Profibus IQ plus 800 Assembly instructions

50955

Profibus

®

DP

Indicator Interface

Indicator Interface for IQ plus

®

800/810 and IQ plus

®

310A Indicators

Version 1.0

Installation and

Programming Manual

R

DISCONTINUED

DISCONTINUED

Copyright © 2000 Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Specifications subject to change without notice.

Version 1.0, September 2000

Contents

About This Manual................................................................................................................................... 1

1.0 Introduction.................................................................................................................................. 1

2.0 Installation................................................................................................................................... 2

2.1 Physical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.1.1 Serial Communications Jumpers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.2 Serial Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.3 Profibus Network Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.4 Bus Termination Jumpers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.5 Installing the 20 mA Current Loop Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 DIP Switch Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 LED Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3.1 External LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3.2 Onboard LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Indicator Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4.1 IQ plus 310A Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4.2 IQ plus 800/810 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.0 Profibus Commands..................................................................................................................... 8

3.1 Integer (20-bit) Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1.1 Integer Command Formats. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1.2 Integer Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Floating Point (32-bit) Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2.1 Floating Point Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3 Status Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.4 Command Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4.1 Retrieve Net Weight Data (20-bit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4.2 Retrieve Net Weight Data (32-bit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4.3 Send Setpoint Value (32-bit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.4.4 Read Setpoint Value (32-bit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.0 Appendix.................................................................................................................................... 15

4.1 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2 Profibus Indicator Interface GSD File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3 Profibus Indicator Interface Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Profibus Indicator Interface Limited Warranty...................................................................................... 18

DISCONTINUED

ii

Profibus DP Indicator Interface Installation and Programming Manual

DISCONTINUED

Introduction

1

About This Manual

This manual provides information needed to install

and use the Rice Lake Weighing Systems ProÞbus

¨

Indicator Interface. The ProÞbus Indicator Interface

allows IQ plus

¨

800/810 and IQ plus 310A indicators

to communicate with a ProÞbus master device using

the ProÞbus-DP communications standard.

1

The ProÞbus Indicator Interface is housed inside the

NEMA 4X stainless steel indicator enclosure to

permit use in washdown environments.

This manual applies to the following software

versions:

¥ ProÞbus Indicator Interface, Version 1.0

¥ IQ plus 800/810, Version 3.1

¥ IQ plus 310A, Version 5.0

Some procedures described in this

manual require work inside the indicator

or Profibus Indicator Interface

enclosure. These procedures are to be

performed by qualified service

personnel only.

Authorized distributors and their employees

can view or download this manual from the

Rice Lake Weighing Systems distributor site

at

www.rlws.com

.

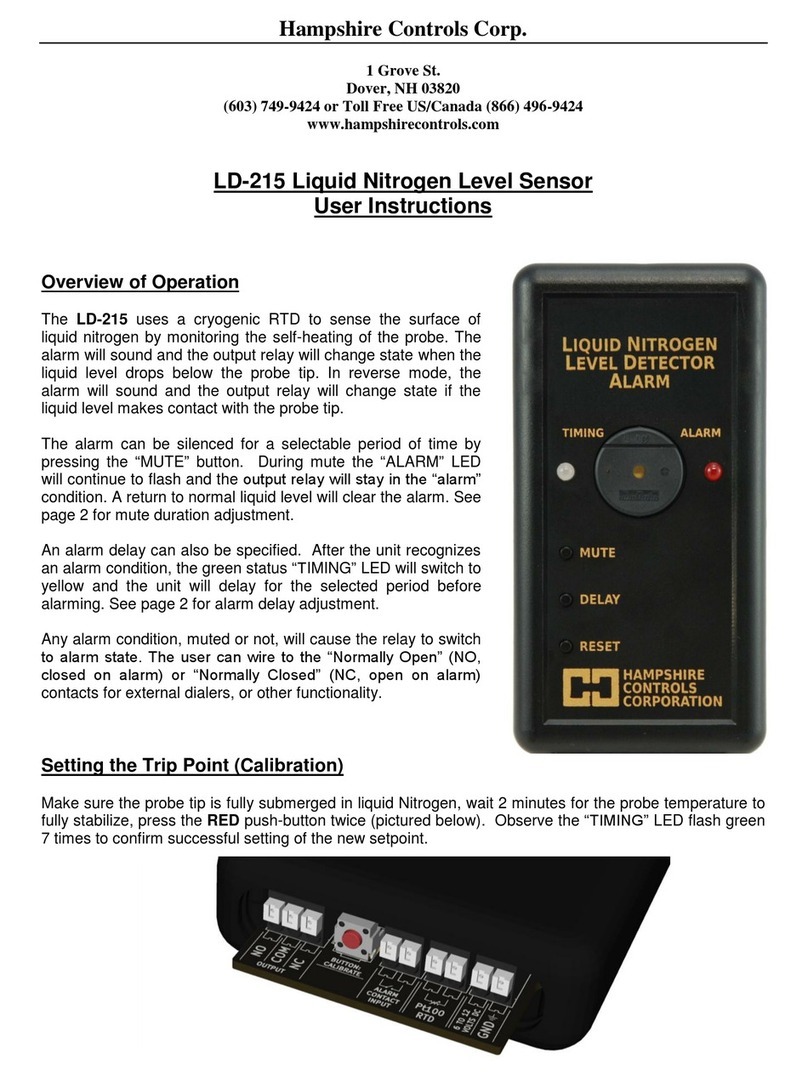

1.0 Introduction

The ProÞbus Indicator Interface provides full control of indicator functions to the PLC programmer and allows

indicator weight and status data to be returned to the ProÞbus DP network. A diskette containing the GSD Þle

used to conÞgure the master device is supplied with the ProÞbus Indicator Interface (see Section 4.2 on page 16).

The following Þgure shows an example of the ProÞbus Indicator Interface used to connect an IQ plus 800/810

indicator to the master device on a ProÞbus DP network.

The ProÞbus Indicator Interface supports two sets of commands: 20-bit integer commands and 32-bit ßoating

point commands (see Section 3.0 on page 8). Both sets are designed for use in demand mode: the master device

sends a command to the ProÞbus Indicator Interface to request information from or pass data to the indicator; the

indicator responds with weight data, status information, or an acknowledgement that the command was executed.

For applications that do not require the capablilities provided by these commands, the ProÞbus Indicator

Interface can be used with the indicator in stream mode. In stream mode, the Display Status command provides

fast, continuous acquisition of indicator weight and status data.

1. Profibus

®

is a registered trademark of Profibus International.

Warning

ZERO NET

GROSS TARE UNITS PRINT

0

.

ENTER

8

79

5

46

2

13

SCALE

#

NEW

L.D.

DISP

ROC

DISP

ACCUM

DATE

TIME/

DISP POINT

SET

CLEAR

Profibus Master Device

Profibus

Indicator Interface IQ plus 810

Scale Platform

DISCONTINUED

2

Profibus Indicator Interface Installation and Programming Manual

2.0 Installation

The ProÞbus Indicator Interface is designed to be mounted on a wall or other vertical surface, with the four status

LEDs on top and the cable connections at the bottom. Before mounting the unit, attach the communications

cables, select the termination resistance, and set the conÞguration DIP switches as described in the following

sections.

2.1 Physical Connections

Initial setup and conÞguration of the ProÞbus Indicator Interface requires opening the Interface enclosure. The

enclosure cover uses 16 screws to ensure proper seating of the cover gasket. Use the torquing pattern shown in

Figure 2-1 to prevent deformation of the gasket when removing and replacing the cover. Torque screws to 15

in-lb when replacing the cover.

Figure 2-1. Torquing Pattern for ProÞbus Indicator Interface Enclosure

Figure 2-2 shows the layout of the ProÞbus Indicator Interface logic board. The following sections describe DIP

switch conÞguration and cable connections to the PLC and indicator.

Figure 2-2. ProÞbus Indicator Interface Logic Board Layout

1

2

3

4

5

6

7

8

9

11

13

10

12

1415

16

U13

C14

C15

U11

1

R3

R4

R5

R6

R7

R68

R69

R70

U3

U12

R71

R73

R72

R74

J2

R2 U2

R19

R27

U14

R76

R77

R78

C19 C3

C5

R29

U4

R28

C4

1

ISOPWR1

U15

C17

R75

C16

R79

C18

C20

R21

R20

R1

R8 U1

R26

C1

C2

U5

CLK1

R25

R24

R22

R23

R31 C6

R38

R39

U6

1

J1

R37

R36

R35

R33

R30

R42

R49

R43

R44

R45

R46

R47

R48

R40

R41

R80

C21

R32

R34

R81

C22 U18 U19

U8

C23

U20

C25C26 C24

C28

J6

R86

R85

R84

C30

C31

C35

C32

C27

C9

C8

U9

R67A1

R67

R66

R66A1

C10

R83

R82A1

R82 C29

U22

RT1

C11

U10

R87A1

R87B1

C13

1

J3

C12

R87

R88

C33

C34

VR1

R57

R56

R55

R54

R53

R52

R62

R61

R60

R59

R58

R50

R51

R63

R64

R65

OUTPUT

PRxD

PTxD

ERROR

RxD

TxD

RxD

20mA/RS485

RS-232

RICE LAKE WEIGHING SYSTEMS

1

1

GND

+5V

TEST

3.3V

20mA

RS-232

1

RS-485

4100 4200

R11

R12

R13

R14

R15

R10

R9

R16

R17

R18

SW1

SW3

JMP3

JMP4

R92

R93

R91

ANALOG

GND

SW2

+5V

GND

RS-232 / TxD

CTS

RTS

+20mA OUT

–20mA OUT

+20mA IN

RESET1

DC/DC Converter J5 Serial Communications

EPROM

20mA Chips

LED connector

GND

GND

J4

Profibus

Communications

GND

12345678

ON

12345678

ON

12345678

ON

U16 U17

U21

U7

RS-232 / RxD

–20mA IN

CABLE

TERMINATION

Install JMP3 &JMP4

DISCONTINUED

Installation

3

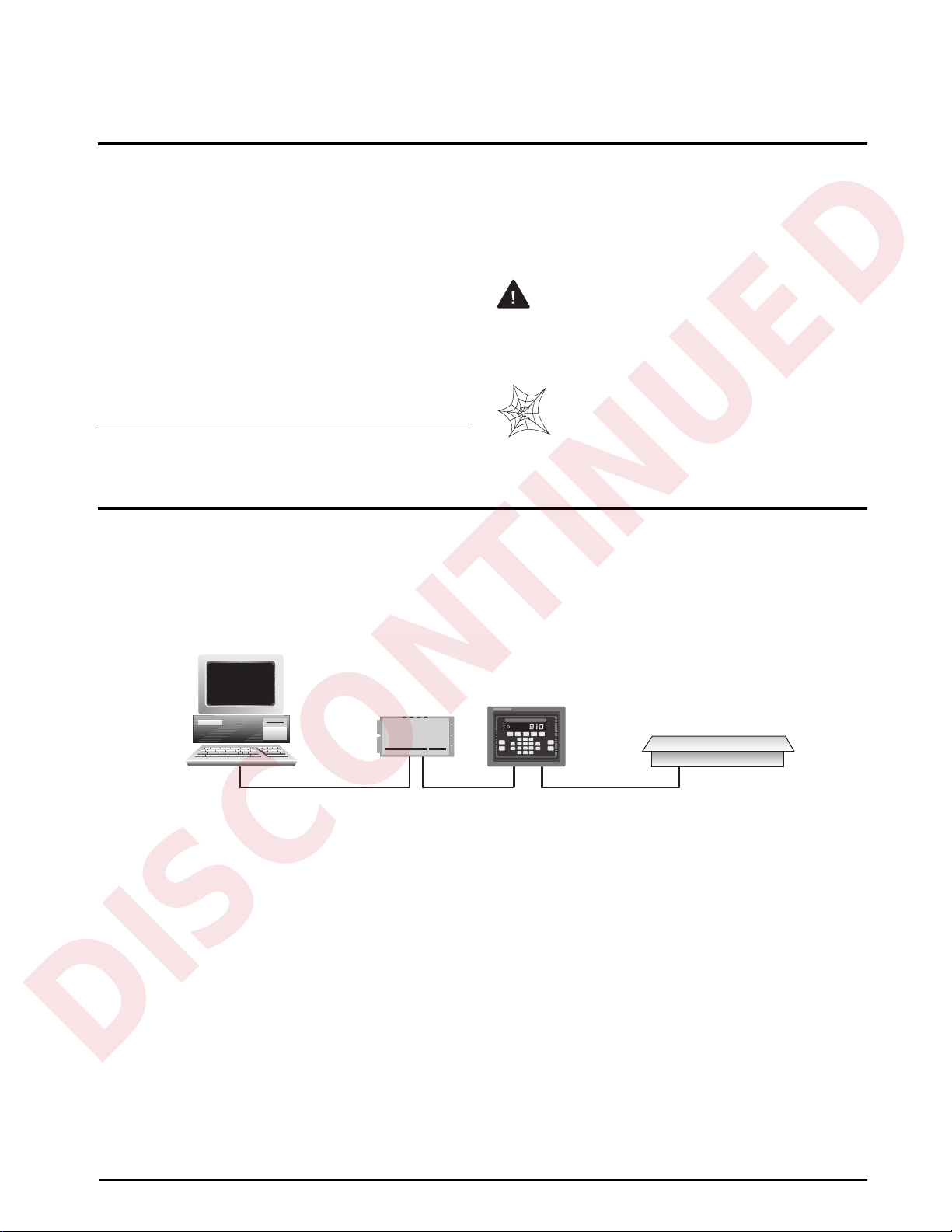

2.1.1 Serial Communications Jumpers

Two jumpers, labeled

RxD

and

OUTPUT

, determine

whether the ProÞbus Indicator Interface uses RS-232

or 20 mA current loop for serial communications with

the indicator. Leave the jumpers in the position shown

in Figure 2-4 for RS-232 communications; move both

jumpers to the

20mA

position if using the 20 mA

current loop option. See Figure 2-2 on page 2 for

board location of the jumpers.

Figure 2-3. RxD and OUTPUT Jumpers, Showing Jumper

Positions for RS-232 Communications

2.1.2 Serial Connections

Serial communications connections to the indicator

are made at connector J5 on the ProÞbus board (see

Figure 2-2 on page 2 for board location of J5).

Figure 2-4 shows the J5 connector layout for the

ProÞbus Indicator Interface. Table 2-1 shows the

serial communications connections between the

ProÞbus Indicator Interface and the IQ plus 800/810

indicators; Table 2-2 shows the serial communications

connections between the ProÞbus Indicator Interface

and the IQ plus 310A indicators.

Figure 2-4. Serial Communications Connections

Table 2-1. IQ plus 800/810 Indicator-to-ProÞbus Serial

Port Pin Assignments

NOTE:

The 20 mA current loop interface connection

requires that the 20 mA option be installed in both the

ProÞbus Indicator Interface and the IQ plus 800/810.

See Section 2.1.5 for information about installing the

20 mA option.

Table 2-2. IQ plus 310A Indicator-to-ProÞbus Serial Port

Connections

2.1.3 Profibus Network Connections

Connections to the ProÞbus network are made at

connector J4 on the ProÞbus board (see Figure 2-2 on

page 2 for board location of J4). Table 2-3 shows the

connections from J4 connector on the ProÞbus board

to the DB-9 ProÞbus connector.

2.1.4 Bus Termination Jumpers

If the ProÞbus Indicator Interface is the last device on

the network bus, install jumpers JMP3 and JMP4 on

the ProÞbus board (see Figure 2-2 on page 2 for

jumper locations).

2.1.5 Installing the 20 mA Current Loop Option

The ProÞbus Indicator Interface can communicate

with IQ plus 800/810 indicators using the 20 mA

current loop interface if the option is installed in both

the Interface and the indicator. Installing the 20 mA

option disables RS-232 communications.

IQ plus 800/810 Indicator Profibus Indicator Interface

Pin Signal Signal J5 Pin

J7-11 RS232/TxD RS232/RxD 8

J7-12 RS232/GND RS232/GND 2

J7-9 RS232/RxD RS232/TxD 3

J7-10 –20mA/TxD –20mA/RxD 8

J7-12 +20mA/TxD +20mA/RxD 7

J7-8 –20mA/RxD –20mA/TxD 6

J7-7 +20mA/RxD +20mA/TxD 5

RxD

20mA

RS-232

OUTPUT

20mA

RS-232

1

J5

Serial Communications

+5V

GND

RS-232 / TxD

CTS

RTS

+20mA OUT

–20mA OUT

+20mA IN

RS-232 / RxD

–20mA IN

IQ plus 310A Indicator Profibus Indicator Interface

Pin Signal Signal J5 Pin

J4-1 RS232/TxD RS232/RxD 8

J4-2 RS232/GND RS232/GND 2

J4-3 RS232/RxD RS232/TxD 3

Profibus

NetworkDB-9

Pin Signal

Profibus

Indicator

Interface J4

Connector Pin

1 Shield ground/Earth ground 10

2

Blank pin

2

3 Profibus B 3

4 RTS 4

5 Power supply common 5

6 +5V 6

7

Blank pin

7

8 Profibus A 8

9

Blank pin

9

NC NC/chassis ground 1

NOTE: If connecting the DB-9 shield ground (pin 1) to J4 pin

10 causes ground loop problems, disconnect.

Table 2-3. ProÞbus Network Connections

DISCONTINUED

4

Profibus Indicator Interface Installation and Programming Manual

Use the following procedure to install the 20 mA

option for the ProÞbus Indicator Interface:

1. Disconnect ProÞbus Indicator Interface from

power source.

2. Remove enclosure cover.

3. Install 20 mA chips in sockets U16 and U17

on ProÞbus board (see Figure 2-2 on page 2).

4. Make cable connections to pins 5Ð8 on

connector J5 (see Table 2-1).

5. Replace enclosure cover and tighten screws

using torquing pattern shown in Figure 2-1.

6. Reconnect power to ProÞbus Indicator

Interface.

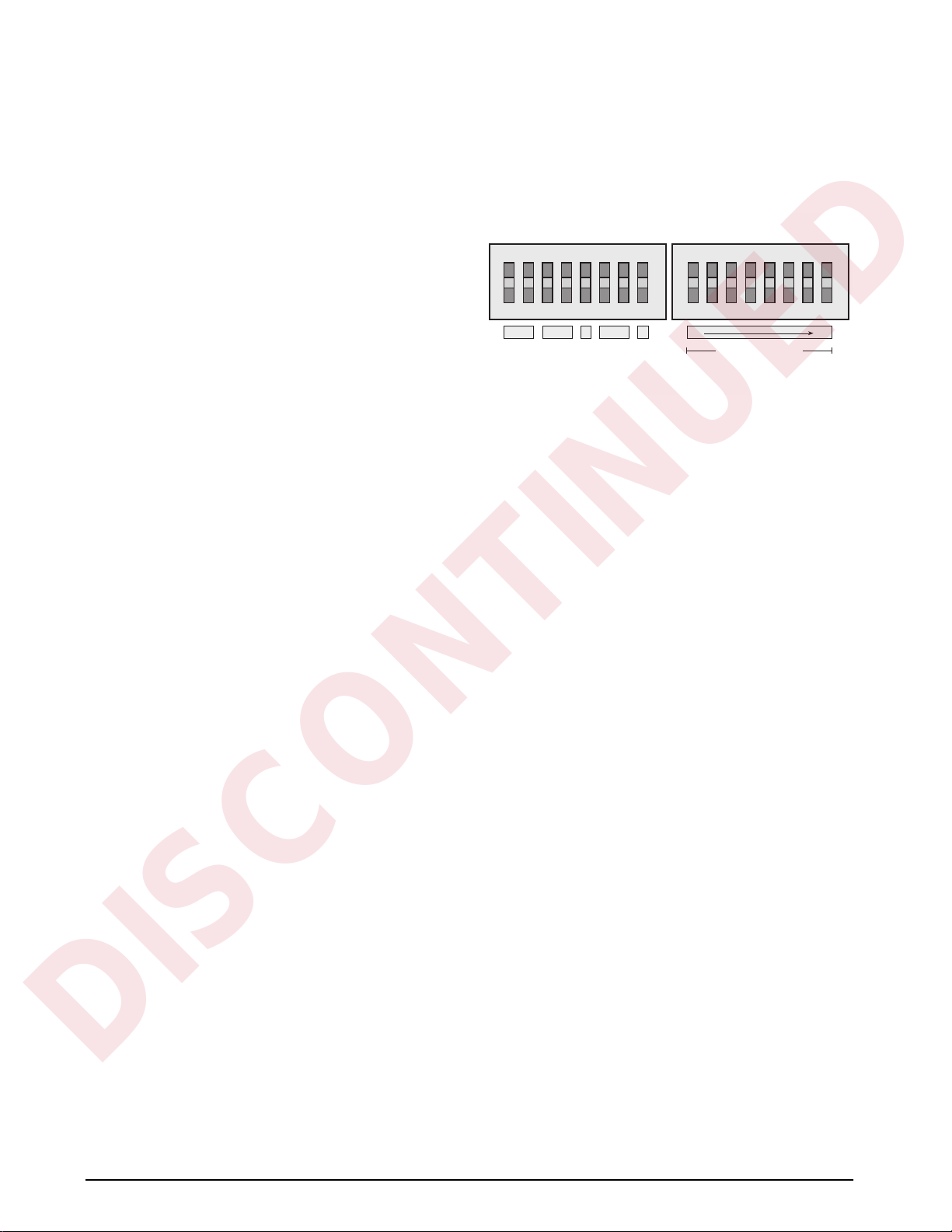

2.2 DIP Switch Configuration

Two banks of DIP switches are used to conÞgure the

ProÞbus Indicator Interface for communication

between the indicator and the network. Figure 2-5

shows the switch assignments for SW1ÐSW3.

Figure 2-5. DIP Switch Assignments

SW2 SW1

MSBLSB

Indicator

Data Rate

Stop Bits

Indicator

Type

Reserved

Profibus Address

Parity

12345678

ON

12345678

ON

DISCONTINUED

Installation

5

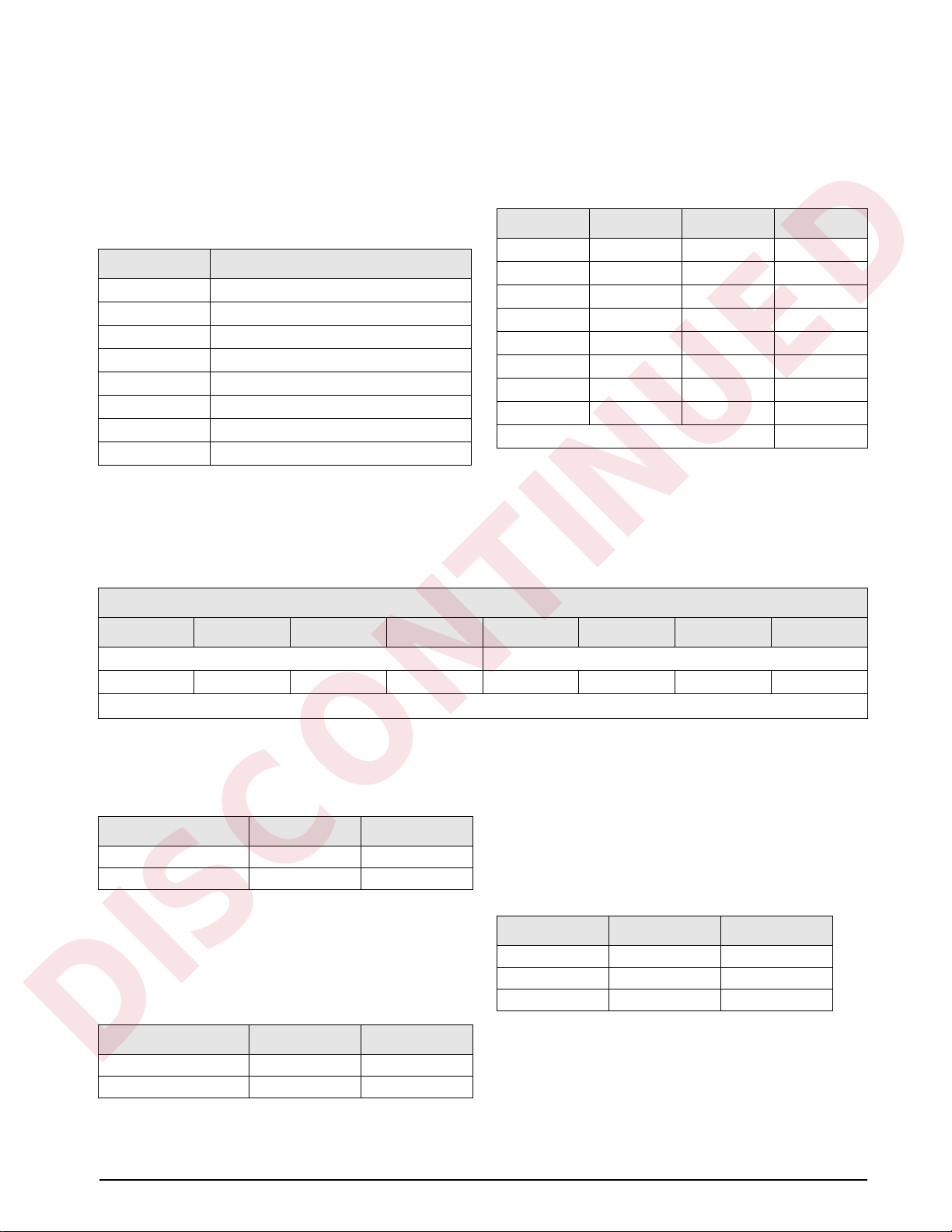

Profibus Address

Switches SW1-1 through SW1-8 are used to set the

address of the ProÞbus Indicator Interface. Use

Table 2-4 to select the correct switch settings for the

network address. Note that setting a switch OFF acts

as a logical Ò0Ó and that SW1-1 represents the least

signiÞcant bit (LSB) of the network address.

The conÞgured address equals the sum of the values

of the switches set on. For example, to set a network

address of 19, SW1 switches would be set as shown in

Table 2-5:

For hexadecimal addressing, SW1 functions as shown in Table 2-6. Repeating the example from Table 2-4,

decimal 19 is hexadecimal 13: Switch 1-5 (1 in byte 1) and switches 1-2 and 1-1 (2+1 = 3 in byte 0) would be set

on for an address of hex 13.

Indicator Type

Switches SW2-1 and SW2-2 set the type of indicator

attached to the ProÞbus Indicator Interface.

Indicator Data Rate

Switches SW2-3 and SW2-4 set the data rate used for

communications between the indicator and the

ProÞbus Indicator Interface. Set to 9600 bps for the IQ

plus 310A.

Stop Bits

Switch SW2-5 sets the number of stop bits used to

communicate with the indicator. Set SW2-5 OFF for

one stop bit, ON for two stop bits.

Parity

Switches SW2-6 and SW2-7 set the type of parity

used to communicate with the indicator.

Switch Decimal Value if Switch=ON

1-1 1

1-2 2

1-3 4

1-4 8

1-5 16

1-6 32

1-7 64

1-8 128

Table 2-4. SW1 Switch Values for Network Addressing

Switch ON Value Switch State Value

1-11ON1

1-22ON2

1-3 4 OFF 0

1-4 8 OFF 0

1-5 16 ON 16

1-6 32 OFF 0

1-7 64 OFF 0

1-8 128 OFF 0

Sum of ON switch values:

19

Table 2-5. SW1 Example for Network Address 19

Switch

1-8 1-7 1-6 1-5 1-4 1-3 1-2 1-1

Byte 1 Byte 0

84218421

2

7

2

6

2

5

2

4

2

3

2

2

2

1

2

0

Table 2-6. Switch Values for Hexadecimal Addressing

Data Rate (bps) SW2-1 SW2-2

IQ plus 310A OFF OFF

IQ plus 800/810 ON OFF

Table 2-7. Indicator Type Switch Settings

Data Rate (bps) SW2-3 SW2-4

9600 OFF OFF

19200 OFF ON

Table 2-8. Network Data Rate Switch Settings

Parity SW2-6 SW2-7

NONE OFF OFF

EVEN OFF ON

ODD ON OFF

Table 2-9. Parity Switch Settings

DISCONTINUED

6

Profibus Indicator Interface Installation and Programming Manual

2.3 LED Indicators

2.3.1 External LEDs

Four LEDs on the top of the ProÞbus Indicator Interface enclosure provide status information for the operator.

Table 2-10 summarizes the function of the LEDs. See Section 4.1 on page 15 for more troubleshooting

information.

2.3.2 Onboard LEDs

Two groups of three amber LEDs on the ProÞbus board itself provide additional diagnostic ßexibility:

¥ LEDs labeled

PTxD

,

ERROR

, and

PRxD

are mounted next to the J1 LED connector

¥ LEDs labeled

RxD

,

TxD

, and

3.3V

are mounted behind the OUTPUT jumper

Table 2-11 summarizes the function of these LEDs:

LED Color Function

Power Red

On when external power applied

ERROR Red

System error

On when communications between indicator

and Profibus Indicator Interface is lost Check that baud rates configured at Profibus

Indicator Interface and at the master are the same

Check wiring at J5 connector

RxD Green

Blinks when data is received from the indicator May appear to be on steady when indicator is

streaming data

TxD Green

Blinks when data is sent to the indicator

Table 2-10. ProÞbus Indicator Interface LED indicators

LED Function

PTxD

Profibus communications status. Same functions as backplate LEDs.

ERROR

PRxD

RxD

Blinks when data received from indicator. Off indicates no transmission from the indicator to the Profibus

Indicator Interface.

TxD

Blinks when data sent to the indicator. Off indicates no transmission from the Profibus Indicator Interface to the

indicator.

3.3V

Off indicates possible failure of 3.3V or 5V power supply.

Table 2-11. Onboard Diagnostic LEDs

DISCONTINUED

Installation

7

2.4 Indicator Setup

Indicators communicate with the ProÞbus Indicator Interface using the indicator EDP port. Both IQ plus 310A

and IQ plus 800/810 indicators support RS-232 communications. The IQ plus 800/810 indicators can also use 20

mA current loop communications providing the 20 mA option is installed in both the indicator and the ProÞbus

Indicator Interface.

2.4.1 IQ plus 310A Configuration

Table 2-12 shows the conÞguration parameters recommended for the IQ plus 310A indicator to communicate

with the ProÞbus Indicator Interface. See the IQ plus 310A Installation & Service Manual for detailed

information about conÞguring the indicator.

2.4.2 IQ plus 800/810 Configuration

Table 2-13 shows the conÞguration parameters recommended for the IQ plus 800/810 indicators to communicate

with the ProÞbus Indicator Interface. See the IQ plus 800/810 Installation Manual for detailed information about

conÞguring the indicator.

IQ plus 310A Configuration Settings Notes

EDP MODE DEMAND Required

BAUD 9600 Must match DIP switch selection on Profibus Indicator Interface

BITS 8 NONE Required

TERMIN CR

EOL DLY 0 MS

FORMAT REMOTE

CASE UPPER

RESPOND STATUS

PRINTER MODE TICKET Specify TICKET mode to improve indicator performance

SETUP KEYBRD DISABLE Select to disable front panel (blind operation)

TARE RS REGULT Required

TARE FN AUTO

Table 2-12. IQ plus 310A ConÞguration Settings

IQ plus 800/810 Configuration Settings Notes

CONFIG FEATURE A/B ON A/B FEATURE is enabled at the factory for indicators ordered

with the Remote I/O option. If the A/B FEATURE is OFF, call

RLWS for information about activating the feature.

SERIAL EDP BAUD 9600 or 19200 Must match DIP switch selection on Profibus Indicator

Interface

BITS 8 NONE Required

TERMIN CR

EOL DLY 0 MS

ABSTRM OFF

STREAM OFF

Table 2-13. IQ plus 800/810 ConÞguration Settings

DISCONTINUED

8Profibus Indicator Interface Installation and Programming Manual

3.0 Profibus Commands

The ProÞbus Indicator Interface uses 20-bit integer and 32-bit ßoating point commands to send and receive data

from the indicator. This section describes the input and output data formats, commands, and status bit

assignments, and provides examples of 20-bit and 32-bit command usage.

3.1 Integer (20-bit) Commands

3.1.1 Integer Command Formats

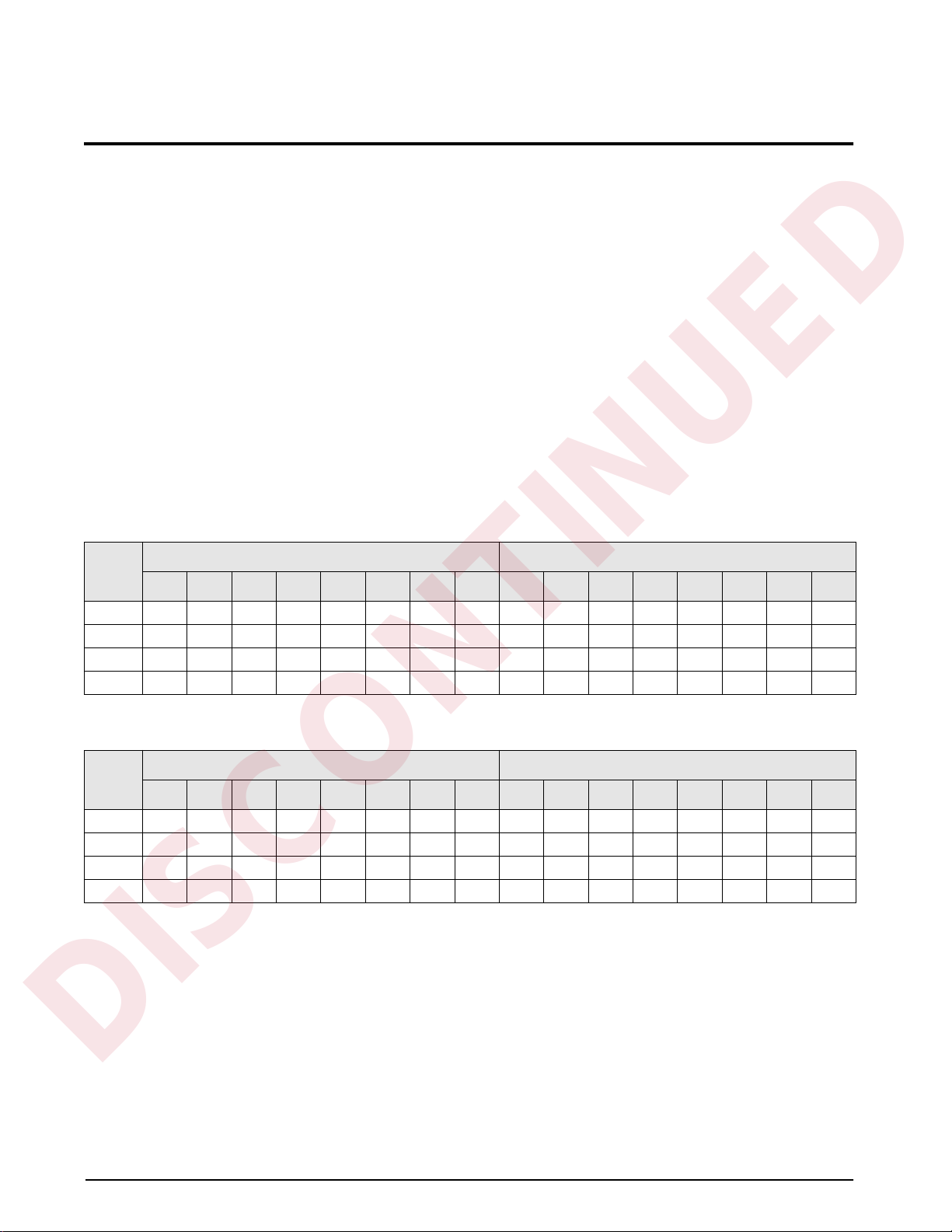

Tables 3-1 and 3-2 show the data formats used to send and receive 20-bit integer commands. Bit assignments as

follows:

R Reserved

s00-s08 Status data

cccc cccc Command number

v00–v19 20-bit integer value

See Table 3-3 on page 9 for a listed of supported commands; see Section 3.3 on page 12 for status bit

assignments.

NOTE: Integer commands return no decimal point information to the master. For example, a value of 750.1

displayed on the indicator is returned to the master as 7501.

Bit

Byte 1 Byte 0

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Word0RRRRRRRRcccccccc

Word1RRRRRRRRRRRRRRRR

Word2RRRRRRRRRRRRv19v18v17v16

Word 3 v15 v14 v13 v12 v11 v10 v09 v08 v07 v06 v05 v04 v03 v02 v01 v00

Table 3-1. ProÞbus 20-bit Integer Output Format

Bit

Byte 1 Byte 0

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Word0RRRRRRRRRRRRRRRR

Word 1 s15 s14 s13 s12 s11 s10 s09 s08 s07 s06 s05 s04 s03 s02 s01 s00

Word2RRRRRRRRRRRRv19v18v17v16

Word 3 v15 v14 v13 v12 v11 v10 v09 v08 v07 v06 v05 v04 v03 v02 v01 v00

Table 3-2. ProÞbus 20-bit Integer Input Format

DISCONTINUED

Profibus Commands 9

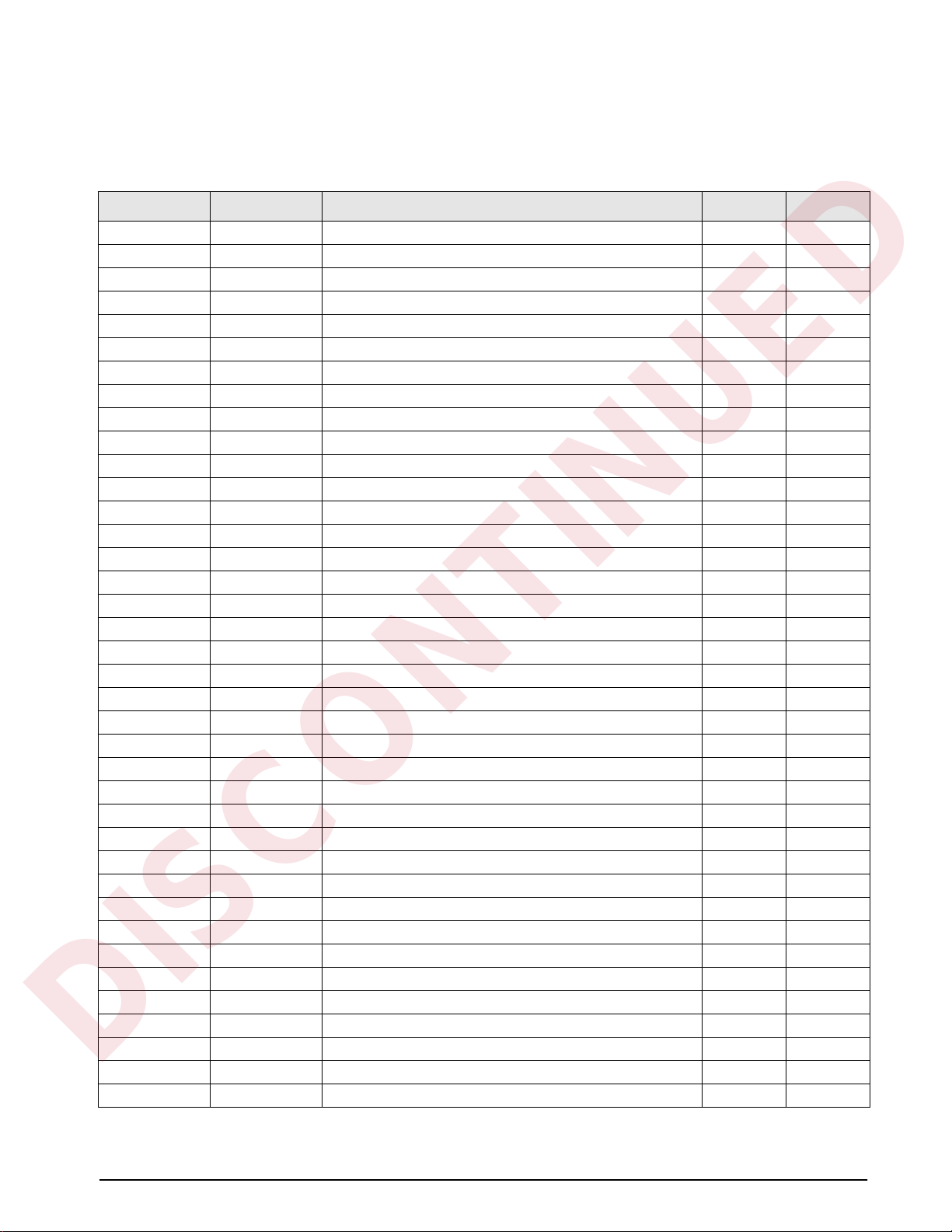

3.1.2 Integer Commands

Table 3-3 lists the integer commands that can be speciÞed for IQ plus 800/810 and IQ plus 310A indicators. Valid

commands for each indicator are indicated by a check mark (Ö). The number representing the indicator command

is sent in the lower byte of word 0 (bits 0Ð7).

Hex Decimal Command 800/810 310A

00 00 Display Status ÖÖ

01 01 Display Channel 0 Ö

02 02 Display Channel 1 Ö

03 03 Display Channel 2 Ö

04 04 Display Channel 3 Ö

05 05 Display Channel 4 Ö

06 06 Display Gross Weight ÖÖ

07 07 Display Net Weight ÖÖ

09 09 Acquire Tare ÖÖ

0A 10 Primary Units Ö

0B 11 Secondary Units Ö

0C 12 Select Pounds Ö

0D 13 Select Kilograms Ö

0E 14 Print Request ÖÖ

10 16 Clear Accumulator, Channel 0 Ö

11 17 Clear Accumulator, Channel 1 Ö

12 18 Clear Accumulator, Channel 2 Ö

13 19 Clear Accumulator, Channel 3 Ö

14 20 Clear Accumulator, Channel 4 Ö

15 21 Clear Tare ÖÖ

16 22 Return Gross, Channel 0 Ö

17 23 Return Gross, Channel 1 ÖÖ

18 24 Return Gross, Channel 2 Ö

19 25 Return Gross, Channel 3 Ö

1A 26 Return Gross, Channel 4 Ö

1B 27 Return Net, Channel 0 Ö

1C 28 Return Net, Channel 1 ÖÖ

1D 29 Return Net, Channel 2 Ö

1E 30 Return Net, Channel 3 Ö

1F 31 Return Net, Channel 4 Ö

20 32 Return Tare, Channel 0 Ö

21 33 Return Tare, Channel 1 ÖÖ

22 34 Return Tare, Channel 2 Ö

23 35 Return Tare, Channel 3 Ö

24 36 Return Tare, Channel 4 Ö

25 37 Return Currrent Display ÖÖ

26 38 Batch Start Ö

28 40 Batch Pause Ö

Table 3-3. IQ plus 800/810 and IQ plus 310A Integer Commands

DISCONTINUED

10 Profibus Indicator Interface Installation and Programming Manual

29 41 Batch Reset Ö

2A 42 Batch Status Ö

2B 43 Zero ÖÖ

2C 44 Enter Tare ÖÖ

2E 46 Return Accumulator, Channel 0 Ö

2F 47 Return Accumulator, Channel 1 Ö

30 48 Return Accumulator, Channel 2 Ö

31 49 Return Accumulator, Channel 3 Ö

32 50 Return Accumulator, Channel 4 Ö

33 51 Return Rate of Change, Channel 0 Ö

34 52 Return Rate of Change, Channel 1 Ö

35 53 Return Rate of Change, Channel 2 Ö

36 54 Return Rate of Change, Channel 3 Ö

37 55 Return Rate of Change, Channel 4 Ö

38 56 Return Peak, Channel 0 Ö

39 57 Return Peak, Channel 1 Ö

3A 58 Return Peak, Channel 2 Ö

3B 59 Return Peak, Channel 3 Ö

3C 60 Return Peak, Channel 4 Ö

3D 61 Push Weight to Accumulator, Channel 0 Ö

3E 62 Push Weight to Accumulator, Channel 1 Ö

3F 63 Push Weight to Accumulator, Channel 2 Ö

40 64 Push Weight to Accumulator, Channel 3 Ö

41 65 Push Weight to Accumulator, Channel 4 Ö

42 66 Lock Indicator Front Panel Ö

43 67 Unlock Indicator Front Panel Ö

44 68 Set Digital Output ON Ö

45 69 Set Digital Output OFF Ö

Hex Decimal Command 800/810 310A

Table 3-3. IQ plus 800/810 and IQ plus 310A Integer Commands (Continued)

DISCONTINUED

Profibus Commands 11

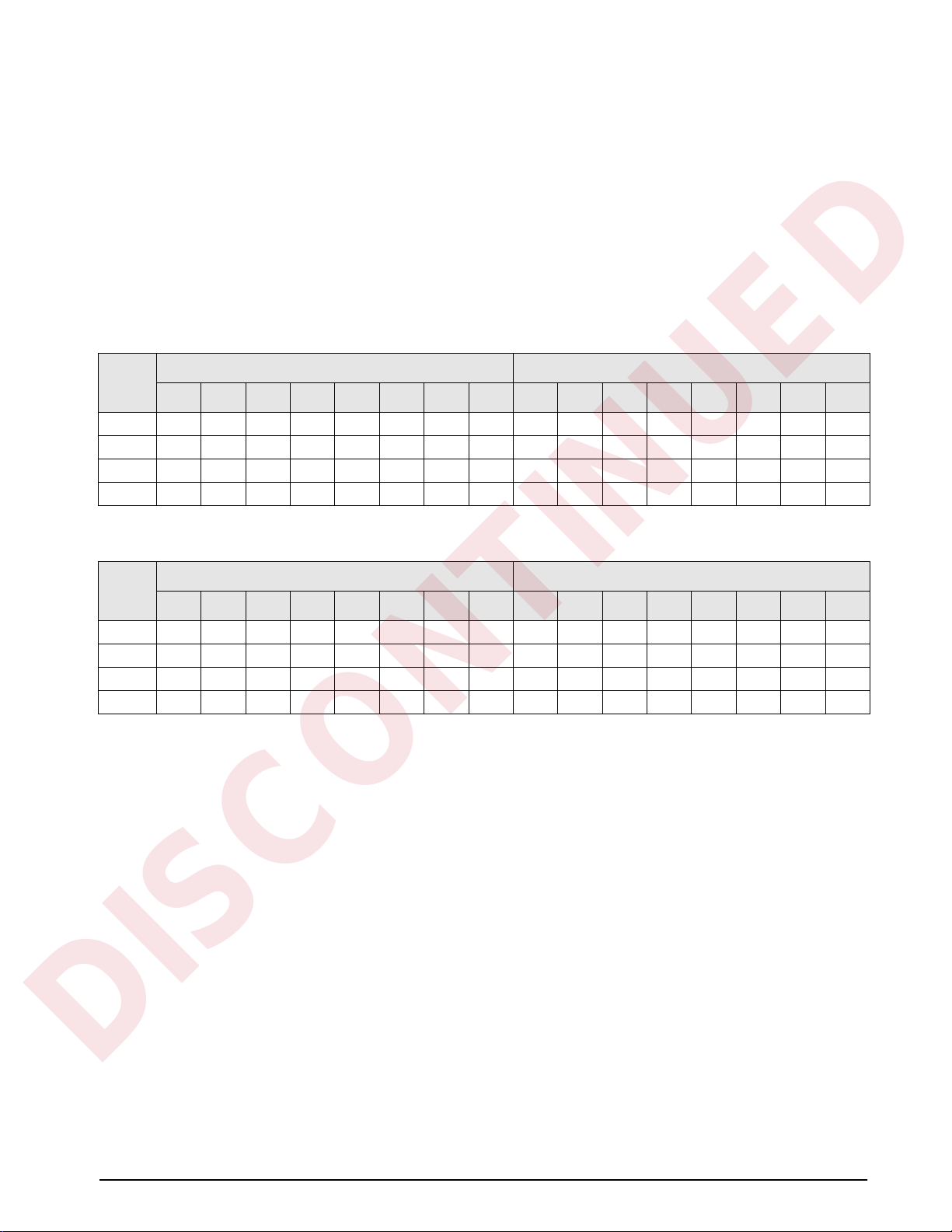

3.2 Floating Point (32-bit) Commands

Tables 3-4 and 3-5 show the data formats used to send and receive 32-bit ßoating point commands. Bit

assignments are as follows:

R Reserved

s00-s08 Status data

n00-n07 Channel number or setpoint number

c cccc cccc Command number

v00–v31 32-bit floating point value

See Table 3-6 on page 12 for a list of supported commands; see Section 3.3 on page 12 for status bit assignments.

NOTE: Floating point commands support decimal point information with no special handling.

Bit

Byte 1 Byte 0

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Word0RRRRRRRccccccccc

Word1RRRRRRRRn07n06n05n04n03n02n01n00

Word 2 v31 v30 v29 v28 v27 v26 v25 v24 v03 v22 v21 v20 v19 v18 v17 v16

Word 3 v15 v14 v13 v12 v11 v10 v09 v08 v07 v06 v05 v04 v03 v02 v01 v00

Table 3-4. ProÞbus 32-bit Floating Point Output Format

Bit

Byte 1 Byte 0

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Word0RRRRRRRccccccccc

Word 1 s15 s14 s13 s12 s11 s10 s09 s08 s07 s06 s05 s04 s03 s02 s01 s00

Word 2 v31 v30 v29 v28 v27 v26 v25 v24 v03 v22 v21 v20 v19 v18 v17 v16

Word 3 v15 v14 v13 v12 v11 v10 v09 v08 v07 v06 v05 v04 v03 v02 v01 v00

Table 3-5. ProÞbus 32-bit Floating Point Input Format

DISCONTINUED

12 Profibus Indicator Interface Installation and Programming Manual

3.2.1 Floating Point Commands

Table 3-6 lists the ßoating point commands that can be speciÞed for IQ plus 800/810 and IQ plus 310A

indicators. Valid commands for each indicator are indicated by a check mark (Ö). The number representing the

indicator command is sent in word 0 (bits 0Ð8).

3.3 Status Data

Table 3-7 shows the remote function status data format; Table 3-8 shows the batch status data format. The batch

status format is used in response to command 42 (hex 2A), Batch Status.

Hex Decimal Command 800/810 310A

101 257 Set Tare ÖÖ

102 258 Read Tare ÖÖ

103 259 Read Accumulator Ö

104 260 Read Gross ÖÖ

105 261 Read Net ÖÖ

106 262 Set Setpoint Value Ö

107 263 Set Setpoint Hysteresis Ö

108 264 Set Setpoint Bandwidth Ö

109 265 Set Setpoint Preact Ö

10A 266 Read Setpoint Value Ö

10B 267 Read Setpoint Hysteresis Ö

10C 268 Read Setpoint Bandwidth Ö

10D 269 Read Setpoint Preact Ö

10E 270 Set Batching State Ö

Table 3-6. IQ plus 800/810 and IQ plus 310A Floating Point Commands

Bit

Status Data

Value=0 Value=1

s00 No Error Error

s01 Tare not entered Tare entered

s02 Not zero Center of zero

s03 Weight OK Weight invalid

s04 Standstill In motion

s05 Primary units Secondary units

s06 Tare not acquired Tare acquired

s07 Gross weight Net weight

s08 Channel 0 or 1 Channel 2, 3, or 4

s09 Not used

s10

s11 Positive weight Negative weight

s12 Not used

s13

s14

s15

Table 3-7. Run Status Word Format

Bit

Status Data

Value=0 Value=1

s00 No Error Error

s01 DIGIN 3 = OFF DIGIN 3 = ON

s02 DIGIN 2 = OFF DIGIN 2 = ON

s03 DIGIN 1 = OFF DIGIN 1 = ON

s04 Batch paused Batch not paused

s05 Batch running Batch not running

s06 Batch not stopped Batch stopped

s07 Not used

s08

s09

s10

s11

s12

s13

s14

s15

Table 3-8. Batch Status Word Format

DISCONTINUED

Profibus Commands 13

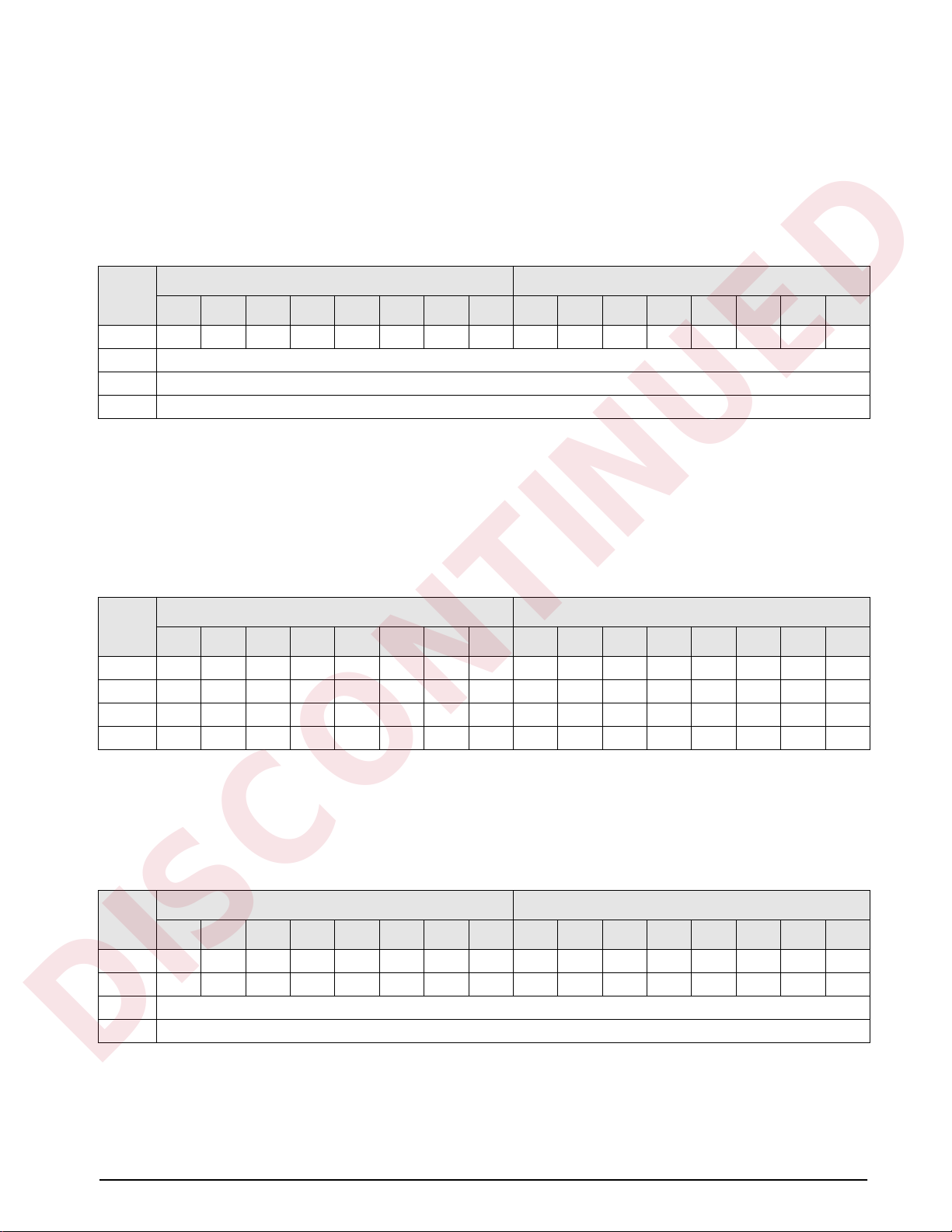

3.4 Command Examples

This section provides examples of 20-bit integer and 32-bit ßoating point commands used to send and receive

indicator data.

3.4.1 Retrieve Net Weight Data (20-bit)

Table 3-9 shows a binary representation of the 20-bit output data used to retrieve net weight from the indicator

using command 28. The output format includes only the command number, in byte 0 of word 0 (0001 1100 =

hex 1C, decimal 28).

Table 3-10 shows the input data returned by the previous command:

¥ The status bits in word 1 (see Section 3.3 on page 12) show that a tare has been performed and the

indicator is in net mode.

¥ Weight data is returned in word 3 (0000 0111 1101 0101 = hex 07D5 = decimal 2005). Assuming the

indicator is conÞgured to display pounds, with one decimal position, the net weight is interpreted as

200.5 LB.

3.4.2 Retrieve Net Weight Data (32-bit)

Table 3-11 shows a binary representation of the 32-bit output data used to retrieve net weight from channel 2 of

an IQ plus 800/810using command 261. The output format includes the command number, in byte 0 of word 0

(0001 0001 1100 = hex 105, decimal 261), the channel number (0100, decimal 2) in the lower byte of word 1.

Bit

Byte 1 Byte 0

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Word0RRRRRRRR00011100

Word 1 Not used

Word 2 Not used

Word 3 Not used

Table 3-9. 20-bit Integer Output to Send Command 28, Return Net Weight, Channel 1

Bit

Byte 1 Byte 0

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Word0RRRRRRRRRRRRRRRR

Word10000000011000010

Word2RRRRRRRR00000000

Word30000011111010101

Table 3-10. 20-bit Integer Input with Returned Net Weight Data

Bit

Byte 1 Byte 0

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Word00000000100000101

Word10000000000000100

Word 2 Not used

Word 3 Not used

Table 3-11. 32-bit Floating Point Output to Send Command 261, Read Net Weight

DISCONTINUED

14 Profibus Indicator Interface Installation and Programming Manual

Table 3-12 shows the input data returned by the previous command:

¥ The command number for which the data is returned is included in word 0 (command 261).

¥ The status bits in word 1 (see Section 3.3 on page 12) show that a tare has been performed and the

indicator is in net mode.

¥ Weight data returned in words 2 and 3 must be copied into a ßoating point storage location before being

read.

3.4.3 Send Setpoint Value (32-bit)

Table 3-13 shows a decimal representation of the

32-bit output data used to set the value of setpoint 1 to

100.5. Note that the setpoint value is not readable as

100.5: The value data must be copied to words 2 and 3

from a ßoating point storage location.

After sending the command, use the Read Setpoint

Value command (decimal 266) to verify that the

indicator received the correct setpoint value.

3.4.4 Read Setpoint Value (32-bit)

Table 3-14 shows the output data used to read the

value of setpoint 1.

Table 3-15 shows the data returned by the previous

command. Again, the value data returned in words 2

and 3 must be copied into a ßoating point storage

location to be read.

Bit

Byte 1 Byte 0

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Word00000000100000101

Word10000000011000010

Word20100001111111010

Word31101100110011010

Table 3-12. 32-bit Floating Point Input with Returned Net Weight Data

Word Value (Decimal) Description

0 262 Command number

1 1 Setpoint number

2 17097 Setpoint value (MSW)

3 0 Setpoint value (LSW)

Table 3-13. 32-bit Floating Point Output to Send Command

262, Send Setpoint Value

Word Value (Decimal) Description

0 262 Command number

1 1 Setpoint number

20Not used

30Not used

Table 3-14. 32-bit Floating Point Output to Send Command

266, Read Setpoint Value

Word Value (Decimal) Description

0 266 Command number

10Not used

2 17097 Setpoint value (MSW)

3 0 Setpoint value (LSW)

Table 3-15. 32-bit Floating Point Input with Returned

Setpoint Value Data

DISCONTINUED

Appendix 15

4.0 Appendix

4.1 Troubleshooting

The following section provides information for diagnosing communications problems between the indicator and

the ProÞbus master. The status of the LEDs on the ProÞbus Indicator Interface can be used to diagnose the

general area of difÞculty, as shown in Table 4-1.

If there is no communication between the indicator and the master device, do the following:

1. Ensure DIP switches on the ProÞbus board are set correctly (see Section 2.2 on page 4).

2. Power down,then power up the ProÞbus Indicator Interface.

3. Ensure the ProÞbus master device is set to send a command to the slave. Commands are listed in

Section 3.0 on page 8.

4. Check the OUTPUT and RxD jumpers to ensure they are set for RS-232 communications (see

Section 2.1.1 on page 3).

5. Check the wiring from the indicator to connector J5 on the ProÞbus board (see Section 2.1.2 on page 3).

6. Ensure the indicator conÞguration is correct.

7. Check that the master is set up correctly to communicate with the slave device.

8. On the ProÞbus board, ensure that the 3.3V LED is lit. If it is not, check connector J6 for a loose or

incorrect connection (see Figure 2-2 on page 2). If the LED is still not lit, replace the ProÞbus Indicator

Interface power supply.

9. Locate EPROM U7 found in the middle of the ProÞbus board (see Figure 2-2 on page 2). Ensure that the

chip is seated by pressing down on the chip.

10. Check that the connector J4 on the ProÞbus board is Þrmly connected.

11. If no problems are found in the checks above, replace the ProÞbus board.

Symptom Possible Cause

POWER LED not lit No power to Profibus board. Ensure connector J6 on the Profibus

board is properly seated.

RxD LED flashes constantly; TxD LED not lit Indicator is streaming data to the Profibus slave. Check indicator

configuration. See Section 2.4 on page 7 for indicator configuration

information.

TxD LED flashes every two seconds; RxD LED not lit Serial connection between the indicator and the Profibus Indicator

Interface is not correct. See Section 2.4 on page 7 for indicator

configuration information.

Table 4-1. Troubleshooting Symptoms Indicated by LEDs

DISCONTINUED

16 Profibus Indicator Interface Installation and Programming Manual

4.2 Profibus Indicator Interface GSD File

;=================================================================

; GSD-File for Profibus Indicator Interface

; Rice Lake Weighing Systems

;

; Version V0.3

;

; Date : 01.02.2000

; File : RLWS088C.GSD

;=================================================================

#Profibus_DP

; <Unit-Definition-List>

GSD_Revision = 1 ; Needed to tell that this file works with text readers.

Vendor_Name = "Rice Lake Weighing Systems "; Used to tell whose file this is.

Model_Name = "Profibus Indicator Interface "; Tells what is supported by this

file.

Revision = "V1.1 "; Tells what version GSD file this is.

Ident_Number = 0x088B; Seperates one manufacturers different part numbers.

Protocol_Ident = 0 ; Profibus DP protocol

Station_Type = 0 ; This is a slave device

FMS_supp = 0 ; No FMS support

Hardware_Release= "Rev B "; Tells that this works with hardware Rev B, not required.

Software_Release= "Rev1.00"; Tells that this file works with Software release 1.00, not

required.

9.6_supp = 1 ; These baud rates with a "1" are supported, "0" is not

19.2_supp = 1

93.75_supp = 1

187.5_supp = 1

500_supp = 1

45.45_supp = 1

1.5M_supp = 1

3M_supp = 1

6M_supp = 1

12M_supp = 1

MaxTsdr_9.6 = 60 ; This is the time delay needed after a message is sent.

MaxTsdr_19.2 = 60

MaxTsdr_93.75 = 60

MaxTsdr_187.5 = 60

MaxTsdr_500 = 100

MaxTsdr_45.45 = 120

MaxTsdr_1.5M = 150

MaxTsdr_3M = 250

MaxTsdr_6M = 450

MaxTsdr_12M = 800

Redundancy = 0 ; Redundancy not supported

Repeater_Ctrl_Sig = 2 ; Repeater control signal TTL RTS (2) not connected (0).

24V_Pins = 0 ; 24 V pins not connected.

Implementation_Type ="SPC3"; Slave-Specification:

Freeze_Mode_supp =0 ; Freeze mode is not supported.

Sync_Mode_Supp = 0 ; Sync-mode is not supported.

Auto_Baud_supp = 1 ; Auto baud rate detection supported.

Set_Slave_Add_Supp = 0 ; Supports function Set_Slave Add

Min_Slave_Intervall = 100 ; Sets the value (multiples of 100us) between two slave poll

cycles of the same slave

Modular_Station = 1 ; Indicates that this is a modular device (device can be set up

multiple ways.)

Max_Module = 1 ; indicates the number of ways -1 that this can be set up.

Max_Input_Len = 128 ; Indicates the max number of bytes of a modular station.

Max_Output_Len = 128 ; Indicates the maximum number of output bytes of a modular

station.

Max_Data_Len = 256 ; Indicates the maximum number of data transferred in bytes to or

from the device.

; Unit_Diag_Bit(0) = ; Usable to indicate status or error messages (bitwise).

Fail_Safe = 0;1 ; Tells if fail safe mode is supported (1) or not (0).

; Max_Diag_Data_Len= 29

Modul_Offset = 0 ; Tells how many to add to "module" number for module numbers.

Slave_Family = 3@TdF@OTHER; USED BY COM PROFIBUS TO SET UP IN SLAVE MODULES MENU

; Below useable for RS485 Adresses?

DISCONTINUED

This manual suits for next models

1

Table of contents

Other Profibus Accessories manuals

Popular Accessories manuals by other brands

Hytronik

Hytronik HMW35 Installation and instruction manual

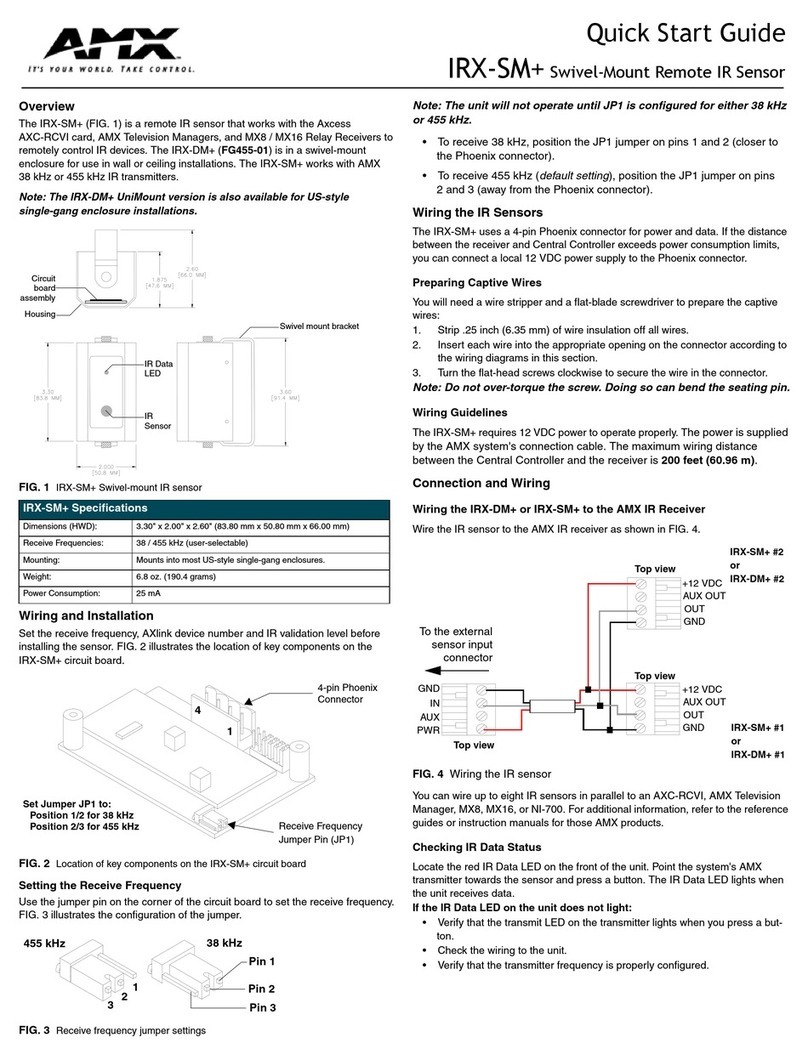

AMX

AMX IRX-SM+ quick start guide

AuVerte

AuVerte GK10 Series quick start guide

Crivit

Crivit SC-1358 Instructions for use

Freescale Semiconductor

Freescale Semiconductor KITMPR03xEVM quick start guide

Becker

Becker SC431-II Assembly and operating instructions