Table of Contents

1. Related Manuals ........................................................................................ 1

2. Terms and Definitions ............................................................................... 2

3. Remarks ..................................................................................................... 3

4. Overview .................................................................................................... 5

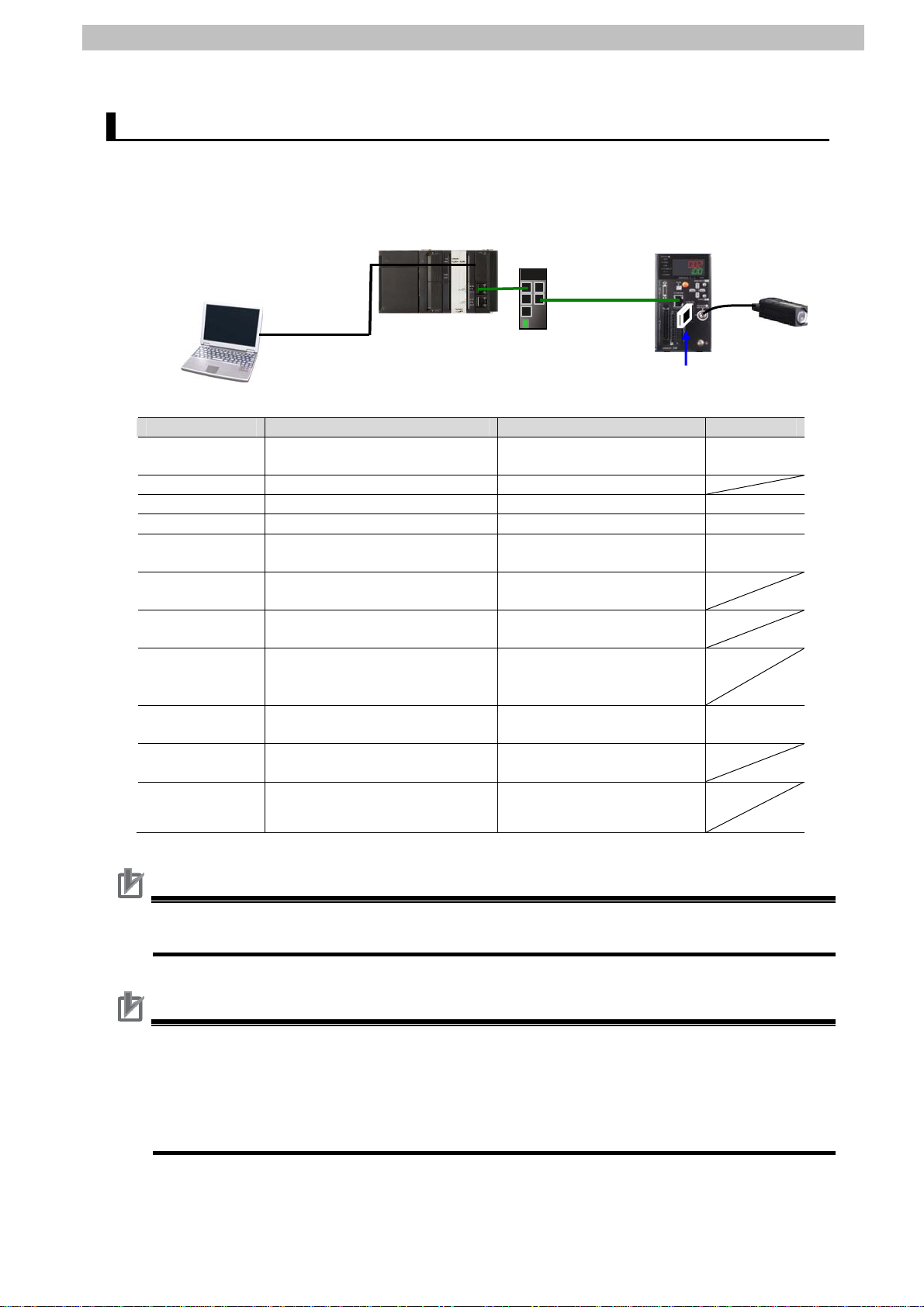

5. Applicable Devices and Support Software.............................................. 6

5.1. Applicable Devices............................................................................. 6

5.2. Device Configuration.......................................................................... 7

6. Ethernet Communications Settings......................................................... 9

6.1. Ethernet Communications Settings.................................................... 9

6.2. Example of Checking Connection .................................................... 10

7. Connection Procedure .............................................................................11

7.1. Work Flow .........................................................................................11

7.2. Setting Up the Displacement Sensor ............................................... 12

7.3. Setting Up the Controller.................................................................. 19

7.4. Checking the Ethernet Communications .......................................... 27

8. Initialization Method................................................................................ 30

8.1. Initializing the Controller................................................................... 30

8.2. Initializing the Displacement Sensor ................................................ 30

9. Program.................................................................................................... 31

9.1. Overview .......................................................................................... 31

9.2. Destination Device Command.......................................................... 35

9.3. Error Detection Processing .............................................................. 39

9.4. Variables .......................................................................................... 42

9.5. ST Program...................................................................................... 47

9.6. Timing Charts................................................................................... 64

9.7. Error Process ................................................................................... 70

10. Revision History .................................................................................. 74