5

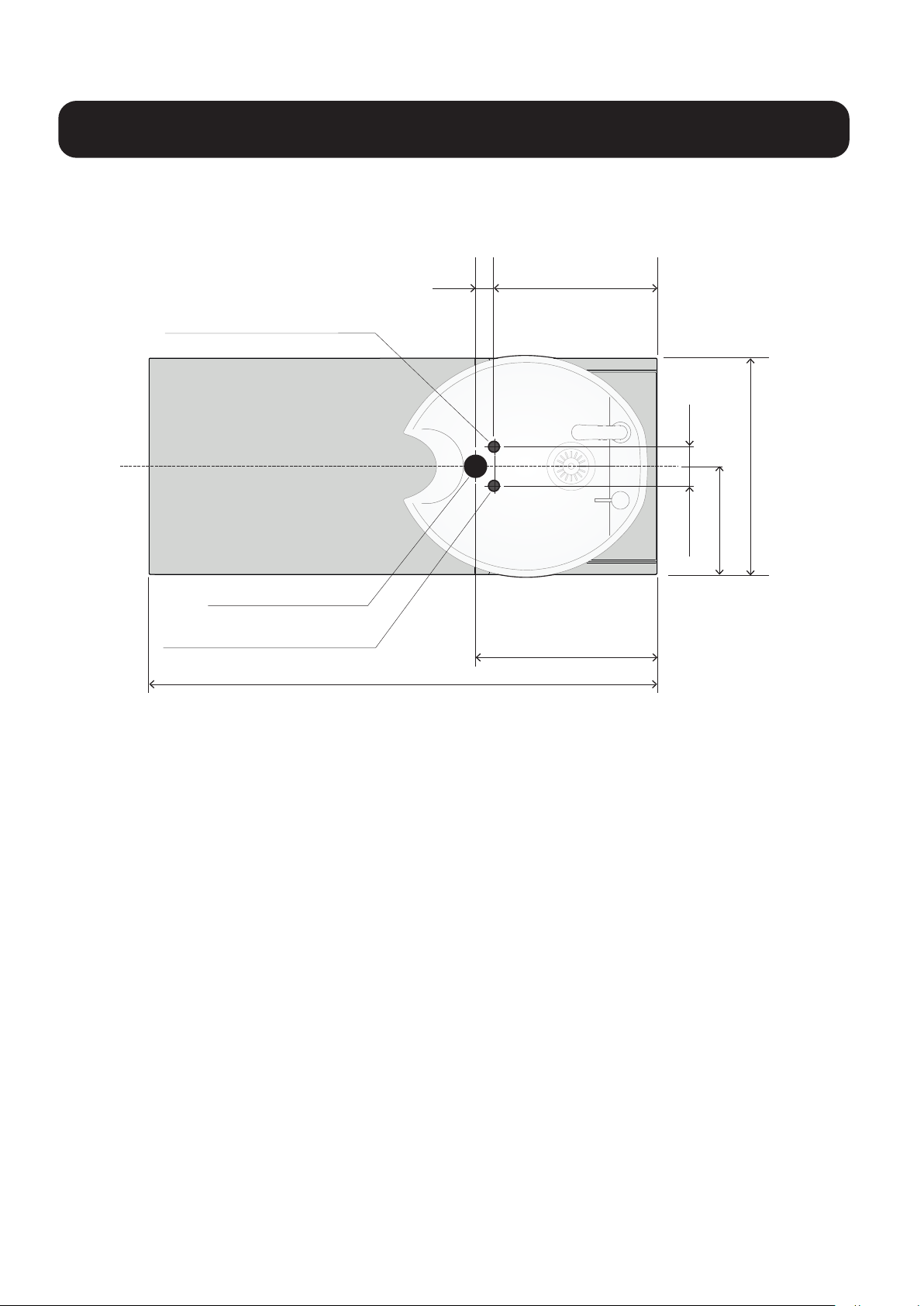

Specifications

Floor surface

°Ensure that the material or finishing of the floor surface is waterproof or has a waterproof coating applied.

°Always ensure that the floor surface is horizontally level.

°Ensure that the floor surface is smooth and free from bumps around the attachment areas.

°If the floor surface is tiled, cracks may occur when fastening the bolts during installation of the SWASH main body.

If this looks likely to happen, use the main body attachment diagram and template as a reference and change the material

of the attachment area that is in contact with the floor to another such as plywood or mortar.

Take care during installation as the entire base surface of the seat body is not in contact with the floor.

°The following levels of strength are required for the floor surface.

Wooden floor Plywood thickness of 30 mm or more (two 15 mm sheets joined together)

Mortar floor Mortar thickness of 50 mm or more

Special floor (stone finish) A foundation with levels of strength listed above around the installation areas is required.

Preventing water leakage

°If this product is to be installed upstairs, ensure that the installation area has been coated with waterproof materials

(waterproof finish, installation of a stainless steel pan or a water leakage sensor).

°Fill the space between the installation area and pipe with caulking materials.

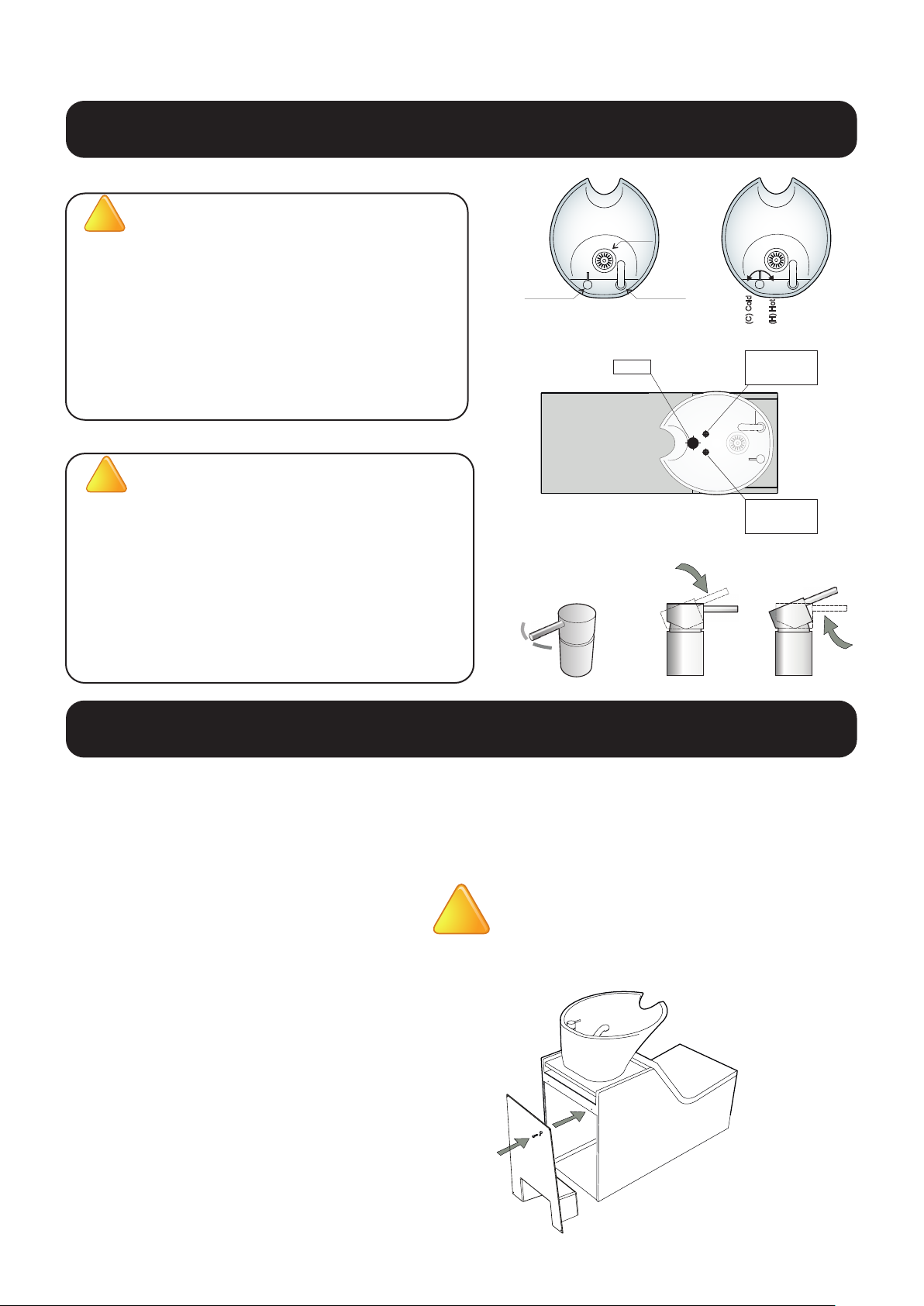

Installation of pipes

The following are important points to adhere to during the installation of pipes.

Read through the details carefully and ensure that the pipes are installed correctly.

°When installing this product, ensure that installation of pipes adheres to the instructions outlined in

"Precautions during installation of pipes". Installing pipes without reading through the precautions will mean water may

not mix properly, and a set temperature will not be achieved.

°This product is designed for indoor installation. Always install this product indoors.

Precautions during installation of pipes

°Do not use pipes made of materials that may introduce rust for the water supply pipe.

°In general, the same diameter and same pressure is recommended for hot water pipes and water supply pipes.

°Always use a reamer to deburr the ends of cut pipes.

°Avoid using inverted U-shaped pipes (siphon) as these can cause air to become trapped.

°Always connect hot water pipes and water supply pipes after removing all contaminants such as dirt, sand and oil

as these can cause problems.

°After connecting the pipes and testing water flow, clean the filter and shower head.

°Do not connect the hot water pipes and water supply pipes in reverse.

Connecting pipes in reverse will mean the temperature of water cannot be controlled properly by the water taps,

which can cause problems including burns.

°Ensure that the hot water pipes from water boilers are only run over a short distance so as to minimize resistance.

Longer pipes can cause fluctuations in temperature and poor hot water delivery.

°Always wrap pipes with lagging material after installation is complete.

°In general, the same diameter and same pressure is recommended for main hot water pipes and main

water supply pipes.

°Equipment comes with hair catchers installed.

Usage conditions

° Public water supply (do not use non-drinkable well water or water that contains rust or sand.)

° If the water hardness is 80 ppm or higher, install a water softener to prevent the buildup of scale

within the basin body. Aeration may be minimal when using shampoo even if drinkable well water

is used, so a water softener should be installed.

° Use a pressure set between 0.1 to 0.4 MPa (1 to 4 kgf/cm2). If multiple SWASH are used,

ensure that the pressure does not drop below 0.1 MPa (1 kgf/cm2).

° Set the water supply pressure > hot water supply pressure.

° Set the difference between the hot water supply pressure and water supply pressure to within

0.2 MPa (2 kgf/cm2).

Water used

Hot water supply,

water supply pressure