Tapeswitch PRSU/M2SI User manual

1

10/2015 EN

ENGLISH

PRSU/M2SI

Multifunctional Downstream Device

0266691

Before installing, operating or maintaining the device, read and

understand this manual.

DANGER

ATTENTION

Dangerous tension.

Danger to life or serious injury.

Disconnect the system and device from the power before

starting work.

A secure device function is only guaranteed with certified

components!

Hints

The products described here are designed to perform safety-related

functions as part of an overall plant or machine. A complete safety-

related system usually contains sensors, evaluation units, signaling

devices and concepts for safe shutdowns. It is the responsibility of the

manufacturer of a system or machine to ensure the correct overall

function. Tapeswitch is unable to guarantee all the features of a

complete system or machine that was not designed by Tapeswitch. The

overall concept of the controller in which the device is integrated must be

validated by the user. Tapeswitch also assumes no liability for

recommendations that are given or implied by the following description.

Due to the following description, no new warranty, warranty or liability

claims beyond the general tapeswitch delivery conditions can be derived.

Safety Regulations

-

-

The device may only be installed and commissioned by

knowledgeable persons who are familiar with this operating manual

and with the applicable regulations on occupational safety and

accident prevention.

Observe the VDE and local regulations, especially with regard to

protective measures.

- Opening the case or unauthorized modifications will invalidate any

warranty.

- Mount the device in a control cabinet with degree of protection IP 54 or

better; Dust and moisture can otherwise lead to impairments of the

functions.

- Provide sufficient protective wiring at all output contacts for capacitive

and inductive loads.

- The safety function must be triggered during commissioning.

If used as directed and in accordance with this manual, no residual risks

are known. Failure to do so may result in personal injury and property

damage.

The PRSU / M2SI is used for the safety-related release and interruption of

a safety circuit. It can be used to protect people and machinery in

applications with emergency stop pushbuttons, safety gates, self-test (type

4) photocells in accordance with IEC / EN 61 496-1, two-hand switches for

metalworking presses, and other working machines with dangerous

closing movements (Type III C according to EN 574) and for safety-related

safety mats, safety edges and band switches.

Intended Use

Device Properties

Your advantages

•two independent safety functions adjustable

out:

-Safety mat / strip, band switch

-photocell

-Emergency stop switch

-Safety gate

-two-hand control

-Antivalent switch

•only one device type, two safety functions at the same time

•manual or automatic start

Characteristics

•complies

- Performance Level (PL) e and Category 4 according to EN ISO

13849-1: 2008

- SIL claim limit (SIL CL) 3 according to IEC / EN 62061

- Safety Integrity Level (SIL) 3 according to IEC / EN 61508 and IEC /

EN 61511

•according to EN 50156-1 for combustion plants

•Line fault detection on the ON button

•Activation via on-button or automatic on-function

•with or without cross-circuit detection

•2-channel design

•positively driven output contacts

•Output: 2 NO contacts per safety function

•1 semiconductor output per safety function

•LED indicators operating voltage, safety function 1, 2 and error

•Device connections: pluggable terminal blocks with screw terminals

Safety Instructions

ATTENTION - AUTOMATIC START!

According to IEC / EN 60 204-1 point 9.2.5.4.2, no automatic start must

be made after stopping in an emergency. Therefore, in the modes with

automatic start, a higher-level control must prevent an automatic start

after an emergency stop.

Terminals

Terminal Designation Signalbeschreibung

A1 + DC24V

A2 0V

13, 14, 23, 24,

43, 44, 53, 54

Normally open for release

circuit

38, 68 Semiconductor monitoring output

GND Reference potential for

semiconductor signal outputs

S11, S21, S31, S41 control outputs

S12, S22, S32, S42,

ST1, ST2, RES

control outputs

ORIGINAL

All information in this manual corresponds to the technical state at the time of issue. We reserve

the right to make technical improvements and changes at any time.

Operating Manual

E-mail: [email protected] • Web: www.tapeswitch.com Phone: 631-630-0442 • Toll Free: 800-234-8273

2

10/2015 EN

Operating instructions ENGLISH

Before installing, operating or maintaining this device, these instructions

must be carefully read and understood.

DANGER

CAUTION

Dangerous voltage.

Electric shock will result in death or serious injury.

Disconnect all power supplies before servicing equipment.

Safe operation of the device is only guaranteed when using certified

components!

Important Notes

The product hereby described was developed to perform safety functions

as a part of a whole installation or machine. A complete safety system

normally includes sensors, evaluation units, signals and logical modules

for safe disconnections. The manufacturer of the installation or machine is

responsible for ensuring proper functioning of the whole system.Tapeswitch

cannot guarantee all the specifications of an installation or machine that

was not designed by Tapeswitch. The total concept of the control system

into which the device is integrated must be validated by the user.Tapeswitch

also takes over no liability for recommendations which are given or implied

inthe followingdescription.The followingdescription impliesno modification

of the general Tapeswitch terms of delivery, warranty or liability claims.

Safety Regulations

- This device must be installed and operated by trained staff who are

familiar with these instructions and with the current regulations for safety

at work and accident prevention.

- Pay attention to applicable local regulations, especially regarding safety

measures.

- Opening the device or implementing unauthorized changes voids any

warranty

- The unit should be panel mounted in an enclosure rated at IP 54 or

superior. Dust and dampness may lead to malfunction.

- Adequate fuse protection must be provided on all output contacts with

capacitive and inductive loads.

- The safety function must be triggered during commissioning

When used in accordance with its intended purpose and following these

operating instructions, this device presents no known residual risks. Non-

observance may lead to personal injuries and damages to property.

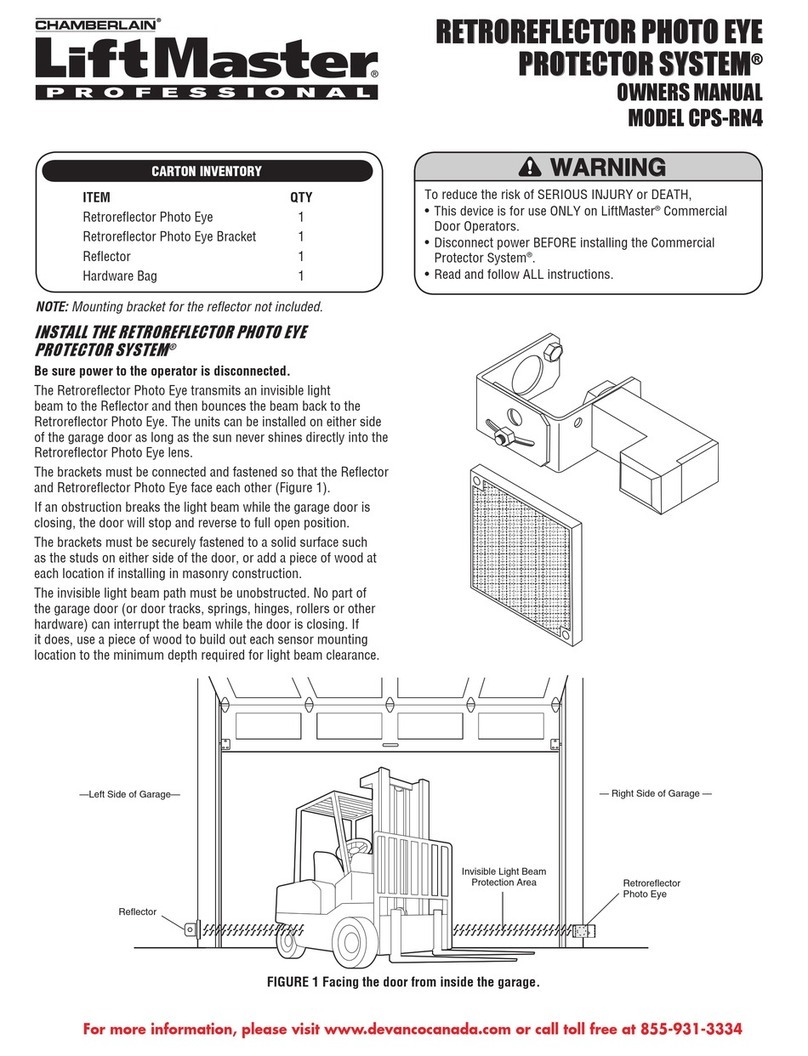

The PRSU/M2SI is used to enable and interrupt a safety circuit in a safe

way. It can be used to protect people and machines in applications with

e-stop buttons, safety gates, light curtains with selftesting (Type 4) acc. to

IEC/EN 61 496-1, 2-hand controls for presses as well as other production

machinery with dangerous closing action (Type III C to EN 574) and for

safety mats, safety edges and tape switches.

Designated Use

Main Features

Your Advantage

•2 independent, separately adjustable safety functions:

- Safety mat / Safety edge / Tapeswitch

- Light curtain

- E-Stop

- Safety gate

- Two-hand control

- Exclusive or contacts

•Only one device, two safety functions at the same time

•Manual or auto start

Features

•According to

-Performance Level (PL) e and category 4 to EN ISO 13849-1: 2008

- SIL Claimed Level (SIL CL) 3 to IEC/EN 62061

- Safety Integrity Level (SIL) 3 to IEC/EN 61508 and IEC/EN 61511

•Acc. to EN 50156-1 for furnaces

•Line fault detection on On-button:

•Manual restart or automatic restart

•With or without cross fault monitoring

•2-channel

•Forcibly guided output contacts

•Output: 2 NO contacts per safety function

•1 semiconductor output per safety function

•LED indicator for operation, safety function 1, 2 and failure

•Removable terminal strips: plug in screw terminals

Safety Notes

ATTENTION - AUTOMATIC START!

According to IEC/EN 60 204-1 part 9.2.5.4.2 and 10.8.3 it

is not allowed

to restart automatically after emergency stop. Therefore the machine

control has to disable the automatic start after emergency stop.

Connection Terminals

0266691

Terminal designation Signal designation

A1 + DC 24 V

A2 0 V

13, 14, 23, 24,

43, 44, 53, 54

Forcibly guided NO contacts for

release circuit

38, 68 Semiconductor monitoring output

GND Reference potential for

Semiconductor monitoring output

S11, S21, S31, S41 control output

S12, S22, S32, S42,

ST1, ST2, RES

control input

PRSU/M2SI

Multifunctional Control Unit

ORIGINAL

All technical data in this manual relate to the state at the moment of edition. We reserve the right

for technical improvements and changes at any time.

3

10/2015 EN

Practical Notes

Operation mode

With the potentiometer on the front plate the operartion mode can be

adjustet. The adjustment must be required before energizied. Adjustment

during energization is not allowed.

Only an automatic start at safety function two-hand control (3) is possible.

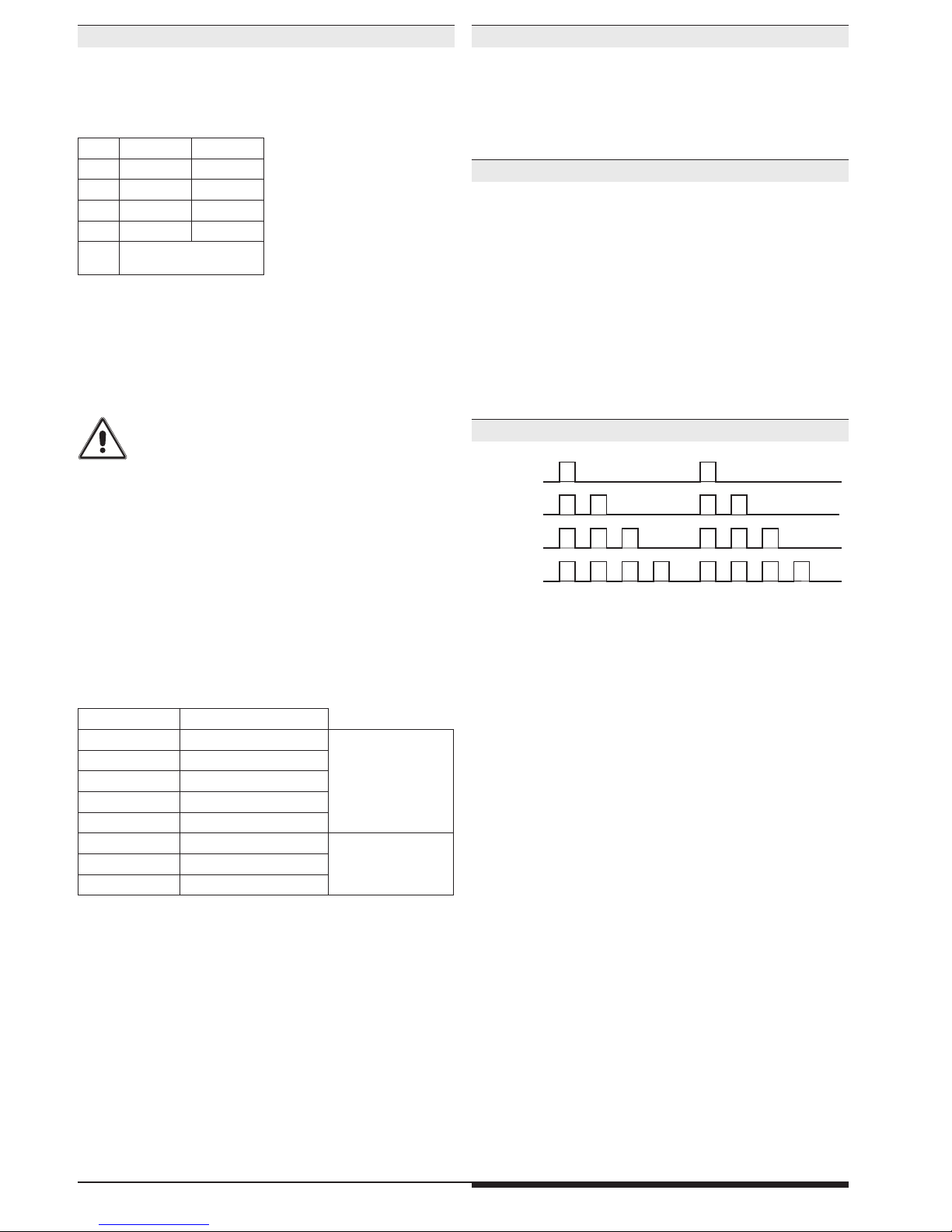

Start Fkt. 1 Fkt. 2

1 MANUAL MANUAL

2 MANUAL AUTO

3AUTO HAND

4AUTO AUTO

5MANUAL with common

button

Line fault detection e.g. monitoring of ON-button

If the On-button pressed more than 3 s the adequate output contacts of the

safety function can't be switch. The output contacts can be energized when

the On-button pressed again (0.1 s < tON < 3 s).

A line fault is detected if the On-button more than 10 s is actuated. The

output contacts of the adeauate safety function can only be energized with

a reset or re-start with on an off switching of power supply.

ATTENTION - AUTOMATIC START!

According to IEC/EN 60 204-1 part 9.2.5.4.2 and 10.8.3 it

is

not allowed to restart automatically after emergency stop.

Therefore the machine control has to disable the automatic

start after emergency stop.

Reset and external failures:

The reset input is used to reset external failures (application failures or

removable external failures as e.g. a line fault on reset button). If the reset

signal is connected to the input for more than 3 sec the unit unit makes a

reset.A new reset is only possible when the reset signal had been switched

off temporarily.

If an external failure occurs because both input channels of a safety function

did not switch on or off within the simultanious time, a reset is only possible

if both channels are switched to off state after removing failure cause.

If an external failure occurs in only one safety function, only this function

will be disconnected. The second safety function still continuous to work.

Function setting

The variants with selectable safety functions have 2 potentiometers Fkt.1

and Fkt.2 to select the required function.The following functions are possible:

Fct. 1 / Fct. 2 Safety function

1 E-Stop

cross fault detection

2 Safety gate

3 Two-hand control

4 Safety mat / Safety edge

5 Exclusive or contacts

6 E-Stop

without

cross fault detection

7 Safety gate

8 Light curtain

Indicators

green LED ON: on, when supply connected

red LED ERR: on, at internal error

flashes at external error

green LED K1/K2: on, when relay K1 and K2 energized

(safety function 1)

flashes at external errors of

safety function 1

green LED K3/K4: on, when relay K3 and K4 energized

(safety function 2)

flashes at external errors of

safety function 2

Operating Potentiometer

Poti "Start" Adjustment of operating mode

Manual- or auto start for Fkt.1 and Fkt. 2.

Poti "Fkt.1" Adjustment of safety function 1

Poti "Fkt.2" Adjustment of safety function 2

Fault Indication by Flashing Code

simultaneity

error

Potentiometer or

adjustment failure

line fault across

start button

Cross fault or

wiring fault

M10697_a

4

10/2015 EN

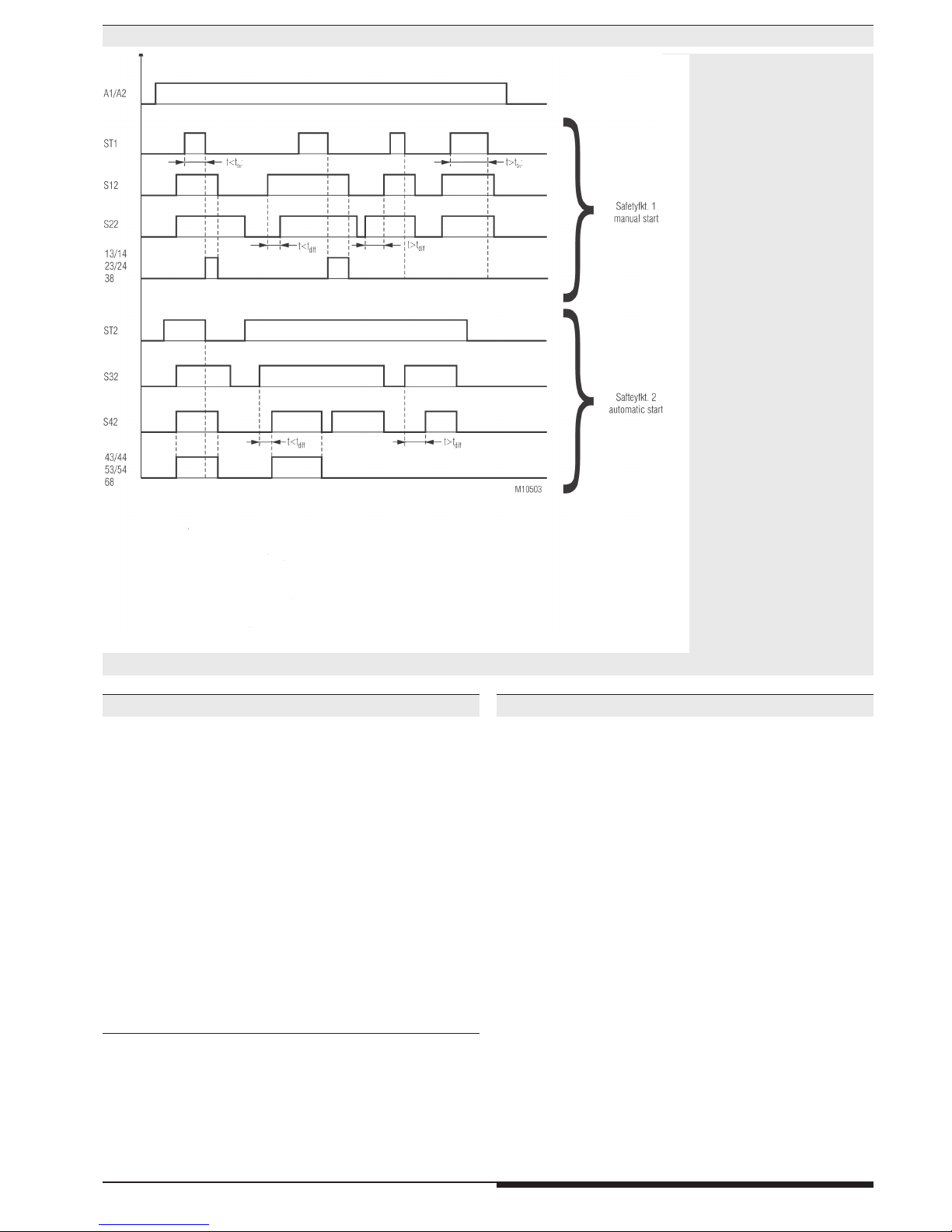

Function diagram

Technical Data Technical Data

Input

Nominal voltage UN: DC 24 V

Voltage range: 0.8 ... 1.1 UN

Nominal consumption: typ. 3.2 W

Short-circuit protection: Internal PTC

Overvoltage protection: Internal VDR

Duty-cycle ON button: 0.1 s < tEIN < 3 s

Duty-cycle Reset button: > 3 s

Safety function

Safety mat / safety edge / Tapeswitch (4)

max. permitted

safety edge contact resistance: 1000 Ω

switching current at short circuit: typ. 15 mA at UN

Light curtains (8)

control current via S12, S22

e.g. S32, S42: typ. 8 mA at UN

Min. voltage on terminals

S12, S22 e.g. S32, S42

when relay activated: DC 10 V

Output

Contacts 2 NO contacts per safety function

The NO contacts can be used for safe braking.

Thermal current Strom Ith: max. 8 A

Safety function

E-Stop (1) (6), Safety gate (2) (7),

Exclusive or contacts (5)

Start up at UN: < 65 ms

Release delay at UN and

disconnecting the supply: < 40 ms

Release delay at UN and

disconnecting S12,S22 or

S32, S42: < 60 ms

Two-hand control (3)

Start up at UN: < 110 ms

Release delay at UN and

disconnecting the supply: < 40 ms

Release delay at UN and

disconnecting S12,S22 or

S32, S42: < 60 ms

simultaneity demand: max. 0,5 s

Safety mat (4) / Safety Edge / Tapeswitch

Start up at UN: < 85 ms

Release delay at UN and

disconnecting the supply: < 40 ms

Release delay at UN and

disconnecting S12,S22 or

S32, S42: < 60 ms

Light curtains (8)

Start up at UN: < 35 ms

Release delay at UN and

disconnecting the supply: < 40 ms

Release delay at UN and

disconnecting S12,S22 or

S32, S42: < 25 ms

tdiff: max. time delay for simultaneity demand

dependent on selected safety function

Safety mat, Sensing Edge,Tapeswitch, E-Stop, Safety Gatetdiff= max. 3s

Light curtain tdiff= max. 1s

Two-hand control tdiff= max. 0,5s

other times on request

tOn: max. actuation time of start button

Standard tOn: max. 3s

other times on request

5

10/2015 EN

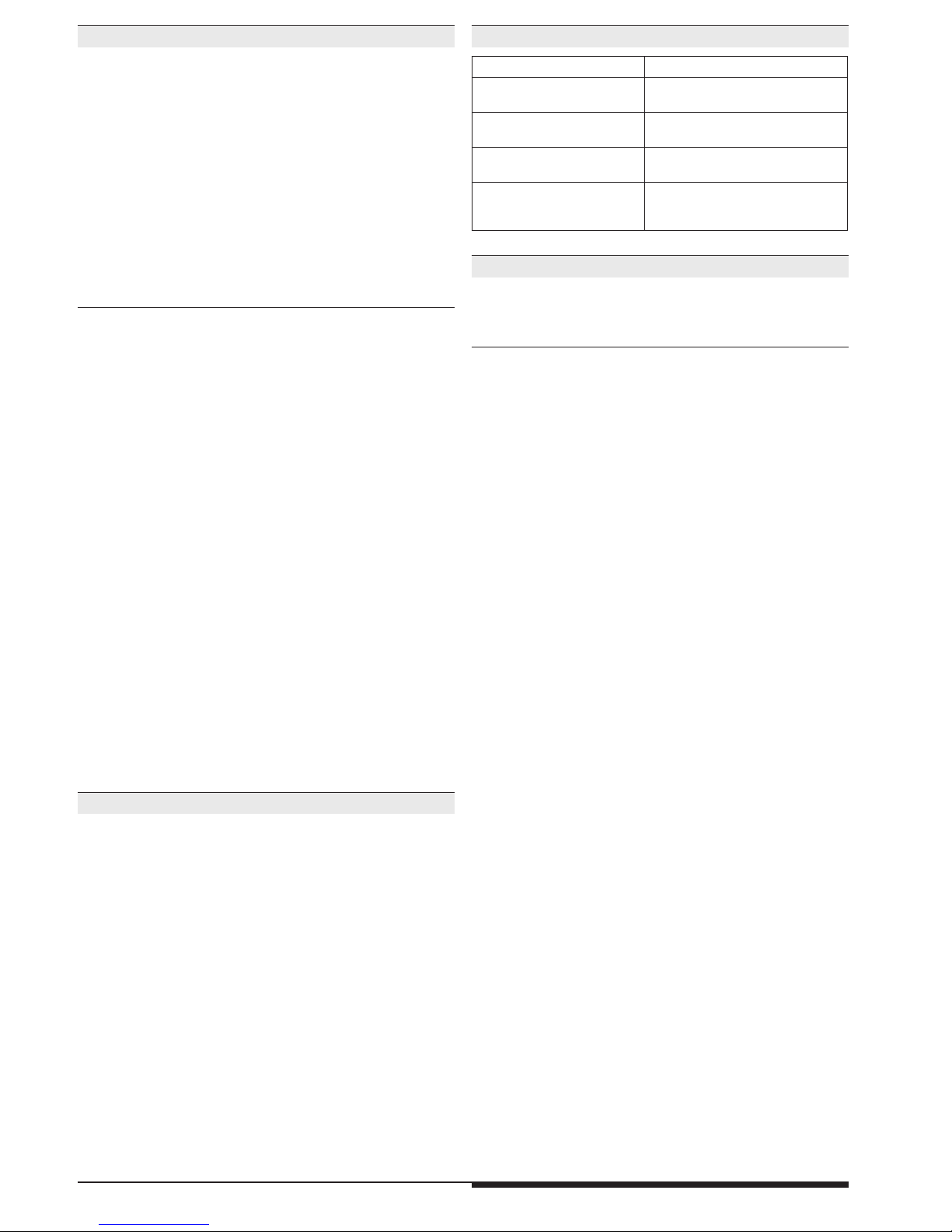

Troubleshooting

Failure Potential cause

LED "ON" does not light up - Power supply A1+/A2

not connected

LED "ERR" flashes

in relation 1:1

- Under- or overvoltage

(check power supply A1+/A2)

LED "ERR" flashes

in relation 4:1

- external failure (see flashing code)

LED "ERR"

continuously on

- system error

(if cannot be removed after restart

unit must be replaced)

Maintenance and Repairs

- The device contains no parts that require maintenance.

- In case of failure, do not open the device but send it to manufacturer

for repair.

Technical Data

Switching capacity

to AC 15

NO contacts: 3 A / AC 230 V IEC/EN 60 947-5-1

to DC 13

NO contacts: 2 A / DC 24 V IEC/EN 60 947-5-1

Electrical life

at 5 A, AC 230 V cos j= 1: > 1.5 x 105switching cycles

Permissible operating frequency

1. safety function: max. 1800 switching cycles / h

2. safety function: max. 360 switching cycles / h

Short circuit strength

max. fuse rating: 6 A gL IEC/EN 60 947-5-1

Mechanical life: 10 x 106switching cycles

Semiconductor monitoring output

(not safety): 1 per safety function

max. 50 mA DC 24 V, plus switching

General Data

Nominal operating mode: continuous operation

Temperature range

Operation: - 15 ... + 55 °C

Storage: - 25 ... + 85 °C

Altitude: < 2.000 m

Clearance and creepage distance

rated impuls voltage /

pollution degree: 4 kV / 2 IEC 60 664-1

EMC

Electrostatic discharge (ESD): 8 kV (air) IEC/EN 61 000-4-2

HF irradiation: 10 V / m IEC/EN 61 000-4-3

Fast transients: 2 kV IEC/EN 61 000-4-4

Surge voltage

between

wires for power supply: 1 kV IEC/EN 61 000-4-5

between wire and ground: 2 kV IEC/EN 61 000-4-5

HF-wire guided: 10 V EN 61 000-4-6

Interference suppression: Limit value class B EN 55 011

Degree of protection

Housing: IP 40 IEC/EN 60 529

Terminals: IP 20 IEC/EN 60 529

Housing: thermoplastic with VO behaviour

according to UL subj. 94

Vibration resistance: Amplitude 0,35 mm

Frequency 10 ... 55 Hz,IEC/EN 60 068-2-6

Klimate resistance: 15 / 055 / 04 IEC/EN 60 068-1

Terminal designation: EN 50 005

Wire connection: DIN 46 228-1/-2/-3/-4

Wire fixing: captive slotted screw

Mounting: DIN rail IEC/EN 60 715

Weight: approx. 275 g

UL-Data

The safety functions were not evaluated by UL. Listing is accom-

plished according to requirements of Standard UL 508, “general use

applications”

Switching capacity:

Ambient temperature 55°C Pilot duty B300, Q300

5A 250Vac Resistive or G.P.

5A 24Vdc Resistive

Ambient temperature 40°C: Pilot duty B300, Q300

8A 250Vac Resistive or G.P.

8A 24Vdc G.P.

Wire connection:: 60°C / 75°C copper conductors only

Terminal: AWG 28 - 12 Sol/Str Torque 0.5 Nm

6

10/2015 EN

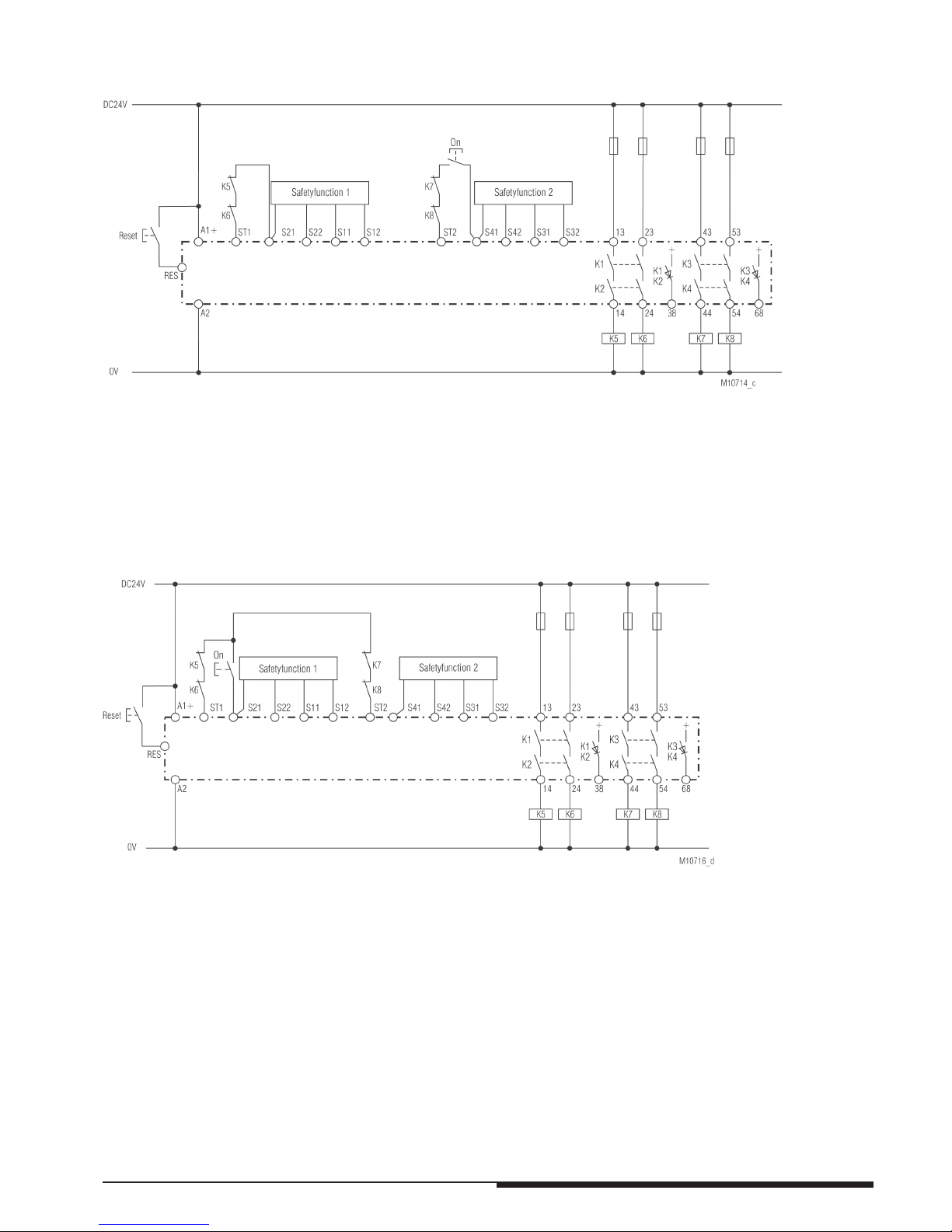

Operating mode: 3 (Fkt1=AUTO ; Fkt2=MANUAL)

Safety function 1: see page 7, Auto-Start

Safety function 2: see page 7, Manual-Start

Operating mode: 5 (MANUAL with common button)

Safety function 1: see page 7, Manual-start with common button

Safety function 2: see page 7, Manual-start with common button

Application examples with safety function

PRSU/M2SI

PRSU/M2SI

7

10/2015 EN

Application examples with safety function 1

Application examples with safety function 2

The safety function 2 is connected as well as safety function 1, but S11 S31, S12 S32, S21 S41 and S22

S42.

S22 S11 S12

M10757

Not-

Aus

S21 S21 S22 S11 S12

Schiebeschutztür

geschlossen

M10756

S1 S2

S22S21 S11 S12

M10750

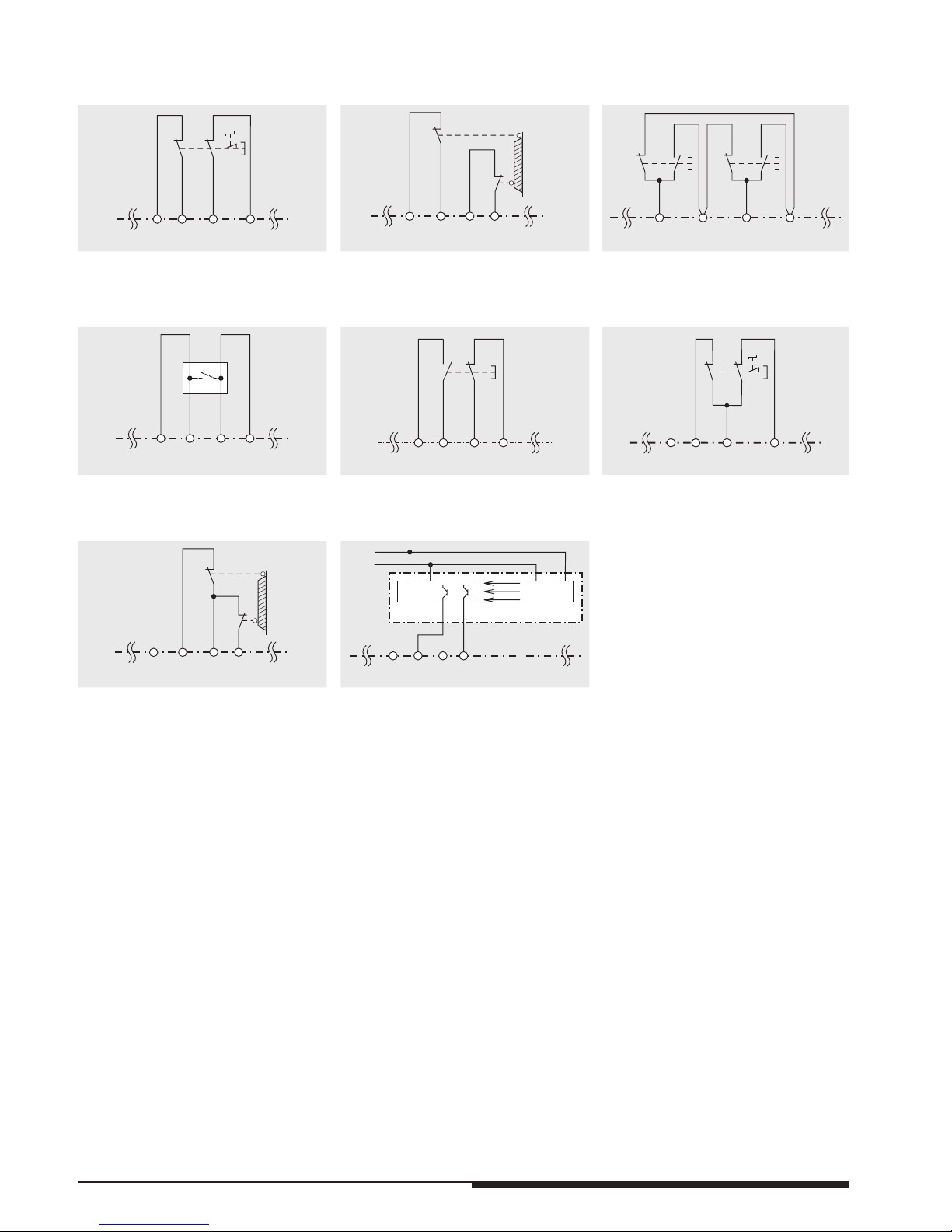

Fct.: E-stop (1),

with cross fault detection

SIL 3, PL e, Cat. 4

Fct.: Safety gate (2),

with cross fault detection

SIL 3, PL e, Cat. 4

Fct.: Two-hand control (3),

with cross fault detection

SIL 3, PL e, Cat. 4

Type III C to EN 574

S21 S22 S11 S12

Schaltleiste

M10754

S22 S11 S12S12

S1

M11124

S21 S22 S11 S12

M10753

Not-

Aus

S21

Fct.: Safety mat / Safety edge / Tape-

switch (4), with cross fault detection

SIL 3, PL e, Cat. 4

Fct.: Exclusive or contacts (5),

with cross fault detection

SIL 3, PL e, Cat. 4

Fct.: E-Stop (6),

without cross fault detection

SIL 3, PL e, Cat. 4 1)

S21 S22 S11 S12

Schiebeschutztür

geschlossen

M10752

OSSD1 OSSD2

S22

S21 S11 S12

Sender

Empfänger

DC

24V

0V

M10751

Fct.: Safety gate (7),

without cross fault detection

SIL 3, PL e, Cat. 4 1)

Fct.: Light curtain (8),

without cross fault detection

SIL 3, PL e, Cat. 4 2)

1) To achieve the stated safety classification the wiring has to be done with crossfault monitoring.

2) To achieve the stated safety classification light curtains with selftest (type 4) according to IEC/EN 61496-1 have to be used.

8

10/2015 EN

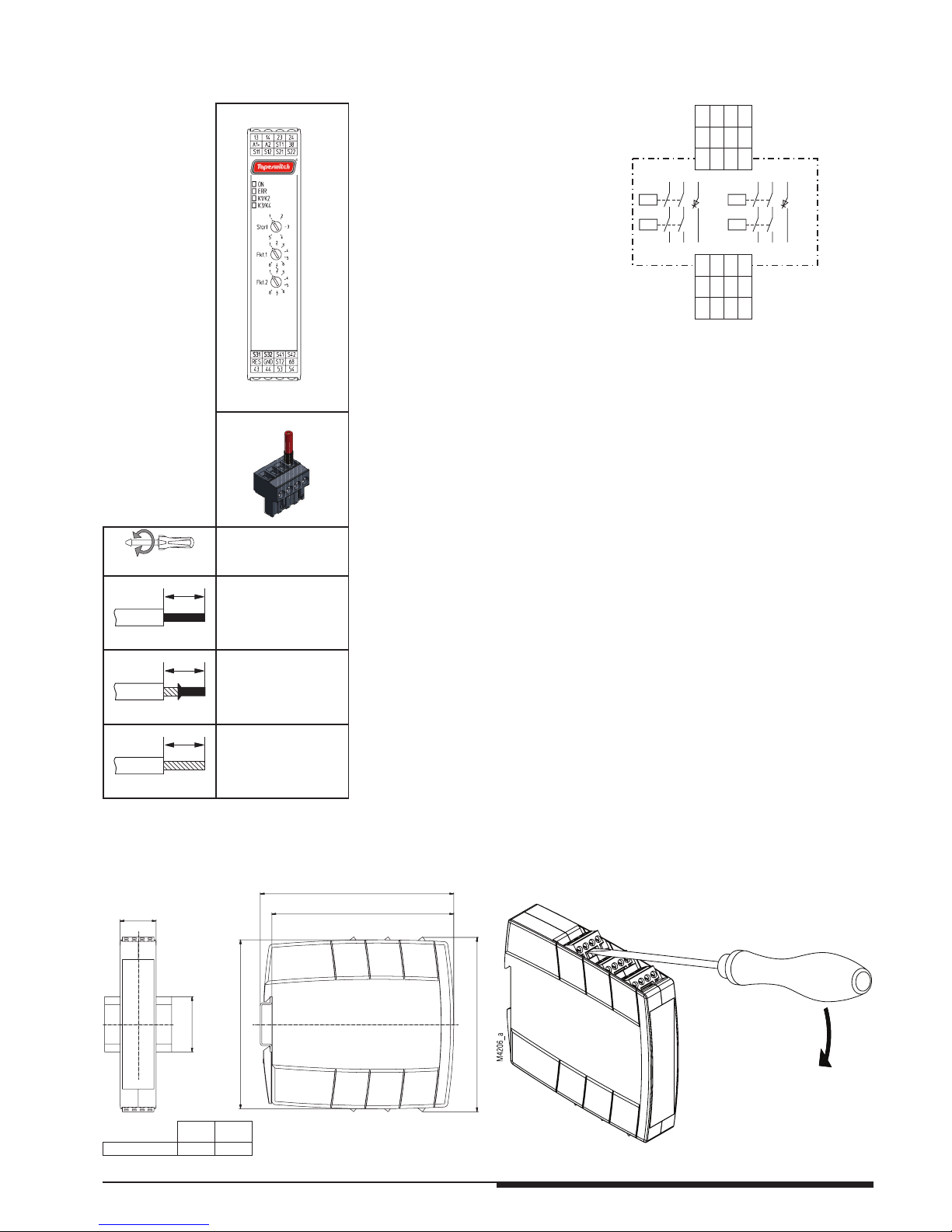

Circuit diagram

S12

A2

14

44

GND

S32

S11

A1+

13

43

RES

S31

S21

ST1

23

53

ST2

S41

S22

38

24

54

68

S42

M10501_a

13 43

K1 K3

K2 K4

23 53

14 44

24 54

K3/K4K1/K2

++

6838

Labeling and connections

M10707

M4288_a

DIN 5264-A; 0,6 x 3,5

0,5 Nm

5 LB. IN

M10248

A

A = 7 mm

1 x 0,2 ... 2,5 mm2

1 x AWG 24 to 12

2 x 0,2 ... 1,0 mm2

2 x AWG 24 to 18

M10249

A

A = 7 mm

1 x 0,25 ... 2,5 mm2

1 x AWG 24 to 12

2 x 0,25 ... 1,0 mm2

2 x AWG 24 to 18

M10250

A

A = 7 mm

1 x 0,2 ... 2,5 mm2

1 x AWG 24 to 12

2 x 0,2 ... 1,5 mm2

2 x AWG 24 to 16

Dimensions (dimensions in mm)

A B

PRSU/M2SI 110 ±1 22,5

M4345_a

M4345_a

35

115,3-0

0,7

+

122,6-0

0,7

+

B

A

106,9

Mounting / disassembly of the terminal blocks

9

10/2015 EN

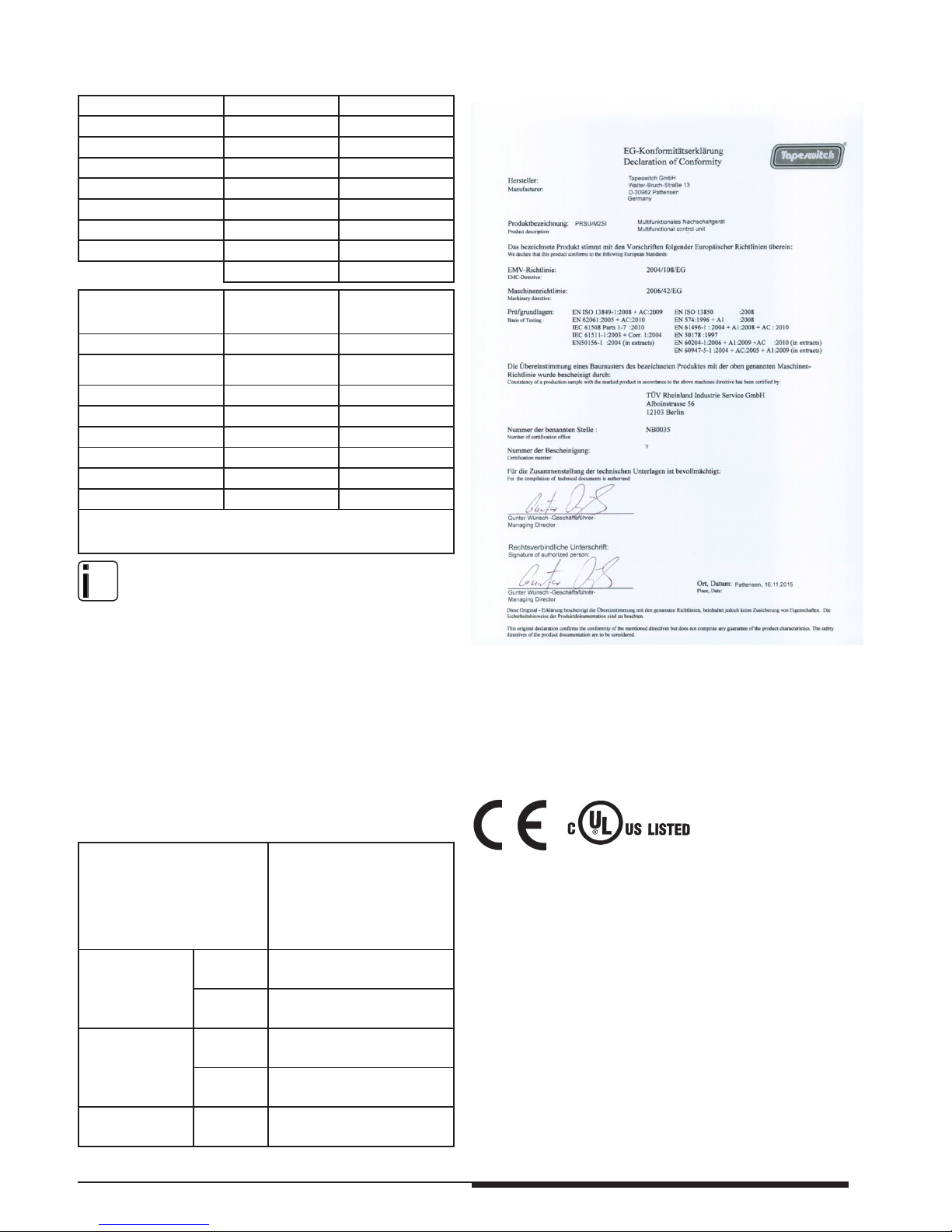

CE-Declaration of Conformity

EN ISO 13849-1:

Category: 4

PL: e

MTTFd: 134,5 a (year)

DCavg: 99,0 %

dop: 365 d/a (days/year)

hop: 24 h/d (hours/day)

tcycle: 3600 s/cycle

1 /h (hour)

IEC/EN 62061

IEC/EN 61508

IEC/EN 61511:

SIL CL: 3 IEC/EN 62061

SIL: 3 IEC/EN 61508 /

IEC/EN 61511

HFT*): 1

DCavg: 99,0 %

SFF: 99,6 %

PFHD: 3,89E-10 h-1

PFD: 3,27E-05

T120 a (year)

*) HFT = Hardware failure tolerance

Safety related data

nfo

The values stated above are valid for the standard type. Safety data for

other variants are available on request.

The safety relevant data of the complete system has to be determined

by the manufacturer of the system.

Approvals and Markings

Demand to our device based on the

evaluated neccessary safety level of

the application.

Intervall for cyclic test of the

safety function

EN ISO 13849-1

PL e with

Cat. 3

or Cat. 4

once per month

PL d with

Cat. 3 once per year

IEC/EN 62061,

IEC/EN 61508

SIL CL 3,

SIL 3

with HFT = 1

once per month

SIL CL 2,

SIL 2

with HFT = 1 once per year

EN 61511, EN 50156-1 SIL 3 once per year

TÜV

Baumuster

geprüft

Tapeswitch Corporation

e-mail: sales

@tapeswitch.com • web: http://www.tapeswitch.com

Phone: 631-630-0442 Toll Free: 800-234-8273

Table of contents

Other Tapeswitch Protection Device manuals

Popular Protection Device manuals by other brands

Frontera

Frontera KoverRoos manual

NewMar

NewMar NAV-PAC NP-24 Installation & operation manual

Chamberlain

Chamberlain LiftMaster Professional Retroreflector Photo Eye Protector System... owner's manual

Gardigo

Gardigo Vario 90801 instruction manual

RCT

RCT Muirihead 3747 product manual

Vetter

Vetter KOALA Series Mounting instructions