TD_IM_009 Page 3 of 11

Rev 3

INTRODUCTION

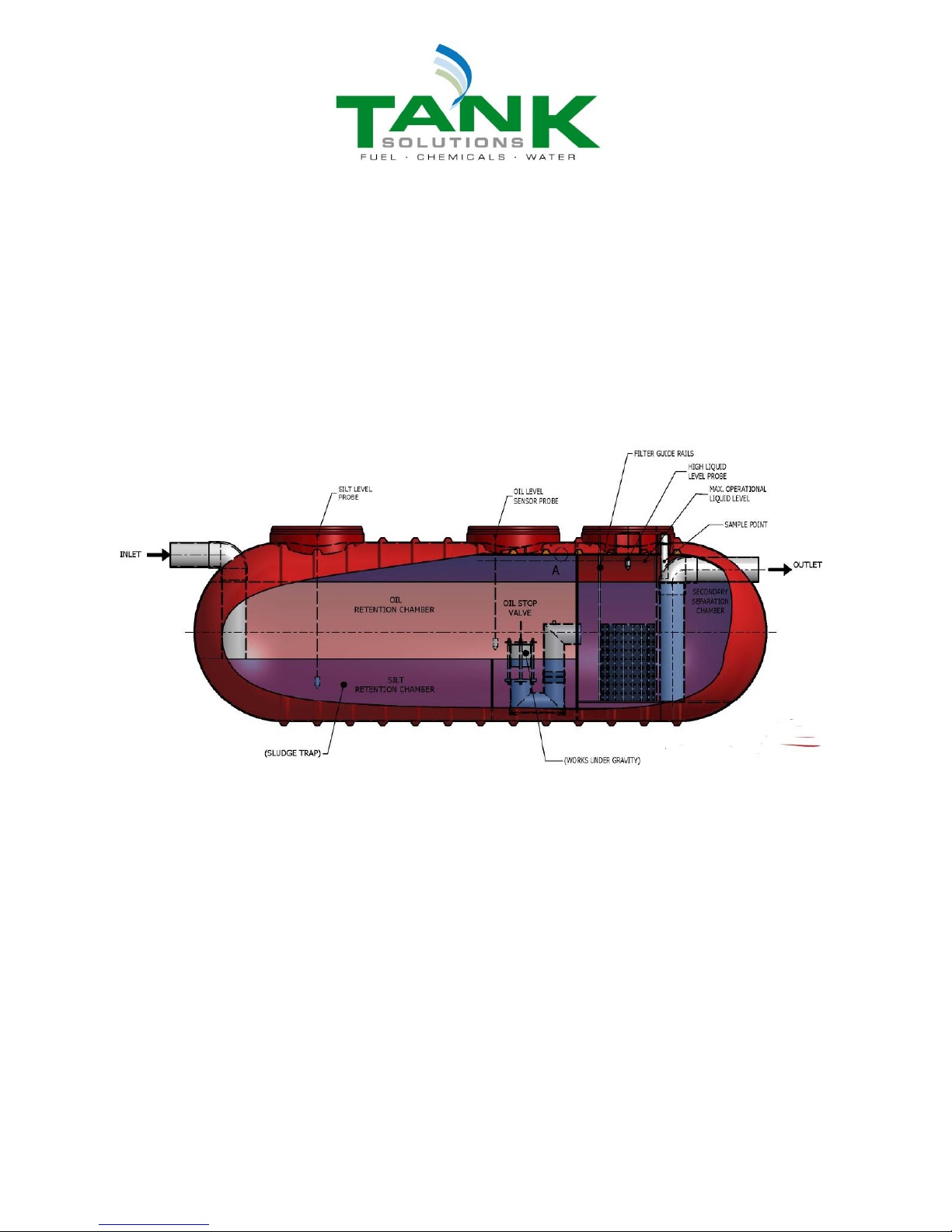

A Tank Solutions Aquator Commercial Oil Water Separator is a high-quality system for removing oil from

water. It is comprised of a standard single wall or double-wall tank that has been modified with piping and

internal components to separate oil from water.

It is important to follow the procedures and instructions in both this Aquator Manual and Tank Solutions

Installation Manual FRP Single Wall and Double Wall F935 (Installation Manual) in order to safely and

properly install, operate and maintain an Aquator and accessories. Failure to follow these instructions will

void the Aquator warranty and may cause Aquator failure, serious personal injury or property damage.

The Tank Solutions warranty applies only to an Aquator installed according to the instructions contained in

this Aquator Manual and the Installation Manual. Since Tank Solutions does not control the parameters of

any installation, Tank Solutions’sole responsibility in any installation is that presented in our warranty.

It is the responsibility of the owner and operator to always follow the operating and maintenance

guidelines set forth in Tank Solutions’applicable warranty. A Tank Solutions warranty is found in the

product brochure or is available upon request from Tank Solutions. It is the responsibility of the owner to

retain this AquatorManual and the Installation Manual for future reference to operating and maintenance

guidelines.

Use the Tank Installation Checklist (included in the Installation Manual) as the installation proceeds.

Retain a copy of the completed Tank Installation Checklist, and any correspondence, certification, etc.,

related to the Aquator. Each Aquator requires a separate Tank Installation Checklist. Consult your Tank

Solutions representative or distributor if additional Tank Installation Checklist forms is needed.

The Aquator owner should retain a copy of the Tank Installation Checklist to facilitate any warranty claim.

Tank Solutions recommends that the installing contractor also retain a copy.

It is important that this document is retained with the equipment for future reference. Should the

equipment be transferred to a new owner, always ensure that all relevant documents are supplied in

order that the new owner can be acquainted with the functioning of the equipment and the relevant

warnings.

For additional information, contact your state and local government authorities, including health, fire or

building departments, and environmental agencies. All work must be performed according to standard

industry practices and OH&S regulations. A Tank Solutions requirement will never take precedence over a

requirement imposed by any federal, state or local code or regulation. In all cases, any such requirement

takes precedence over any provision of the Tank Solutions manual. Tank Solutions must authorise any

variation to, or deviation from, these instructions. This authorisation must be made in writing, prior to tank

installation.

Comply with all applicable regulations and standards regarding the disposal of separated oil and solids.

Federal, state and local codes and regulations always take precedence over a Tank Solutions

requirement. Tank Solutions must authorize –in writing and prior to Aquator installation –any variation to,

or deviation from, these Aquator Manual instructions. All correspondence regarding variations must be

retained. If you have questions or encounter situations not covered in this Aquator Manual or the

Installation Manual, contact technical support at Tank Solutions.