3Installation

3.1Installingtheunit

ThePGKductcoolerisdesignedforusingchilledwaterasthecoolingmedium.Theductcoolercoil

consistsofcoppertubesandaluminiumns.

Warning

Thecoolingcoilmustnotbeusedfordirect-expansionrefrigerant.

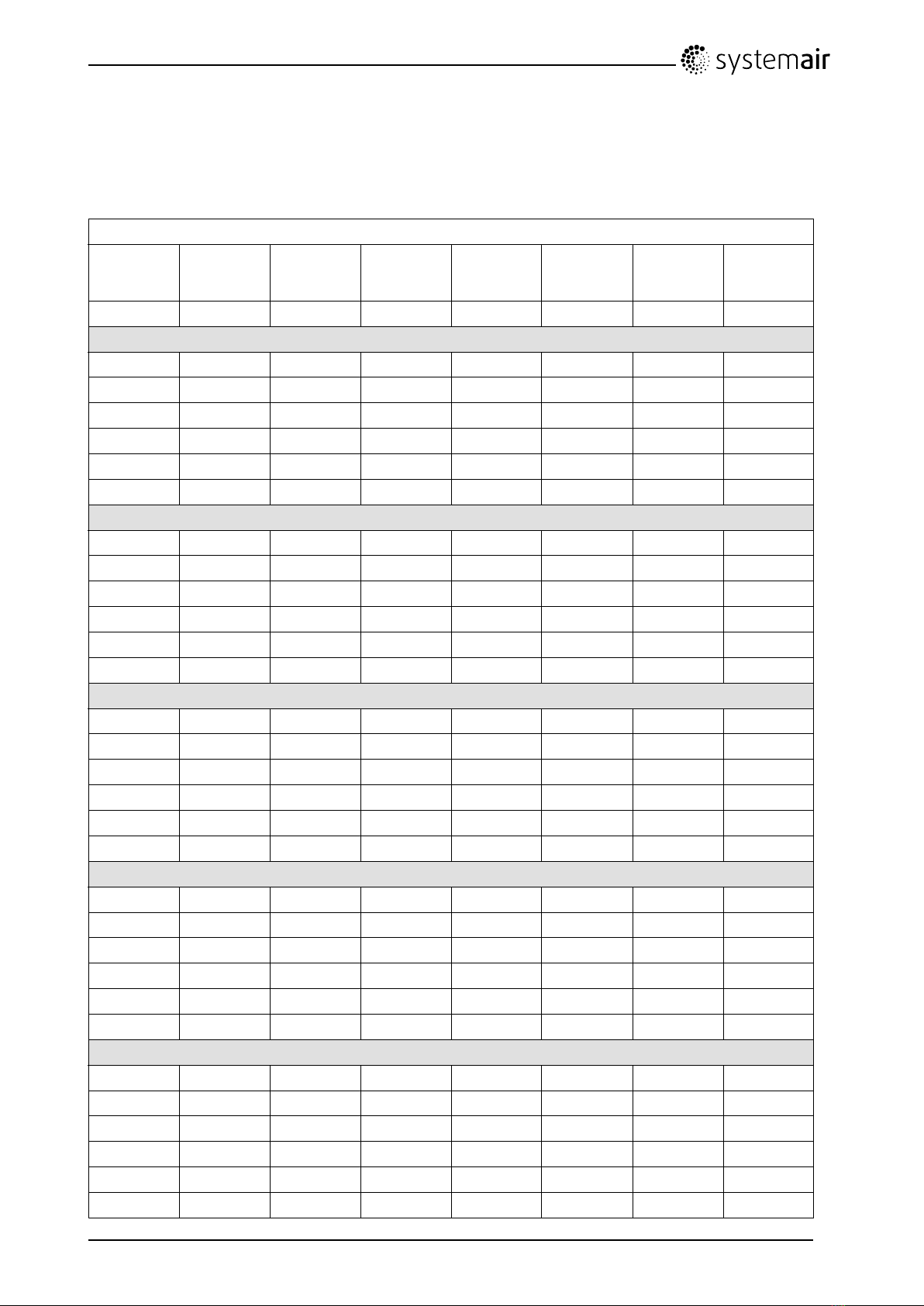

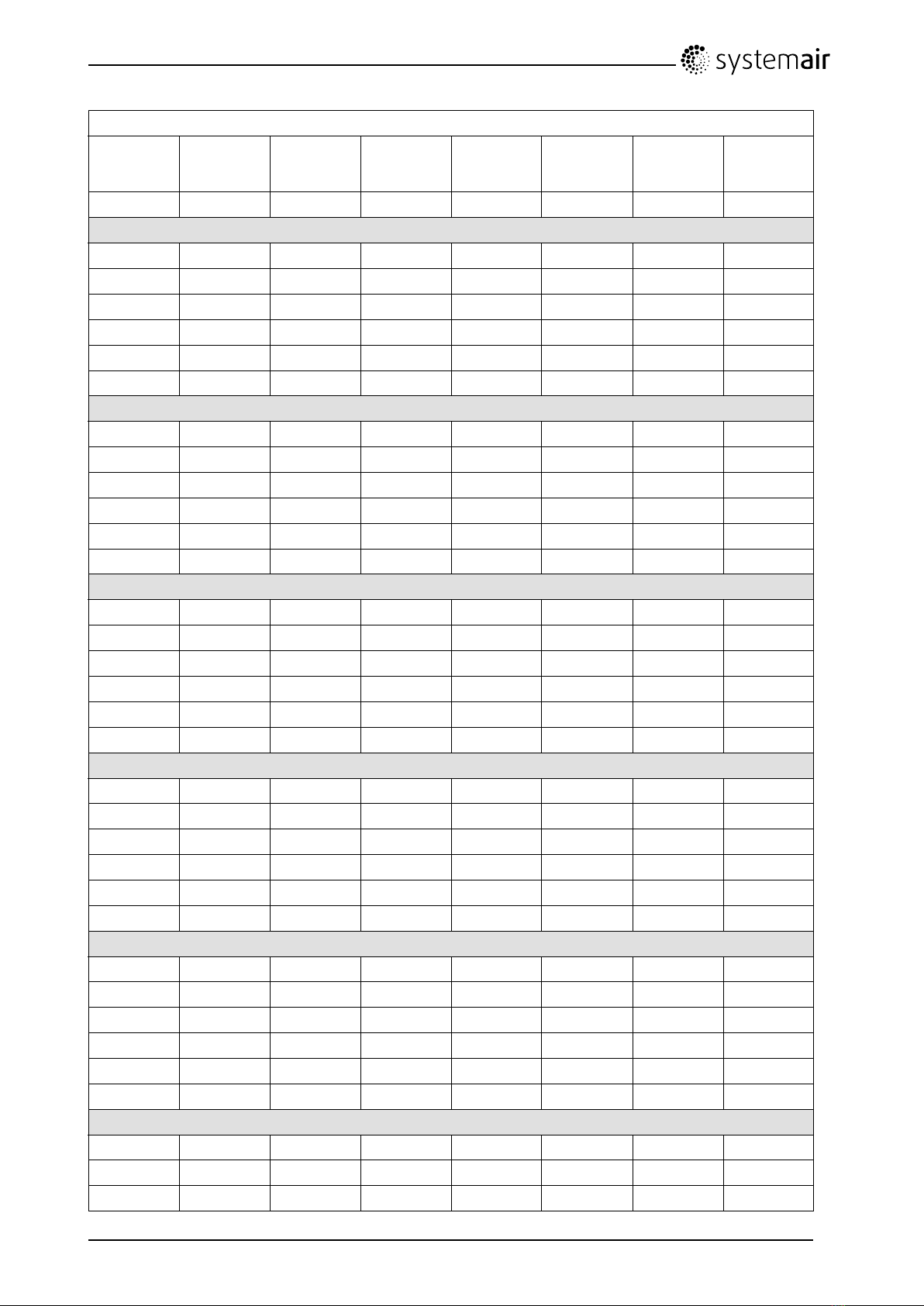

Forairow,waterowandothertechnicalparticulars,seetabellsinchapter4.

Thecoolershouldnotbeinstalledclosetoafanoutletoraductbend,sincetheairowacrossthecoil

wouldthenbeunevenandthecoolingcapacitywouldthusbeimpaired.

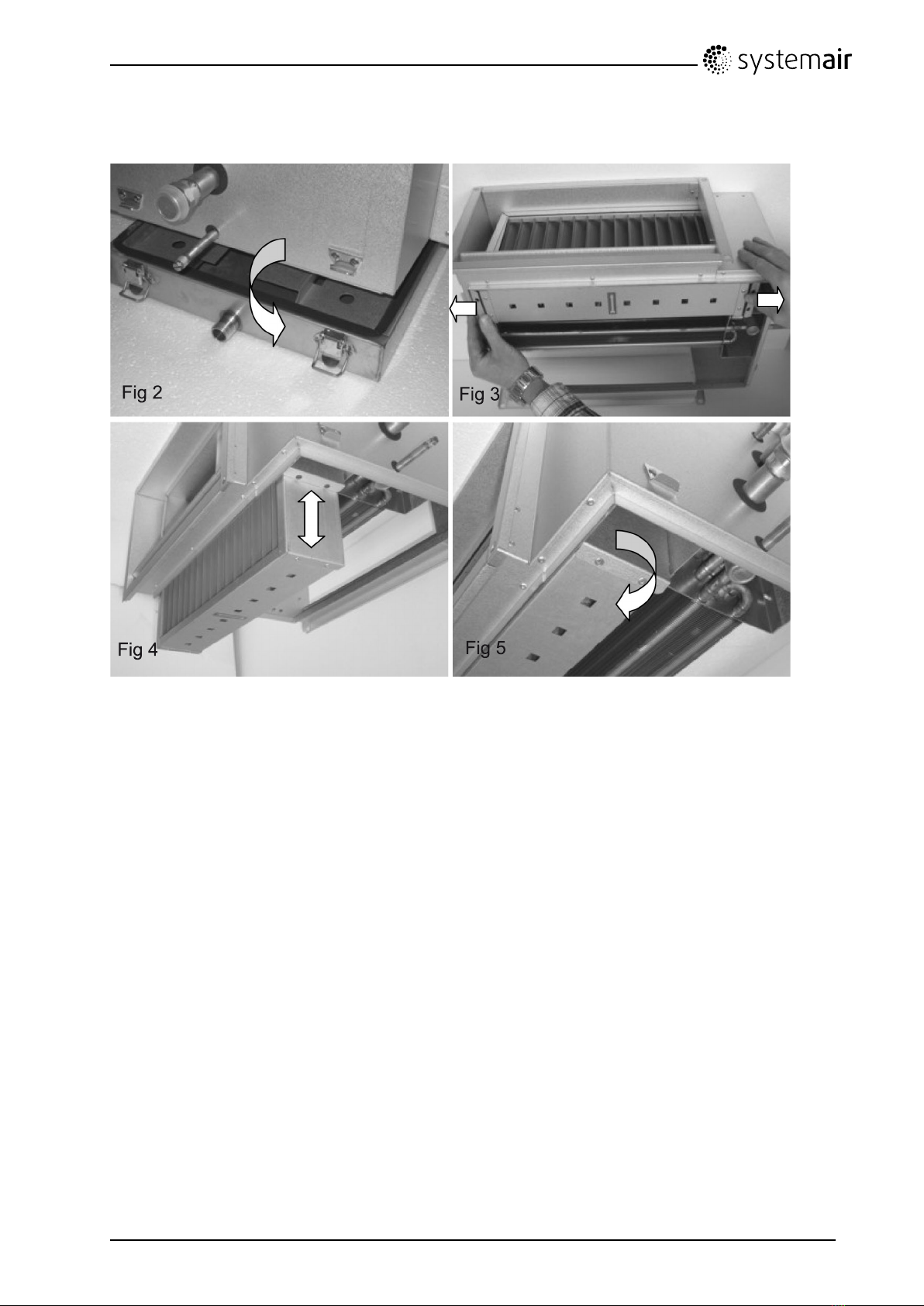

Makesurethatthecoolerisinstalledsothatthennedcoil,driptrayandcondensateoutletareaccessible

forcleaning(chapter5).Theductcoolershouldbeinstalledinahorizontalduct,buttheairowmaybein

eitherdirection.Securetheductcoolertotheductsystembymeansofscrewsorslipjoints.

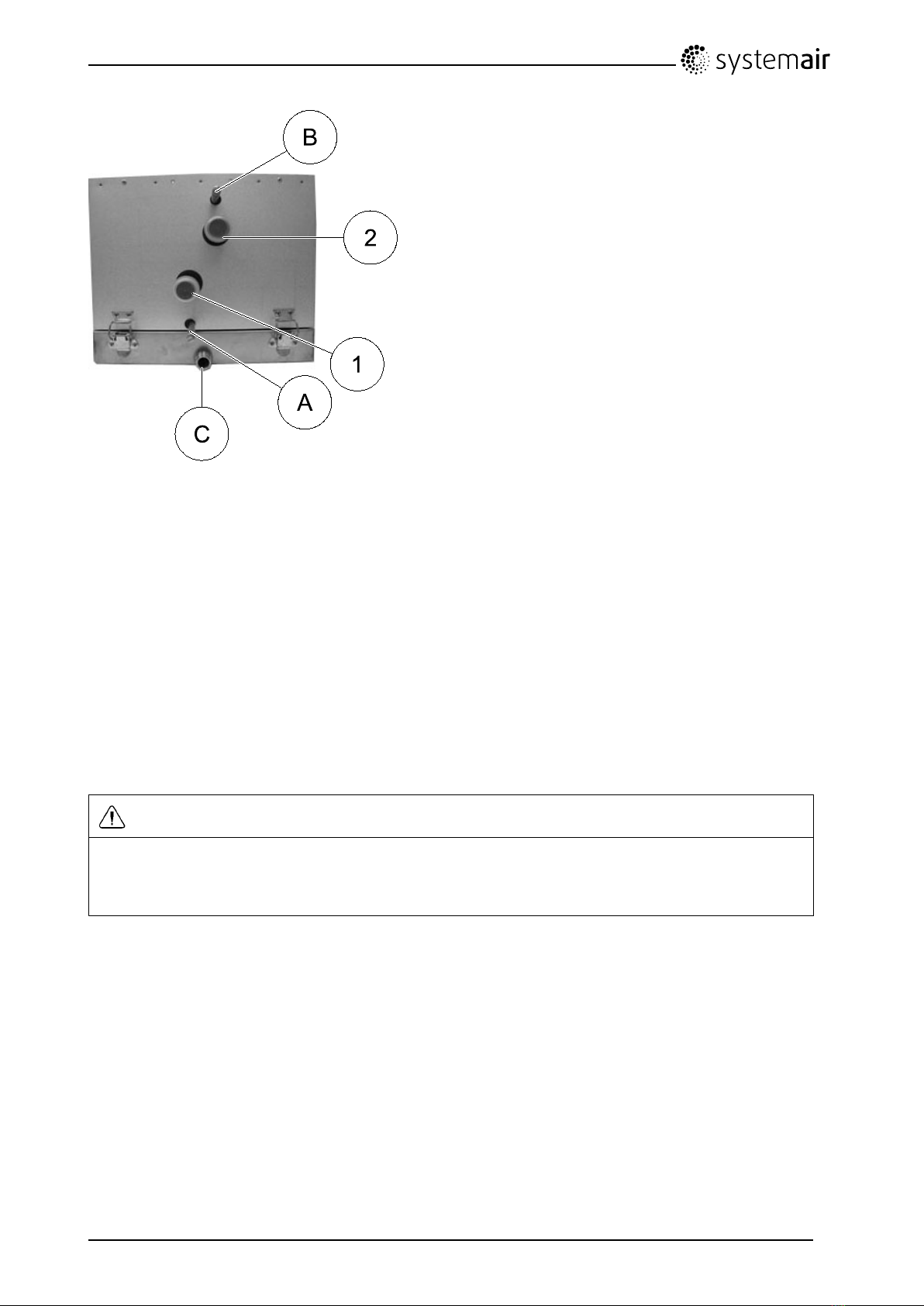

Thecondensateoutlet(posC)ingure2shouldbeconnectedacrossawatertrapinordertoavoid

airleakage.

Note:

Thesizeoftheoutletshouldbesuchthatnowaterwillremaininthedriptray.Whenthedriptrayistobe

removed,ensurethatthecondensateoutletiseasytodisconnect.

Anefcientlterisrecommendedinthesysteminordertoreducefoulingandthusalsocutdownthe

needformaintenance(seechapter5).

Theductcoolershouldbeinstalleddownstreamofthefanunit,althoughitcanalsobeinstalledupstream,

butcareshouldthenbetakentoensurethatthefanmotorandothercomponentswillnotbeharmedby

thehumidairdownstreamofthecooler.

Theductcoolermustbeinsulatedontheoutside,sothatnocondensatewillform.Theductsthatcarry

thechilledairmustnormallyalsobeinsulated.

3.2Waterconnections

Operatingdata:Max.operatingtemperature/operatingpressure100°C/1.0MPa(10bar)

PGKInstallationandService

1723912SystemairAB