APPLICA ION:

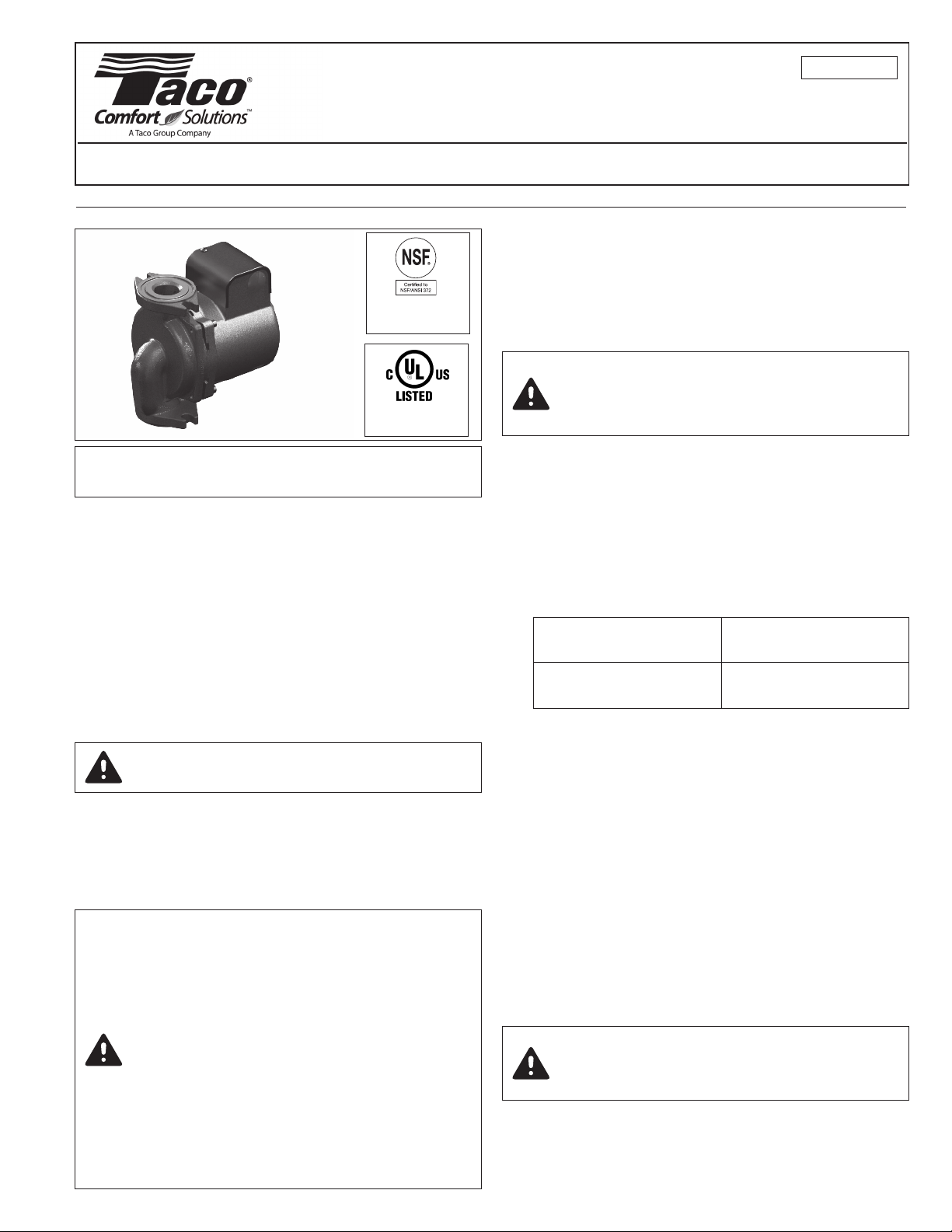

The Taco 2400 Series Hi-Capacity circulators are designed

for use on a wide range of hydronic heating, cooling or

domestic water re-circulating systems. Features include a

quiet running, close-coupled, thermally protected motor

assembly with permanent split-capacitor and permanently

lubricated bearings. A stainless steel face plate and shaft,

carbon/silicon-carbide mechanical seal and non-ferrous

impeller make the 2400 series an ideal choice for years of

maintenance-free operation on open or closed systems.

Note: Always use Stainless Steel body circulators on

open, fresh water systems.

OPERA ING SPECIFICA IONS:

• Maximum Working Pressure: 150 psi (1000 kPa)

• Maximum perating Temperature: 225ºF (107ºC)

• Electrical Rating: 115V/60Hz/1Ph or 230V/60Hz/1Ph

REMOVAL OF EXIS ING PUMP FROM SYS EM PIPING:

1. Disconnect and lock-out electrical supply to pump.

2. Close isolation valves on suction and discharge sides

of pump. If valves are not installed, the system may

need to be drained.

3. Remove capacitor box cover and disconnect electrical

supply lines to pump.

4. Loosen flange bolts and shift pump body slightly to

relieve any remaining system pressure.

5. Remove flange nuts/bolts and pump from system.

REPLACING HE MECHANICAL SEAL: Refer to Fig. 1

on back page.

1. Follow steps 1 thru 5 in section “Removal of existing

pump from system piping”.

2. Loosen the four body bolts that attach the motor hous-

ing to the casing. While supporting the motor, remove

the four bolts and carefully remove the motor and

impeller assembly from the casing.

3. To remove the impeller, first insert a screwdriver into

the motor ventilation slots to make contact with one of

the rotor cooling fins. While holding the rotor in place

with the screwdriver, turn the impeller clockwise to

loosen and remove from shaft.

4. Remove the seal assembly from the impeller shaft.

Note: 2400 models with suffix “3P” are provided with a

3-piece rotating seal.

5. Remove the seal face plate by gently prying it away

from the housing.

Instruction Sheet

Mechanical Seal Replacement

2400 Series Hi-Capacity Circulator

102-414

SUPERSEDES: December 19, 2014 EFFECTIVE: March 2, 2015

Plant ID# 001-3933

INS ALLER: Please leave these instructions for

owner’s use.

CAU ION: aco “2400 Series” circulators are

designed for indoor use only.

CAU ION: o prevent injury, allow system

water to cool to 100ºF before removing old

pump or draining system. Leave drain valve

open until service/replacement is complete.

* Includes new body gaskets

CAU ION: Do not allow screwdriver to make

contact with motor windings or insulation.

Permanent damage to motor may result.

MECHANICAL SEAL

OP IONS SEAL KI NUMBER*

Standard Seal

Carbon/Silicon-Carbide 2400-029RP

CAU ION: he majority of mechanical seal

failures are due to poor media (fluid) quality

in the system. o maximize seal life, media

quality must be maintained in the system,

and DS ( otal Dissolved Solids)/ SS ( otal

Suspended Solids) should not exceed

500ppm with standard Carbon/Silicon-

Carbide seals. he use of inhibitor based

glycols is acceptable, but additional

inhibitors should not be added. Always fol-

low the glycol manufacturer’s specification

for system preparation and water quality.

reatment with silicates should not be used.

Failure to maintain media quality will void the

standard aco warranty.

STAINLESS STEEL

MODELS ONLY

FOR INDOOR

USE ONLY