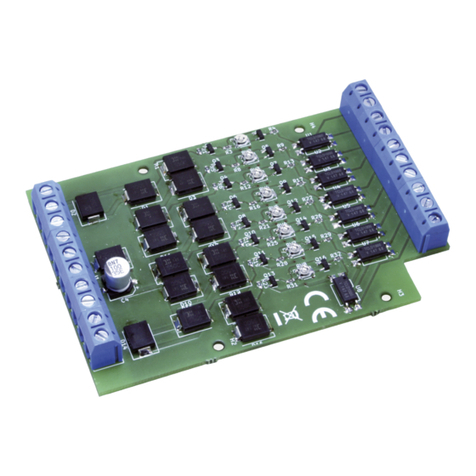

tams elektronik GBM-1

Contents

1. Getting started.............................................................................................................4

1.1. Contents of the package.......................................................................................4

1.2. Accessories..........................................................................................................4

1.3. Intended use.......................................................................................................5

1.4. Safety instructions................................................................................................5

1.5. Care....................................................................................................................5

2. Operation overview.......................................................................................................6

3. Assembling the kit........................................................................................................8

3.1. Safety instructions................................................................................................8

3.2. Soldering properly................................................................................................9

3.3. Preparation........................................................................................................10

3.4. PCB layout and parts list.....................................................................................12

3.5. Assembly...........................................................................................................13

3.6. Performing a visual check...................................................................................14

3.7. Performing a functional test................................................................................14

4. Connecting the track busy indicator.............................................................................15

4.1. Pin assignment...................................................................................................15

4.2. Connections.......................................................................................................15

4.3. Connection of the track sections..........................................................................17

4.4. Connection to the voltage supply.........................................................................17

4.5. Connecting lamps or LEDs...................................................................................18

5. Connecting subordinate circuits...................................................................................19

5.1. Connection of digital feedback modules...............................................................19

5.2. Application example: Block section control...........................................................19

6. Checklist for troubleshooting and error correction.........................................................22

6.1. Technical Hotline................................................................................................23

6.2. Repairs..............................................................................................................23

7. Technical data............................................................................................................24

8. Warranty, EU conformity & WEEE................................................................................26

8.1. Guarantee bond.................................................................................................26

8.2. EU Declaration of Conformity..............................................................................27

8.3. Declarations on the WEEE Directive.....................................................................27

Contents 3