AU

3

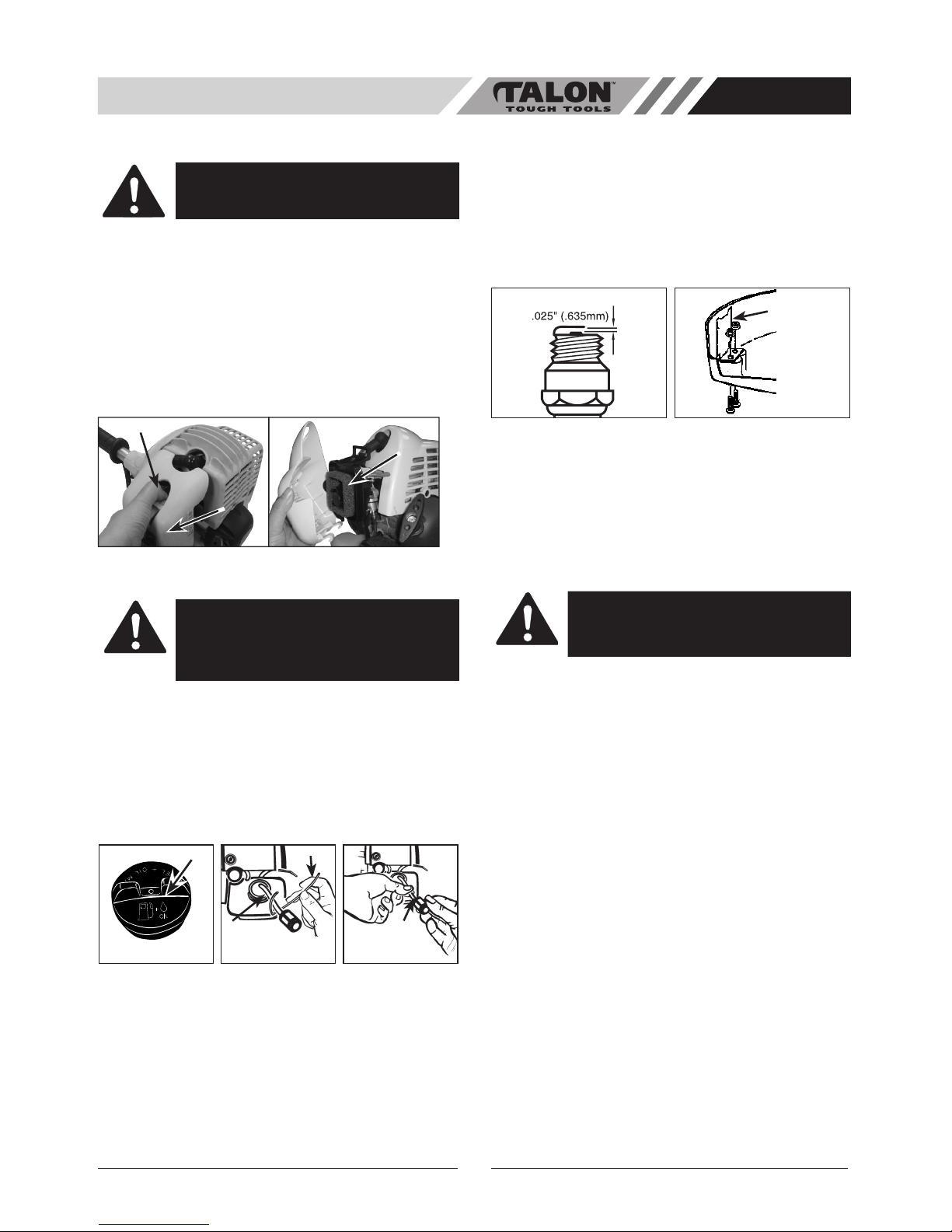

GENERAL TROUBLESHOOTING GUIDE

Unit will not start. Incorrect starting procedures. Follow correct starting procedures in user

manual.

ON/OFF switch in the “OFF” position. Turn ON/OFF switch to the “ON” position.

Primer bulb not pressed 10 times. Press primer bulb 10 times.

Throttle trigger not fully depressed when

starting.

Ensure that the throttle trigger is

depressed when starting.

Incorrect fuel/oil mix. Ensure that the correct fuel/oil mix (25:1

mixture) is used. Too little oil will damage

the engine while too much oil will foul the

spark plug.

Dirty spark plug. Check that the spark plug is clean and

properly fitted.

Not running smoothly. Dirty air cleaner. Check air cleaner is free and clear of

blockages.

Stale fuel. Drain and use fresh fuel.

Trimming line will not feed. No line in head. Check to see that there is line in the head.

If not replace with 2.0mm trimming line.

Line has been wound incorrectly around

spool.

Ensure that the line has been wound

in the correct direction. Refer to the

“Replacing Trimming Line” section of this

user manual.

Incorrect size line used. Ensure that only 2.0mm size line is used

in this machine.

Inner spool. Check the inner spool for dirt, burs or

warping. Excessive heat build-ups can

cause damage to the inner spool. If spool

is damaged, replace inner spool.

Worn bump head. If the bump knob has excessive wear it

indicates that the head is being rubbed

on the ground during operation or is being

“tapped” on a concrete surface. Both

these situations can contribute to line

feed, and other product problems. The

cutting head should be off the ground

at all times when cutting and the head

should only be “tapped” on a flat surface.

No drive to shaft. Bump head incorrectly installed. Ensure that the bump head is correctly

fitted.

Collars and spacers incorrect fitted

(Straight shaft units only).

Ensure that the collars and spacers are

correctly fitted.

The following basic troubleshooting checks can be easily carried out to determine whether or not the unit is running cor-

rectly. If the unit will not operate after these checks then the product should be taken to an Authorised Service Agent for

further inspection.

Ensure a small amount of fresh 2 stroke fuel (25:1 fuel:oil) is either in the tank or available for use during

troubleshooting.

4

Meaning of symbols marked on the product

Read the user manual before using the machine

Whenever the machine is in use, safety goggles must

be worn to safeguard against flaying object, as must

ear protectors, such as a soundproof helmet, in order to

protect the operator’s hearing. If the operator is working

in an area where there is a risk of falling objects, a safety

helmet must also be worn.

Warning! Hot surface

Keep people or animals at least 15m away from the

machine during operation

Wear gloves to protect your hands

Wear safety boots to protect against electric shock

Danger : Objects thrown up by machine

Acoustic power level LWA accordance with directive

2000/14/EC

Maximum revolution frequency of the drive shaft

Never use blades

WARNING! When using petrol tools, basic safety precautions, including the following, should always be followed to

reduce the risk of serious personal injury and/or damage to the unit.

Read all these instructions before operating this product and save these instructions.

This power unit can be dangerous! Operator is respon-

sible for following unit manual instructions and warnings.

Read entire operator’s manual before using unit! Be

thoroughly familiar with the controls and the proper use of

the unit. Restrict the use of this unit to persons who read,

understand, and follow unit, manual instructions and warn-

ings. Never allow children to operate this unit.

1. Wear close fitting, tough work clothing that will

provide protection, such as long slacks or trousers,

safety work shoes, heavy duty work gloves, hard hat,

a safety face shield, or safety glasses for eye protec-

tion and a good grade of ear plugs or other sound

barriers for hearing protection.

2. Store in a safe place.

Open fuel cap slowly to release

any pressure which may have formed in fuel tank. To

prevent a fire hazard, move at least 10 feet (3 meters)

from fueling area before starting.

3. Turn unit off before setting it down.

4. Always hold unit firmly with both hands, the thumb

and fingers encircling the handles.

5. Keep all screws and fasteners tight. Never operate

your equipment when it is improperly adjusted or not

completely and securely assembled.

6. Keep handles dry, clean and free of fuel mixture.

7. Keep linehead as close to ground as practical.

Avoid hitting small objects with linehead. When cut-

ting on a slope, stand below linehead. NEVER cut

or trim on a hill or slope, etc. if there is the slightest

chance of slipping, sliding or losing firm footing.

8. Check area you will be trimming for debris that

may be struck or thrown during operation.

9. Keep all parts of your body and clothing away

from linehead when starting or running engine.

Before starting engine, make sure linehead will not

come in contact with any obstacle.

10. Stop engine before examining cutting line.

11. Store equipment away from possible flammable

materials, such as gas-powered water heaters,

clothes dryers, or oil-fired furnaces, portable heaters,

etc.

12. Always keep the debris shield, linehead, and engine

free of debris build-up.

13. Operation of equipment should always be restricted

to mature and properly instructed individuals.

14. WARNING: The emission of exhaust gases is toxic.

15. Emergency Stopping Procedure. When it is neces-

sary to stop engine immediately, DEPRESS the

switch to stop.

1. DO NOT USE ANY OTHER FUEL than that recom-

mended in your manual. Always follow instructions

in the Fuel and Lubrication section of this manual.

Never use gasoline unless it is properly mixed with 2-

cycle engine lubricant. Permanent damage to engine

will result, voiding manufacturer’s warranty.

2. DO NOT SMOKE while refueling or operating equip-

ment.

3. DO NOT OPERATE UNIT WITHOUT A MUFFLER

and properly installed muffler shield.

4. DO NOT TOUCH or let your hands or body come in

contact with the muffler. Hold unit with thumbs and

fingers encircling the handles.

5. DO NOT OPERATE UNIT IN AWKWARD POSITIONS,

off balance, outstretched arms, or one-handed.

Always use two hands when operating unit with

thumbs and fingers encircling the handles.

6. DO NOT RAISE LINEHEAD above ground level while

unit is operating. Injury to operator could result.

DANGER: Never use blades, wire or flailing

devices. Unit is designed for line trimmer use

only. Use of any other accessories or attach-

ments will increase the risk of injury.

WARNING: Keep children, bystanders,

and animals 50 feet (15 meters) away. If

approached stop unit immediately.

WHAT NOT TO DO

AU

GENERAL SAFETY RULES