Maintenance for DriveSets

Content

1Understanding the system set-up and functionality.............................5

1.1 System philosophy ..................................................................................5

1.2 Linear axes, rotary modules ....................................................................5

1.3 Motors ....................................................................................................5

1.3.1 Motors on Xemo R/S Compact Controllers..............................................5

1.3.2 Motors on Xemo P Controllers ................................................................6

1.4 Wiring.....................................................................................................6

1.4.1 Wiring on Xemo Compact Controllers ....................................................6

1.4.2 Wiring on Xemo P Controllers.................................................................6

1.5 Xemo controllers.....................................................................................6

1.5.1 Xemo R/S Compact Controllers...............................................................6

1.5.2 Xemo P Controllers .................................................................................7

2General notes on maintenance and service..........................................8

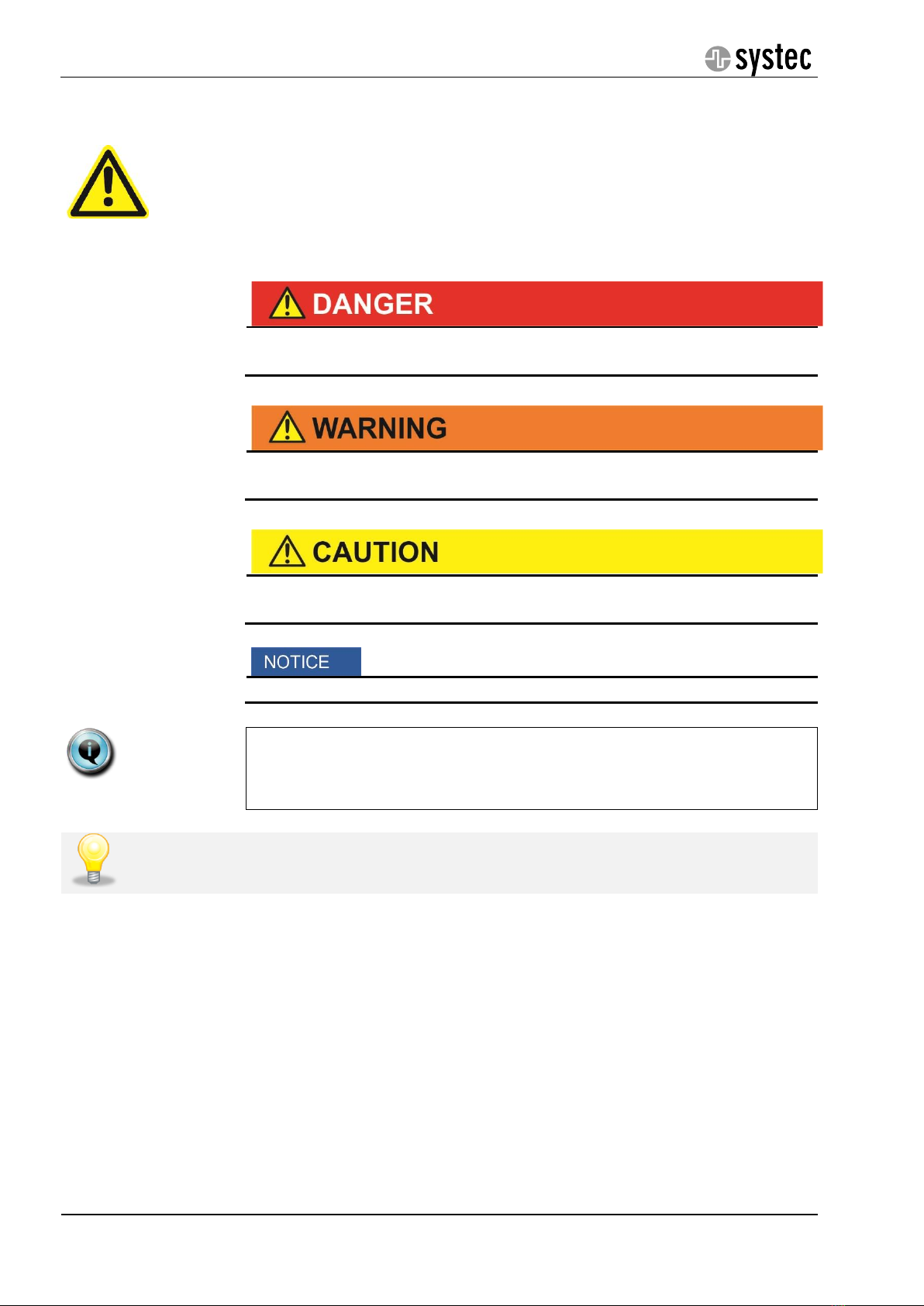

2.1 Important symbols in this manual ...........................................................8

2.2 Warning and safety information..............................................................9

3Life expectancy ....................................................................................10

3.1 Kinematics ............................................................................................10

3.2 Motors ..................................................................................................10

3.3 Hybrid cables........................................................................................10

3.4 Xemo controllers...................................................................................10

4Regular checks.....................................................................................11

4.1 Wiring...................................................................................................11

4.2 Dust deposits ........................................................................................11

5Preventive maintenance ......................................................................12

5.1 Linear axes............................................................................................12

5.2 Guide shafts..........................................................................................12

5.3 Castors..................................................................................................12

5.4 Spindles ................................................................................................12

5.5 Motors ..................................................................................................12

5.6 Xemo controllers...................................................................................12

5.6.1 General comments................................................................................12

5.6.2 Xemo R/S Compact Controllers.............................................................13

5.6.3 Xemo P Controllers ...............................................................................13

6Maintenance of linear axes .................................................................14

6.1 Cleaning axis type DuoLine ..................................................................14

6.2 Exchanging cover bands EL_ 100, 125 ..................................................14

6.3 Belt exchange .......................................................................................15

6.3.1 Axis type ELZ ........................................................................................15

6.4 Checking and adjusting belt tension......................................................17

6.4.1 Belt tension ELZ....................................................................................17

6.4.2 Tooth belt tension axis type DuoLine Z ................................................18

6.5 Adjusting roller castor ...........................................................................20

6.5.1 Adjusting roller castor axis type LLZ60 ..................................................20