5

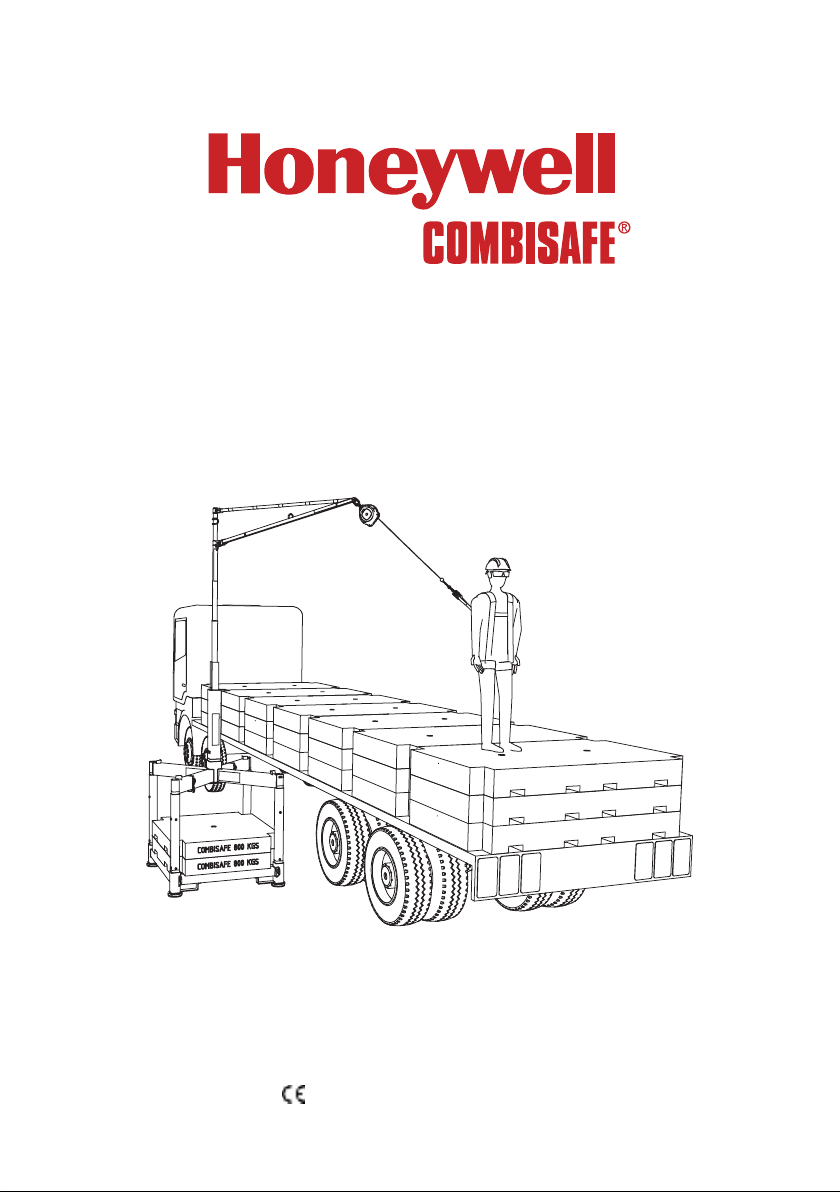

Loading System MkII Safety instructions

Safety instructions

The Loading System MkII is intended for the purpose stated

in this user instruction only, any other use is not allowed. The

product is used to protect workers operating at height. If used

incorrectly there is a potential risk of accidents to both the

user and other people in the vicinity. Please read this manual

carefully before use.

• Under no circumstances may the product be used as a makeshift

crane or lifting/lowering device.

• Under no circumstances may any items other than those provided

with the system be used either in replacement or through choice as

this may affect the performance of the product.

• Care should be taken in the transportation of the product between

locations. If any damage is found on any part, the item must be

withdrawn from use, inspected by a trained person and replaced if

required.

• Care should be taken while installing the product and if any damage

occurs or is found in any part, the item should be withdrawn from use,

inspected by a trained person and replaced if required.

• The site location where the Loading System MkII is being used must

have a rescue plan in place, in case of a fall arrest incident.

• The device is intended for use by one person at a time only. Under no

circumstances may multiple persons be attached to the device.

• Where the base is positioned directly onto rough ground, as opposed

to hard standing concrete, sole plates of suitable size and strength

should be placed under the feet of the base to safely transmit and

sustain a load of up to 2,5 N/mm².

• Do not lift the Loading System MkII unit with SkyReach Anchor by

crane together. Loading System MkII or SkyReach Anchor can be

lifted only separately. When lifting by crane all safety risks must be

eliminated to ensure safety for all personnel on site. Only trained per-

sonnel can operate the crane.

• The SkyReach Anchor is designed to be used within a zero factor fall

arrest system. Make sure that the anchorage is always overhead and

the self-retracting lifeline is taut between the anchorage point and

the worker.

• The maximal vertical deflection of the anchor point that can occur

during service is 0,7 m.

• In case this product is re-sold outside the original country of destina-

tion, it is essential that the reseller provides user instructions in the

language of the country in which the system is to be used.