10

Bolts to be used

(Accessory to shampoo unit):

Plywood floor:

Hex head tapping bolt + Plain washer

(8 mm x 50)

Concrete floor:

Anchor bolt + Plain washer

(M8 x 70, Anchor hole 8.5 m/m)

(Use a wrench with across flat 12 mm.)

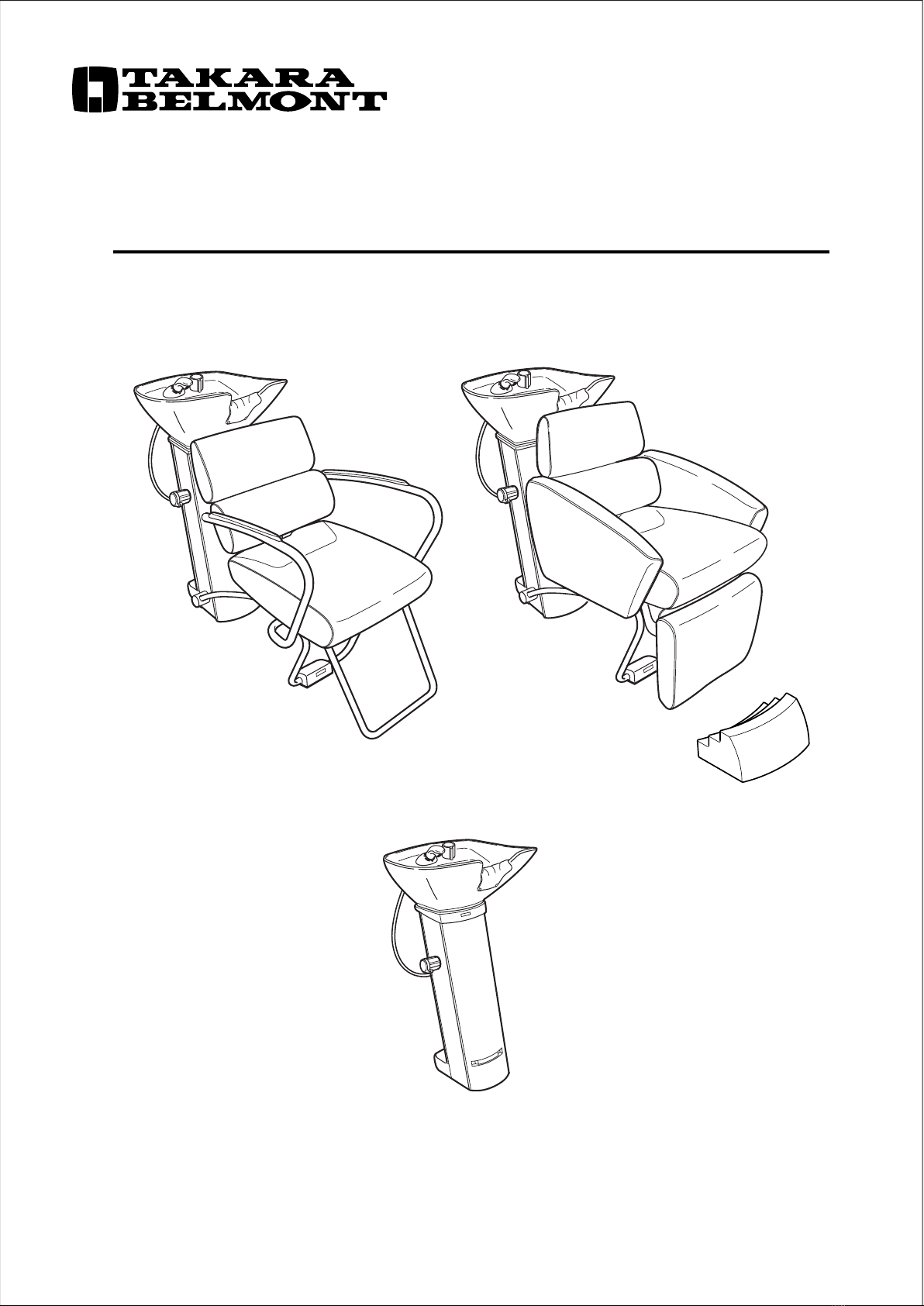

Fixing the shampoo unit.

1

Attach the shampoo unit to the base bracket securely.

2Detach the four screws on the shampoo unit.

3Attach the chair mount frame to the shampoo unit.

Then fix the shampoo unit temporarily with the

screws detached in 2 .

4Fix the chair mount frame on the floor at the marked

position with the chair mount frame packing inserted.

5Tighten the screws that were loosely fastened in 3 .

CAUTION

When using anchor bolts, do not use the spare hole in the

rear side. The bolts will make contact with the cover.

CAUTION

If the anchor bolt is tapped with its end contacting the bottom of the hole, the strength will be lowered. Proper

clearance must exist between the end of the anchor bolt and the bottom of the hole.

CAUTION

• Be sure to use the chair mount frame packing when fixing the chair mount frame.

• Be sure to use the plain washer when tightening the bolt.

• The center of the shampoo unit must be aligned with the center of the chair mount frame. (The center of

the chair mount frame is the notch of the chair mount frame packing.)

3

Anchoring procedure

Attaching the chair mount frame cover and frame receiver cover.

Attach the chair mount frame cover on the chair mount frame.

4

Chair mount

frame cover

Place the frame receiver

cover on the chair mount

frame and press it firmly to

the end.

8.5 mm

Depth of

anchor hole:

Min. 50 mm

Pattern

paper

Floor

Rod

2 to 5

mm

Plain

washer Nut

4Adjust the fastening strength

of the nut using a wrench etc.

3Insert the anchor, tapping it

lightly with a hammer to seat

it. Position the material, and

then drive the rod into the

anchor until it is snug.

2Clean each anchor hole

thoroughly using a vacuum

cleaner, with a narrow nozzle

attachment to reach into the

hole and remove all debris.

1Drill the anchor holes of a

specific diameter and depth.

Chair mount frame packing

Center line