MAN-AT-A1 Manual Aquatop (2019) 3

Influence of water quality on plastic parts, more specific slats :

•T&A slats are made of high quality PVC and PC. Overdosing Cholrine and/or other

pool related chemicals might shorten the life time of parts and slats.

•All slats, with the exception of white and beige (sand color) PVC, require to be

protected from direct sun exposure at all times when not in contact with the pool

water.

•PVC- as well as PC solar slats require to be cooled at all times whenever the cover is

closed, i.e. on the pool water surface. As such, the pool circultation/filtration pump

needs to be in operation from the moment the cover is closed.

T&A control boxes for covers can easily be used to control the pool circulation/

filtration pump.

ATTENTION : Variable speed pumps require a minimum capacity sufficient to

circulate the water underneath the cover. Otherwise, low circulation might overheat

solar slats. Overheating of slats might cause deformation of the slats which is

irreversible at all times.

•Because of differences in pool water- and ambient temperature, a bi-metal effect might

occur. This will result in having the ends of the slats bend downwards (when the

ambient air is warmer than the pool water) or in having the ends bend upwards (when

the pool water is warmer than the ambient air). This effect occurs more frequent in

case of darker (slat)colors.

•Plastic slats are extruded products. A deviation in straightness (both horizontally and

vertically) of 2 mm/m is within tolerance.

•In case of partial replacement or add-ons at later date, slight color differences might

occur.

•When using a pump with adjustable speed, make sure the water circulation under the

closed cover is still high enough to avoid the slats from burning

•The slats may only be exposed to sunlight when they are in full contact with the water.

Sole exception on this rule : white and sand coloured (beige) slats

The use of natural tropical wood as a finishing material :

•T&A uses premium quality IPE tropical wood which is a 100% natural product. As

such; color differences, minor cracks and deformation are a normal behavior of the

product and impossible to foresee. T&A cannot be held responsible or liable for this

natural process.

•Tropical IPE wood becomes naturally grey because of sun exposure. In case you want

to maintain the original color, it is recommended to treat the wood by professional

products on a regular base.

•Tropical IPE wood contains natural oils which might, in combination with rain or pool

water, mark spots on surrounding surfaces. Cleaning and sanding the wood before

mounting is advisable.

The use of panels and benches made out of fiberglass/composite

•T&A uses fibreglass with different layers of Polyester + Vinylester.

•The standard colour is white but a limlited choice of other colours is available.

•The products made out of fibreglass/composite meet the European standard. For more

details please consult the standard EN 16582-1 annex D.

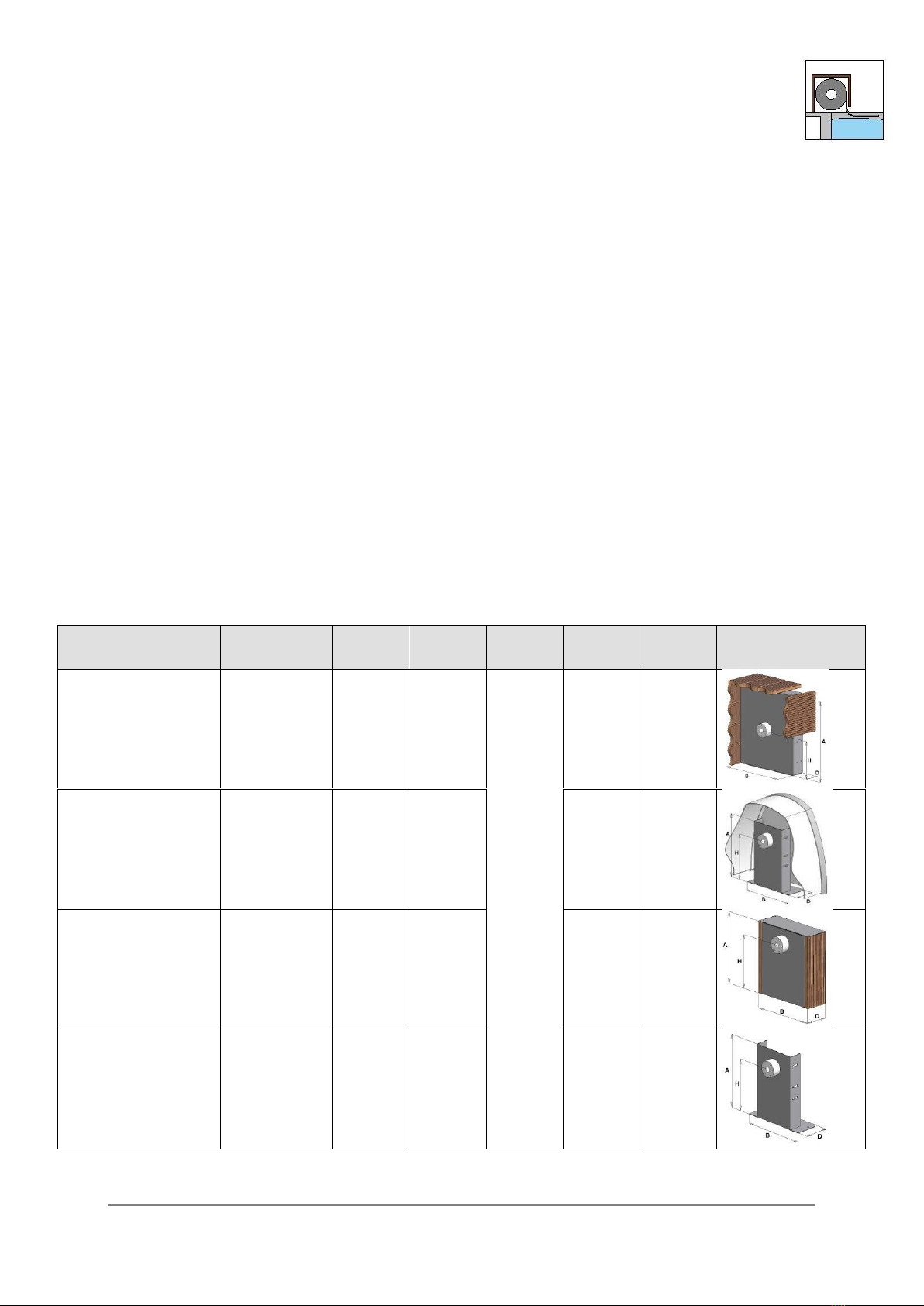

Our standard plugs are made out of polyamide. These need to be fixed in full concrete or

masonry. It is the responsibility of the installer to check the stability and if needed replace with

chemical anchoring.