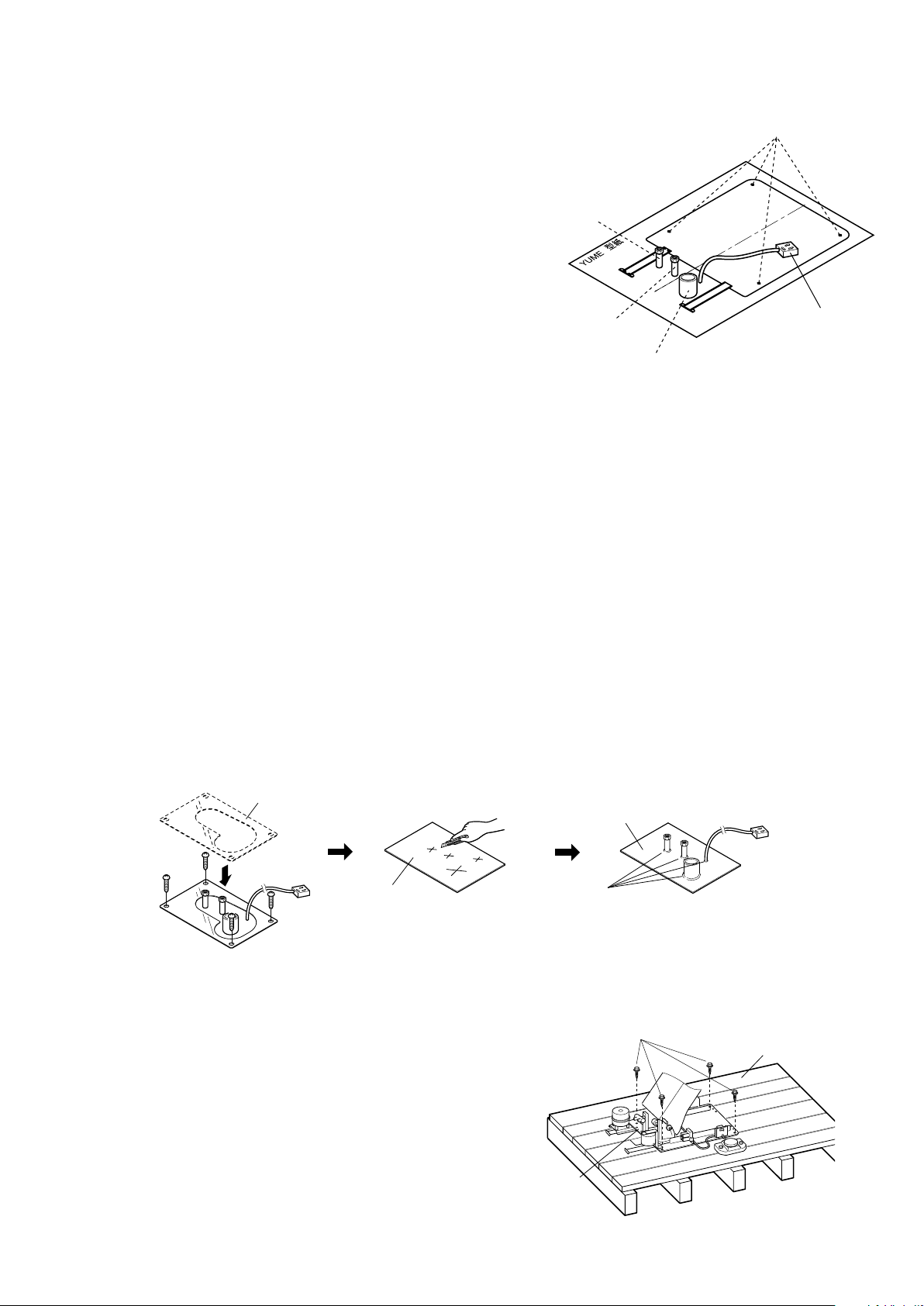

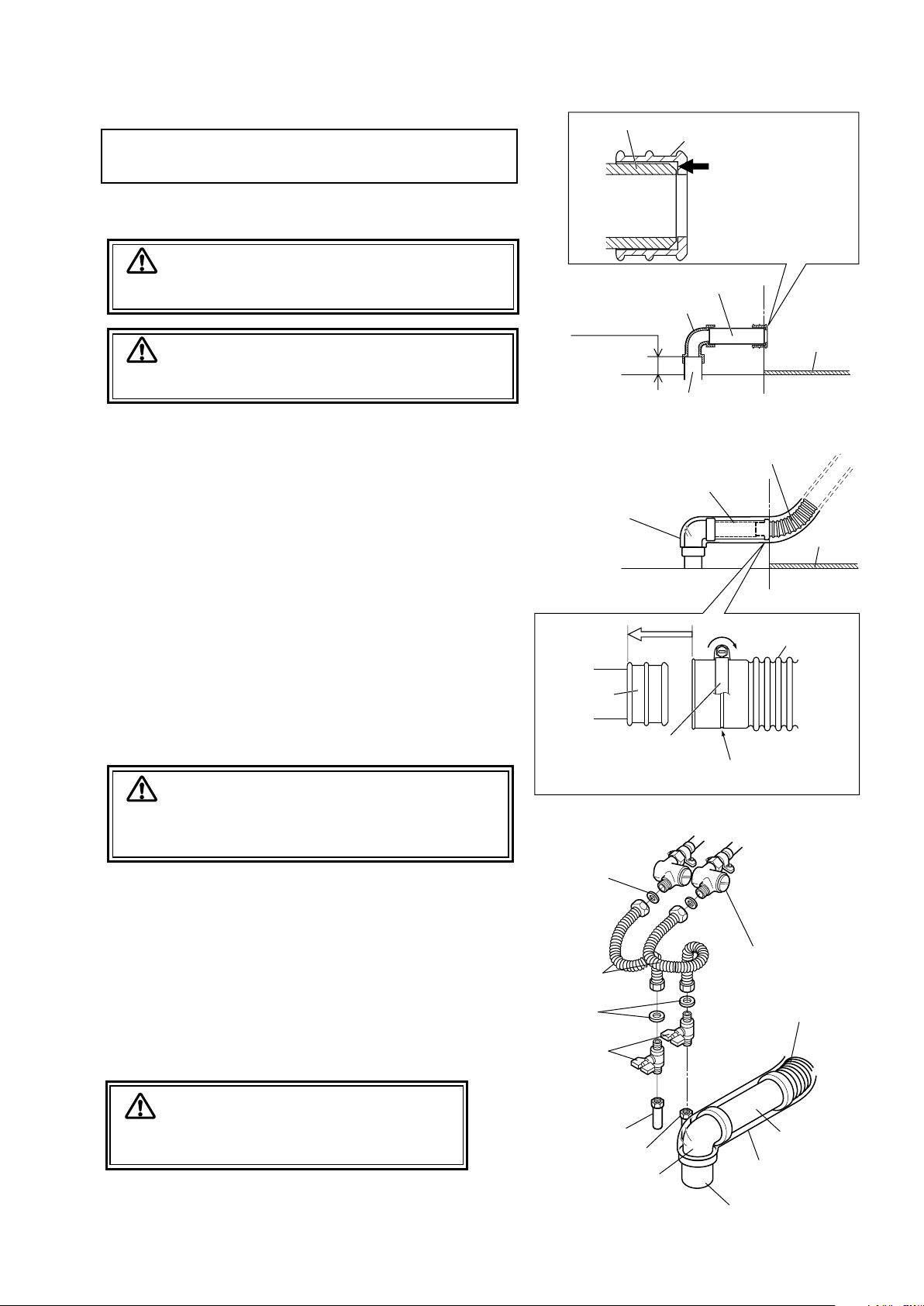

Check Valve

Flexible Pipe

Packing

Stop Valve

Water Supply

Hot Water Supply

Drain Hose

Vinyl

Drain Pipe

Elbow

Packing

The height of drain pipe should be less than 60mm.

CAUTION

1. Insert the elbow to the drain pipe from floor with seals.

2. Adjust the length of drain pipe(VU40), so that the

one end of drain pipe(VU40) may become on the

edge of the base, and connect to elbow with seals.

3. Connect the drain hose packing to the drain pipe(VU40).

4. Through the drain hose clamp to the drain hose, and

connect the drain hose to the drain hose packing.

•The drain hose shall be free of dent.

•Attach the drain hose so as not to be folded.

5. Fasten the screw of the drain hose clamp for

drain hose.

•Tightening too hard may damage the drain hose.

Do not tighten too hard.

6. Cover the elbow part with the vinyl.

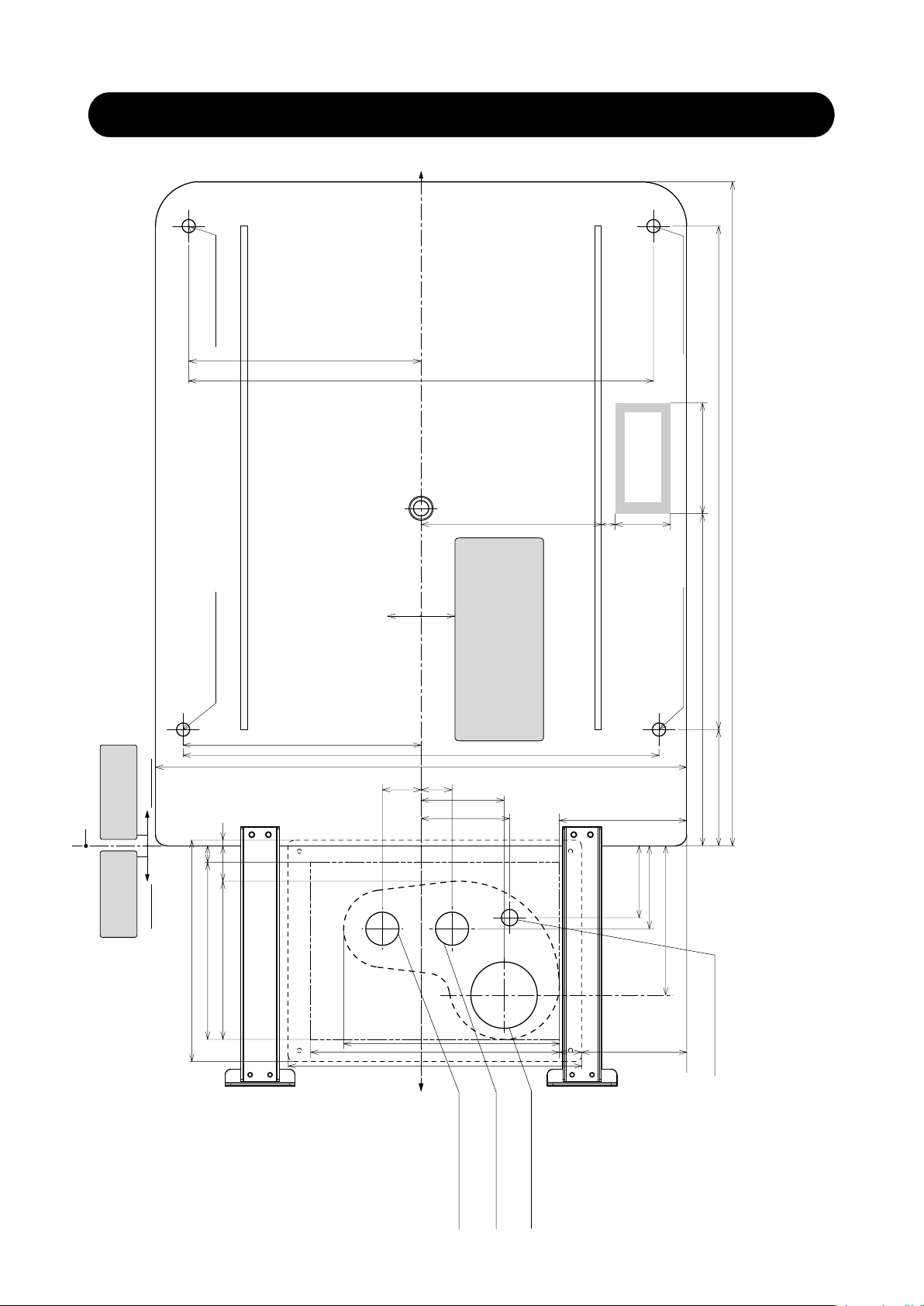

5-6. Drain Pipe Connection

5-7. Water and Hot Water Supply Line Connection

1. Install the stop valve to each supply pipe.

2. Bend each flexible pipe to a suitable angle for

connection.

Check the each connection for leaks.

3. Connect the each Check Valve to the each stop

valve with the flexible pipe.

Make sure all connection is surely fixed.

please confirmed the water does not leak.

Drain Pipe(VU40)

CAUTION

CAUTION

Elbow and drain pipe(VU40) are not included

with shipment. Please prepare it beforehand.

Do not tear up the vinyl which is covered the drain hose.

CAUTION

F.L.

F.L.

Drain Hose Packing

Drain pipe(VU40)

Stepped Section

Drain pipe(VU40)

Elbow

Less than 60mm

Drain Pipe

from Floor

Edge of Base Plate

Base Plate

Insert the drain hose packing

to the drain pipe(VU40) until

the stepped section hit to the

end of drain pipe(VU40).

Drain Hose

Base Plate

Edge of Base Plate

Vinyl

Drain pipe(VU40)

Drain Hose

Packing

Drain Hose Clamp

Drain Hose

Insert it in

this line

Match the center of the drain hose clamp

to this line of the drain hose.

Fastening