7

TRADITIONAL BENDINGTECHNIQUES

Helpful Hints forTrim Work

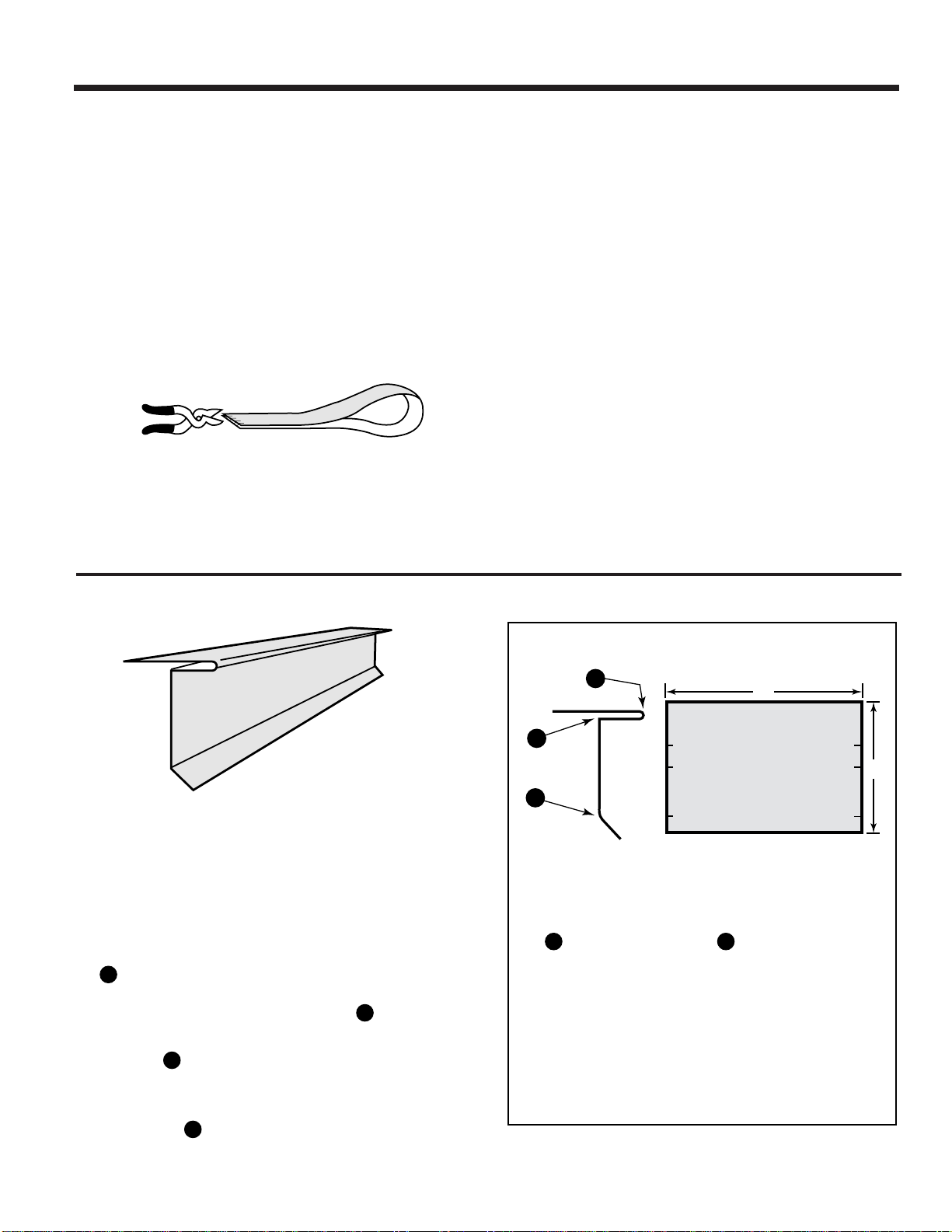

Material: Aluminum coil 43/4inches

wide x the desired length. (For

practice, use only about 1foot

length coil)

Finish

Side

Up

Finish

Side

Up

Finish

Side

Down 2"

1

3

2

11/2"

1/2"

3/4"2"

23/4"

41/4"

2"

23/4"

41/4"

12"

43/4"

Mark with pencil

Then snip in from

edge 1/4"

1

2

2

3

1 2

When breaking material, bending to just 45°will avoid round-

ing the edge. The

Pro Cut-Off

was designed to safely and

easily cut your material in seconds. See page 12.

5. For bending, follow the suggested sequence of bends on

pages 8 and 9. For actual bending techniques see “Bending

the Roof Drip Edge” below.

6. Don’t fityour trim parts tootight. Thiswill complicate the joints

where parts overlap. A one inch (1") lap joint is enough to

allow for expansion and contraction.

Trim should be lapped

so that laps are facing away from traffic areas.

7. Try to nail the trim parts on an area that will make the nails

less conspicuous. Fasten at laps. When face nailing, use just

enough nails to secure trim; DO NOT DRIVE NAILS TOO

TIGHT!!

8.

Remember,

when designing shapes you are hanging a cover

over the wood parts, not laminating a skin-tight surface. This

is called “Floating Your Trim”. Allow for irregularities in the

wood because your formed trim shapes are straighter than

the wood trim moldings or boards you are covering.

9. With practice, you’ll learn to overbend or underbend certain

sections to achieve a pressure fit of your trim parts which

will, in turn, require fewer nails and give your job a more

wood-like appearance.

10.Hemming (making a 180°bend on the edge of a sheet) will

give your shape a “Factory Edge Look” and will stiffen the

entire trim piece to help eliminate “oil canning”. See page 6.

1. Measure the total length of the particular trim area to be cov-

ered and divide by the length of your Bender to determine

the number and length of trim pieces needed.

2. Determine the dimensions of each section of the desired trim

shape by measuring that particular profile to be covered. As

an aid, make a pattern out of a 1" strip of coil to get your

exact profile.

3. Transfer the dimensions in Hint #2 to each end of a piece of

trim coil by making a 1/4"slit in the metal with a pair of shears.

These marks now become the bending points and makes

the bending marks visible from either side. On longer lengths

fold the coil over as shown and snip both ends at once. This

saves time and ensures accuracy. The

Tapco Pro-Filer

was

designed to make this time consuming part of your job easier

and more accurate. See page 13.

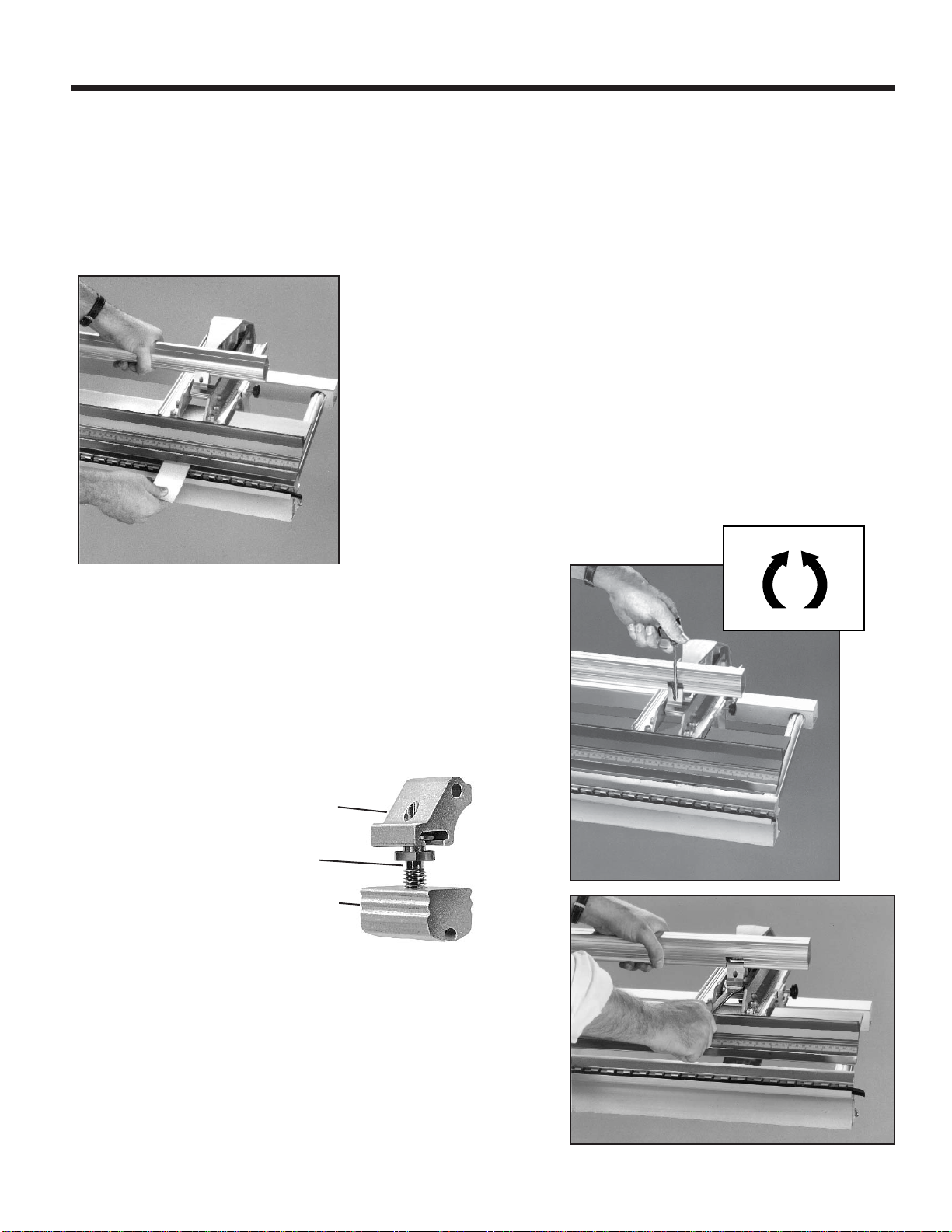

4. Lock the pre-marked coil blank into the Bender with the cut

marks located directly under the outer edge of the Stainless

Bending Edge. Lock Bender. To cut off the coil with a razor

knife, score the metal against the Stainless Bending Edge.

Now

bend the metal up and push back down by hand until the

exposed

section breaks off. It may require 2 or 3 repetitions.

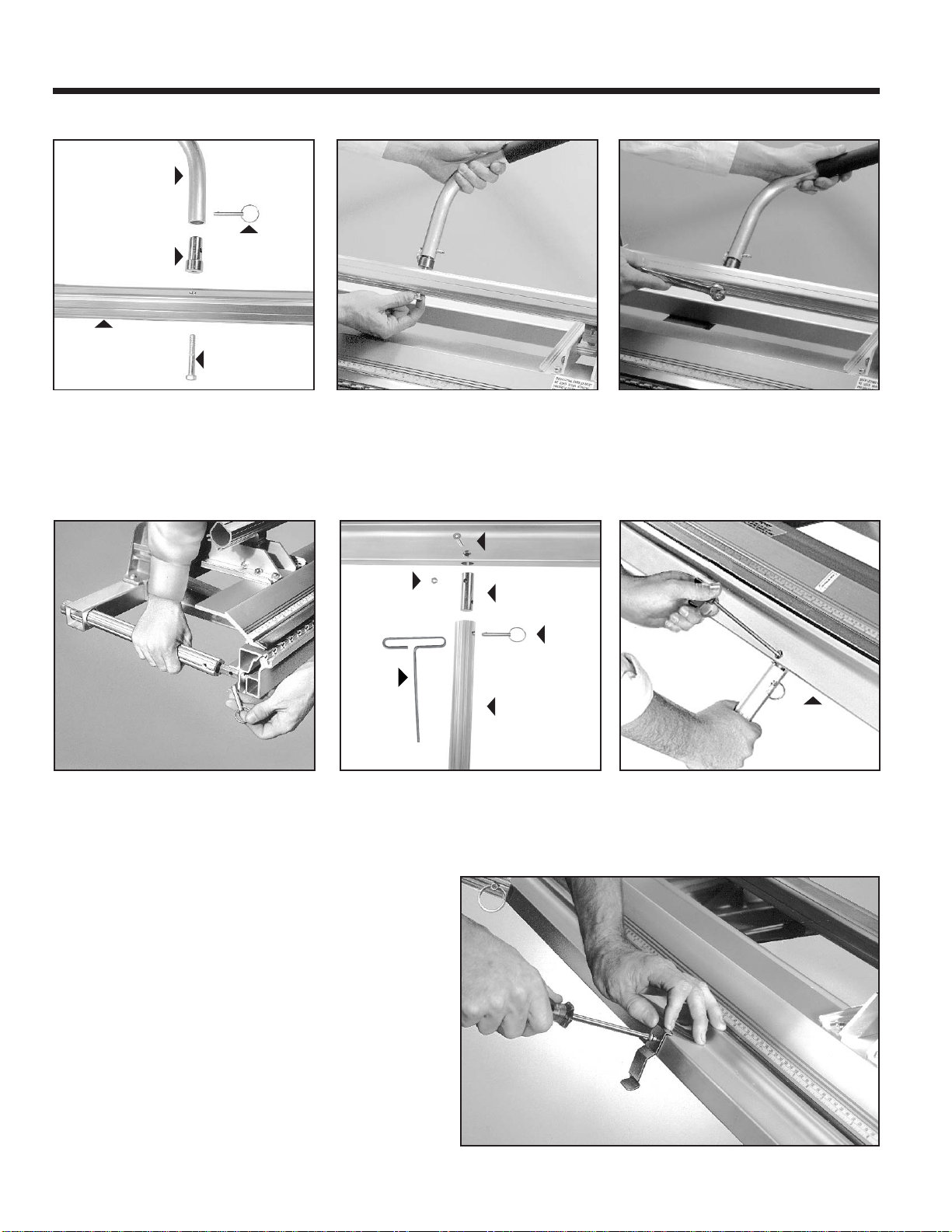

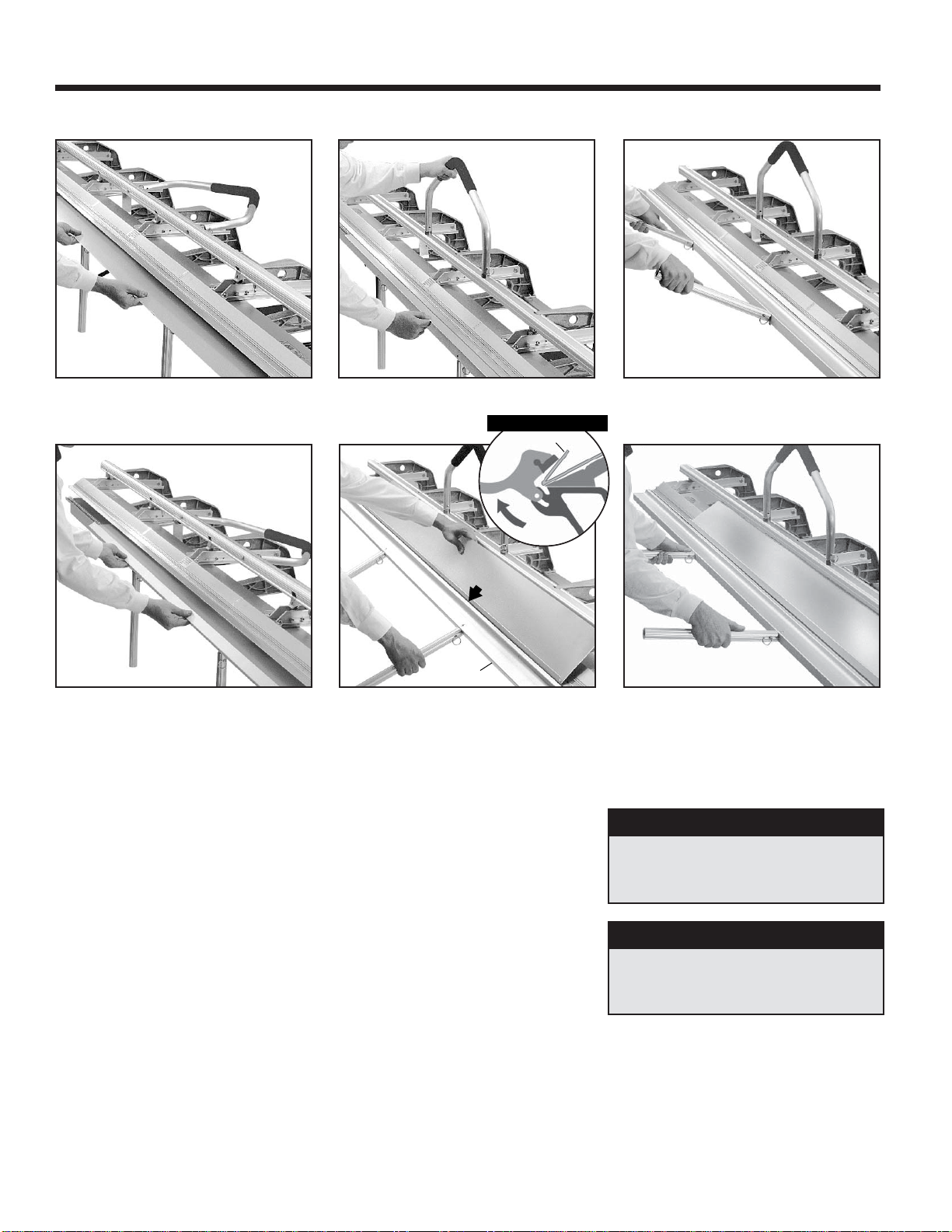

1. Numbers show the sequence of the bends; thus,

would be the first bend, the second bend, etc.

2."Finish Side Up" indicates that the finished or

exposed side of the trim is to be put into the Bender

FACING UP.

3. "Finish Side Down" indicates that the finished or

exposed side of the trim is to be put into the Bender

FACING DOWN.

4. The symbol *means the bend is to be 180°.

Roof Drip Edge

*

1. This shape is basic to all the other shapes contained in this

manual. Practice this shape before you proceed with the other

trim pieces illustrated on pages 8 and 9.

2. To begin, cut off a piece of coil 43/4inches wide by about 1

foot long (As shown at right.)

3. Mark your coil with a pencil at 2", 23/4"and 41/4"on both ends.

Then snip these marks in about 1/4" (so they will be visible on

both sides of the coil).

4. Put your coil into the Bender with the Finished Side Up. Bend

is the 23/4"mark, so lock the Bender on the mark; then,

bend 90°.

5. Remove the coil from the Bender. Bend will be at the 2"

mark on the coil, so now put the coil into the Bender with the

Finished Side Down. Lock the Bender on this 2" mark. Note

that Bend shows the symbol *which means the bend is to

be 180°. Bend this as far as it will go (about 165°). Then pro-

ceed to hem it in the Bender as shown on Page 12 in “Basic

Hemming and Folding.”

6. Now to Bend put your coil back into the Bender Finished

Side Up and lock on the 41/4"mark. Bend this approximately

45°as shown to complete the shape.

Bending the Roof Drip Edge (General instructions for all examples)