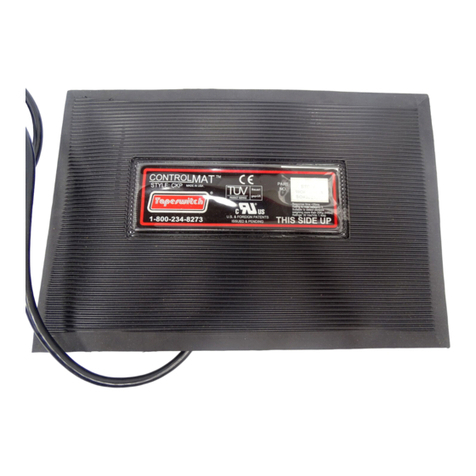

Tapeswitch GS-120 User manual

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

GS-120 Photo-Electric Light Curtain Systems

Technical Manual

WARNING

Tapeswitchphoto-electric safetysystemsareintendedtoprotect operatorsworkingatornear

dangerous machinery. They can only perform this function if they are correctly fitted to a

suitable machine. It is essential that the full contents of this manual and all the international

documents referred to herein are fullyunderstood before any attempt at installationis made.

If in doubt, contact Tapeswitch Corporation.

IMPORTANT

This manual must accompany the product throughout its working life. Those persons

responsible for the product must ensure that all persons involved in the installation,

commissioning, operation, maintenance and servicing of the product have access to all the

information supplied by the manufacturers of the machine and its safety system.

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard 2Fax: 631-630-0454

Farmingdale, New York 11735 www.tapeswitch.com

TABLE OF CONTENTS

1.0 GENERAL

1.1 INTRODUCTION 4

1.2 PRODUCT Range 4

1.2.1 General 4

1.2.2 Detection Capability 5

1.2.3 Protected Heights 5

1.2.4 Accessories 5

1.2.4.1 Mirror Units 5

1.2.4.2 Mounting Stands 7

1.3 ORDERING INFORMATION 7

1.3.1 GS-120 Light Curtain Order Code 8

1.32 GS-120 Multi-Beam Order Code 8

1.3.3 Cable Options 9

1.3.4 Interface and Programming Units 9

2.0 TECHNICAL DESCRIPTION 9

2.1 CURTAIN 9

2.2 COMMUNICATIONS 10

2.3 TEST INPUT 10

2.4 INDICATORS 11

2.4.1 LED Option 11

2.4.2 Diagnostic Option 12

3.0 INSTALLATION 13

3.1 GENERAL 13

3.2 MECHANICAL INSTALLATION 13

3.2.1 General Considerations 13

3.2.1.1 Multi-Sided Guarding 15

3.2.2 Curtain Dimensions 16

3.2.2.1 GS-120 Basic System 16

3.2.2.2 GS-120 Multi-Beam System 17

3.2.2.3 GS-120 Cascaded System 18

3.2.3 Separation Distance 19

3.2.3.1 Normal Approach 19

3.2.3.2 Parallel Approach 21

3.2.3.3 Angled Approach 22

3.2.3.4 Approach to ‘L’ Installation 22

3.2.4 Optical Alignment 23

3.2.5 Reflective Surfaces 23

3.2.6 Systems in Close Proximity 24

3.2.7 Mounting Brackets 24

3.3 ELECTRICAL INTERFACE, OPERATION, AND INSTALLATION 27

3.3.1 General 27

3.3.2 Emitter Unit 27

3.3.2.1 General 27

3.3.2.2. Test Input 28

3.3.3 Receiver Unit 28

3.3.3.1 General 28

3.3.3.2 PNP Version 29

3.3.3.3 SSR Version 30

3.3.4 Interfacing to a Machine 31

3.34.1 PNP Version Manual Reset 31

3.34.2 PNP Version Auto Reset 32

3.34.3 SSR Version 33

3.4 INITIAL CHECKING AND ALIGNMENT 34

4.0 INTERFACE AND AUXILIARY UNITS 35

4.1 GENERAL 35

4.1.1 Methods of Interfacing 35

4.1.2 Special Interfacing Considerations 36

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard 3Fax: 631-630-0454

Farmingdale, New York 11735 www.tapeswitch.com

4.1.2.1 PNP Version Manual Reset 36

4.1.2.2 PNP Version Auto Reset 36

4.1.2.3 SSR Version 36

4.1.3 Connections to an AS-i System 37

5.0 PERIODIC CHECKING, SERVICING, AND MAINTENANCE 38

5.1 PERIODIC CHECKING 38

5.1.1 Commissioning Checks 38

5.1.2 6 or 12 Month Periodic Checks 38

5.1.3 Daily/Setting Examination 39

5.1.4 Checking Detection Capability 39

5.1.4.1 GS-120 System 39

5.1.4.2 GS-120 Multi-Beam System 40

5.2 SERVICING 41

5.3 MAINTENANCE 41

6.0 TECHNICAL SPECIFICATIONS (GS-120Series Emitter & Receiver) 42

APPENDIX A: BSRSA INTERFACE UNIT 43

APPENDIX B: BSRUA-2 INTERFACE UNIT 49

APPENDIX C: SRUB INTERFACE UNIT 57

APPENDIX D: SRUS INTERFACE UNIT 63

APPENDIX E: C6 MULTIFUNCTION INTERFACE CONTROLLER 67

APPENDIX F: GDC-1 24 VDC POWER SUPPLY 68

APPENDIX G: LAT LASER ALIGNMENT TOOL 69

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard 4Fax: 631-630-0454

Farmingdale, New York 11735 www.tapeswitch.com

1.0 GENERAL

1.1 INTRODUCTION

Tapeswitch GS-120 light curtains are through-beam

photo-electric machine guarding devices, designed to

protect operators working at or near dangerous

machinery. They meet the requirements for EN61496

Type 2 light curtains and Category 3 safety control units

as defined in EN954-1.

When correctly installed on a suitable machine, the

system will detect a person (or part of aperson)entering

a dangerous area in the vicinity of the machine, and will

signal the dangerous motion to cease before that

person can reach a position where injury could occur.

Tapeswitch GS-120 light curtains use infra-red

technology. A curtain of infra-red light is projected

across the dangerous area. Intrusion into this curtain by

a person or part of a person will be detected by the

system. This will cause safety output signals to be

generated which will stop the dangerous motion of the

machine.

WARNING

The information in this manual relates to the

use of the basic GS-120 light curtain, to provide

a basic safety switching device.

In some applications, a GS-120 light curtain

may be used together with other Tapeswitch

equipment to provide additional functions and

features. The additional information necessary

for the correct use of a GS-120 light curtain

when used with other Tapeswitch equipment is

provided within this manual.

In such cases, some installation parameters,

notably the mounting position of the light

curtain in relation to the dangerous part of the

machine, can be affected and close attention

must be paid to all the information supplied

with all equipment.

INTERNATIONAL CONSIDERATION: Theheritage of

the Tapeswitch GS-120 system is strongly grounded in

international commerce and standards. They were

developed by Tapeswitch Ltd., of Chorley, England.

Both Tapeswitch Ltd. and Tapeswitch U.S. are part of

Indel Corporation, a private U.S industrial group. The

GS-120 product line was developed to meet published

and proposed safety standards for the United States,

Germany, England, Finland, and Sweden,as wellasthe

common market unified standard. GS-120 systems are

manufactured both in England and the United States.

Tapeswitch GS-120 products have been independently

third party tested to IEC 61496 by BG, and are certified

to this standard (CE approval/certification). Contact

Tapeswitch for more details.

Tapeswitch can provide additional assistance to

customers wishing to use GS-120 guards in

international applications. Some foreign language

technical manuals are available.

1.2 PRODUCT RANGE

1.2.1 GENERAL

The GS-120 light curtains are available in a range of

different protected heights and detection capabilities.

These two parameters are known by many other names

and therefore it may be useful to define them here, as

they are intended to be used in this manual. To make

this clearer it is also necessary to define two further

parameters, detection zone and operating range:

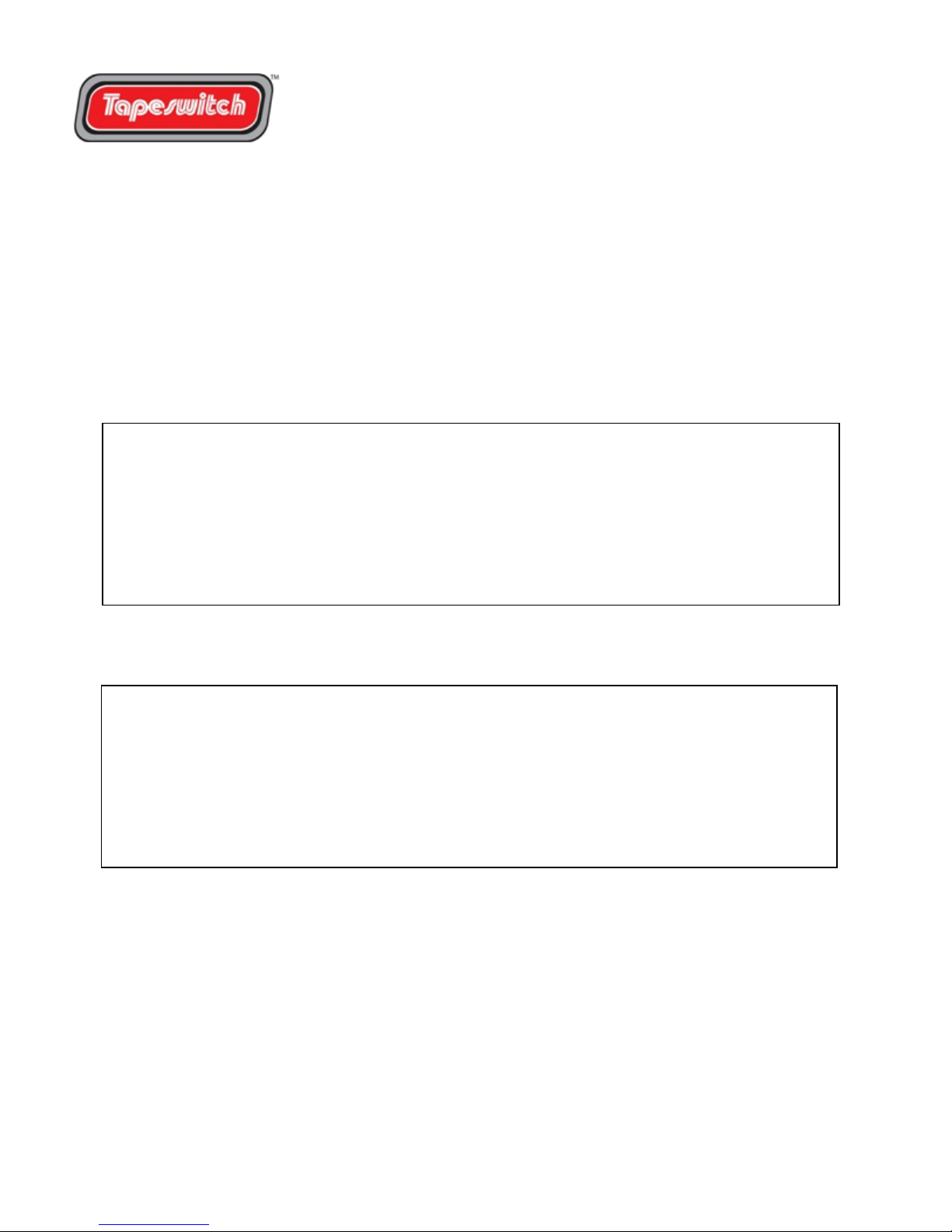

Detection Zone: This is the actual curtain of infra-red

light generated between the emitter and receiver units

within which an appropriately dimensionedobject will be

reliably detected and, for the GS-120, can be

considered to be a two dimensional, rectangular plane

(see Figure 1).

Operating Range: One dimension of the detection

zone rectangle is given by the distance between the

emitter and receiver units. This is the operating range

(see Figure 1).

Protected Height: The other dimension of the

detection zone rectangle is commonly known as the

protected height. The word “height” has been adopted

in the latest standards for this equipment because most

curtains are mounted vertically. The protected height is

often related to, but is not the same as, the length of the

emitter and receiver units (see Figure 1).

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard 5Fax: 631-630-0454

Farmingdale, New York 11735 www.tapeswitch.com

Figure 1

Detection Capability: This is the minimum dimension

of an opaque object which will be reliably detected

anywhere within the detection zone.

NOTE: The spacing or pitch of the beams or lenses in a

light curtain is not the same as the detection capability.

The detection capability is always greater than the

spacing or pitch. Spacing or pitch should not be used in

the calculation of separation distances (see Figure 2).

1.2.2 DETECTION CAPABILITY

GS-120 light curtains are available with detection

capabilities of 30mm or 70mm.

Figure 2

1.2.3 PROTECTED HEIGHTS

GS-120 light curtains are available with nominal

protected heights as follows:

Detection Capability Nominal protected heights

(in mm and inches)

30mm (1-3/16 in.) 200-300-400-600-800-900-

1000-1200-1400-1600 mm

(8-12-16-24-32-36-40-48-56-

64-72 inches)

70mm (2-3/4 in.) 600-800-1000-1200-1400-

1600-1800 mm

(24-32-40-48-56-64-72

inches)

The minimum separation distance is 0.5 m.

Note:

The actual protected height is 8 mm greater than the

nominal protected height.

1.2.4 ACCESSORIES

1.2.4.1 Mirror Units

A range of mirror units are available to enable a single

curtain to be used to guard two or three sides of a

machine or to avoid structural obstructions.

The mirror assembly consists of a high quality silver-

backed glass mirror adhesively attached to a length of

extruded aluminum. Two pivot brackets are bolted to

the aluminum extrusion and can be adjusted anywhere

along the length for mechanical attachment. The actual

length of the mirror is 4 inches (1000mm) larger than the

active curtain length to accommodate a wide tolerance

for height alignment. All of the necessary hardware is

supplied to facilitate mounting to the mounting/floor

stands. The dimensions of the pivot brackets, extruded

aluminum and overall mirrors are shown below in

millimeters.

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard 6Fax: 631-630-0454

Farmingdale, New York 11735 www.tapeswitch.com

40mm

6.8mm

40mm

6.8mm

X

Glass Reflective

Surface

Overall Length =

Protective Height + 4"

180°Rotation

in this Plane

Pivot Brackets

(180°Rotation;

Distance X is Adjustable)

Supplied with:

1. 1-40mm x 40mm extrusion, 100mm larger than

protective height.

2. 1-silver backed mirror, 100mm larger than

protective height.

3. 2-pivot joints.

4. 2-40mm x 40mm end covers.

5. 4-5mm T slot nuts.

6. 4-#12 flat washers.

7. 4-5mm spring washers.

8. 4-5mm x 5/8 hex bolts.

Curtain Lengths Mirror Assembly

Length P/N

200mm - 8" 300mm - 12" 0960

300mm - 12" 400mm - 16" 0961

400mm - 16" 500mm - 20" 0962

600mm - 24" 700mm - 28" 0963

800mm - 32" 900mm - 36" 0964

900mm - 36" 1000mm - 40" 0965

1000mm - 40" 1100mm - 44" 0966

1200mm - 48" 1300mm - 52" 0967

1400mm - 56" 1500mm - 60" 0968

Pivot Bracket

Extrusion Dimensions

For units greater than 56 inches, custom mirrors are available.

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard 7Fax: 631-630-0454

Farmingdale, New York 11735 www.tapeswitch.com

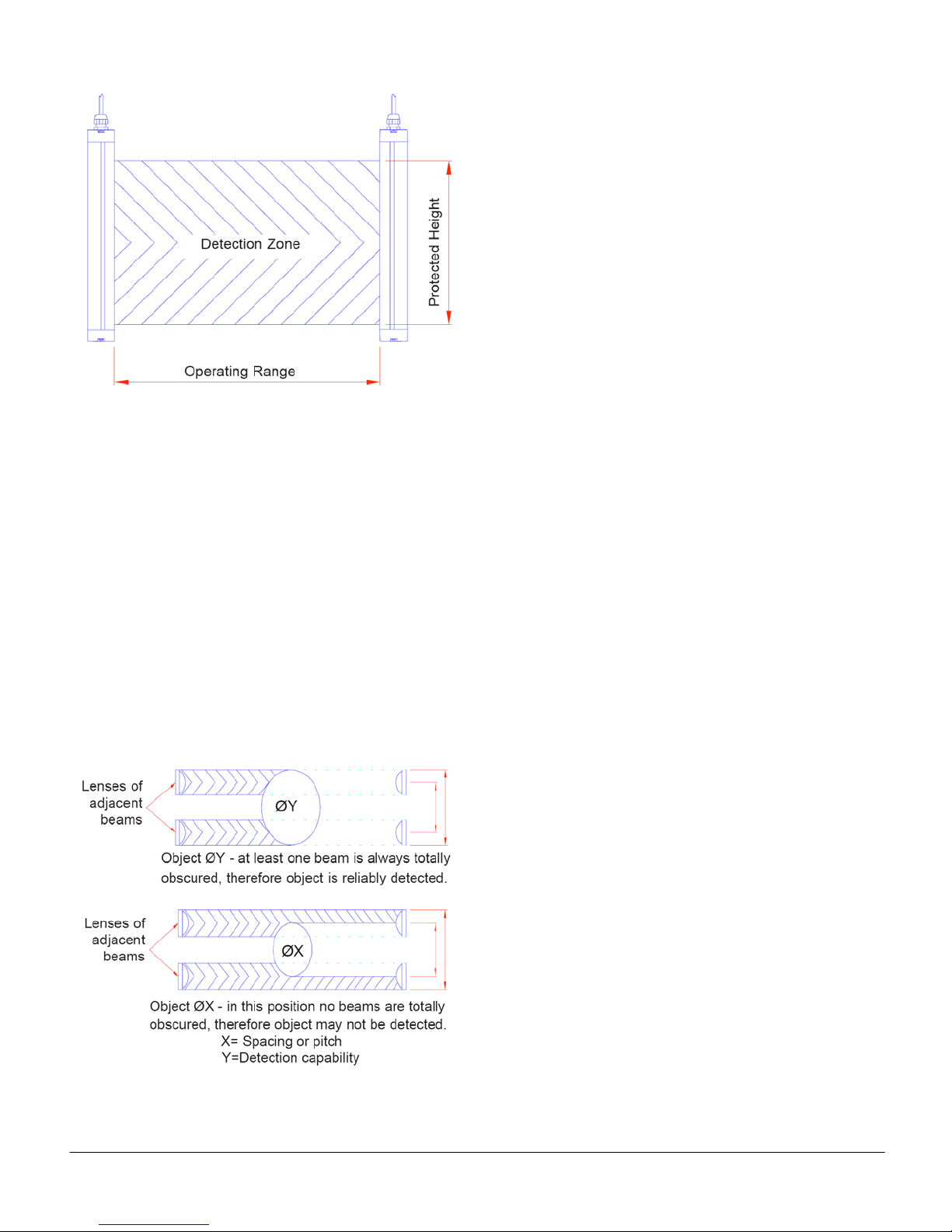

3/8" holes

3 leveling bolts

P/N 0957

Supplied with:

1. 5 ft.item 40mm X40mm extrusion

2. 1-base stand.

3. 1-40mm X40mm end cap.

4. 2-T slot nuts M5.

5. 2-M5 X12mm hexhead.

6. 2-M5 spring lock washers.

7. 2-flatwashers 5/5.3mm.

8. 2-5/16 bolts.

9. 3-3/8 24 x1/2"hexhead.

5"

5"

5

4"

4"

1.2.4.2 Mounting Stands

Floor mounting stands are available for use where the

guard cannot be mounted directly to the machine.

The mounting stand set includes a floor-mounted base

into which the 5-foot mounting post can be secured.

The floor base is steel and can bepermanentlymounted

to the floor surface with the pre-drilled mounting holes.

The post is extruded aluminum with slots to allow the

light curtain to be positioned anywhere along its length.

The mounting stands are supplied with all of the

necessary hardware to facilitate mounting a standard

GS-120 light curtain. Leveling bolts allow for minor

adjustments to the floor stand orientation.

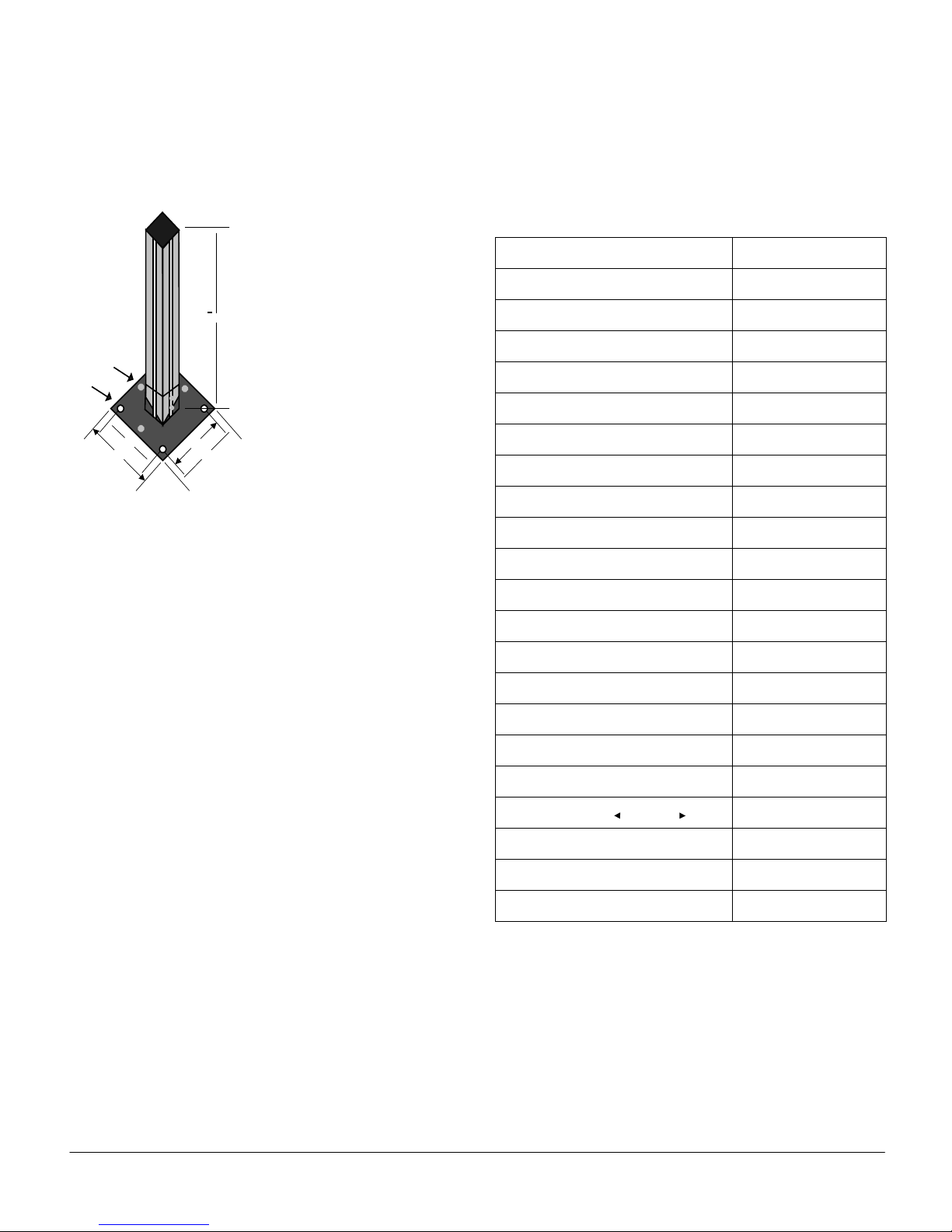

1.3 ORDERING INFORMATION

Part numbers for the various models are shown in the

table on the right. To fully specify a model and its

options use an order code as shown in sections 1.3.1

and 1.3.2 on the following page.

Model Number Part Number

GS-120/8”(208mm)/30 0801

GS-120/12”(308mm)/30 0802

GS-120/16”(408mm)/30 0803

GS-120/24”(608mm)/30 0804

GS-120/32”(808mm)/30 0805

GS-120/36”(908mm)/30 0806

GS-120/40”(1008mm)/30 0807

GS-120/48”(1208mm)/30 0808

GS-120/56”(1408mm)/30 0809

GS-120/64”(1608mm)/30 0810

GS-120/72”(1808mm)/30 0811

GS-120/24”(608mm)/70 0821

GS-120/32”(808mm)/70 0822

GS-120/40”(1008mm)/70 0823

GS-120/48”(1208mm)/70 0824

GS-120/56”(1408mm)/70 0825

GS-120/64”(1608mm)/70 0826

GS-120/72”(1808mm)/70 0827

GS-120-4 0828

GS-120-3 0829

GS-120-2 0830

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard 8Fax: 631-630-0454

Farmingdale, New York 11735 www.tapeswitch.com

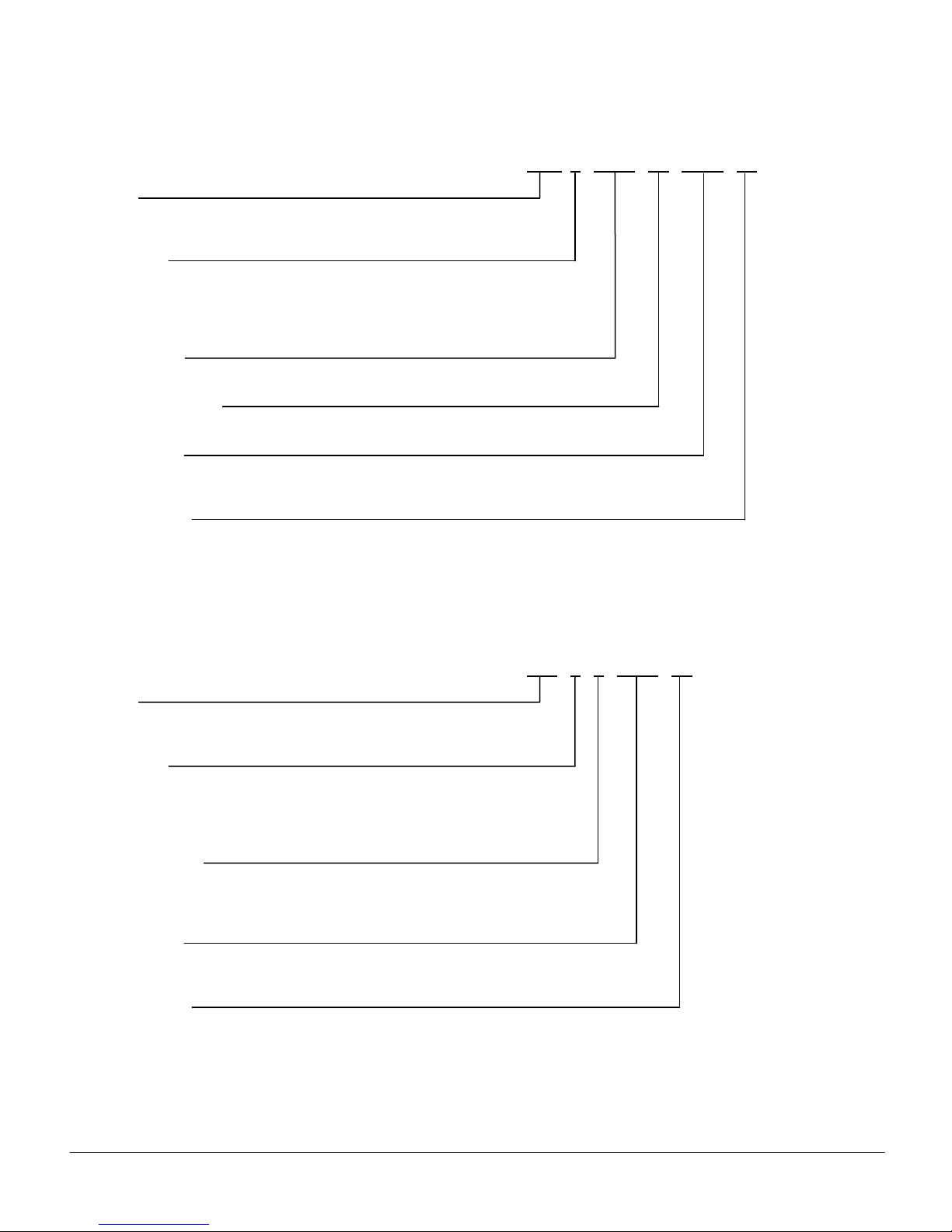

1.3.1 GS-120 LIGHT CURTAIN ORDER CODE

GS120 / XXX / X / XXXX / XX / XXXX / XX

Outputs:

PNP = 2 x PNP outputs

SSR = 2 x Solid-State Relays

Curtain Type:

S = Single Unit

M = Master Unit

A = Slave Unit

D = Double-Ended Slave Unit

Curtain Length:

200 mm to 1800 mm

Detection Capability:

30 mm or 70 mm

Curtain Display:

LED - Discrete LEDs

DIAG - Dot Matrix Diagnostic Display

Bracket options:

CB = Clamp Bracket

AB = Adjustable Bracket

EB = End Cap Bracket

1.3.2 GS-120 MULTI-BEAM ORDER CODE

GS120 / XXX / X / X / XXXX / XX

Outputs:

PNP = 2 x PNP outputs

SSR = 2 x Solid-State Relays

Curtain Type:

S = Single Unit

M = Master Unit

A = Slave Unit

D = Double-Ended Slave Unit

Number of Beams:

2

3

4

Curtain Display:

LED - Discrete LEDs

DIAG - Dot Matrix Diagnostic Display

Bracket options:

CB = Clamp bracket

AB = Adjustable bracket

EB = End cap bracket

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard 9Fax: 631-630-0454

Farmingdale, New York 11735 www.tapeswitch.com

1.3.3 CABLE OPTIONS

Cable assemblies are used to connect the GS-120

emitter and receiver units to a controller or machine.

The emitter has a 5-wire cable and the receiver has an

8-wire cable. One end of each cable has a keyed quick-

disconnect connector and the other end is unterminated.

The cables are IP68 rated, and UL and CSA

recognized.

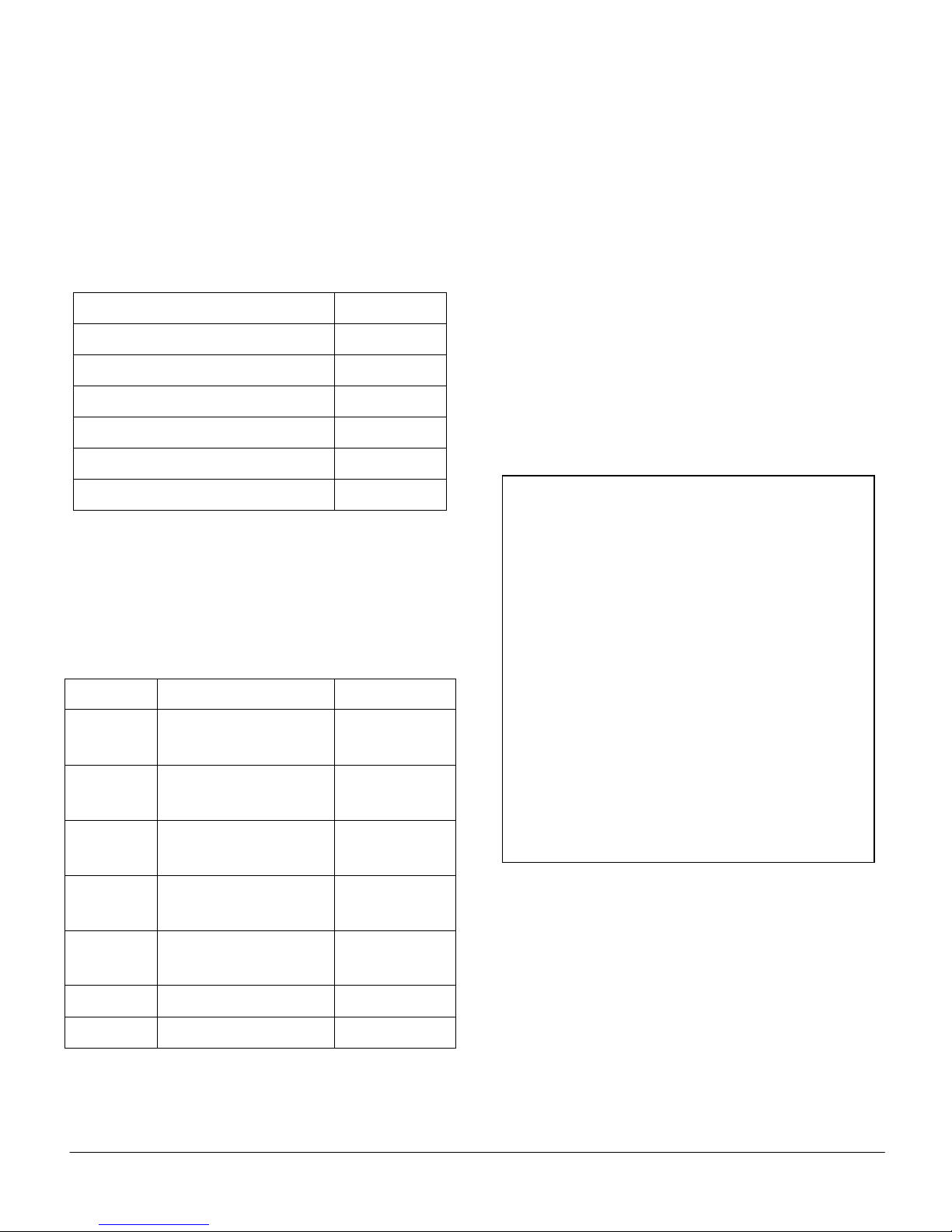

Order cable options using the following part numbers:

Description Part Number

Emitter Cable, 15 ft, 5 Conductor 0972

Emitter Cable, 30 ft, 5 Conductor 0973

Emitter Cable, 98 ft, 5 Conductor 0976

Receiver Cable, 15 ft, 8 Conductor 0974

Receiver Cable, 30 ft, 8 Conductor 0975

Receiver Cable, 98 ft, 8 Conductor 0977

1.3.4 INTERFACE AND PROGRAMMING

UNITS

(See electrical interface and operation for technical

details)

Order interface and programming units using the

following part numbers:

Model Description Part Number

BSRSA Wall-mounted box

110/240 Vac or 24 Vdc 0950

BSRUA-2 DIN rail mount

110/240 Vac or 24 Vdc 0951

SRUB DIN rail mount

24 Vdc 0952

SRUS DIN rail mount

24 Vdc 0949

C6 Wall-mounted box

Multi-zone 0480

GDC1 24 Vdc power supply 0953

LAT Laser alignment tool 0956

2.0 TECHNICAL DESCRIPTION

2.1 CURTAIN

A basic GS-120 light curtain consists of two units: an

emitter unit and a receiver unit. Both units are identical

in shape and size. The units are enclosed in a robust

extruded aluminum section with reinforced composite

end covers.

The emitter and receiver units together generate a

curtain of infra-red light between them. This curtain is

mounted in such a position in relation to the dangerous

parts of a machine that a person or part of a person

approaching those dangerous parts must first penetrate

the curtain. This penetration is detected by the light

curtain system and, by means of its output switching

devices, the light curtain system causes the dangerous

parts to go to a safe state (e.g. by stopping moving

parts) before the person can reach them.

IMPORTANT

From the information above, it can be seen

that safe use of a light curtain relies not only

on the safety integrity of the curtain itself but

also on its proper mechanical and electrical

interfacing to the machine.

The safety integrity of the light curtain itself is

the responsibility of Tapeswitch and the

remainder of this section describes the

features of the design by which safety

integrity is ensured.

Proper mechanical and electrical interfacing

of the overall system is the responsibility of

the user. Comprehensive information for this

purpose is provided in sections 3 and 4 of

this manual.

The emitter unit contains a number of infra-red light

emitting diodes (LEDs). The quantity and spacing of

these LEDs depends on the protected height and the

detection capability of the particular light curtain. The

devices are arranged equally-spaced in an array.

The receiver unit contains a corresponding number of

infra-red photodiodes similarly arranged.

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard 10 Fax: 631-630-0454

Farmingdale, New York 11735 www.tapeswitch.com

Each LED and photodiode is fitted with a precision lens,

which produces an evenly intense, slightly diverging

beam of infra-red light from each LED and an evenly

sensitive, slightly converging ‘reception cone’ into each

photodiode. This arrangement provides a high signal-

to-noise ratio and maximum operating range for the

system together with ease of alignment and rejection of

extraneous reflected light sources.

The function of each LED and photodiode is controlled

by its own dedicated, specially-designed ASIC

(Application Specific Integrated Circuit). All the circuitry

necessary for the operation of an LED or photodiode is

contained within this single component, resulting in a

very low component count and consequent

improvement in system reliability.

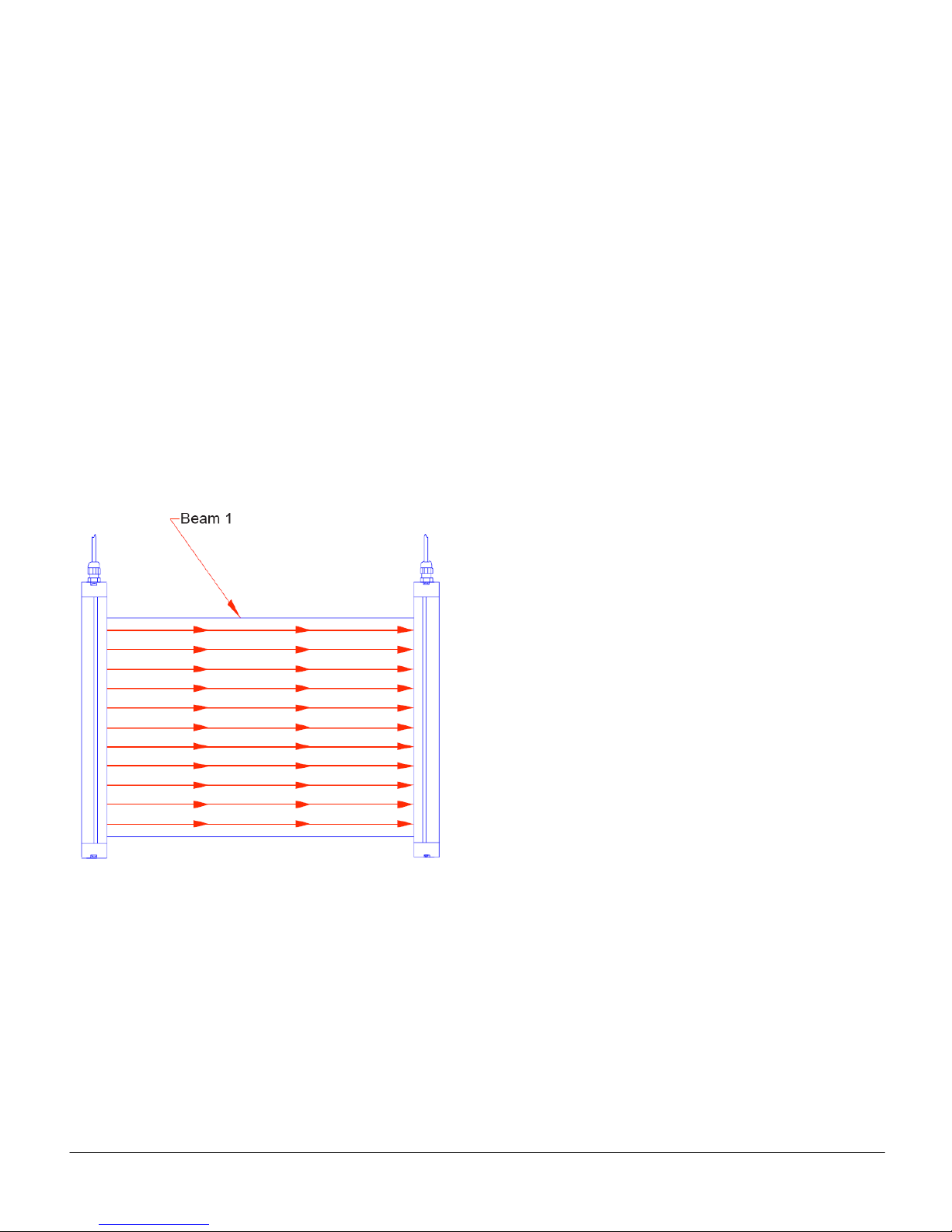

For each LED in the emitter unit there is a

corresponding photodiode at the same relative position

in the receiver unit. Each LED/photodiode pair makes a

‘beam’ and the curtain is made up of a number of such

beams, all parallel to each other. (See Figure 3.)

Figure 3

Only one LED and one photodiode are active at any

time. The emitter unit runs independently from the

receiver unit. There are no connections between the

units.

The emitter unit activates each of its LEDs in turn and

the receiver unit synchronizes with the emitter unit.

Each receiver ASIC, in its turn, generates an output

signal which is proportional to the level of infra-red it

receives from its corresponding LED. Signals from

other sources, such as background lighting, are filtered

out inside the ASIC.

There is one microprocessor in the emitter unit and two

in the receiver unit. All three microprocessors perform

exhaustive checks on their own hardware and software,

prior to and during operation.

The two in the receiver unit continually communicate

their results to each other such that if a fault occurs in

one device the other can shut the system down.

In the receiver unit there are two independent switching

channels each containing an output signal switching

device (OSSD). Each of the two microcontrollers in the

receiver unit controls one of these OSSDs and monitors

the other.

The OSSDs are very robust solid state devices. These

devices are intended to be connected directly to the

machine control system, a Tapeswitch interface unit or

a suitable safety relay such that if one or both of them

are in the OFF state, the machine will go to or remain in

a safe condition, for example, by stopping dangerous

motion or bypreventing dangerousmotionfromstarting.

2.2 COMMUNICATIONS

The receiver unit incorporates a serial communications

port. Various auxiliary Tapeswitch units can be

connected to this port for the purposes of programming

functions within the light curtain and for interrogatingthe

system.

No equipment other than Tapeswitch brand should be

connected to this port. Full instructions for the use of

this port with auxiliaryequipmentareprovided within this

manual.

2.3 TEST INPUT

A pair of terminals is provided across which a pair of

normally closed, volt free contactsshould be connected.

When these contacts are opened the emitter unit will

stop scanning, forcing the OSSDs to the OFF state.

This input simulates a curtain obstructed condition.

NOTE: This input is provided to allow the GS-120 to be

used with machine control systems which need to cycle

thesafety circuit prior tooperation. The GS-120system

itself does not require this input to be used. If this input

is not used it should be jumpered and remain jumpered

at all times.

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard 11 Fax: 631-630-0454

Farmingdale, New York 11735 www.tapeswitch.com

2.4 INDICATORS

2.4.1 LED OPTION

The standard/master receiver unit has four status

indicators as shown in Figure 4. The standard/master

emitter unit has two status indicators as shown in

Figure 5. The slave emitter and receiver have one

status indicator as shown in Figure 6.

A description of each indicator is given in Table 1.

Figure 5

Standard & Master Emitter

Figure 4

Standard & Master Receiver

Figure 6

Slave Emitter & Receiver

Table 1 – LED Indicator Descriptions

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard 12 Fax: 631-630-0454

Farmingdale, New York 11735 www.tapeswitch.com

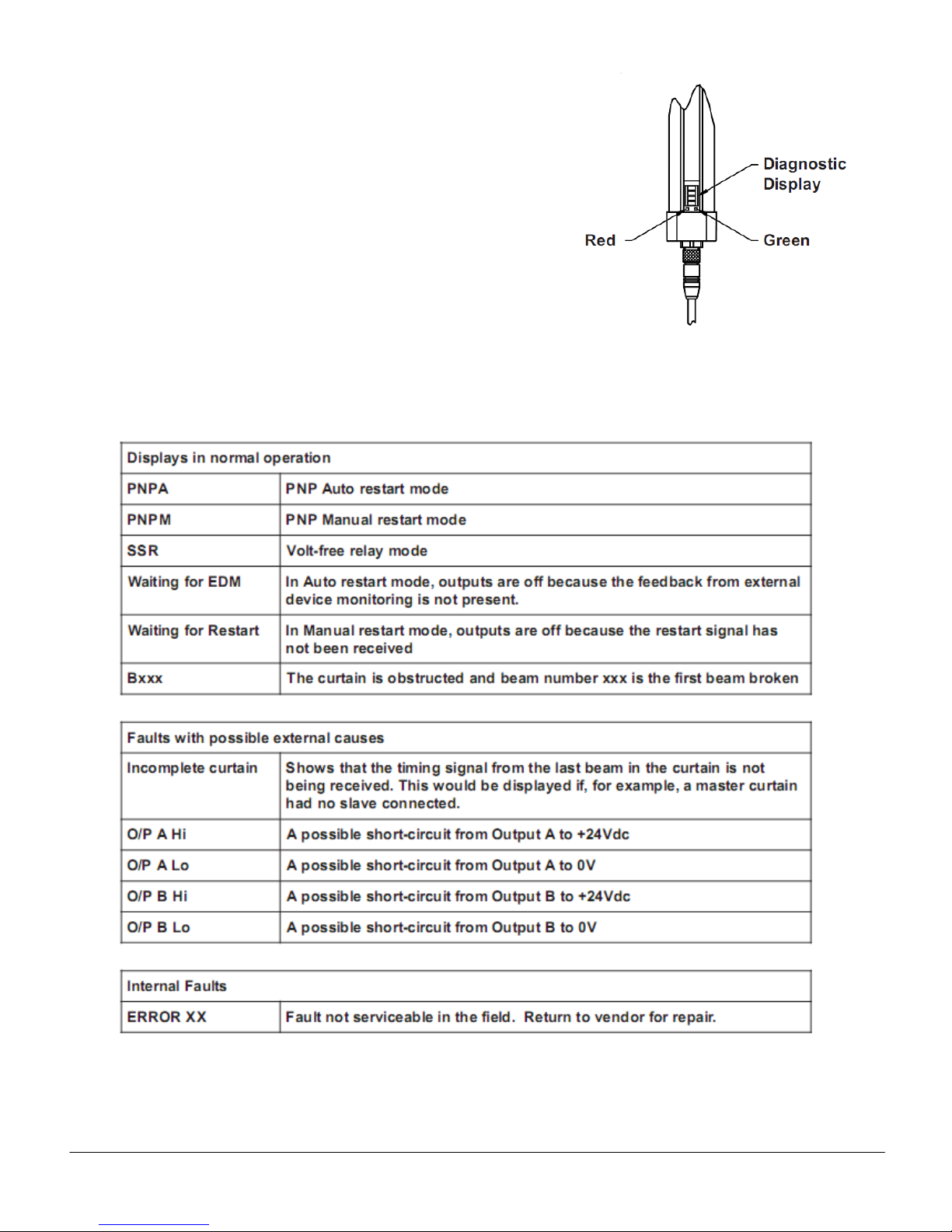

2.4.2 DIAGNOSTIC OPTION

For this option, the LED indicators on the standard and

master emitter units and all slave units are the same as

shown for the LED option above in Figures 4, 5, and 6.

However, the standard and master receiver units

contain a scrolling 4-digit alphanumeric display, shown

in Figure 7, which is used for diagnostic purposes.

The various displays and their meanings are shown in

Table 2.

Figure 7

Diagnostic Receiver

Table 2 – Diagnostic Displays

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard 13 Fax: 631-630-0454

Farmingdale, New York 11735 www.tapeswitch.com

3.0 INSTALLATION

3.1 GENERAL

WARNING

Tapeswitch GS-120 systems are designed to

protect operators working at or near

dangerous machinery. Theycan onlyperform

this function if they are correctly fitted and

interfaced to a suitable machine. Those

persons responsible for the machine must

ensure that all persons involved in the

installation of the photo-electric safety

system have the necessary knowledge,

training and experience and that theyarefully

aware of all laws, rules, regulationsand codes

of practice pertaining to their task.

The attention of the installer is drawn to following

general requirements for the installation of a GS-120

system:

(a) The dangerous motion of the machine must be

electrically controllable.

(b) The machine response/stopping performance must

be adequate and consistent.

(c) It must be possible to stop the dangerous motion of

the machine at any point in its operation, in any

operating mode.

(d) The control system as a whole must be designed

and constructed to provide the appropriate category of

safety integrity as defined in EN954-1 'Safety of

machinery: Principles for the design of safety related

control systems'. The appropriate categoryshouldbeas

prescribed in the relevant C type EN standard for the

type of machine concerned. In the absence of such a

standard the appropriate category of safety integrity

should be determined by performing a risk assessment

as described in EN1050 'Safety of machinery: Risk

assessment

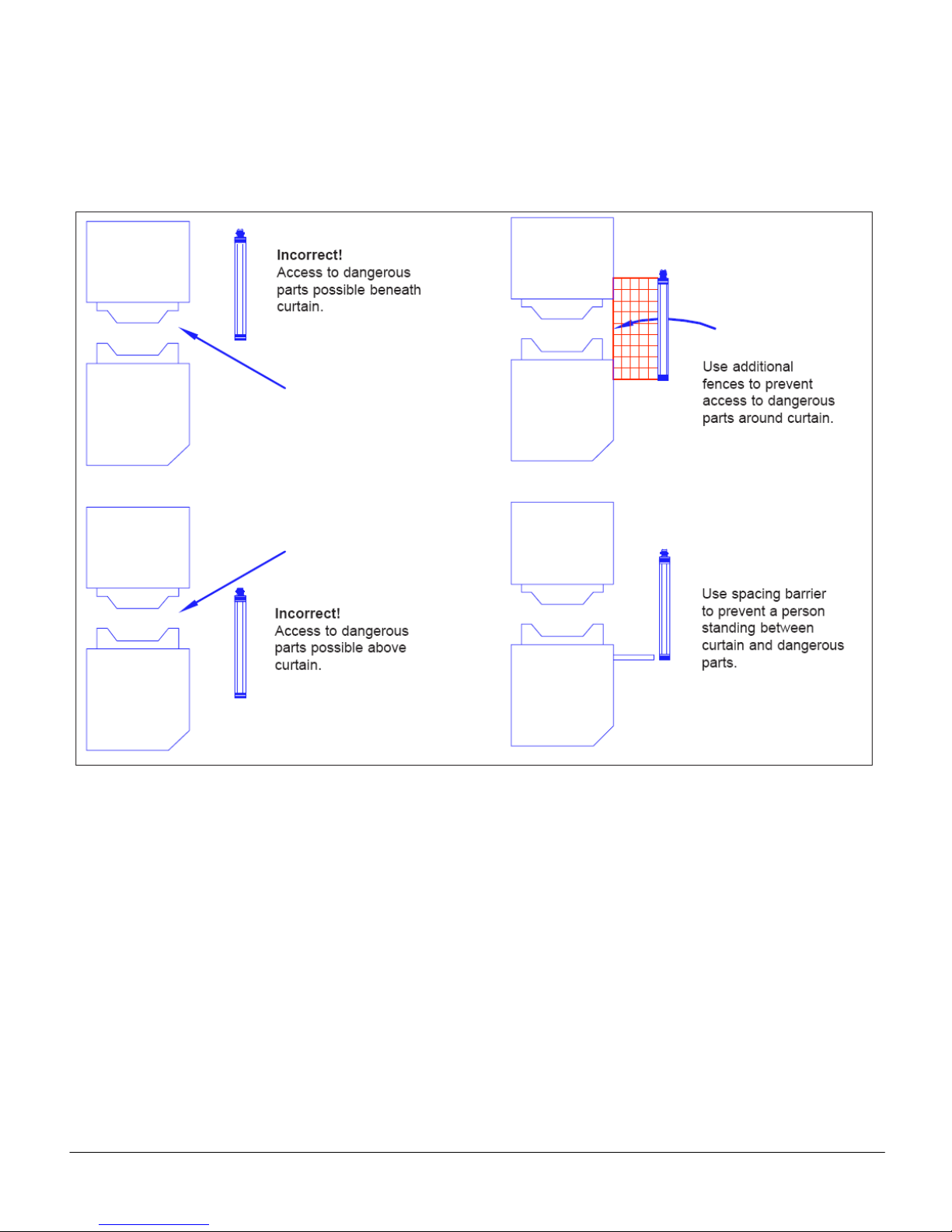

(e) Steps must be taken to prevent access to the

dangerous parts of the machine from any direction not

covered by the photo-electric curtain. Such steps could

include fixed or interlocking fences or screens,

additional photo-electric devices or pressure sensitive

mats. Similar steps should be taken to preventa person

from standing between the curtain and the dangerous

parts of the machine.

(f) No devices other than those specified in this manual

should be connected to the internally-generated power

supply of the system.

(g) After installation, the machine/guardsystem mustbe

commissioned in accordance with the requirements of

section 5.1.1 of this manual.

(h) Any covers removed during installation must be

replaced as soon as possible.

(i) At power on, after a power interruption or after the

curtain has been actuated, it must not be possible for

the machine to start (or restart) until a manual control

has been operated. This is known as “start/restart

interlock”. The GS-120 can provide this function, but if it

is not installed, it must be provided elsewhere within the

safety system

(j) To avoid nuisance tripping, if a fluorescent lamp with

an electronic ballast is located within 5 feet (1.5 meters)

of the receiver unit, it must be outside of a 20º field of

view from the receiver unit (±10º about the center line).

If this is not practical, a 60 Hz fluorescent light fixture

should be used.

3.2 MECHANICAL INSTALLATION

3.2.1 GENERAL CONSIDERATIONS

ANSI B11.19-1990 gives guidance on the dimensions

and positioning of photo-electric safety devices fitted to

industrial machines. The main considerations are

described below and are illustrated in Figure 8.

(a) The appropriate protected height must be selected.

The curtain must be of sufficient height such thataccess

to thedangerous parts, from the directionofapproach of

the operator, is only possible by obstructing the curtain

taking into account all possible operator positions.

(b) The correct minimum separation distance must be

observed. The curtain must be mounted in the correct

position in relation to the dangerous parts of the

machine to take account of the stopping performanceof

the machine, the curtain format used and the detection

capability of the curtain.

(c) Steps must be taken to prevent access to the

dangerous parts from any direction not covered by the

curtain and to prevent an operator from standing

between the curtain and the dangerous parts without

obstructingthe curtain. Additionalmechanical guarding

will usually be necessary to achieve this.

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard 14 Fax: 631-630-0454

Farmingdale, New York 11735 www.tapeswitch.com

The physical parameters affecting the positioning are

the dimensions of the detection zone of the light curtain

(i.e. the protected height and the range) and the

minimum separation distance. These are described in

the following sections.

Figure 8

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard 15 Fax: 631-630-0454

Farmingdale, New York 11735 www.tapeswitch.com

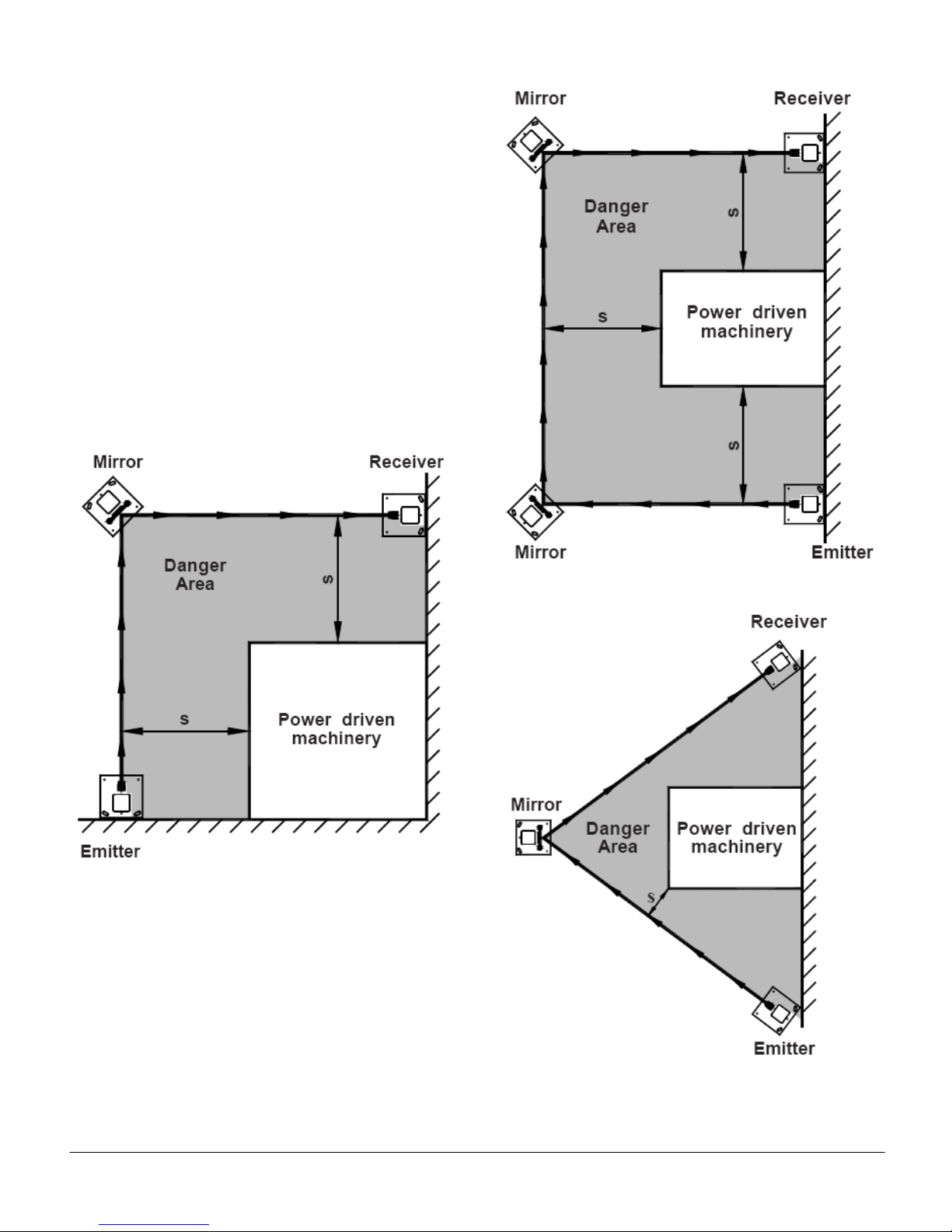

3.2.1.1 Multi-Sided Guarding

By using mirror columns the light curtain beams can be

deflected around corners to form two and three sided

guard configurations. It should be borne in mind that for

each mirror used therange is reduced by approximately

20%. Also the alignment of systems with mirrors can be

difficult especially where the mounting surfaces are

uneven. It is therefore recommended that no more than

two mirrors are used between any pair of emitter and

receiver units. See Figures 9, 10, and 11 for different

multi-sided guarding configurations.

Note: The arrangement shown in Figure 11 is not

recommended, as it is very difficult to determine thatthe

safety distance S is correct.

Figure 9 - Guarding a two-sided area

Figure 10 – Guarding a 3-sided area

Figure 11 – Incorrect use of two-sided guarding

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard 16 Fax: 631-630-0454

Farmingdale, New York 11735 www.tapeswitch.com

3.2.2 CURTAIN DIMENSIONS

3.2.2.1 GS-120 Basic System

The curtain dimensions are defined by the protected

height and the range (i.e. the distance between the

emitter and receiver units). The protected height must

be selected to suit the application. The minimum range

for all systems is 500 millimeters. The maximum range

for systems with 30mm or 70mm detection capability is

15 meters (50 feet).

All the dimensions relating to the curtain, for each of the

GS-120 systems are shown in Figure 12. The upper

and lower boundaries of the curtain are indicated by

arrows on the front window labels of each unit.

Figure 12

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard 17 Fax: 631-630-0454

Farmingdale, New York 11735 www.tapeswitch.com

3.2.2.2 GS-120 Multi-Beam System

All the dimensions relating to the curtain, for

each of the Multi-beam systems (or multi-beam

slave systems) are shown in Figure 13.

Figure 13

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard 18 Fax: 631-630-0454

Farmingdale, New York 11735 www.tapeswitch.com

3.2.2.3 GS-120 Cascaded System

Additional flexibility to facilitate guarding in more than

one plane is provided, by the capability to connect slave

units to a basic or multi-beam master system.

The slave units can be basic or multi-beam systems,

with any of the defined detection characteristics of

30mm or 70mm.

The dimensions relating to the curtains, for each slave

unit are as defined in the previous sections for each

model. The upper and lower boundaries of each curtain

are indicated by arrows on the front window labels of

each unit.

A maximum of two sets of slave units can be connected

to a master system as shown in Figure 14. Each

emitter-receiver pair has a type designation where:

Type GS-120/M is a master

Type GS-120/A is a slave

Type GS-120/D is a slave with a connector at each end

Master and slave units can be assembled up to a

maximum of 240 beams. Where:

30mm detection - 12 beams per 200mm curtain

70mm detection -4 beams per 200mm curtain

Examples:

GS-120/M/1000/30 = 60 beams

GS-120/A/0400/70 = 8 beams

So, total = 68 beams

Notes:

1. When master/slave emitter-receiver sets have

different range capabilities, these must be

respected when systems are configured.

2. When master/slave emitter-receiver sets have

different detection capabilities, the separation

distance must be calculated and adhered to for

each set separately.

Figure 14

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard 19 Fax: 631-630-0454

Farmingdale, New York 11735 www.tapeswitch.com

3.2.3 SEPARATION DISTANCE

Any machine, regardless of the efficiency of its braking

system, will take a certain time to come to rest after a

stop signal is generated.

The time from the instant that the curtain is broken to

the instant that dangerous motion actually ceases is

called the “overall system response time”. The

dangerous parts will obviously continue to move during

this time. The curtain must therefore be positioned at a

certain minimum distance from the dangerous parts to

prevent a person who has obstructed the curtain from

reaching the dangerous parts beforetheyhave stopped.

This distance is the “minimum separation distance” and

is defined as the distance, in the direction of approach,

between the physical point at which the curtain detects

an obstruction and the nearest dangerous parts.

ANSI B11.19-1990 provides guidelines on how to

determine the minimum separation distance for a given

application. Tapeswitch GS-120 systems are primarily

intended for use in normal approach format where the

curtain is perpendicular to the direction of approach,

although they can be used in parallel and angled

approach formats.

3.2.3.1 Normal Approach

Normal approach format is shown in Figure 15. For

normal approach format the inner edge of the front

window of each unit (i.e. the edge which is nearest to

the machine) should be considered to be the point at

which an obstruction is detected. See plane X as

shown in Figure 15.

The effective sensing field of the device shall be located

at a distance from the nearest recognized hazard such

that the operator or others cannot reach the hazard with

a hand or other body part before stopping of the motion

during the hazardous portion of the machine cycle.

Figure 15

Release 7/2009 Ver. 1.0 Technical Manual: GS-120 Light Curtain Systems

TAPESWITCH CORPORATION Phone: 631-630-0442

100 Schmitt Boulevard 20 Fax: 631-630-0454

Farmingdale, New York 11735 www.tapeswitch.com

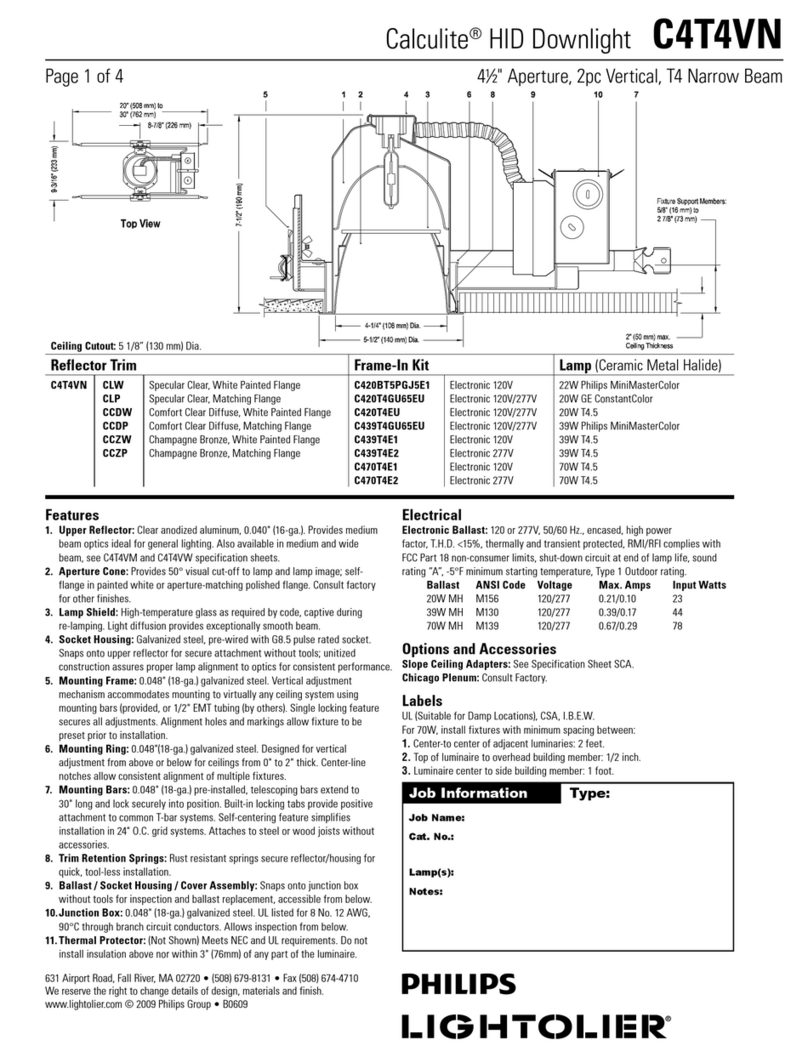

2.5

2.0

1.5

1.0

0.5

0.0

0.0 8.07.06.05.04.03.02.01.0

Blanked Dimensions or Minimum

Object Sensitivity in Inches

Penetration Factor D(pf) in Inches

DPF

1 inches

3.1 inches

8 inches

Detection

14mm

30mm

70mm

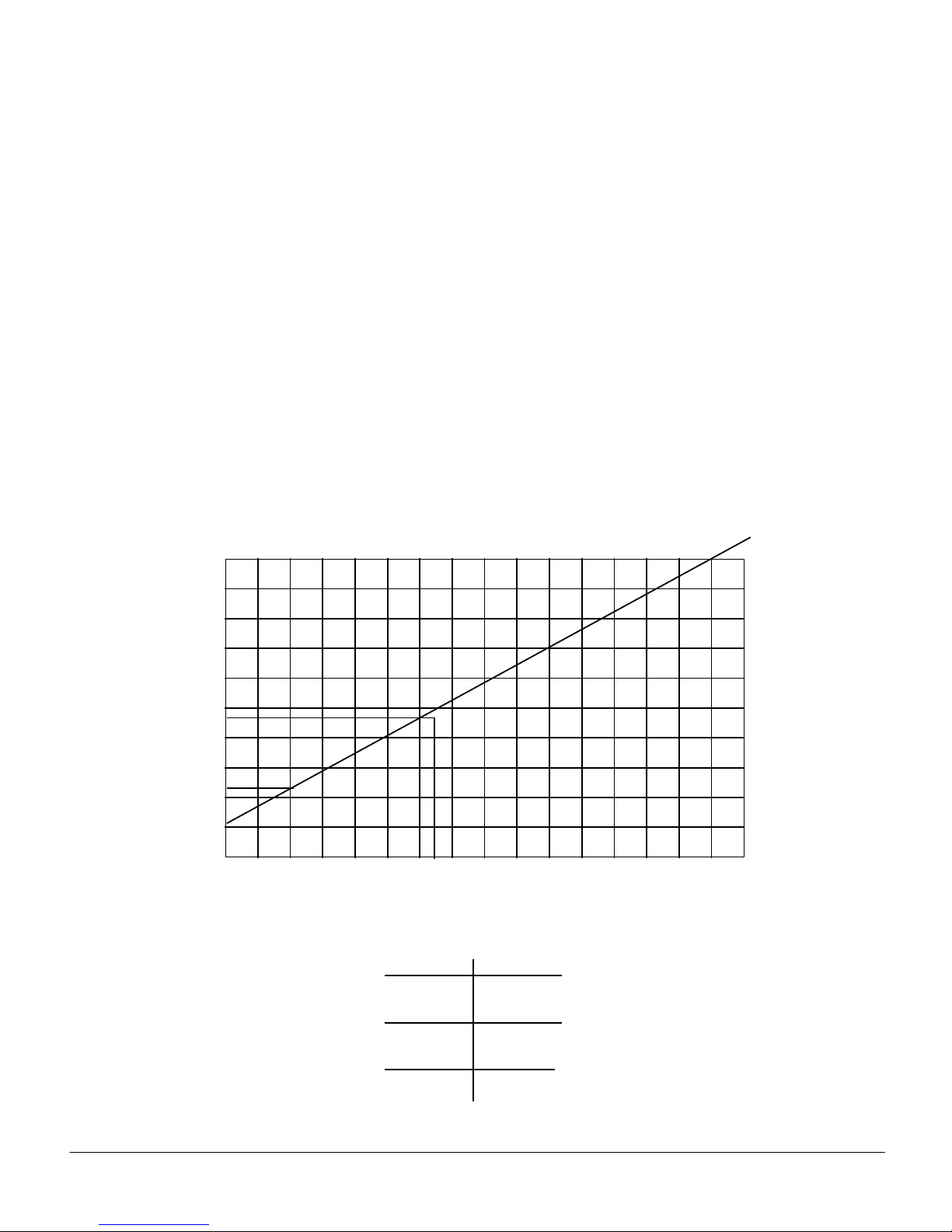

The minimum separation distance depends on the

application. Thefollowing formula shouldbeusedwhen

calculating this distance:

DS= K x (TS+ TR+ TC+ TBM) + DPF

where:

DS= Minimum separation distance between the

device and the nearest point of operation

hazard in inches.

K = Hand speed constant.

See note.

TS= Stop time of the machine tool measured at

the final control element.

TC= Response time of the control system.

NOTE: TSand TC are usually measured by

a stop-time measurement device.

TR= Response time of the presence-sensing device

and its interface, if any, as stated by the

manufacturer or as actually measured.

TBM = Additional time allowed for the brake monitor (if

used) to compensate for variations in normal

stopping time.

DPF = Added distance due to the penetration factor,

as recommended in the illustration below. The

minimum object sensitivity is stated by the

manufacturer. If beam blanking or floating

window features are used, these figures should

be added to the object sensitivity figure before

using the chart.

NOTE: The value of the hand speed constant, K, has

been determined by various studies.

Although these studies indicate speeds of 63

in/sec to over 100 in/sec, they are not

conclusive determinations. The employer

should consider all factors, including the

physical ability of the operator, when

determining the value of K to be used.

Table of contents

Other Tapeswitch Lighting Equipment manuals