WIB-33.2 Engli h

Operation in analogue mode

The carriage lighting WIB-33.2 can al o be u ed in analogue model

railway layout . When putting the vehicle on the rail the decoder

recognize automatically if it i run in analogue or digital mode and et

the corre ponding operation mode. The automatic recognition of the

analogue mode can be witched off.

Switching the LED and the function output on or off i not po ible in

analogue mode. They can be programmed o that they are either

witched on or off in analogue mode. The effect et for the output

are active in analogue mode a well.

In analogue layout upplied with d.c. voltage, the function output

witched with F0 are witched on and off according to the direction of

travel. Thi i not po ible in analogue a.c. layout a the decoder doe

not recognize the impul e for changing the direction of travel.

Activating the LEDs

The eight LED can be witched on and off individually, in group or

corporately. By programming the decoder accordingly you can

et the LED ´ brightne individually for each LED,

witch the LED according to the direction of travel,

imulate fluore cent tube when witching on the LED ,

et the duration of the witching on of the fluore cent tube

imulation until reaching a con tant light and a defective fluore cent

tube individually for each LED.

You can witch from tandard lighting to orientation light with a

function key (e.g. for holded carriage or leeping car ). The orientation

light´ brightne i et corporately for all LED .

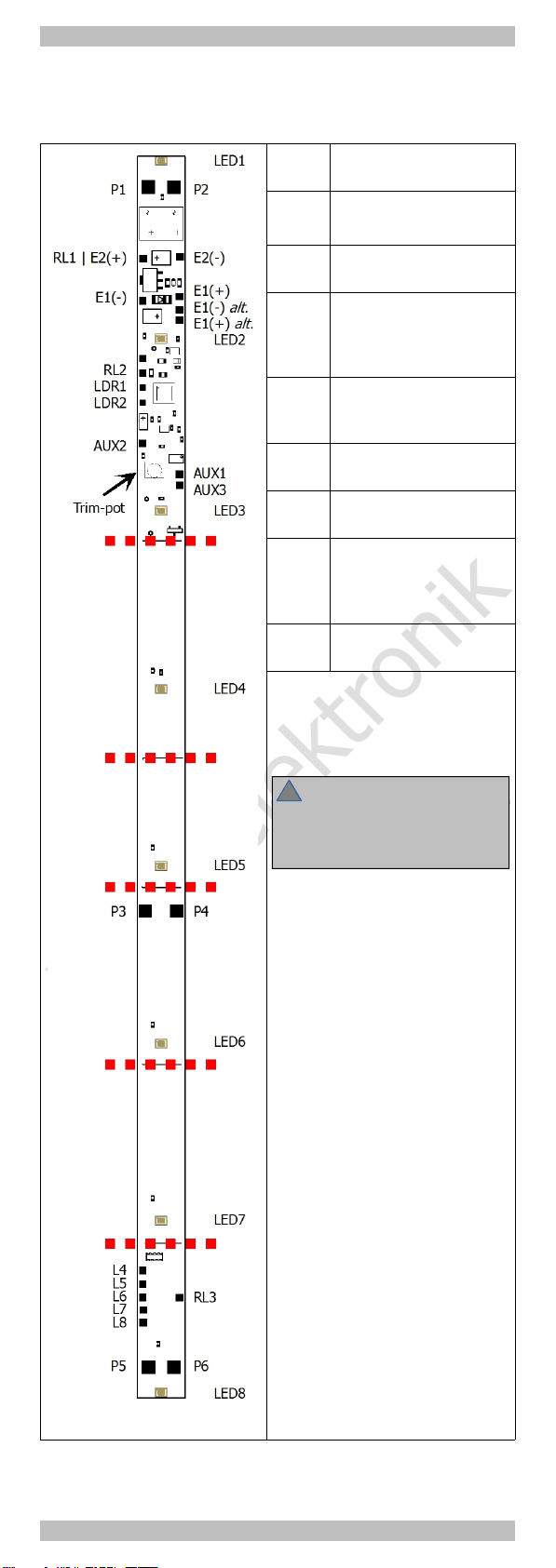

In tead of programming the LED ´ brightne with a digital control unit

you can et it with a trim-pot (corporately for all LED ). The brightne

programmed via CV or regi ter remain active, the etting at the trim-

pot only alter the brightne with a factor valid for all LED .

Activating the addtional function outputs

There are three output for external load on the PCB controlled by the

integrated decoder. The output AUX2 i de igned for the connection of

LED for the back lighting. The nece ary erie re i tor are integrated

on the PCB.

The two output AUX1 and AUX3 are available e.g. for the connection

of additional lighting (e.g. in the driver´ cabin or in the toilet cabin) or

electric coupling . Their maximum current i 300 mA.

It i po iblie to witch all output dependent on the direction of travel

and to dim them.

Be ide , the two output AUX 1 and AUX 3 provide:

Kick function for pecial type of electric coupling needing a

reduction of the connected voltage after the witching operation in

order to protect the coupling.

Random witch witching on and off the output in irregular interval

(e.g. for the lighting of a toilet cabin).

Connecting a light dependent resistor

When a light dependent re i tor i connected, the LED and the

decoder´ function output can be witched on and off automatically

depending on the urrounding lighting. The en ivity i et via CV or

regi ter . You can activate the dim witch with a function key.

The dim witch effect only tho e output witched on. A oon a the

output have been witched off by the dim witch they cannot be

witched on with a function key. In thi ca e the dim witch ha to be

deactivated fir t.

With the initial etting the LED are witched on a oon a the

urrounding lighting under-run the et limit value. It i po ible to

invert thi functionality, e.g. in order to automatically witch off the

lighting in a hadow tation.

lickering protection

An integrated moothing capacitor upplie the LED when hort

current interruption occur, which prevent the lighting from flickering

when point or mudge on the rail are cro ed. In ca e the integrated

moothing capacitor i not ufficient, you can connect an additional

external bridging capacitor with a minimal voltage u taining capability

Page 7