Safety Precautions

4.Pay attention to the job at hand. Do not let your mind lose concentration on

what you are doing.

5.Use your seat belt and R.O.P.S. (Roll Over Protective Structure) when operating

the skid-steer loader. Keep belt and R.O.P.S. in good repair. Do not modify

R.O.P.S. or seat belt. Do not remove R.O.P.S. or seat belt. Overturning the skid-

steer loader without proper R.O.P.S. and seat belt can result in death.

6.Fasten your seat belt before and during skid steer loader operation. Remain

seated at all times.

7.Do not take passengers on the skid steer loader or attachment. There is no

safe place for a passenger.

8.Use hand hold when getting on and off the skid-steer loader. Failure to do so

could cause a fall.

9.Inspect the skid steer loader before you try to operate the unit. Check for

needed maintenance or repairs and have them done before using the equipment.

10.Never leave the skid steer loader running unattended. Always lower lift arms,

set parking brake, turn off engine, and remove key.

11.Wear appropriate clothing such as safety glasses, ear plugs, etc. Do not wear

loose fitting clothing; it may catch on the equipment. Always wear a hardhat

when operating the skid-steer loader to prevent head injury.

12.When driving on public roads use safety light, reflectors, slow moving vehicle

sign, etc., to prevent accidents. Check with local governments for regulations

that may affect you.

13.Turn off the skid-steer loader before performing maintenance. If the lift arms

must be left raised for any reason, use a positive lift arm lock to secure arms in

place. Serious damage or personal injury could result from lift arms accidentally

lowering.

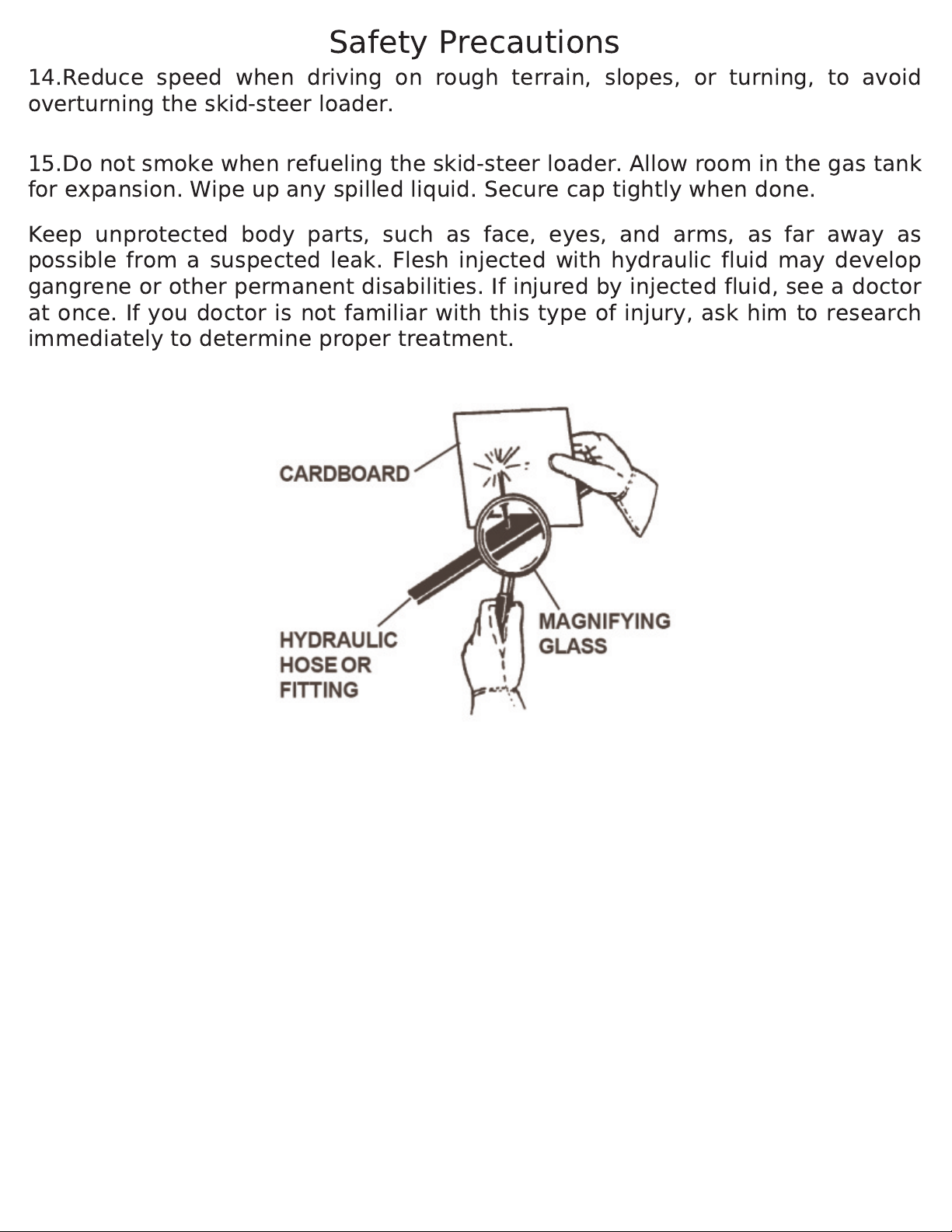

Escaping fluid under pressure can have efficient force to penetrate the skin

causing serious personal injury. Fluid escaping from a very small hole can be

almost invisible. Use a piece of cardboard or wood, rather than your hands, to

search for suspected leaks.