Tapeswitch CKP/Solo Sensors User manual

IMPORTANT

Thismanualmustaccompanytheproductthroughoutitsworking

life. Those persons responsible for the use of the product must

ensurethatallpersonsinvolvedintheinstallation,commissioning,

operation, maintenance and servicing of the product have access

to all the information supplied by the manufacturers of the

machine and its safety system.

WARNING

Tapeswitch safety mat systems are intended to protect operators

working at or neardangerous machinery. They can only perform

thisfunctioniftheyarecorrectlyfittedandinterfacedtoasuitable

machine. It is essential that the full contents of this manual and

all the authoritative documents referred to herein are fully

understoodbeforeanyattemptatinstallationismade.Ifindoubt

contact Tapeswitch or your Tapeswitch distributor.

TAPESWITCH

SAFETY MATS

CKP/Solo Sensors

TECHNICAL MANUAL 343184-01

English

2

CONTENTS

1.GENERAL

2.TECHNICALDESCRIPTION

2.1 SYSTEM OVERVIEW

2.2 SENSORS

3.DETERMINETHEDIMENSIONSOFTHESENSOR

4.INSTALLATION

4.1 GENERAL

4.2 SENSOR INSTALLATION

5.PERIODICCHECKING

5.1 GENERAL

5.2 COMMISSIONING CHECKS

5.3 SIX MONTHLY CHECKS

5.4 DAILY/SETTING CHECKS

6.OPERATION,MAINTENANCEANDSERVICING

6.1 OPERATION

6.2 MAINTENANCE

6.3 SERVICING

7.TECHNICALSPECIFICATION

7.1 CKP/Solo SENSORS

7.2 MATERIAL SPECIFICATION

7.3 ORDERING INFORMATION

8.CONTACTS

3

1.GENERAL

The CKP/Solo mat is a pressure sensitive

safety device designed to protect operators

working at or near dangerous machinery.

Thematisdesignedtomeettherequirements

ofBSEN1760-1:1998andcontainsanintegral

fail-safe functionwhichmonitorstheswitching

elementstoCategory3ofEN954-1providing

dual channel outputs.

Whencorrectly installedat and interfacedto

a machine via a suitable control, which

monitors the dual outputs of the mat, the

CKP/Solomatwill:

(a) detect a person present in the dangerous

area and prevent dangerous motion from

occurring.

(b) detect a person entering the dangerous

area and cause dangerous motion to cease

before the person can reach the dangerous

parts.

(c) a combination of (a) and (b). The area

covered by the sensor depends on which of

thefunctions(a),(b)or(c)istobeperformed.

NOTE:TheCKP/Solomatisnotsuitablefor

detectingchildren.

The CKP/Solo mat is ideal for use with

safety bus systems. The mats can connect

directly to the same kind of standard safety

bus I/O connection modules that are used to

connect E-Stop switches over the

bussystem.Thisismuchmoreconvientthan

thealternativeofhavinganadditionalcontrol

unitclosetothematsothatitcanprovidethe

volt-free,normallyclosedconnectionstothe

safety bus I/O module.

WARNING

The information contained in this

manual relates to the use of a CKP/Solo

mat, to provide a basic safety switching

device.

In some applications the CKP/Solo mat

may be used together with other

equipment to provide additional

functions and features i.e. for use with

Safety Bus systems. Any other

documentationsuppliedmustbeusedin

conjunction with this manual.

In some cases some installation

parameters, notably the positioning of

the mat in relation to the dangerous

parts of the machine, can be affected

and close attention must be paid to all

informationsuppliedwithallequipment.

4

2.TECHNICALDESCRIPTION

2.1 SYSTEM OVERVIEW

A sensor may consist of a single mat sensor

or a combination of mat sensors. When a

personstandsonthesensoritisdetected,and

bymeansofitsoutputswitchingdevices,the

sensor causes dangerous motion to cease or

be prevented.

IMPORTANT

From the above it can be seen that the

safe use of the CKP/Solo Mat relies not

only on the safety integrity of the mat

itself but also on its mechanical and

electrical interfacing to the machine.

The safety integrity of the CKP/Solo

mat itself is the responsibility of

Tapeswitch.

Proper mechanical and electrical

interfacing is the responsibility of the

user. Comprehensive information for

this purpose is provided in section 4 of

this manual.

2.2 SENSORS

2.2.1 SENSOR SHAPES AND SIZES

Mat sensors can be produced in any shape

andsizewhichmeetsthefollowingrestrictions:

- all corners, internal or external, to be 90º.

- the maximum width of a mat is 1200 mm.

- the maximum length of a mat is 2400 mm.

- the maximum total area is 2.88m².

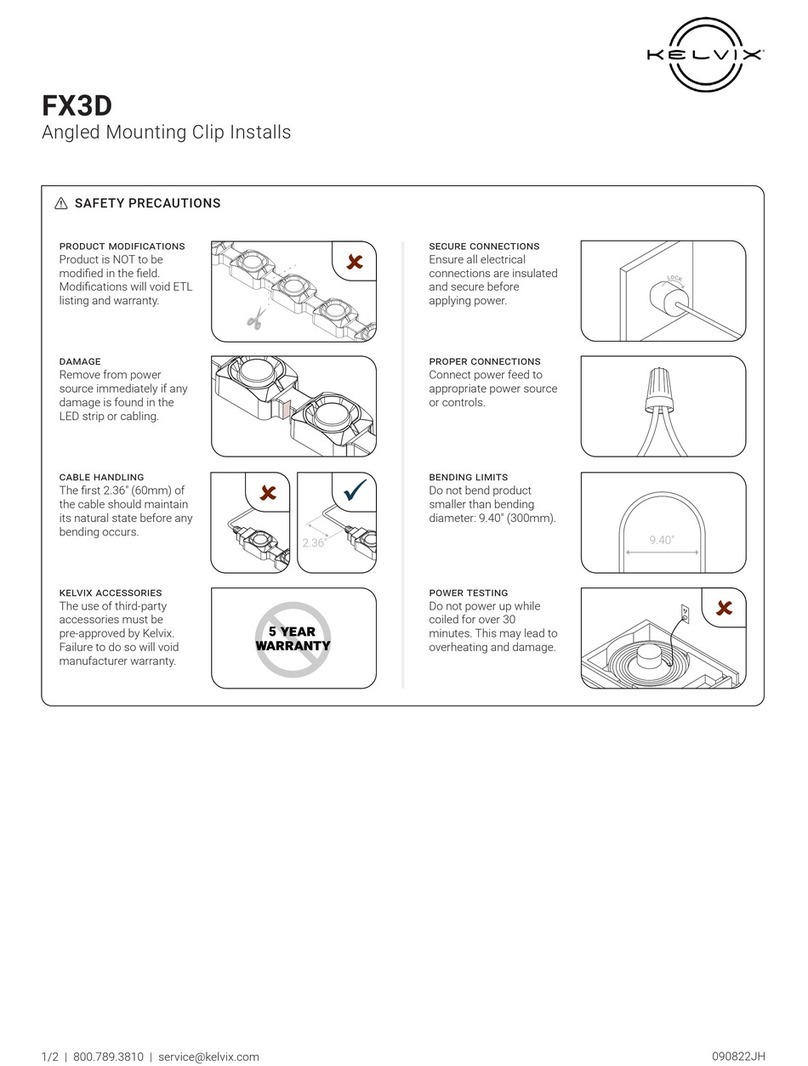

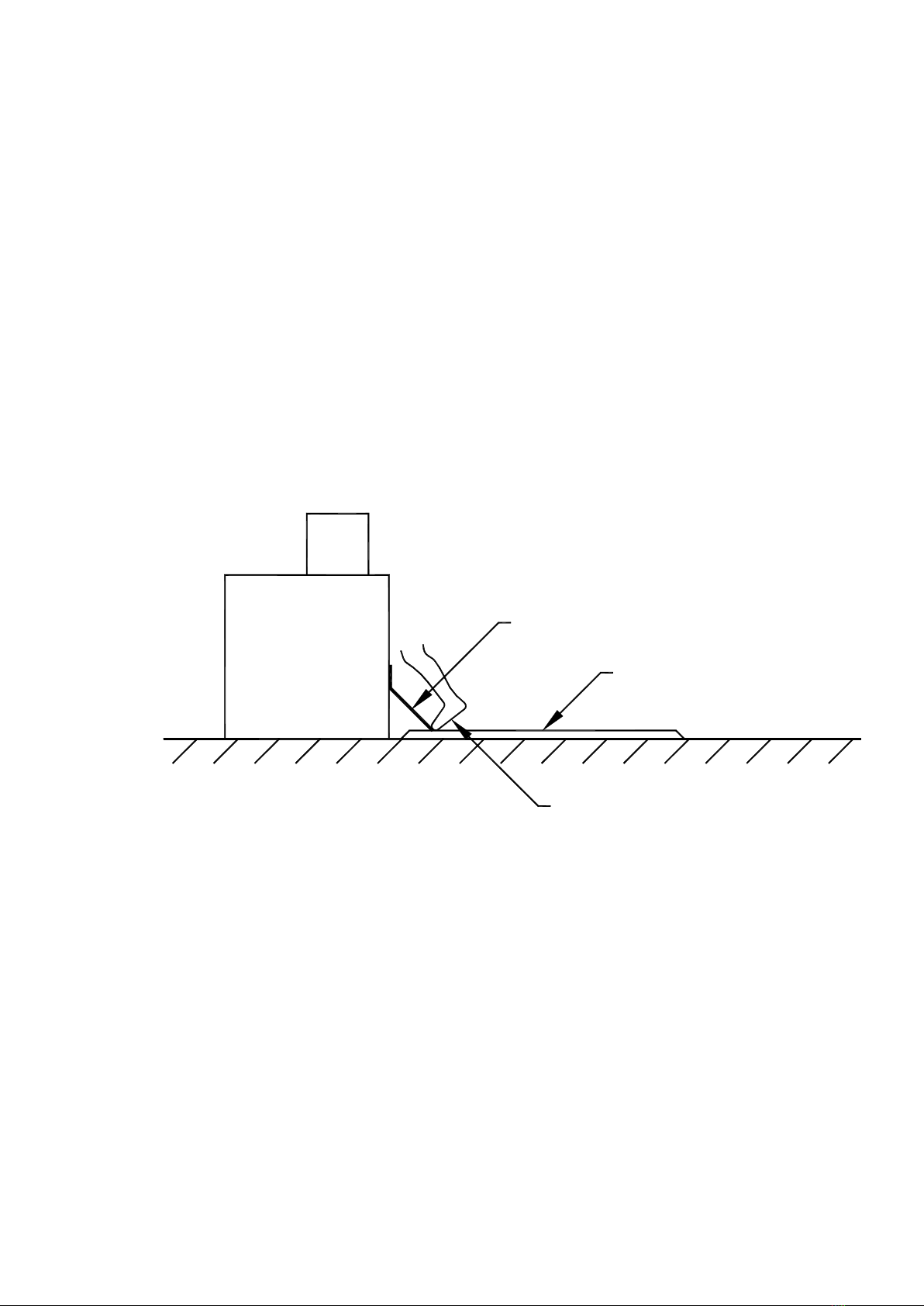

Figure1 - Dimensions of the inactivearea

around outer edge of sensor

The dimensions of sensors and their layout

must be such access to the machine is not

possible without stepping on a sensor. It

should not be possible to move the sensors

or bridge them using boards, plates etc.

NOTE - CKP/Solo sensors have a 30mm

inactive area around the outer edges, which

means that the dimensions of the active area

(i.e. the area within which the application of

pressurewillactuatethesensor)is60mmless

than the overall dimensions of the mat as

showninFigure1.Thisshouldbekeptinmind

whenspecifyingthesizeofmatforaparticular

application.

2.2.2 CKP/Solo SENSORS

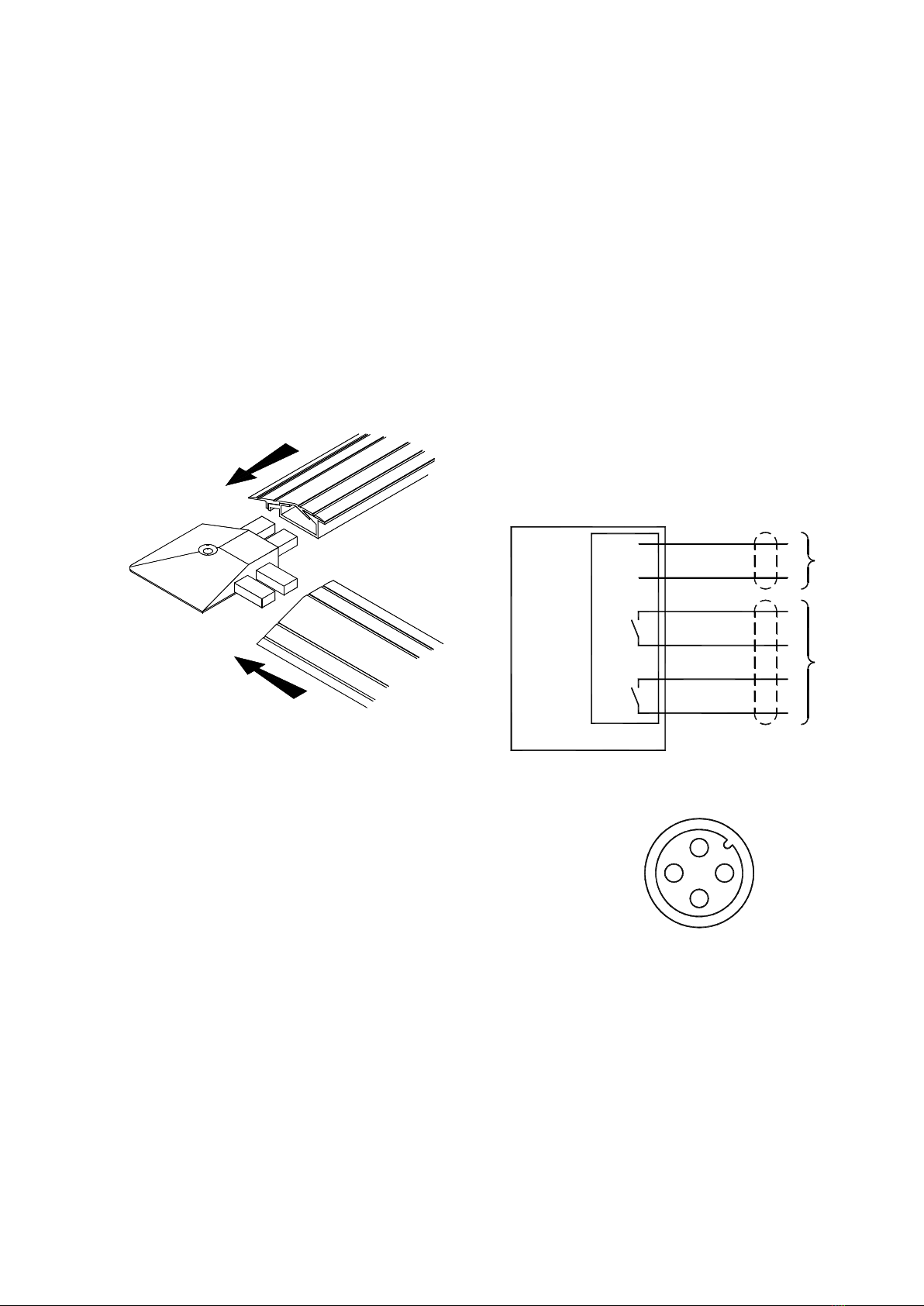

The construction of the CKP/Solo sensor is

shown in Figure 2.Anetwork of Tapeswitch

ribbon switching elements is sandwiched

between two thick sheets of PVC material.

The switching elements are connected in

series and are connected to the integral

fail-safe monitor. The switch elements are

adhered to the bottom layer.

30

ACTIVE

AREA

30

30 30

5

Thetoplayer isasheetof ribbed,heavyduty

mattingmaterial.Thismaterialisoflaminated

construction and is PVC based with special

additives and fillers to increase its abrasion

and chemical resistance. This material can

withstand years of pedestrian traffic and is

resistanttomostchemicalscommonlyfound

inanindustrialenvironmentincludingwater,

coolant, oil and hydraulic fluid.

The bottom sheet is a solid smooth rubber

mattingsheet.

Thetopsheet is 6.5mm thickandthe bottom

sheet is 6mm thick.

All the upper conductors of all the switch

elementsareconnectedtogetherandalllower

conductorsareconnectedtogether,effectively

creatingasinglenormallyopenswitch.Heavy

gauge tin plated copper wire is used for all

internal wiring and all connections to the

switching elements are direct solder joints.

The switches are self-bottoming and as a

resulttheycanwithstandveryhighloadsand

repeatedoperation.Severalmillionoperations

istypical.

Figure 2 - Construction of CKP/Solo

Mat Sensor Figure 3 - Construction of Tapeswitch

Switch Elements

TheconstructionoftheTapeswitchelements

isshowninFigure3.Eachswitchingelement

is a long normally open switch. The switch

consistsoftwocopperplatedsteelconductors

held apart at the sides by an insulator. When

pressure is applied to the bead, the two

conductors are forced together in the centre,

closing the switch.

PVC SLEEVE

UPPER CONDUCTOR

LOWER CONDUCTOR

INSULATOR

PVC SLEEVE

UPPER CONDUCTOR

LOWER CONDUCTOR

TOP

LAYER

SWITCH

LAYER

BOTTOM

LAYER

FAILSAFE

CONTROLLER

6

3.DETERMINETHEDIMENSIONS

OF THE SENSOR

The dimensions of the sensors and their

layoutmustbesuchthat,accesstothemachine

isnotpossiblewithoutsteppingonthesensor.

Thedimensionsofthedangerousareadepend

ontheparticularapplication.Theparameters

to be considered include:

- Speed of walk or arm movement

(typically1.6m/s).

- Armlength(typically0.85m).

- Length of stride (typically 0.7m).

- Response time of system.

- Position of dead zones.

- Overtravel of dangerous parts after

stop signal is generated

To determine the size of sensor needed, use

thissimpleformulabelow:

Active + 60mm = Overall Sensor

Area length or width

i.e.Forasensormeasuring2000mmx1000mm

the size of active area = 1940mm x 940mm.

Note that if the sensor is to be supplied and

fittedwithAE-13Aluminiumedgingthen:

Total Area = Overall Sensor + 126mm

Coveredwith length or width

AE-13Edging

i.e.Forasensormeasuring2000mmx1000mm

thetotalareacovered=2126mmx1126mm.

Inordertodeterminethepositionofthefront

edge of the active zone it is necessary to

consider the stopping performance of the

machine.

Anymachineregardlessoftheefficiencyofits

brakingsystem,willtakeacertainamountof

time to come to rest after a stop signal is

generated. From the instant that a persons

foot touches the sensor to the instant that the

dangerousmotionactuallyceasesiscalledthe

overall system response time.

Theoverallsystemresponsetime,T,isgiven

bythefollowingcalculation:

T = t1 + t2

where t1 = the maximum response time of

the safety device between the

actuation of the sensor and the

generation of the stop signal.

andt2 = theresponsetimeofthemachine

between receiving a stop signal

from the safety device and the

dangerous parts coming to rest.

Thedangerouspartswillobviouslycontinue

to move during this time. The sensor must

thereforebedimensionedsuchthatthenearest

point at which a person could first touch the

mat is a certain minimum distance from the

dangerous parts, to prevent the person from

reachingthedangerouspartsbeforetheyhave

stopped.

This must take into account the worst case

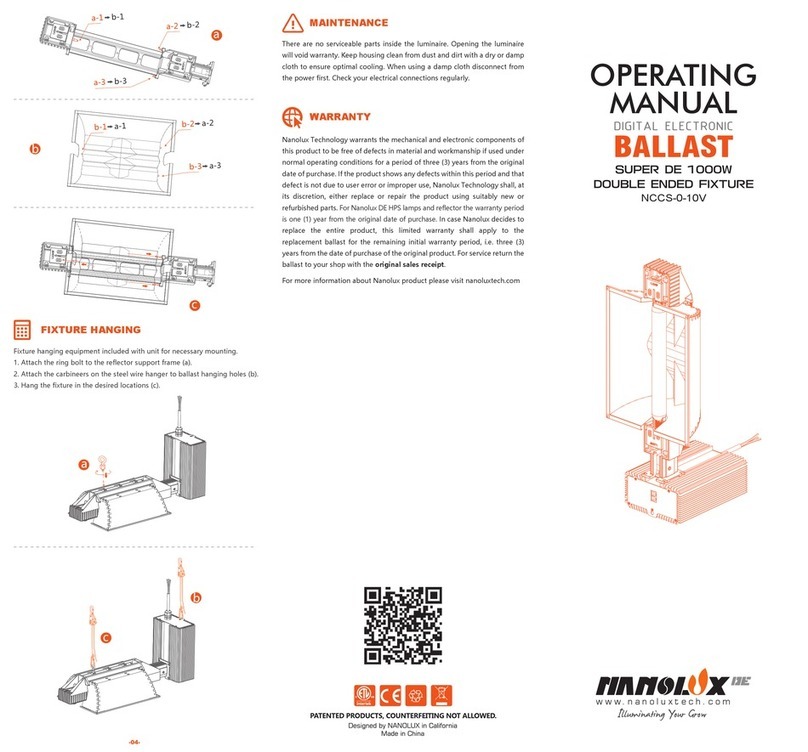

conditions illustrated in Figure 4 where a

person could be a full stride onto the sensor

beforethesensorisactuated.Thismeansthat

a certain distance from the front edge of the

sensor and the dangerous parts must be

maintained.

7

This distance is the minimum separation

distance.Allpossibledirectionsofapproach

mustbeconsidered.Theminimumseparation

distance, S, can be calculated using the

followingformula:

S = (1600 x T) + 1200

The overall system response time, T, should

be measured several times and the highest

valuerecorded,plusasuitableallowancefor

brake deterioration, should be used in the

calculationoftheminimumseparationdistance.

Figure 4 - Minimum Separation Distance

MINIMUMSEPARATION

DISTANCE 'S'

DANGEROUS

PARTS

MACHINE

WORST CASE

POINT OF

DETECTION

BEST CASE

POINT OF

DETECTION

FRONTEDGEOFACTIVEZONE

NEAREST DANGER POINT

8

4.INSTALLATION

WARNING

TAPESWITCH SAFETY MAT SYSTEMS ARE DESIGNED TO PROTECT

OPERATORS WORKING AT OR NEAR DANGEROUS MACHINES. THEY CAN

ONLY PERFORM THAT FUNCTION IF THEY ARE CORRECTLY FITTED AND

INTERFACED TO A SUITABLE MACHINE. EVERY EFFORT HAS BEEN MADE IN

THE PRODUCTION OF THIS MANUAL TO PROVIDE COMPREHENSIVE AND

ACCURATE INFORMATION. IT IS THE RESPONSIBILITY OF THE USER TO

ENSURE THAT ALL PERSONS INVOLVED IN THE INSTALLATION OF THE

PRODUCTHAVETHEKNOWLEDGE,TRAININGANDEXPERIENCENECESSARY

AND THAT THEY ARE FULLY CONVERSANT WITH ALL LAWS, RULES,

REGULATIONS AND CODES OF PRACTICE PERTAINING TO THEIR TASK.

4.1GENERAL

The attention of the installer is drawn to the

following general requirements for the

installationofaTapeswitchsafetymatsystem:

(a) The machine must be electrically

controllable.

(b) It must be possible to stop the dangerous

motion of the machine at any point in its

operation, in any operating mode.

(c) The control system as a whole must be

designedtoprovidethelevelofsafetyintegrity

determined by the risk assessment.

(d) Steps must be taken to prevent access to

thedangerous partsof themachine fromany

direction not covered by the sensor. Such

stepscouldincludefixedorinterlockingfences

orscreens,additionalpressuresensitivemats

or photo-electric devices.

(e) Steps must be taken to prevent a person

standinginthedangerousareawithoutstanding

on the sensor. The inner surfaces of fixed

mechanicalfencingshouldbedesignedsuch

that there are no ledges or steps on which a

person could stand and thereby avoid the

sensor. It may be necessary to fit additional

mechanicalbarriers,coversetc.tocoverany

surfaceswithin thedangerous areaonwhich

a person could stand, such as the feet of the

machine. Particular attention should be paid

totheedgeofthematnearesttothemachine.

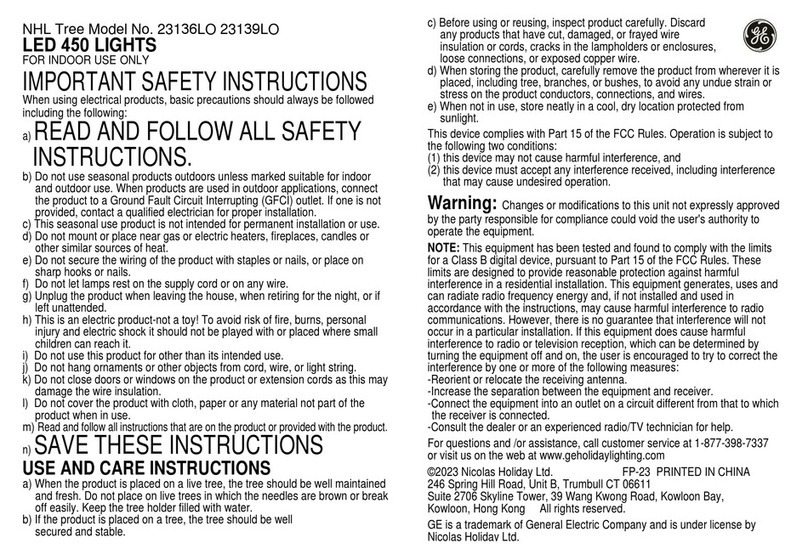

Ensurethatapersontip-toeingatthefrontof

themachinewillstillbestandingontheactive

area of the mat. See Figure 5.

(f) Wherever possible rectangular mats of

standard sizes should be used. Where this is

not possible, due to obstructions, mats with

edge or corner cutouts and even with holes

can be specified. This should only be done

where the obstructions are permanent.

9

(g) Under no circumstances should a mat

sensor be cut or drilled. It is not possible for

the user to modify the size or shape of a mat

sensor.

(h)Greatcareshouldbetakenwhenhandling

matsensors.Neverpickthesensorupordrag

it around using the cables. Never bend a mat

ataradiuslessthan300mm.Keepmatsensors

flatwheneverpossible.Alwaysstoreflat.Mat

sensors with one edge longer than 1 metre

should be handled by two people.

Figure 5 - Ensure operator is always standing on active area of sensor

(i)Afterinstallationthemachine/matsystem

must be commissioned in accordance with

section 5 of this manual.

(j) Any covers removed during installation

must be replaced as soon as possible.

SLOPING SKIRT FIXED TO MACHINE

MAT

OPERATOR ON TIPTOE ALWAYS

ON ACTIVE ZONE OF SENSOR

MACHINE

10

Figure 6 - AE-13 Sensor Edging

32 69

94

ø6

32

69 94

17

Figure 7 - AE-13 Sensor Edging

4.2 SENSOR INSTALLATION

4.2.1 SENSOR MOUNTING SURFACE

The surface on which the sensor is mounted

must be sound and reasonably flat. The

sensor can tolerate minor irregularities but

sharpedges orprojections greaterthan 1mm

maycauseprematuredegradation.Wherethe

surface is rough, cracked or breaking up, it

should be treated using proprietary sealing

and levelling compounds.

4.2.2 SENSOR FIXING

The sensor(s) must be fixed permanently in

position. Tapeswitch aluminium edging

AE-13shouldbe used aroundtheouter edge

ofthesensor.Thisspeciallydesignededging

comes in two parts, a base and a cover. The

cover provides a 20 degree ramp to prevent

a tripping hazard at the outer sensor edges.

TypeAE-13 edging is illustrated in Figure 6

and AE-C corner pieces in Figure 7. At the

junction of several mats, the mats should be

fixed to the floor using double sided tape.

4.2.3 INSTALLATION PROCEDURE

Step1-Planthelayout.Markoutonthefloor

the position and size of each sensor. Take

care to use the overall dimensions of mat

sensors.

Step 2 - Cut all edging to size. Remove any

burrs and sharp edges with a file.

Note: If AE-C corner pieces are used then:

the cut length = mat dimension - 12mm.

of AE-13

Step 3 - Mark the positions of the sensor

cables and cut slots in the inner face of the

edgingbaseextrusiontoallow accessforthe

sensor cables.

71

8

17

11

Figure 8 - AE-13 & AE-C Installation

NOTE: MAT SENSORS MUST BE

FITTED WITH THE LABEL SIDE UP.

Step4-Positionthebasesectionsaroundthe

mat and fit AE-C corner pieces. Drill pilot

holesthrougheach corner piece andholesin

thebasesectionsifapplicable. Removebase

sections/cornerpiecesanddrillandplugthe

floor. Refit base sections and corner pieces

and secure in position with the screws

provided, as shown in figure 8. Ensure the

cable exits neatly through the slot(s) in the

base section.

Figure 9 - CKP/Solo Connection Details

4.2.4 ELECTRICAL INSTALLATION

TheCKP/Solomatissuppliedwith2x4core

cables0.5mlong,eachcableisfittedwithan

M12 plug.Theconnectionstothematsensor

are shown in Figure 9.

Onecableisusedforthed.c.supply,andone

cableisusedforthe Volt-FreeSafetyOutputs.

NOTE: In order to achieve EN954-1

Category3safety integrity, theoutputs must

bewiredastwoseparatechannelstoasuitable

control capable of monitoring them for

equivalence.

Step 5 - Route the cable(s) to the interface.

The cable(s) should exit from the edging as

close to the interface position as possible.

The cables should be protected in suitable

conduitbetweentheedgingandtheinterface.

Protectanyedgesoverwhichthecablespass

withgrommetstrip orsimilar.

Step6- Fitthecoverextrusionof theedging

using suitable self-tapping screws.

+24V

0V

O/P

1

O/P

2

CKP/SoloSENSOR

BROWN

BLUE

BROWN

WHITE

BLUE

BLACK

1

3

1

2

3

4

CABLEB

CABLEA

2

4

31

12

5.PERIODICCHECKING

5.1GENERAL

Thefollowingsectionsdescribethe periodic

checks to be performed on a machine fitted

with a Tapeswitch safety mat system. If the

machineisfittedwithadditionalsafetydevices

the periodic checks prescribed by the

manufacturer of these devices should be

incorporatedintotheperiodiccheckingregime

described below.

If the machine fails any of the prescribed

checksthemachinemustbeisolatedandmust

notbeuseduntilthefaulthasbeenidentified

andrectified.

5.2 COMMISSIONING CHECKS

Thecommissioningchecksshouldbecarried

out by persons who are competent and who

have access to all the information supplied

with the machine and its safety equipment.

The results of the examination should be

recorded and copies of this record should be

kept by the user and the employer of the

personperformingtheexamination.

The person carrying out the examination

should,asaminimum,performthefollowing

checks:

(a) Check that the CKP/Solo is suitable for

usein theapplication:

(i)Checkthatthelevelofsafetyintegrity

providedbytheCKP/Soloissuitablefor

thelevelofriskpresentedbythe machine.

(ii)Checkthattheenvironmentissuitable

for the use of the CKP/Solo.

(b)Checkthatthedimensionsandpositionof

theCKP/Soloarecorrecttakingintoaccount

theoperatingmode.Forthispurposeitwillbe

necessarytochecktheoverallsystemresponse

timeusingadevicedesignedforthispurpose.

(c)Check that adequate measures have been

takentopreventaccesstothedangerousparts

ofthemachinefromanydirectionnotcovered

by the CKP/Solo.

(d) Examine the machine controls and

connections to the CKP/Solo to ensure that

therequirementsdescribedinthismanualand

inthemachine manual havebeenmet.

(e) Check that the CKP/Solo is fixed in

position and that no trip hazards are present

within the dangerous area.

(f) Exceptwherethedeviceis usedsolelyas

a trip device, check that it is not possible for

a person to stand in the dangerous area

without actuating the CKP/Solo.

(g) Check that it is not possible for the

dangerous parts of the machine to be set in

motion while the CKP/Solo is actuated.

(h) Check that actuation of the CKP/Solo

duringa dangerousphase ofoperationofthe

machineresults inthe dangerousparts being

arrested, or where appropriate, assuming an

otherwise safe condition, before any part of

a person could reach them.

13

(i) Check that, after the machine has been

stopped by the actuation of the CKP/Solo, it

is not possible for the dangerous parts to be

set in motion until the CKP/Solo has been

cleared, the reset button has been operated

and released, and the machine start control

has been re-operated.

(j)Checkthattheremovalofpowerfromthe

CKP/Solo prevents further operation of the

machine. It should not be possible for the

dangerous parts of the machine to set in

motion until power has been restored, the

reset button has been actuated and released,

and the machine start control has been

actuated.

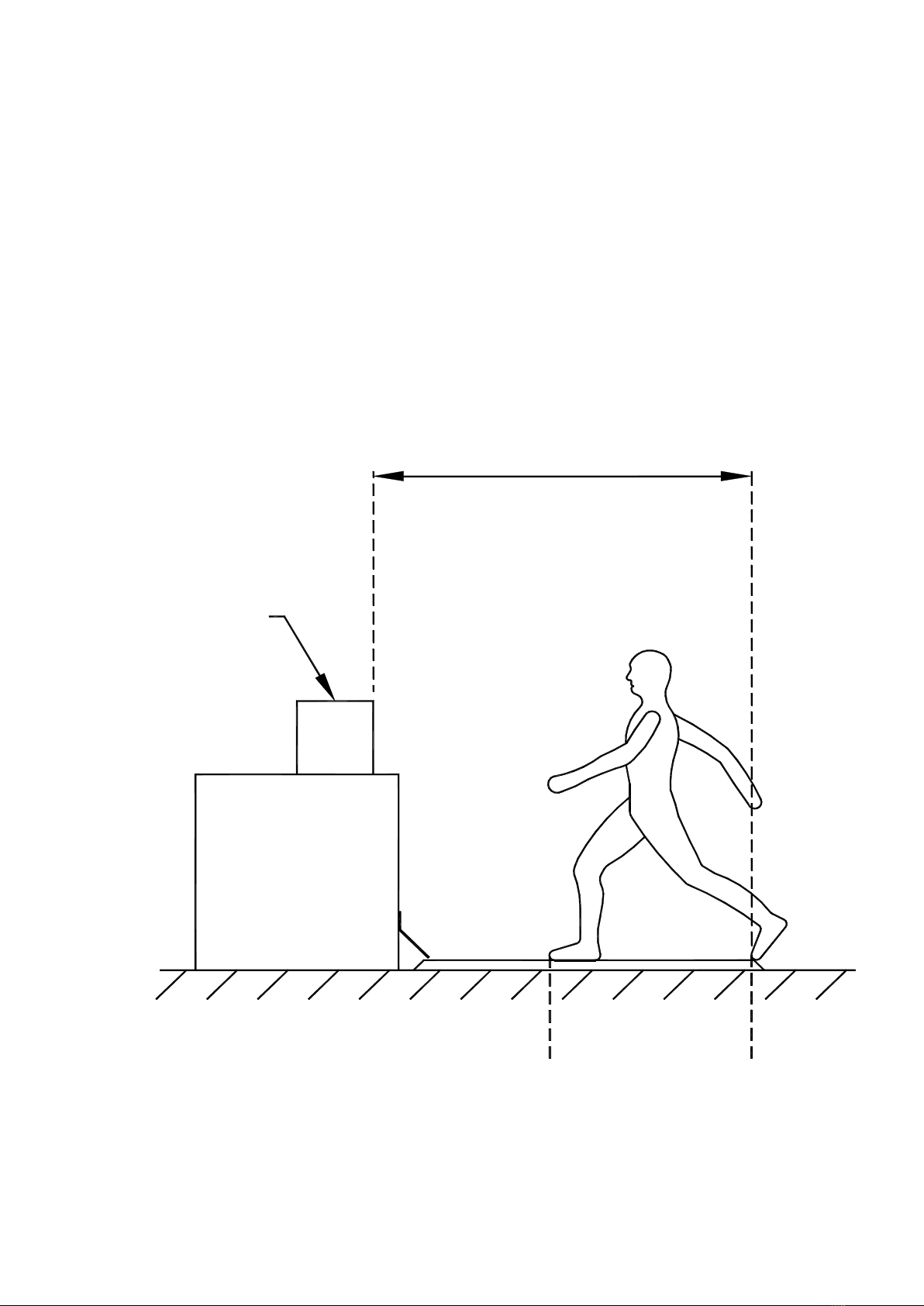

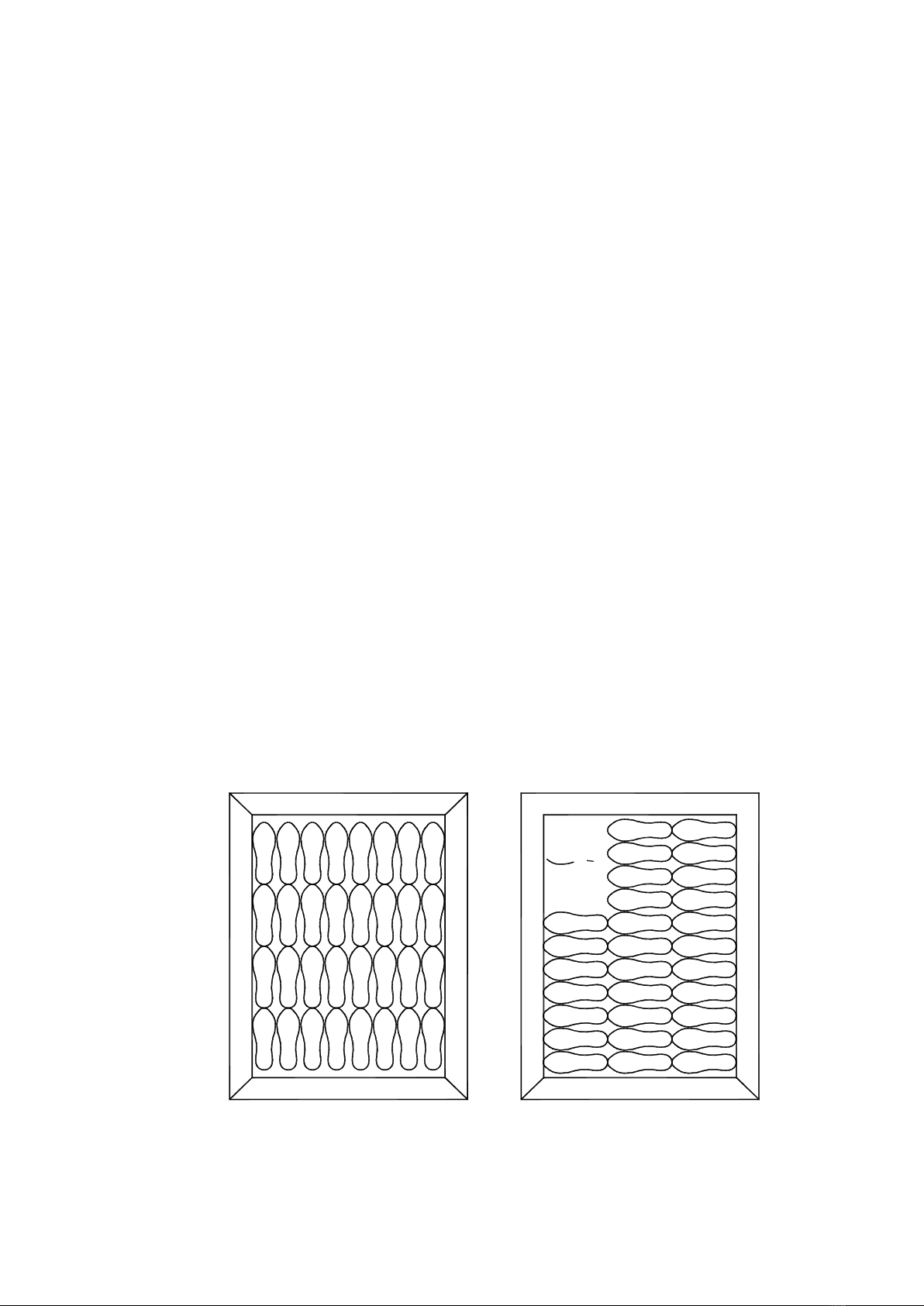

(k) Check that the CKP/Solo operates over

thewholeactiveareabywalking,‘heeltotoe’,

over the whole area in two directions, as

shown in Figure 10.

(l)Examinethestoppingperformancemonitor

(iffitted)toensurethatitisfittedandfunctioning

correctly.Ensurethatthemeansbywhichthe

stoppingperformancecanbeassessedbythe

operator is indicating correctly.

(m)Test the muting arrangements (if fitted).

Ensurethatthemutingisonlypossibleduring

non-dangerousoperationandensurethatthe

safetylevelofthemutingdeviceisatorabove

that of the safety mat but never below.

(n)Examinebrakesandclutches(iffitted)as

recommended.

NOTE: No stopping performance monitor

or muting facilities are provided with the

Tapeswitchsafetymatsystemandthereisno

means provided for the connection of such

devices to the system. These devices may

howeverhavebeenprovidedelsewhereinthe

machine control system.

Table of contents

Other Tapeswitch Lighting Equipment manuals