WARNING

• Petrol is explosive under certain conditions.

• Refuel in a well-ventilated area with the engine stopped. Do not smoke or allow flames or sparks in

the area where the engine is refueled or where gasoline is stored.

• Do not overfill the fuel tank (there should be no fuel in the filler neck.) After refueling, make sure the

tank cap is closed properly and securely.

• Be careful not to spill fuel when refueling. Spilled fuel or fuel vapor may ignite. If any fuel is spilled,

make sure the area is dry before starting the engine.

• Avoid repeated or prolonged contact with skin or vapor.

PETROL CONTAINING ALCOHOL

If you decide to use a gasoline containing alcohol (gasohol), be sure it's

octane rating is at least as high as that recommended by Talon. There

are two types of gasohol :one containing ethanol, and the other

containing methanol. Do not use gasohol that contains more than 10%

ethanol. Do not use gasoline containing methanol (methyl or wood

alcohol) that does not also contain cosolvents and corrosion inhibitors

for methanol. Never use gasoline containing more than 5% methanol,

even if it has cosolvents and corrosion inhibitors.

NOTE

• Fuel system damage or engine performance problems resulting from the use of fuels that contain

alcohol is not covered under warranty. Talon cannot endorse the use of fuels containing methanol

since evidence of their suitability is as yet incomplete.

• Before buying fuel from an unfamiliar station, try to find out if the fuel

contains alcohol, if it does, confirm the type and percentage of alcohol

used. If you notice any undesirable operating symptoms while using a

gasoline that contains alcohol, or one that you think contains alcohol,

switch to a gasoline that you know does not contain alcohol.

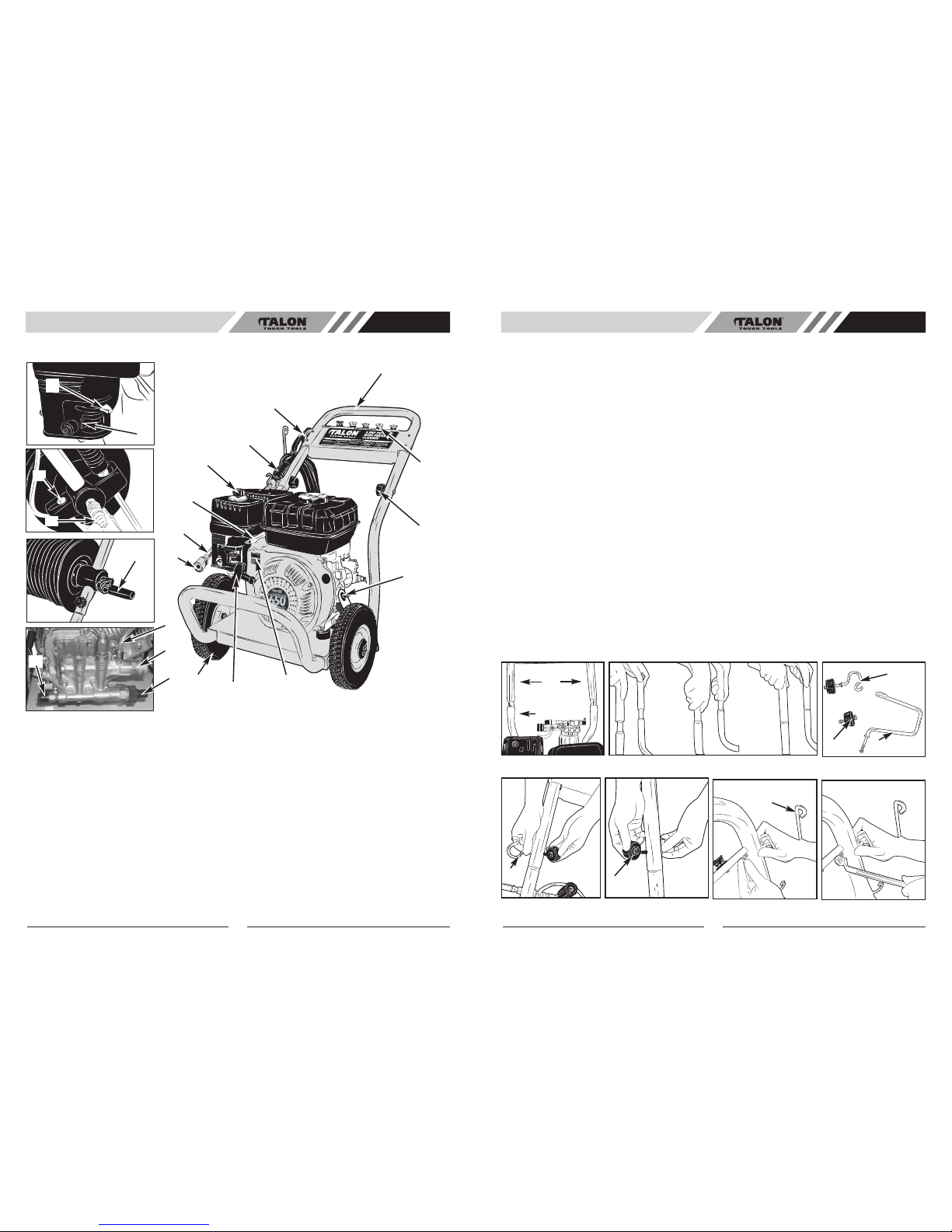

5.3 AIR CLEANER SERVICE (Fig 5-3A)

Remove the knob, washer and air cleaner cover. Check the element for

dirt or obstruction. Clean the element if necessary.

1. Unscrew the wing nut, remove the air cleaner cover and remove

the air cleaner element.

2. Wash the air cleaner element in a solution of household detergent

and warm water, or wash in

nonflammable or high flashpoint solvent. Allow the element to dry thoroughly.

3. Soak the element in clean engine oil, and squeeze out the excess oil. The engine will smoke during

initial start-up if too much oil is left in the foam.

4. Reinstall the air cleaner element and the cover.

16 17

Fig 5-2A

Fig 5-3A

Air Cleaner

Element

Air Cleaner

Cover

PRE-OPERATION AU

6. OPERATION

6.1 STARTING

Prior to starting, refer to your engine manual for proper starting procedure.

1. In a well ventilated outdoor area add fresh, high quality, unleaded gasoline with a pump octane rating

of 91 or higher. Do not overfill. Wipe up spilled fuel before starting the engine. Refer to Engine Owners

Manual for correct procedure.

2. Check engine oil level. See Engine Owners Manual for correct procedure.

NOTE: There will be a slight amount of oil in the engine from factory testing.

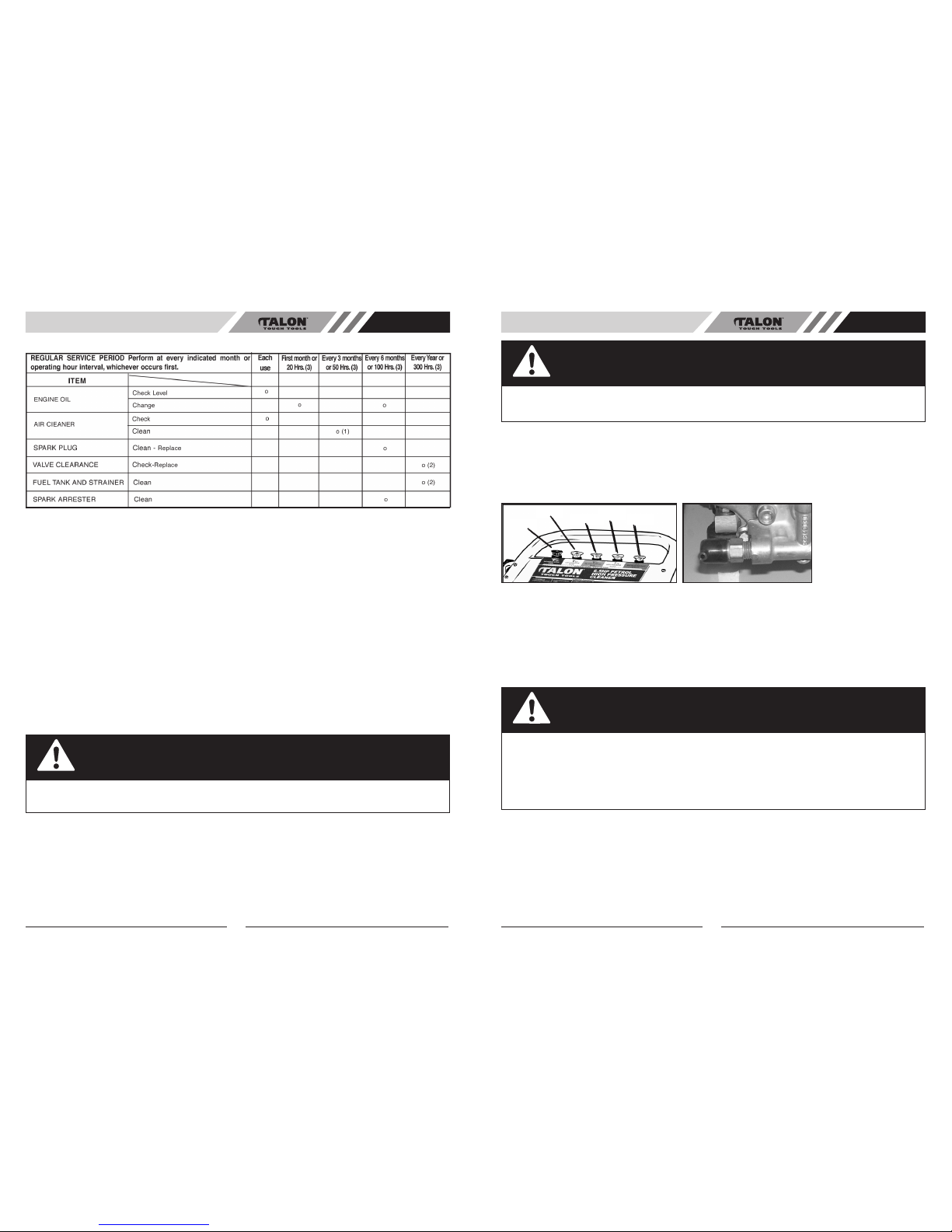

3. Verify the filter screen (Fig. 6-1A) is in water inlet of pump. NOTE: Cone side faces out.

4. Connect water source to pump inlet.

NOTE: Water source must provide a minimum of 1.3L per minute at 20

PSI.

5. Connect high pressure hose to pump outlet.

6. If applying a chemical or cleaning solution, see How To Apply

Chemicals/Cleaning Solvents instructions in this section.

7. Turn water source on.

NOTE: Failure to do so could cause damage to the pump.

8. Start engine. See Engine Owners Manual for correct procedure.

NOTE: When engine rope is pulled, pressure starts building in the gun.

If the engine does not start after two pulls, pull the gun trigger to relieve this pressure.

9. Depress trigger on gun to start water flow.

NOTE: Stand on a stable surface and grip gun/spray wand firmly with both hands. Expect the gun to

kick when triggered.

10. Release trigger to stop water flow.

11. Adjust spray for the task being performed by changing quick connect nozzle. See How To Use Spray

Wand instructions in this section.

WARNING

Once the engine is running, never let the spray gun stop spraying water for more than 2 minutes.

The circulating water in the pump can accumulate heat and cause internal damage to the pump.

6.2 SHUTTING DOWN

1. After each use, if you have applied chemicals, place chemical hose into container of clean water and

draw clean water through chemical injection system to rinse system thoroughly. NOTE: Failure to do so

could cause damage to the pump.

2. Turn engine off. See Engine Owner’s Manual. NOTE: NEVER turn the water off with the engine

running.

3. Turn water source off.

4. Pull trigger on spray gun to relieve any water pressure in hose or spray gun.

5. See Storage section in this manual for proper storage procedures.

Fig 6-1A

OPERATION AU