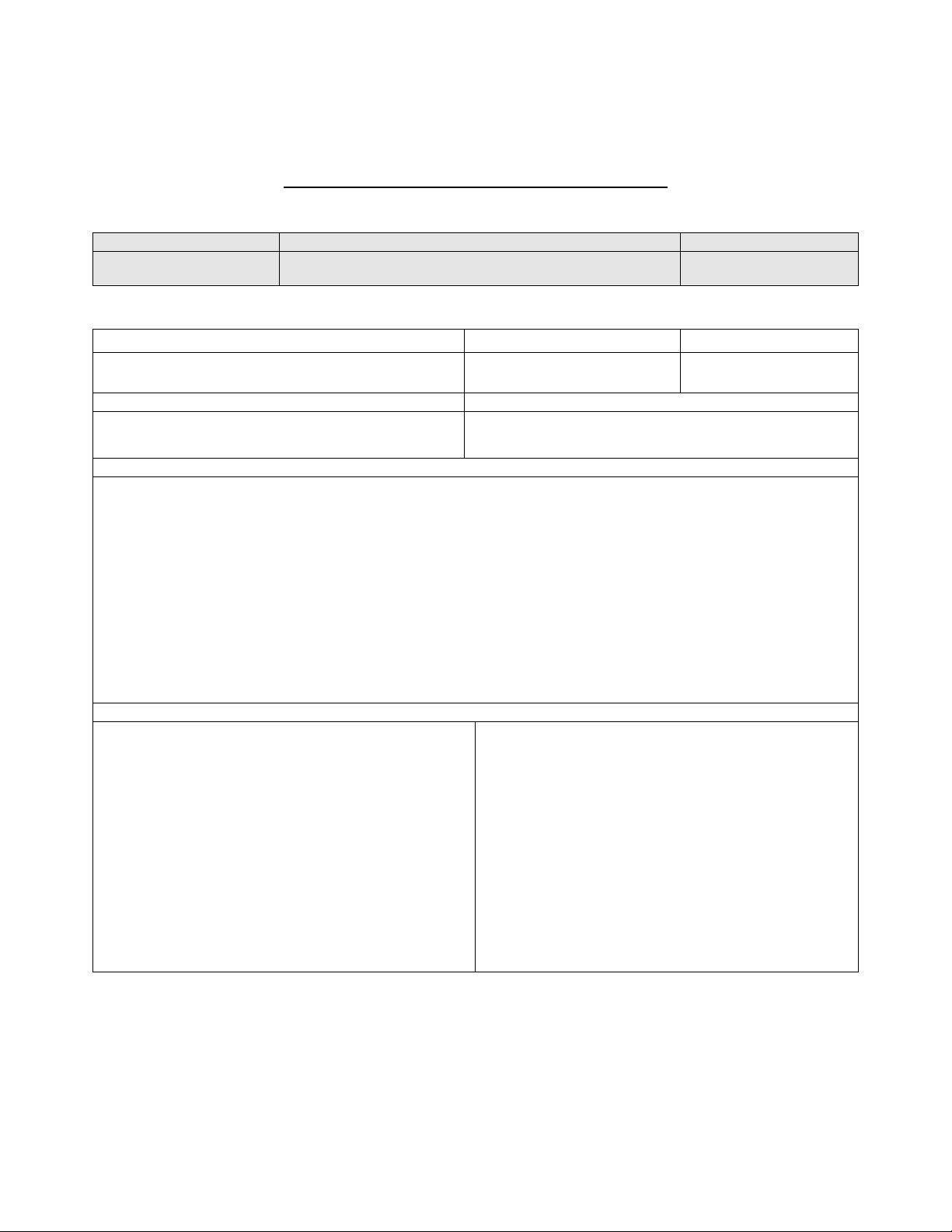

FOR GUIDANCE

Diagnosis of low frequency driver failures resulting from

misuse:-

SYMPTOM PROBABLE CAUSE

Charred voice coil Under powered amplifier clipping; Excessive peak amplifier

power; DC at amp output (amp failure)

F u s e d , b r o k e n o r b l a c k e n e d l e a d o u t w i r e s

Under powered amplifier clipping; Excessive peak amplifier

power; Excessive low frequency equalisation applied

Voice coil out of gap

Excessive peak amplifier power; Excessive low frequency

equalisation applied

Coil rubbing

Excessive continuous amplifier power resulting in separation of

coil former from cone or suspension; Coil delamination due to

excessive temperatures generated; Improper mounting of driver

resulting in deformation of frame; Dropping of cabinet resulting in

deformation of frame or shifted pole piece

Broken frame or misaligned magnet assembly Dropping of cabinet ; careless transportation

Torn or punctured cone Excessive low frequency equalisation applied; Excessive peak

amplifier power; vandalism

Cone to coil joint failure Excessive low frequency equalisation applied

Suspension to coil/cone joint failure Excessive low frequency equalisation applied

Diagnosis of high frequency driver failures resulting

from misuse:-

SYMPTOM PROBABLE CAUSE

Charred voice coil Under powered amplifier clipping; Excessive peak amplifier

power; DC at amp output (amp failure)

Fused or broken leadout wires Excessive amplifier power; connection to low frequency or

midrange amplifier in active system

Leadout to coil joint failure (solder) Excessive amplifier power generating excessive temperatures

which melts solder >300°C

Coil rubbing Excessive continuous amplifier power resulting in separation of

coil former; Coil delamination due to excessive temperatures

generated; Improper replacement of diaphragm assembly;

Dropping of cabinet resulting shifted pole piece

Diaphragm cracked or pulverised Excessive continuous amplifier power (often frequency related);

Under powered amplifier clipping; Connection to low frequency

or midrange amplifier in active system.

Misaligned magnet assembly Dropping of cabinet ; careless transportation

Diagnosis of manufacturing defects:-

DEFECT TEST RESULT

Insufficient glue on:-

Cone to coil/suspension

Cone to surround

Surround to frame

Suspension to frame

Sine wave sweep

Buzzing sounds due to separation of

defective joints

Incomplete bonding of voice coil to

diaphragm or insufficient glue on rubber

surround to phase corrector joint

Sine wave sweep Buzzing sounds; Coil rubbing; Separation

of the coil from the diaphragm

Dry solder joints on leadouts DC resistance of voice coil termination Coil resistance greater than the rated

impedance, or open circuit

Faulty welds at the voice coil terminations

on the coil former

DC resistance of voice coil termination

Coil resistance infinite or intermittent

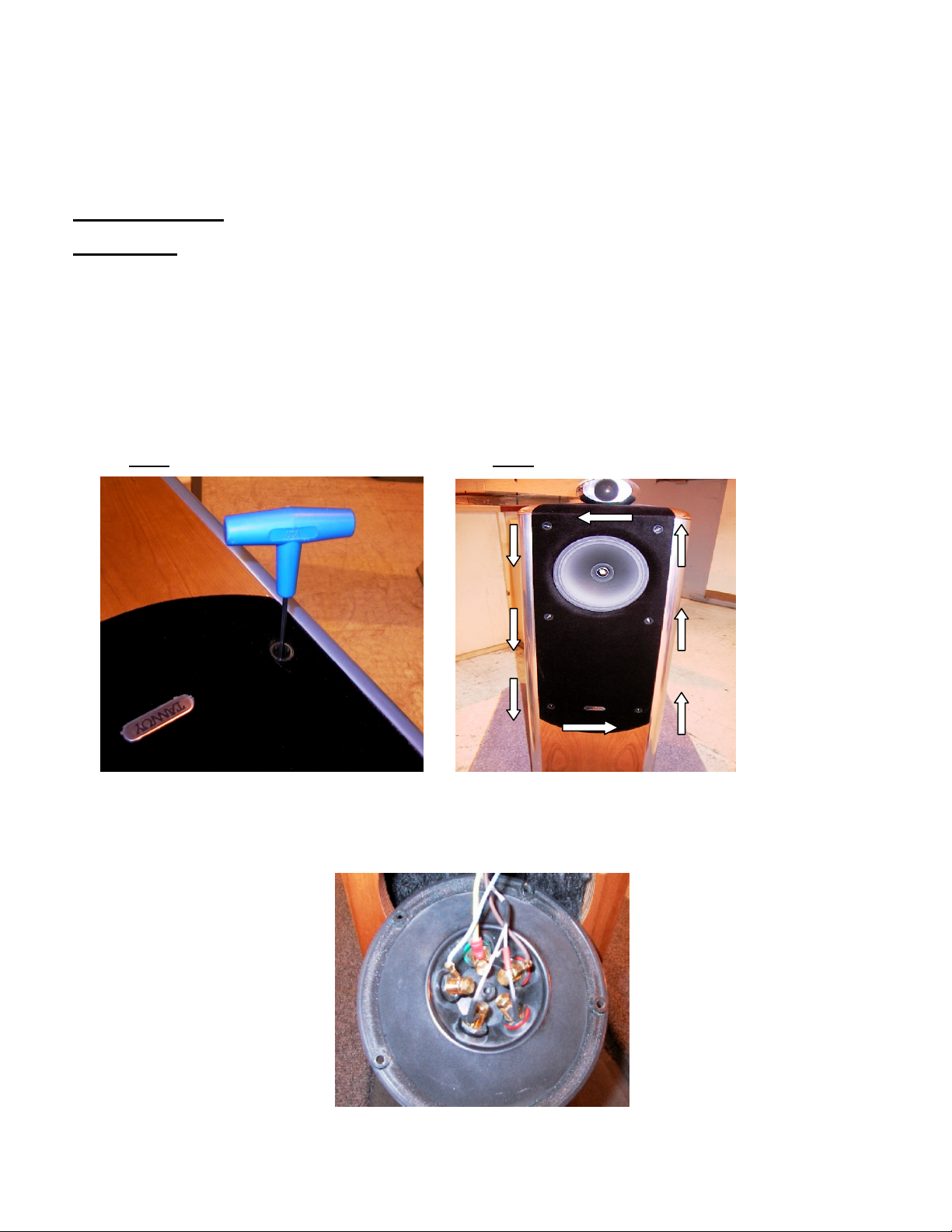

Poorly assembled driver Visual check

Sine wave sweep

Buzzing sounds; Loose parts; Coil

rubbing; foreign particles in magnetic gap

Page 9