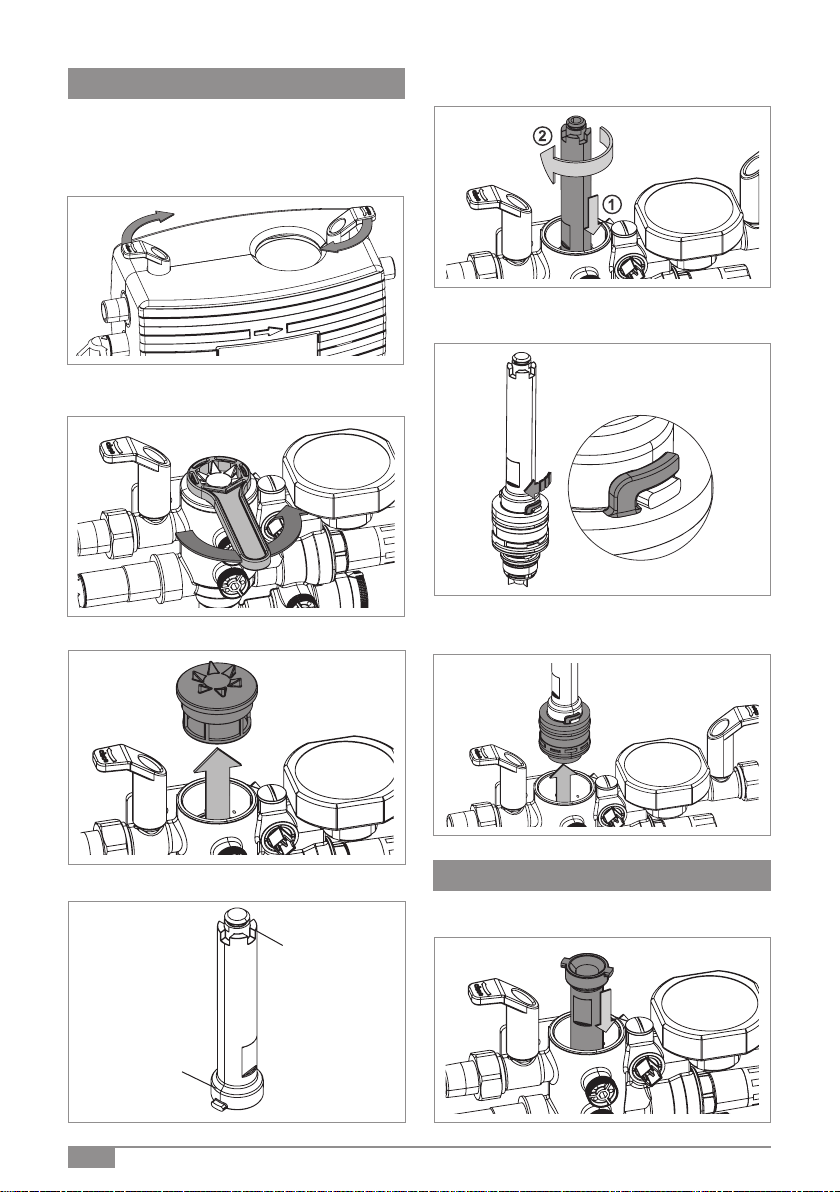

Installation

Mount the wall bracket on the wall.

Make sure that the water supply line is installed in such a

way that stagnation does not occur and that the escaping

water can drain off with a free gradient.

Flush the pipe carefully before installing the connection

centre.

Remove the pressure gauge plug.

Attach the wall bracket at this point of the connection

centre and lock it in place using the screw connections.

Mount the drain valve on the other side.

The wall bracket optionally can be mounted on both

sides.

An easily accessible installation location simplifies mainte-

nance and inspection. Make sure that the location is pro-

tected against flooding and frost and is well ventilated. The

drain pipe must be provided with sufficient capacity.

In order to ensure permanent and perfect functioning, we

recommend the installation of a drinking water filter accor-

ding to DIN EN 13443, Part 1 immediately after the water

meter.

The maintenance intervals of the BA backflow preventer

must be observed. For connecting the tundish to the drai-

nage system, the applicable standard DIN EN 12056 must be

observed.