P3/19

IOM_FIH210201_HALIOS STD-PREM_EN

The technical data and performance may be modified

without prior notice depending on the technical advances.

FOLLOW OPERATING INSTRUCTIONS!

WARNING

It is strictly forbidden to modify,

remove, by-pass or override the safety

installations.

In the absence of prior written approval by the manufacturer, do

not carry out any modifications to the accessories and equipment

surrounding the hydrant which may jeopardise safety! Changes

at the hydrant carried out on one’s own authority void the

manufacturer’s liability for any damage resulting therefrom.

This applies also to installation and setting of safety devices and

hydrant, as well as welding at supporting parts.

1.2.4 Dangers when handling the hydrant

Our hydrants are designed to the state of the art and according

to the approved safety rules. However, these hydrants can

constitute a danger for persons and property especially when

handled by untrained staff in an unskilled manner or when

they are not used in accordance with their proper purpose. This

may cause danger to life and limb of the user or third parties or

damage to the hydrants and other property.

Access to the danger zone shall only be possible when the hydrant

is out of operation and when it is ensured that the conveying units

and the following units are shut down, in order to avoid danger to

the operating and maintenance staff.

Whoever, in the user’s facilities, is engaged in mounting,

dismantling or remounting, operation and service (inspection,

maintenance, repair) of the hydrants, must familiarise

themselves with the applicable regulations in force locally.

Work at the hydrant site (as e.g. control, maintenance and repair

work) shall only be carried out when the area has been secured

and shut down and when power at the area has been switched

off.

Before removing safety devices and/or carrying out work on the

hydrants, the pipe section must be made pressureless to avoid

risk. Unauthorized, erroneous or unexpected operation, as well

as dangerous movements caused by stored energy (compressed

air, pressurized water, hydraulic system), must be avoided.

A copy of the operating and maintenance instructions must

always be available on site and must be protected against oil and

grease.

If necessary, or as specified by the rules, use suitable personal

protective equipment!

Any instructions concerning safety and dangers at the working

area must be observed and a written copy must be maintained

in legible condition and periodically renewed or replaced, if

necessary.

During operation, protective gloves must be worn.

In the event of changes to the hydrant or its operating

performance which might affect safety aspects, operation must

be stopped immediately and the problem reported to the relevant

department/person!

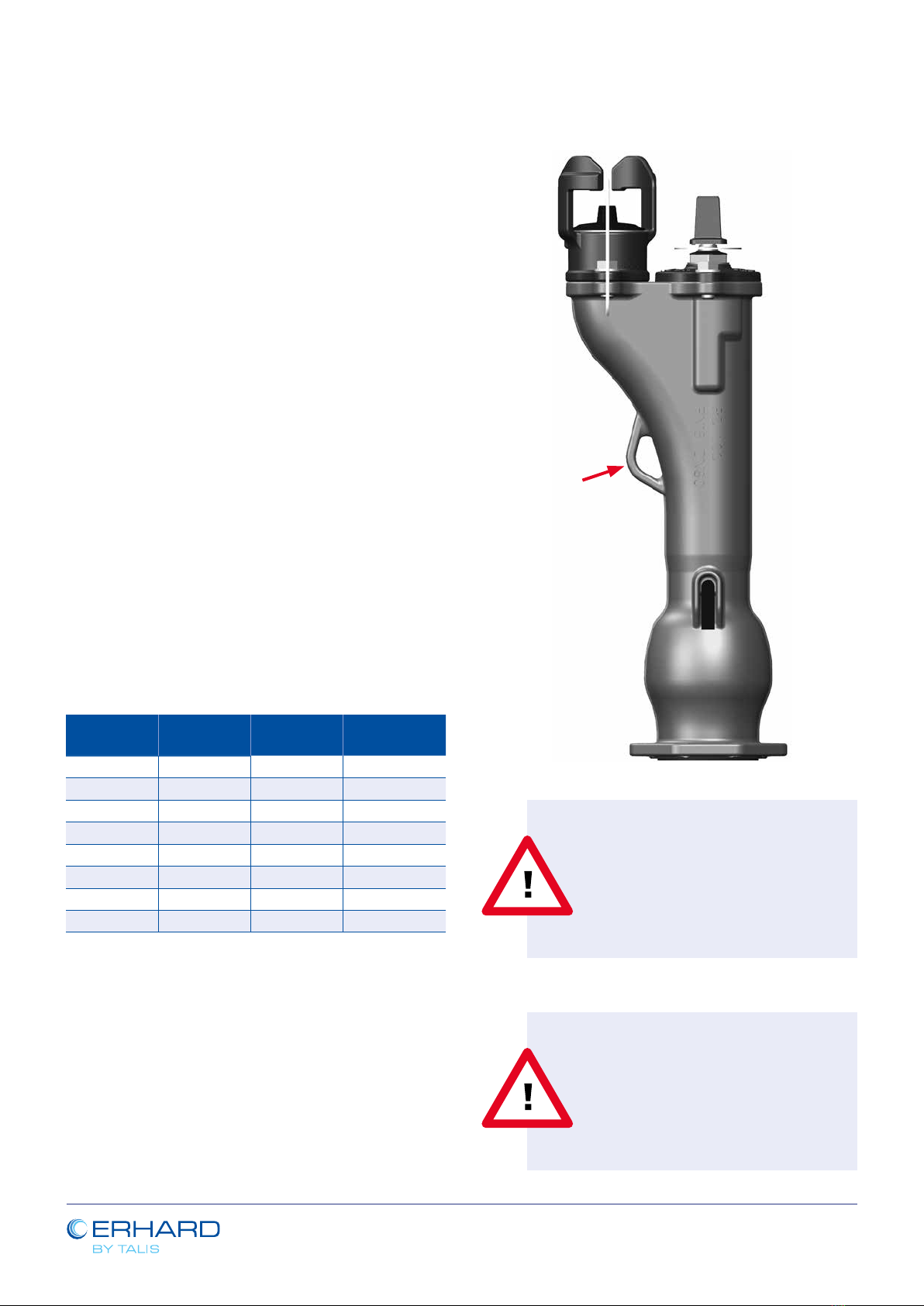

Before any maintenance operation on the hydrant, the network

section where the hydrant is installed must be isolated upstream,

and depressurized in order to relieve the hydrant free from

pressure. Failure to comply with this recommendation will lead

to a situation of danger to persons and property.

When maintenance and repair work at the hydrant has been

finished prior to commissioning of the hydrant, check whether all

safety devices and equipment have been remounted and make

sure that they are operative.

If work is carried out in the vicinity of the hydrant that may lead to

soiling (e.g. concrete work, masonry, painting, sandblasting) the

hydrant must be covered effectively.

1.2.5 Working conditions for operators

Take care that there is sufficient space available for operation,

mounting and maintenance work. Access to the hydrant must be

provided in such a way that this work can be carried out by using the

appropriate technical means (tools, measuring instruments, etc.)

The operator should not work directly above the hydrant to

prevent personal injury.

The operator should not work directly above the hydrant to

prevent personal injury.

The user must provide adequate instructions in order to ensure

that the working area is clean and suitably arranged.

WARNING

Observe the applicable rules concerning

safety, and wear the necessary personal

protective equipment. Risk of injury!

1.2.6 Safety and protective equipment (graphics)

Use ear muffs and helmet

Use eye protection Use protective gloves

Wear safety boots