Underbody Clamp Operating instructions

(from week 14/2015)

Subject to technical modifications. 14.11.2018

TÜNKERS®Maschinenbau GmbH Am Rosenkothen 8 • D-40880 Ratingen Tel. 02102 4517-0 • Fax 02102 445808 Internet www.tuenkers.de

1. Description

The Underbody clamp is a high-performance tool, which is

designed for clamping tasks in metal processing. It consists of a

pneumatic cylinder, a metal case with front and back attachment

options and a centering mandrel with an integrated tension hook.

The pneumatic cylinder influences on one or two tension hooks

during the clamping process, which clamp the work piece guided

by a platform. The position control of the clamping arm is optional

via an integrated inductive query.

2. Safety

The Underbody clamp is not designed as a ready-to-use

freestanding tool, and is therefore not equipped with its own safety

devices. Only through the proper installation in a manufacturing

system and the establishment of a corresponding safety control

unit are the technical safety requirements fulfilled.

Shut down the Underbody clamp immediately in the event of any

malfunction that is likely to affect personal safety. Maintenance

work may only be performed by properly trained skilled personnel -

while the equipment is shut down.

Ensure that all safety devices are refitted correctly after

maintenance work has been carried out.

Maximum load depends on diameter of dowel pin and geometry of

the hook.

3. Assembly of the Underbody clamp

Installation of the clamp via 4 cheese-head screws on the front

or back support surface.

Create a compressed air supply between the pneumatic

control unit and the clamp (connections "N").

Caution: The use of external flow control valves is

recommended for the fine tuning of the speed of the clamping

process.

If using magnetic switches, assemble and connect these.

Inductive query (T12)

Attach the electric coupling according to the electric construction

of the pneumatic clamp to the connection plug "C" and tighten.

Attention: When operating a KN 40 UZ version „B“ the adjusting

screw „A“ must be set to position „V“ (see pic. 3) so that the

blocking system is activated.

Caution: An operation with the incorrect or excessive voltage may

result in short circuiting and physical injuries.

The function check of the integrated LED is as follows:

green................... Operating voltage

yellow.................. Clamp open

red ...................... Clamp closed

4. Adjusting the Underbody clamp

Caution! Risk of crushing injuries!

There is danger of fingers being crushed or amputated during

adjustment of the clamping hook! Do not reach into the swivel area

of the clamping hook while the Underbody clamp is operating.

Interrupt the compressed air supply prior to working in the tool

area.

Move the Underbody clamp to the open position, clamping

hook is retracted in centering pin.

Place the work piece on the centering pin and move to the

desired position.

Move the clamp with compressed air to the closed position, so

that the clamping hooks contact the work piece.

If the end position is not shown by the position check of the

switches (clamp closed, LED red), the placement of the work

piece (adjusting plate, base plate) must be corrected

accordingly.

5. Blocking system „B“

KN 40 UZ clamps version "B" are equipped with a mechanical

blocking system acting in „open“-direction. In case of a

spontaneous failure of the compressed air supply, the movement

of the clamp arm in "open" direction will be prevented.

Operating mode:

The blocking system consists of balls which are arranged in a

cone concentric to the piston rod. The balls are pressed into the

cone by spring force. This leads to jamming of the piston rod in

the intended movement direction for opening.

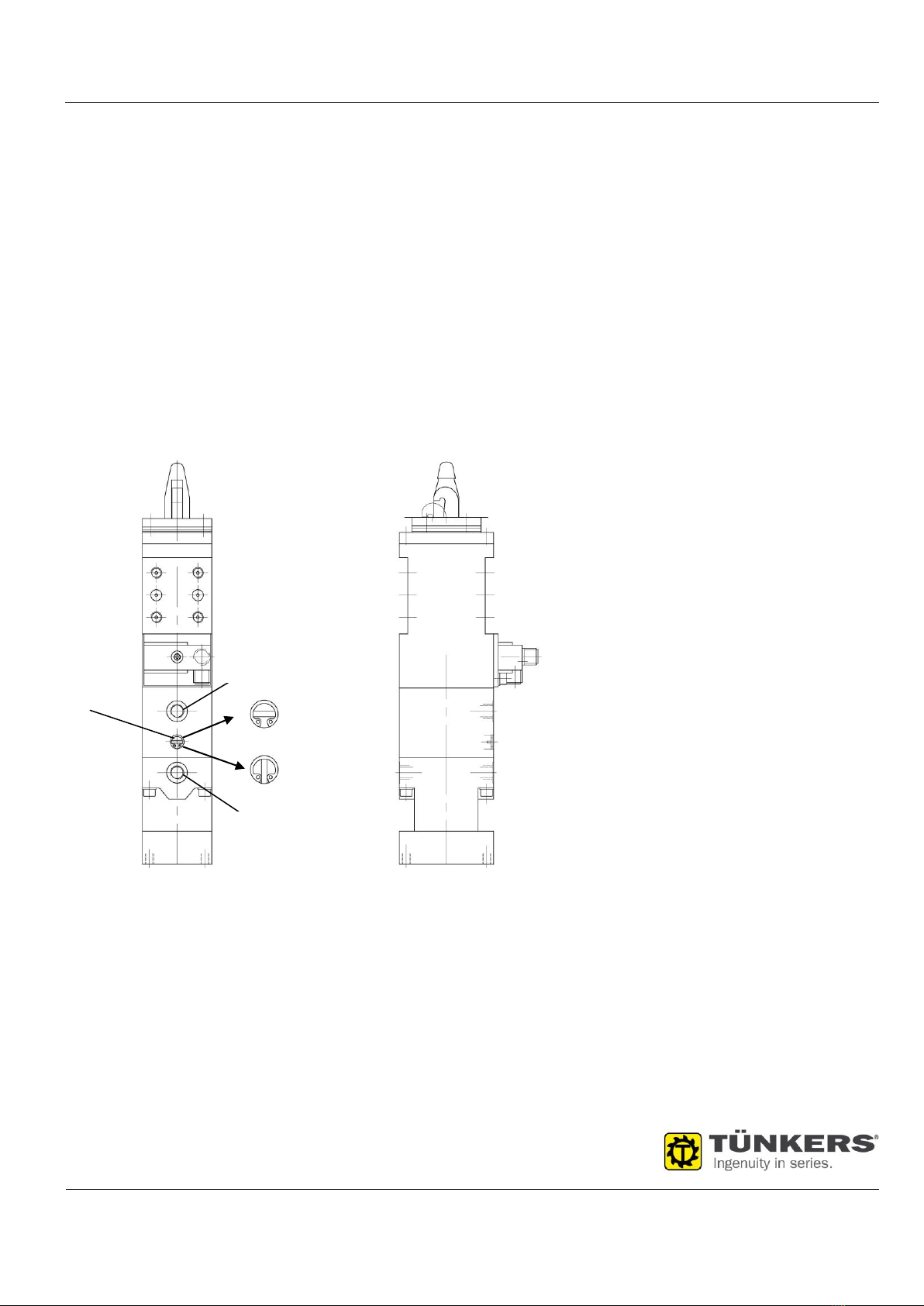

Pic. 2: Blocking system „B“