DBI SALA 3M Flexiguard M200 User manual

© 3M 2020

1

A

A

8530886 1

8530887 2

8530888 3

8530889 4

8530920 5

8530921 6

1 2 3 4 6

5

C

8530912

USER INSTRUCTIONS

3MTM DBI-SALA®FlexiguardTM

Modular Jib System M200

Adjustable Jib Boom

W H

x1

x2

B

8530891 115.0 ft.

(4.6 m) 12.3 ft. - 15.0 ft.

(3.8 m - 4.6 m) 945 lb.

(429 kg)

8530892 115.0 ft.

(4.6 m) 14.8 ft. - 20.0 ft.

(4.5 m - 6.1 m) 1,057 lb.

(479 kg)

8530893 115.0 ft.

(4.6 m) 17.3 ft. - 25.0 ft.

(5.3 m - 7.6 m) 1,169 lb.

(530 kg)

8530894 115.0 ft.

(4.6 m) 19.8 ft. - 30.0 ft.

(6.0 m - 9.1 m) 1,281 lb.

(581 kg)

8530895 112.0 ft.

(3.7 m) 12.3 ft. - 15.0 ft.

(3.8 m - 4.6 m) 1,011 lb.

(459 kg)

8530896 112.0 ft.

(3.7 m) 14.8 ft. - 20.0 ft.

(4.5 m - 6.1 m) 1,123 lb.

(509 kg)

8530897 112.0 ft.

(3.7 m) 17.3 ft. - 25.0 ft.

(5.3 m - 7.6 m) 1,235 lb.

(560 kg)

8530898 112.0 ft.

(3.7 m) 19.8 ft. - 30.0 ft.

(6.0 m - 9.1 m) 1,343 lb.

(609 kg)

8530899 215.0 ft.

(4.6 m) 15.0 ft. - 20.0 ft.

(4.6 m - 6.1 m) 818 lb.

(371 kg)

8530900 215.0 ft.

(4.6 m) 20.0 ft. - 25.0 ft.

(6.1 m - 7.6 m) 930 lb.

(422 kg)

8530901 215.0 ft.

(4.6 m) 25.0 ft. - 30.0 ft.

(7.6 m - 9.1 m) 1,041 lb.

(472 kg)

8530902 212.0 ft.

(3.7 m) 15.0 ft. - 20.0 ft.

(4.6 m - 6.1 m) 850 lb.

(386 kg)

8530903 212.0 ft.

(3.7 m) 20.0 ft. - 25.0 ft.

(6.1 m - 7.6 m) 961 lb.

(436 kg)

8530904 212.0 ft.

(3.7 m) 25.0 ft. - 30.0 ft.

(7.6 m - 9.1 m) 1,073 lb.

(487 kg)

OSHA 1926.502 OSHA 1910.140

EN 795:2012

Type E

CEN/TS 16415:2013

Type E

CE Type Test

No. 2797

BSI

The Netherlands B.V.

Say Building

John M. Keynesplein 9

1066 EP

Amsterdam

Netherlands

CE Production Quality Control

No. 2797

BSI

The Netherlands B.V.

Say Building

John M. Keynesplein 9

1066 EP

Amsterdam

Netherlands

W

H

12

W

H

AA

2

2

F

M

D

E

C

A

K

K

H

I

G

H

K

H

D

E

D

C

K

G

A

J

B

F

N

L

N

N

N

N

3 4

A

3

5 6

A. B. C. D.

E. F. G.

A B C

7

A

AA

A

A

A

B

A

1 2

3 4

4

7

C

A

B

AA

=0°

=360°

AB

X

5

6

5

8

A

B

B

A

B

C

H

R

L

X

X

1 2

3

6

9

B

A

A

10

B

A

A

B

CC

B

A

A

A

1 2 3

1 2 3

4 5

7

10

A

B

x2

11

A

B

1

6

8

11

A

B

A

B

12

1

2

3

A

1

A

3

2

B

B

A

A

2 3

9

13

C

B

A

A

B

D

14

9515101 REV. A

=360°

=0°

C

A

B

C

9515111 Rev. A

D

A

9514429 Rev. B

Mfrd. (yr, mo) Model No.:

Fabr. (aa, mm) N° de Modelo:

Serial no / N° de serie:

3M.com/FallProtection

Red Wing, MN 55066, USA

B

A B

C

D

AC

B

D

E

F

G

2797

EN795:2012 "TYPE E"

CEN/TS 16415:2013 "TYPE E"

OSHA 1926.502 & 1910.140

8530902 850 lbs. (386 kg)

8530903 961 lbs. (436 kg)

8530895 1,011 lbs. (459 kg)

8530896 1,123 lbs. (509 kg)

9515112 REV. A

8530904 1,073 lbs. (487 kg)

8530897 1,235 lbs. (560 kg)

8530898 1,343 lbs. (609 kg)

x

≤ 6 kN

(1350 lbs.)

≤ 140 kg

(310 lbs.)

≤ 140 kg

(310 lbs.)

#

+

lb.(kg)

AC

B

D

E

F

G

A A

FORM NO: 5908278 REV: A 10

SAFETY INFORMATION

Please read, understand, and follow all safety information contained in these instructions prior to the use of this Flexiguard System.

FAILURE TO DO SO COULD RESULT IN SERIOUS INJURY OR DEATH.

These instructions must be provided to the user of this equipment. Retain these instructions for future reference.

Intended Use:

This Flexiguard System is intended for use as part of a complete fall protection or rescue system.

Use in any other application including, but not limited to, material handling, recreational or sports related activities, or other activities not described in

the User Instructions, is not approved by 3M and could result in serious injury or death.

This system is only to be used by trained users in workplace applications.

!WARNING

This Flexiguard System is part of a personal fall protection or rescue system. It is expected that all users be fully trained in the safe installation and

operation of the complete system. Misuse of this system could result in serious injury or death. For proper selection, operation, installation,

maintenance, and service, refer to all Product Instructions and all manufacturer recommendations, see your supervisor, or contact 3M Technical Service.

• To reduce the risks associated with transporting a Flexiguard system which, if not avoided, could result in serious injury or death:

- Ensure the system is properly secured or congured prior to transport. Refer to the User Instructions for detailed transportation requirements.

- Only transport below 5 mph (8 km/h) and at inclines of 10° or less, or as outlined in the User Instructions.

- Ensure the system will not contact overhead objects or electrical hazards while transporting or in use.

• To reduce the risks associated with working with a Flexiguard system which, if not avoided, could result in serious injury or death:

- Inspect all components of the system before each use, at least annually, and after any fall event, in accordance with the User Instructions.

- If inspection reveals an unsafe or defective condition, remove the system from service and repair or replace according to the User Instructions.

- Any system that has been subject to fall arrest or impact force must be immediately removed from service. Refer to the User Instructions or

contact 3M Fall Protection.

- The substrate or structure on which the system is attached/positioned must be able to sustain the static loads specied for the system in the

orientations permitted in the User Instructions or Installation Instructions.

- Do not exceed the number of allowable users as per the User Instructions.

- Never attach to a system until it is fully assembled, positioned, adjusted, and installed. Do not adjust the system while a user is attached.

- Never work outside the safe work area as dened by the User Instructions.

- Do not connect to the system while it is being transported or installed.

- Always maintain 100% tie-o when transferring between anchor points on the system.

- Use caution when installing, using, and moving the system as moving parts may create potential pinch points.

- Ensure proper lockout/tagout procedures have been followed when applicable.

- Only connect fall protection subsystems to the designated anchorage connection point on the system.

- When drilling holes for assembly or installation of the system, ensure no electric lines, gas lines, or other critical materials or equipment will be

contacted by the drill.

- Ensure that fall protection systems/subsystems assembled from components made by dierent manufacturers are compatible and meet the

requirements of applicable standards, including the ANSI Z359 or other applicable fall protection codes, standards, or requirements. Always

consult a Competent or Qualied Person before using these systems.

• To reduce the risks associated with working at heights which, if not avoided, could result in serious injury or death:

- Ensure your health and physical condition allow you to safely withstand all of the forces associated with working at height. Consult with your

doctor if you have any questions regarding your ability to use this equipment.

- Never exceed allowable capacity of your fall protection equipment.

- Never exceed maximum free fall distance of your fall protection equipment.

- Do not use any fall protection equipment that fails pre-use or other scheduled inspections, or if you have concerns about the use or suitability

of the equipment for your application. Contact 3M Technical Services with any questions.

- Some subsystem and component combinations may interfere with the operation of this equipment. Only use compatible connections. Consult

3M prior to using this equipment in combination with components or subsystems other than those described in the User Instructions.

- Use extra precautions when working around moving machinery (e.g. top drive of oil rigs) electrical hazards, extreme temperatures, chemical

hazards, explosive or toxic gases, sharp edges, or below overhead materials that could fall onto you or the fall protection equipment.

- Use Arc Flash or Hot Works devices when working in high heat environments.

- Avoid surfaces and objects that can damage the user or equipment.

- Ensure there is adequate fall clearance when working at height.

- Never modify or alter your fall protection equipment. Only 3M or parties authorized in by 3M may make repairs to the equipment.

- Prior to use of fall protection equipment, ensure a rescue plan is in place which allows for prompt rescue if a fall incident occurs.

- If a fall incident occurs, immediately seek medical attention for the fallen worker.

- Do not use a body belt for fall arrest applications. Use only a Full Body Harness.

- Minimize swing falls by working as directly below the anchorage point as possible.

- If training with this device, a secondary fall protection system must be utilized in a manner that does not expose the trainee to an unintended

fall hazard.

- Always wear appropriate personal protective equipment when installing, using, or inspecting the device/system.

EN

11

;Prior to installation and use of this equipment, record the product identication information from the ID label in the

Inspection and Maintenance Log (Table 2) at the back of this manual.

;Always ensure you are using the latest revision of your 3M instruction manual. Visit the 3M website or contact 3M

Technical Services for updated instruction manuals.

PRODUCT DESCRIPTION:

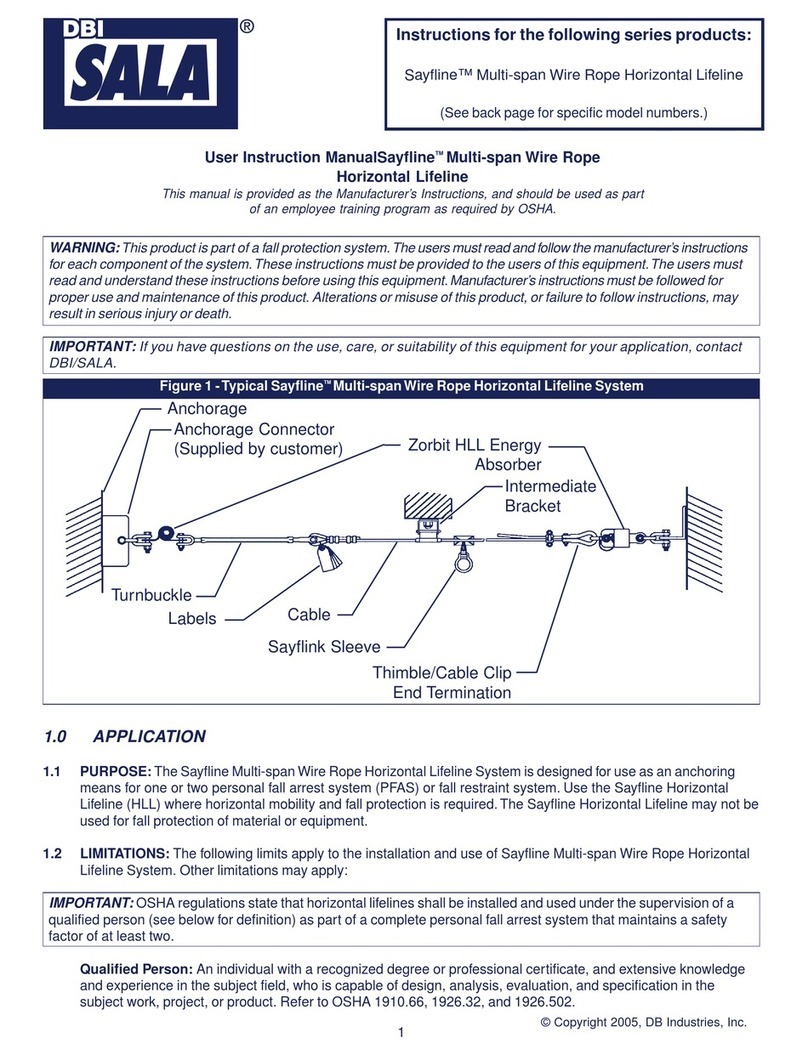

Figure 1 illustrates the 3M™ DBI-SALA®Flexiguard™ Modular Jib System M200 Adjustable Jib Boom. The M200 Jib System

is used to to provide an adjustable Fall Arrest anchor point for one or two workers. These instructions cover use of the

M200 Jib Boom, but use of the M200 Jib System requires use of a Jib Base (sold separately) in addition to the Jib Boom. For a

list of compatible Jib Base models, see Figure 1.

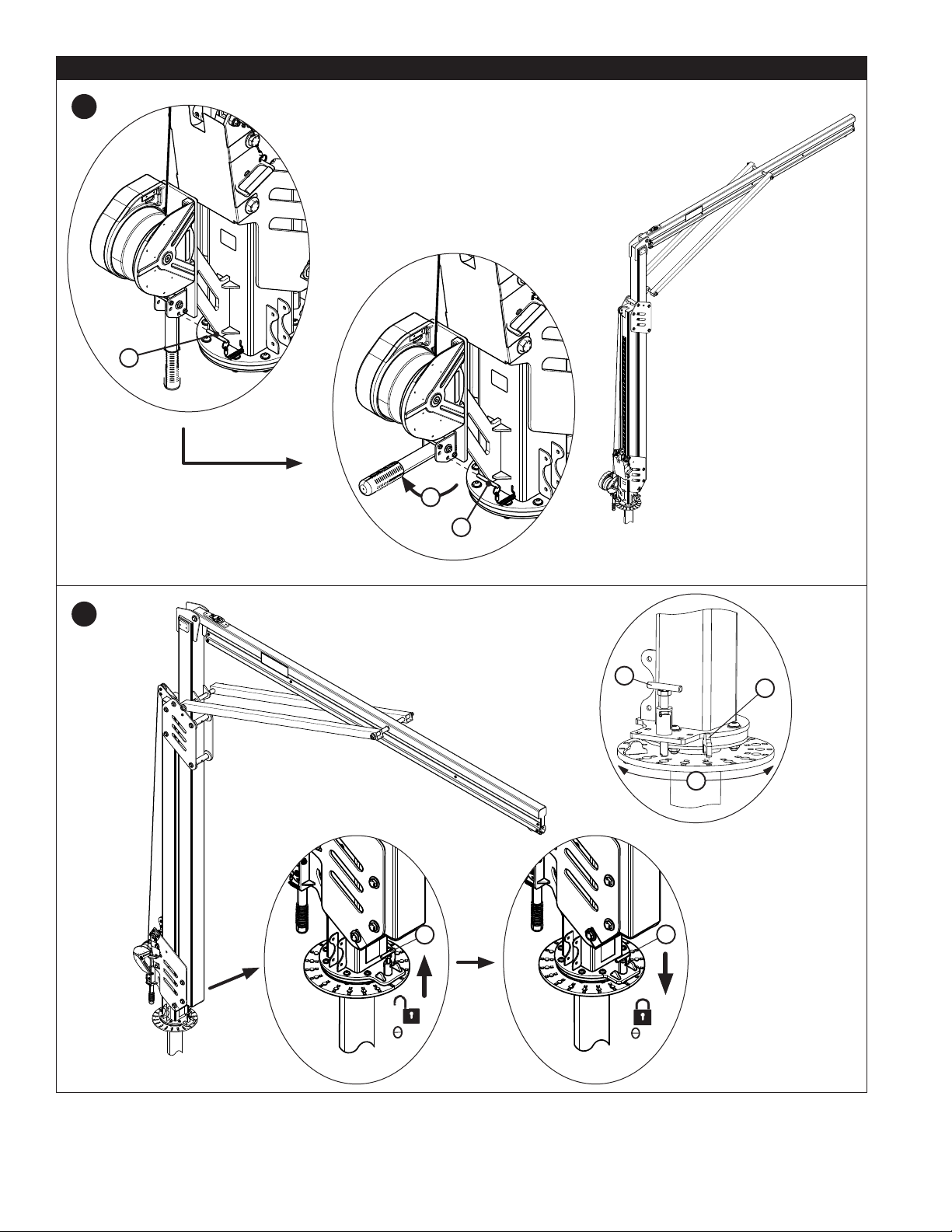

Figure 2 illustrates components of the M200 Jib Boom. See Table 1 for Component Specications.

The Fixed Upright Assembly (A) serves as the main body of the Jib Boom. The Gusset (C) braces the Rail Assembly (D), which

lets the user move within the established work area. The Connection Eye (E) secures an SRD as a connection point for the user.

The Lifting Ring (F) is used to secure a chain or web strap for transporting the system. For B2 Jib Boom models, the Adjustment

Channel (M) enables height adjustment of the Jib Boom. For B1 Jib Boom models, the Adjustable Upright Assembly (B) enables

height adjustment in coordination with the Adjustment Winch (G). The cable of the Adjustment Winch is connected to the Jib

Boom through a series of pulleys, including the Lower Pulley of the Locking Assembly (I) and Upper Pulley (J). The Rotation

Handle (H) allows for rotation of the Jib Boom after placement. The Rotation Pin (K) may be engaged to prevent rotation of the

Jib Boom. The Rotation Stops (N) may be used to limit Jib Boom rotation when the Rotation Pin is not engaged. For B1 Jib Boom

models, the Transportation Pin (L) is used to secure the Jib Boom during transportation.

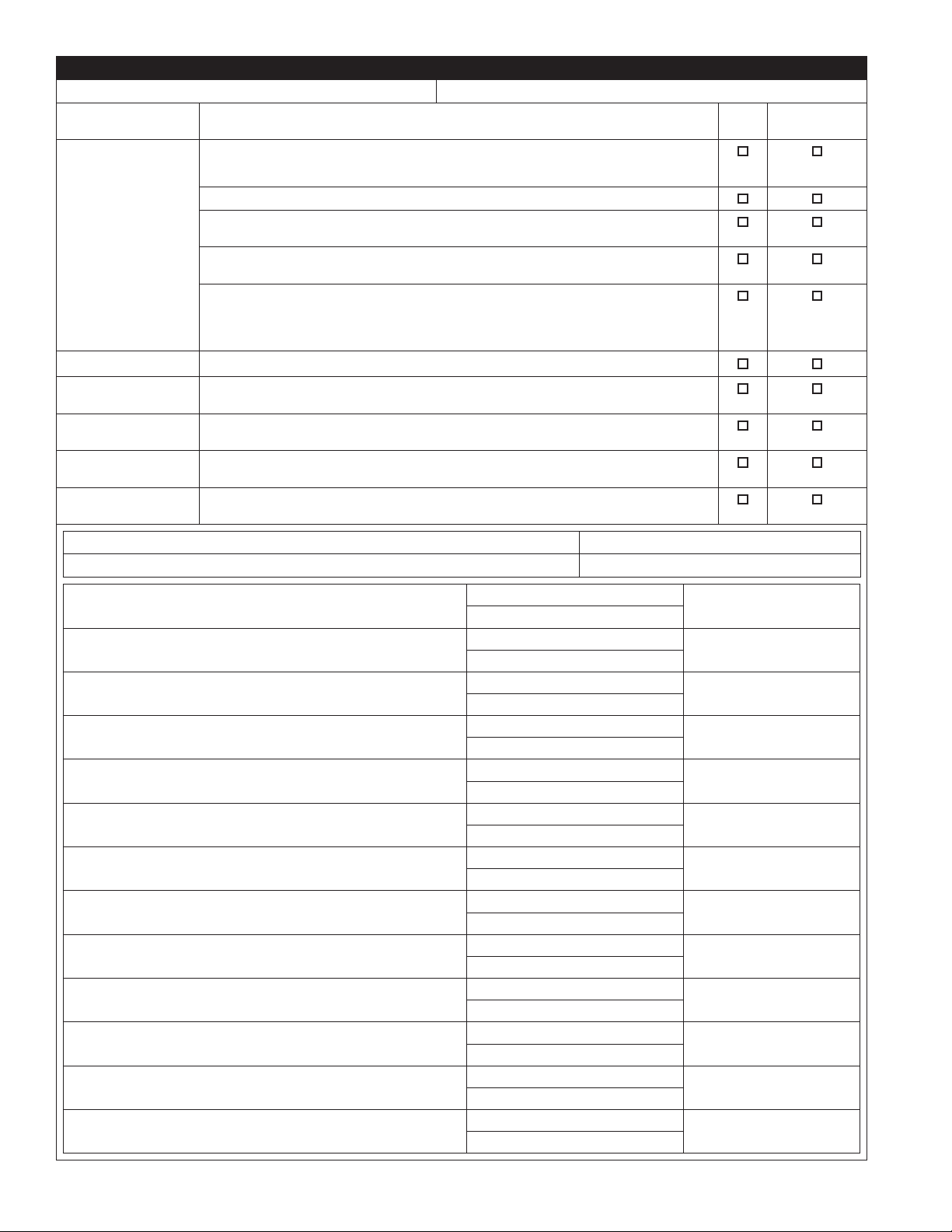

Table 1 – Specications

System Specications:

Capacity: Each user must have a combined weight (clothing, tools, etc.) of no more than 310 lb. (140 kg).

Anchorage: See the User Instructions for your Jib base for more information on loading requirements of structure.

Dimensions: See Figure 1 for the dimensions of each M200 Jib Boom model.

Product Weight: See Figure 1 for the weight of each M200 Jib Boom model.

Maximum

Arresting Force: All connecting subsystems (SRDs, Energy Absorbing Lanyards, etc.) used with the Jib Boom must limit

the Maximum Arresting Force to 1,350 lbf (6 kN).

Maximum

Deection: The Maximum Deection of the system during a fall arrest is measured to be 20.0 in. (508 mm). This

value should be added to any calculated Fall Clearance requirements for your connecting subsystem.

Certication:

The Jib Boom models covered by this instruction meet the test requirements of the standards listed on

the front cover of these instructions. The certication of your Jib Boom depends on the Series it is part

of. See Figure 1 for more information.

Jib Boom

Series Max Users Applicable Standards Jib Boom

Series Max Users Applicable Standards

11 user EN795.2012, Type E

OSHA 1910.140

OSHA 1926.502

21 user EN795.2012, Type E

OSHA 1910.140

OSHA 1926.502

2 users EN795.2012, Type E

CEN/TS 16415.2013, Type E

OSHA 1910.140

OSHA 1926.502

2 users EN795.2012, Type E

CEN/TS 16415.2013, Type E

OSHA 1910.140

OSHA 1926.502

M200 Adjustable Jib Booms when used with 3M Jib Bases:

Portable Bases EN795.2012 CEN/TS

16415.2013 OSHA 1926.502

OSHA 1910.140

8530886 Certied (Type E) Certied (Type E) Certied

8530887 Certied (Type E) Certied (Type E) Certied

Permanent Bases

8530888 Meets (Type A) Meets (Type A) Certied

8530889 Meets (Type A) Meets (Type A) Certied

8530920 Meets (Type A) Meets (Type A) Certied

8530921 Meets (Type A) Meets (Type A) Certied

Jib Boom

Compatibility: The M200 Jib Boom models covered in these instructions are compatible only with those Jib Base models

listed on the front cover of these instructions.

12

Table 1 – Specications

Component Specications:

Figure 2

Reference Component Materials

A Fixed Upright Assembly Steel

B Adjustable Upright Assembly Steel

CGusset Steel

D Rail Assembly Aluminum

EConnection Eye Stainless steel, plastic wheels

F Lifting Ring Steel

G Adjustment Winch Plastic, steel, aluminum

HRotation Handle Rubber, steel

I Locking Assembly Plastic, steel

J Upper Pulley Plastic

KRotation Pin Steel

L Transportation Pin Steel

M Adjustment Channel Steel

N Rotation Stop Steel

13

1.0 PRODUCT APPLICATION

1.1 PURPOSE: Jib Booms are designed to provide anchorage connection points for a Fall Protection system.

1.2 STANDARDS: Your Jib Boom conforms to the national or regional standard(s) identied on the front cover of these

instructions. If this product is resold outside the original country of destination, the re-seller must provide these

instructions in the language of the country in which the product will be used.

1.3 SUPERVISION: Installation of this equipment must be supervised by a Qualied Person1. Use of this equipment must be

supervised by a Competent Person2.

1.4 TRAINING: This equipment must be installed and used by persons trained in its correct application. This manual is to be

used as part of an employee training program as required by national, regional, or local standards. It is the responsibility

of the users and installers of this equipment to ensure they are familiar with these instructions, trained in the correct care

and use of this equipment, and are aware of the operating characteristics, application limitations, and consequences of

improper use of this equipment.

1.5 RESCUE PLAN: When using this equipment and connecting subsystem(s), the employer must have a rescue plan and

the means at hand to implement and communicate that plan to users, authorized persons3, and rescuers4. A trained, on-

site rescue team is recommended. Team members should be provided with the equipment and techniques to perform a

successful rescue. Training should be provided on a periodic basis to ensure rescuer prociency.

1.6 AFTER A FALL: If this equipment is subjected to fall arrest or impact forces, remove it from service immediately. Clearly

tag it “DO NOT USE”. See Section 5 for more information.

2.0 SYSTEM REQUIREMENTS

2.1 ANCHORAGE: Anchorage requirements vary with the fall protection application. Structure on which the Flexiguard

Anchorage System is placed or mounted must meet the Anchorage specications dened in Table 1.

2.2 FALL ARREST SYSTEM: Fall Arrest systems used with the Jib Boom must meet applicable Fall Protection standards,

codes, and requirements. Refer to the instructions included with your connecting subsystem for additional fall

requirements. The Fall Arrest system must incorporate a Full Body Harness and limit Arresting Force to the values

specied in Table 1.

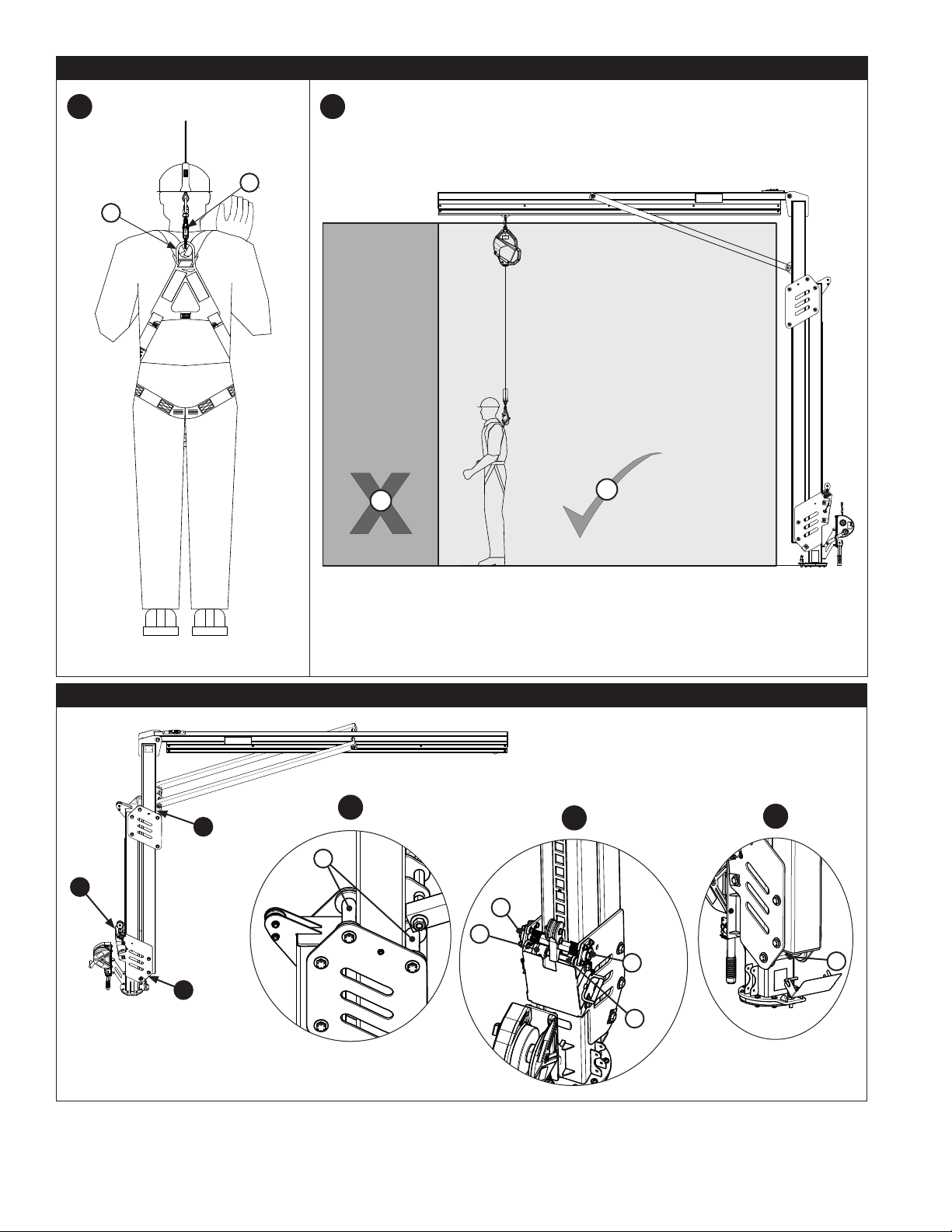

2.3 FALL PATH AND SRD LOCKING SPEED: A clear path is required to assure positive locking of an SRD. Situations

which do not allow for an unobstructed fall path should be avoided. Working in confined or cramped spaces may not allow

the body to reach sufficient speed to cause the SRD to lock if a fall occurs. Working on slowly shifting material, such as

sand or grain, may not allow enough speed buildup to cause the SRD to lock.

2.4 HAZARDS: Use of this equipment in areas with environmental hazards may require additional precautions to prevent

injury to the user or damage to the equipment. Hazards may include, but are not limited to: heat, chemicals, corrosive

environments, high voltage power lines, explosive or toxic gases, moving machinery, sharp edges, or overhead materials

that may fall and contact the user or Personal Fall Arrest System.

2.5 FALL CLEARANCE: There must be sucient clearance below the user to arrest a fall before the user strikes the ground

or other obstruction. Fall Clearance is dependent on the following factors:

• Deceleration Distance • Worker Height • Elevation of Anchorage Connector

• Free Fall Distance • Movement of Harness Attachment Element • Connecting Subsystem Length

See the instruction manual of your connecting subsystem for specics regarding Fall Clearance calculation.

2.6 SWING FALLS: Swing Falls occur when the anchorage point is not directly above the point where a fall occurs (see Figure

3). The force of striking an object in a swing fall may cause serious injury or death. Minimize swing falls by working as

directly below the anchorage point as possible. Do not permit a swing fall if injury could occur. Swing falls will signicantly

increase the clearance required when a Self-Retracting Device or other variable length connecting subsystem is used.

2.7 SHARP EDGES: Avoid working where Lifeline or Lanyard components of the Fall Arrest system can contact or abrade

against unprotected sharp edges or abrasive surfaces (see Figure 4). Where contact with a sharp edge or abrasive surface

is unavoidable, cover the edge with protective material (A).

2.8 COMPONENT COMPATIBILITY: 3M equipment is designed for use with 3M-approved components and subsystems

only. Substitutions or replacements made with non-approved components or subsystems may jeopardize compatibility of

equipment and may aect the safety and reliability of the complete system.

2.9 CONNECTOR COMPATIBILITY: Connectors are considered to be compatible with connecting elements when they

have been designed to work together in such a way that their sizes and shapes do not cause their gate mechanisms to

inadvertently open regardless of how they become oriented. Contact 3M if you have any questions about compatibility.

Connectors must comply with EN 362. Connectors must be compatible with the anchorage or other system components.

Do not use equipment that is not compatible. Non-compatible connectors may unintentionally disengage (see Figure 5).

Connectors must be compatible in size, shape, and strength. If the connecting element to which a snap hook or carabiner

attaches is undersized or irregular in shape, a situation could occur where the connecting element applies a force to the

gate of the snap hook or carabiner (A). This force may cause the gate to open (B), allowing the snap hook or carabiner to

disengage from the connecting point (C).

1 Qualied Person: A person with a recognized degree, certicate or professional standing, or who by extensive knowledge, training and

experience has successfully demonstrated his ability to solve or resolve problems relating to Fall Protection systems to the extent required by

OSHA or other applicable federal, state, and local regulations.

2 Competent Person: One who is capable of identifying existing and predictable hazards in the surroundings or working conditions which are

unsanitary, hazardous, or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate them.

3 Authorized Person: A person assigned by the employer to perform duties at a location where the person will be exposed to a fall hazard.

4 Rescuer: Person or persons other than the rescue subject acting to perform an assisted rescue by operation of a rescue system.

14

2.10 MAKING CONNECTIONS: Snap hooks and carabiners used with this equipment must be self-locking. Ensure all

connections are compatible in size, shape and strength. Do not use equipment that is not compatible. Ensure all

connectors are fully closed and locked.

3M connectors (snap hooks and carabiners) are designed to be used only as specied in each product’s user’s instructions.

See Figure 6 for examples of inappropriate connections. Do not connect snap hooks and carabiners:

A. To a D-ring to which another connector is attached.

B. In a manner that would result in a load on the gate. Large throat snap hooks should not be connected to standard

size D-rings or similar objects which will result in a load on the gate if the hook or D-ring twists or rotates, unless the

snap hook complies is equipped with a 16 kN (3,600 lbf) gate. Check the marking on your snap hook to verify that it

is appropriate for your application.

C. In a false engagement, where features that protrude from the snap hook or carabiner catch on the anchor, and

without visual conrmation seems to be fully engaged to the anchor point.

D. To each other.

E. Directly to webbing or rope lanyard or tie-back (unless the manufacturer’s instructions for both the lanyard and

connector specically allows such a connection).

F. To any object which is shaped or dimensioned such that the snap hook or carabiner will not close and lock, or that

roll-out could occur.

G. In a manner that does not allow the connector to align properly while under load.

15

3.0 INSTALLATION

3.1 PLANNING: Plan your Fall Protection system prior to installation of the Jib Boom. Account for all factors that may aect

your safety before, during and after a fall. Consider all requirements, limitations, and specications dened in Section 2

and Table 1.

3.2 PLACING THE JIB BOOM: Before the Jib Boom can be used, it must be secured to a Jib Base. See Figure 7 for

reference. To secure the Jib Boom to a Jib Base:

1. Install and prepare the Jib Base (A) per its User Instructions. See Figure 1 for a list of compatible Jib Base models.

2. Secure the Rail Assembly and Gusset to the Upright Assembly using the 1.0 in. hardware provided. Torque hardware

to 130 ft-lb (176 N-m).

3. Connect the Jib Boom to the lifting device (forklift, overhead crane, etc.) that will transport the system. Insert the

Transportation Pin (B) before lifting the Jib Boom. Ensure that the Jib Boom is lifted by the Lifting Ring (A) located

atop the Gusset.

4. Transport the Jib Boom to the Jib Base. Lower the Jib Boom onto the Jib Base (A).

;When transporting the Jib Boom via forklift, driving speed must not exceed 5 mph (8 kpm).

5. After placement of the Jib Boom, rotate the Jib Boom to its desired work position by means of the Rotation Handle.

First, remove the Locking Pin (A) from the Rotation Handle. Then, lift the Rotation Handle to its perpendicular position

(B), and secure the handle by reinserting the Locking Pin (C).

6. To lock rotation of the Jib Boom, position the Locking Pin (A) over one of the holes on the Jib Base and then engage

the Locking Pin to secure the Jib Boom. Alternatively, the Locking Pin may be kept retracted to allow the Jib Boom to

rotate freely. Rotation Stops (B) may be inserted to limit System Rotation (X) within a desired range.

3.3 TRANSPORTING AFTER PLACEMENT: The Jib System may be moved after placement on some Jib Base models. For

more information, see the manufacturer instructions for your Jib Base model.

3.4 ADJUSTING THE HEIGHT OF THE JIB BOOM: After securing the Jib Boom to the Jib Base, you may adjust the

height of the Jib Boom. Height adjustment procedures vary based on your Jib Boom model. See Figure 1 for Jib Boom

identication.

• B1 MODELS: This series of M200 Jib Boom models is adjustable through means of an Adjustment Winch attached to

the base of the Jib Boom. See Figure 8 for reference.

INSTALLING THE ADJUSTMENT WINCH CABLE:

;This series of the M200 Jib Boom is shipped with the cable of the Adjustment Winch already routed through the

M200 Jib Boom. If the cable is already routed, skip to “Using the Adjustment Winch”.

1. Pay out the Cable (B) of the Adjustment Winch (A) by rotating the handle counterclockwise.

2. Extend the cable slowly as you thread it rst through the Upper Pulley (A), then around the Lower Pulley (B) of

the Locking Assembly. From the Lower Pulley, guide the cable back towards the Upper Pulley, then attach the cable

thimble to the 1/2 in. Anchor Bolt (C) between the spacer washers. Torque hardware to 60 ft-lb (81 N-m).

USING THE ADJUSTMENT WINCH:

3. After securing the cable through the system, the System Height (H) of the Jib Boom may be adjusted by turning

the handle of the Adjustment Winch. By turning the handle clockwise (R), the Jib Boom is raised. By turning the

handle counterclockwise (L), the Jib Boom is lowered. The height of the Jib Boom may be set anywhere between

the Side Plates (X) at the top and bottom of the Jib Boom. The Jib Boom may be raised until the Side Plates touch

at the top of the system.

• B2 MODELS: This series of M200 Jib Boom models is adjustable through means of the Adjustment Channel attached

to the Fixed Upright Assembly. See Figure 9 for reference. To adjust the height of the Jib Boom:

1. Remove the two Channel Fasteners (A) from the Adjustment Channel (B).

2. Set the Jib Boom to the desired height. Each hole in the Adjustment Channel adjusts the height of the system by

6.0 in. (15 cm).

3. Fasten the two Channel Fasteners (A) to secure the Adjustment Channel at its new height. Torque 3/4 in. hardware

to 130 ft-lb (176 N-m).

3.5 CONNECTING A SELF-RETRACTING DEVICE (SRD): To connect to the M200 Jib System, the user must rst connect

an SRD to the Jib Boom. See Figure 11 for reference. To connect an SRD to the Jib Boom:

1. Secure the top connector of your SRD (A) to the Connection Eye (B) on the Rail Assembly.

2. Secure the end connector of your SRD (B) to the D-Ring (A) on your Full Body Harness.

3. When using the SRD with the Jib System, stay within the Safe Working Area (A) of the Jib Boom. The user should

remain as directly below the Connection Eye as possible when using the system. For more information on safe work

area, see Section 4.

3.6 INSTALLATION AND USE OF THE FORK POCKET KIT (8530912): For B1 Jib Boom models, a Fork Pocket kit (sold

separately) may be secured to the Jib Boom to facilitate easy transport without use of a Jib Base or the D-Ring atop the

Gusset. See Figure 10 for reference. To connect the Fork Pockets to the Jib Boom and transport:

1. Remove the Fasteners (A) from the Steel Plates (B) at the base of the Upright Assembly.

2. Place the Fork Pockets (C) on either side of the Jib Boom, ush against the Steel Plates (B) with their mounting holes

aligned. Insert the new Fasteners (A) to secure, threading through both the Fork Pockets and both the Steel Plates.

Torque 5/8 in. hardware to 75 ft-lb (102 N-m).

3. Verify that the Fork Pockets are securely installed. The Tri-Screws located on the bottom of the forks should be facing

downward.

16

4. To transport, insert the blades of the forklift through the Fork Pockets. Raise the forklift blades to the top of the Fork

Pocket tubes.

;When using the Fork Pockets, always approach from the front of the Jib Boom.

;Use caution when inserting the blades of the forklift through the Fork Pockets. Moving parts may create pinch

points and cause injury.

6. Tighten the Tri-Screws (A) at the base of each Fork Pocket tube to secure each tube to the forklift blades.

7. Verify that the Jib Boom is secured by its Fork Pockets to the forklift. Secure the Fork Pockets to the forklift by

attaching a Chain (A) from each Fork Pocket Connection Ring (B) to the forklift.

4.0 USE

4.1 BEFORE EACH USE: Verify that your work area and Fall Protection system meet all criteria dened in these instructions.

Verify that a formal Rescue Plan is in place. Inspect the system per the ‘User’ inspection points dened in the

“Inspection

and Maintenance Log” (Table 2).

If inspection reveals an unsafe or defective condition, or if there is any doubt about its

condition for safe use, remove the system from service immediately. Clearly tag the system “DO NOT USE”. See Section 5

for more information.

4.2 SAFE WORKING AREA: The Safe Working Area of the Jib Boom does not extend beyond the length of the Jib Boom

itself. See Figure 11.3 for reference. When using the M200 Jib Boom, the user should remain within the indicated Safe

Working Area (A). Leaving the Safe Working Area to an Outside Location (B) is dangerous and could result in serious

injury or death. When working on either side of the M200 Jib System, it is recommended that the user keep the anchor

point as directly overhead as possible. This will minimize the potential for swing falls and any fall distance, in addition to

ensuring the safety of a second user, should the rst user fall.

When two users are attached to the system, it is recommended that rotation of the Jib Boom is locked with the rotation

pin. See Section 3.2. Each user must stay within 30 degrees of either side of the anchor point and never work past the

end of the rail.

5.0 INSPECTION

;After product has been removed from service, it may not be returned to service until a Competent Person conrms in

writing that it is acceptable to do so.

5.1 INSPECTION FREQUENCY: The product shall be inspected before each use by the user and, additionally, by a

Competent Person other than the user at intervals of no longer than one year. A higher frequency of equipment use

and harsher conditions may require increasing the frequency of Competent Person inspections. The frequency of these

inspections should be determined by the Competent Person per the specic conditions of the worksite.

5.2 INSPECTION PROCEDURES: Inspect this product per the procedures listed in the “Inspection and Maintenance Log”.

Documentation of each inspection should be maintained by the owner of this equipment. An inspection and maintenance

log should be placed near the product or be otherwise easily accessible to users. It is recommended that the product is

marked with the date of next or last inspection.

5.3 DEFECTS: If the Jib Boom cannot be returned to service because of an existing defect or unsafe condition, then either

destroy the system or contact 3M or a 3M-authorized service center about possible repair.

5.4 PRODUCT LIFE: The functional life of the Jib Boom is determined by work conditions and maintenance. As long as the

product passes inspection criteria, it may remain in service.

6.0 MAINTENANCE, SERVICE, and STORAGE

6.1 CLEANING: Periodically clean the metal components of the Jib Boom with a soft brush, warm water, and a mild soap

solution. Ensure parts are thoroughly rinsed with clean water.

6.2 SERVICE: Only 3M or parties authorized in writing by 3M may make repairs to this equipment.

6.3 STORAGE: If applicable, store the Jib Boom and associated Fall Protection equipment in a cool, dry, clean environment

out of direct sunlight. Avoid areas where chemical vapors may exist. Thoroughly inspect components after extended

storage.

;Some Jib Base models used with the M200 Jib System are permanent. The Jib Boom may be removed from these

Jib Bases for storage or transport, but the Jib Base will have to remain.

17

7.0 LABELS and MARKINGS

7.1 LABELS: Figures 13 and 14 illustrate labels present on the Jib Boom. Figure 13 illustrates label locations and Figure

14 displays those associated labels. Labels must be replaced if they are not present or are not fully legible. Information

provided on each label is as follows:

AThe label present on Location A varies based upon whether your system allows one or two simultaneous users.

Label 9515103 - 1 user

Label 9515112 - 2 users

A) 3M Logo B) Applicable Standards C) Read all instructions.

D) Jib Boom Model Numbers and Weight Values E) Maximum Arresting Force 1,350 lbf (6 kN)

F) Capacity - Each user must have a combined weight (clothing, tools, etc.) of no more than 310 lb. (140 kg).

BA) Manufactured (Year/Month) B) Model Number C) Serial Number

CA) Engage the Locking Pin to prevent rotation of the system.

B) Disengage the Locking Pin to enable full rotation of the system.

C) Maximum System Rotation is equivalent to the limits allowed by engagement or disengagement of the pin.

DA) 3M Logo

Table 2 – Inspection and Maintenance Log

Inspection Date: Inspected By:

Components: Inspection: (See Section 1 for Inspection Frequency)User Competent

Person

Jib Boom

(Figure 2)

Inspect the entire system for damage, deformation, corrosion, and rust. Look

for cracks, bends, dents, or wear that could aect strength and operation of the

system.

Inspect all fasteners for damage or corrosion. Tighten as necessary.

Inspect all moving parts for chips, cracks, breaks, or worn areas that can cause

malfunction during operation.

Verify that all adjustment points (pins, bolts, tri-screws, adjusting screws, etc.)

are in full functional condition and are adjusted properly.

Fully lower the Jib Boom to take tension o the cable. Verify that the springs in

the Lower Pulley (I) are functional and free of rust or other obstructions. Verify

that the cable of the Adjustment Winch (G) has no frays or tearing. Ensure the

locking assembly engages.

Winch Assembly Inspect the Winch Assembly per 3M instruction manual 8511324.

Rollers and Bearings

(Figure 12) Grease the Rollers (A) and Bearings (B) of the Adjustable Upright Assembly for

B1 Jib Boom models. Ensure that all Roller locations are greased.

Anchor Connection

Points Ensure Anchor Connection Points are free of corrosion, cracks, or other

imperfections that my cause malfunction during operation.

Labels

(Figures 13 and 14) Verify that all labels are present and fully legible.

Fall Protection

System Additional Fall Protection equipment (winches, SRDs, etc.) that are used with

the system should be inspected per the manufacturer instructions.

Serial Number(s): Date Purchased:

Model Number: Date of First Use:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

Corrective Action/Maintenance: Approved By: Next inspection due:

Date:

GLOBAL PRODUCT WARRANTY, LIMITED REMEDY

AND LIMITATION OF LIABILITY

WARRANTY: THE FOLLOWING IS MADE IN LIEU OF ALL WARRANTIES OR CONDITIONS, EXPRESS

OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OR CONDITIONS OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE.

Unless otherwise provided by local laws, 3M fall protection products are warranted against factory

defects in workmanship and materials for a period of one year from the date of installation or fi rst use

by the original owner.

LIMITED REMEDY: Upon written notice to 3M, 3M will repair or replace any product determined by

3M to have a factory defect in workmanship or materials. 3M reserves the right to require product be

returned to its facility for evaluation of warranty claims. This warranty does not cover product damage

due to wear, abuse, misuse, damage in transit, failure to maintain the product or other damage beyond

3M’s control. 3M will be the sole judge of product condition and warranty options.

This warranty applies only to the original purchaser and is the only warranty applicable to 3M’s fall

protection products. Please contact 3M’s customer service department in your region for assistance.

LIMITATION OF LIABILITY: TO THE EXTENT PERMITTED BY LOCAL LAWS, 3M IS NOT LIABLE

FOR ANY INDIRECT, INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES INCLUDING, BUT NOT

LIMITED TO LOSS OF PROFITS, IN ANY WAY RELATED TO THE PRODUCTS REGARDLESS OF THE

LEGAL THEORY ASSERTED.

GLOBAL PRODUKTGARANTI, BEGRÆNSEDE RETSMIDLER

OG BEGRÆNSNING AF GARANTIFORPLIGTELSER

GARANTI: FØLGENDE ERSTATTER ALLE GARANTIER ELLER BETINGELSER, UDTRYKKELIGE ELLER

UNDERFORSTÅEDE, HERUNDER DE UNDERFORSTÅEDE GARANTIER ELLER BETINGELSER FOR

SALGBARHED ELLER EGNETHED TIL ET SPECIFIKT FORMÅL.

Bortset fra hvad der sikres ved gældende love, er 3M’s produkter til faldsikring omfattet af en garanti

mod fabriksdefekter i den håndværksmæssige udførelse og materialer i en periode på et år fra

installationsdatoen eller den første ejers ibrugtagningsdato.

BEGRÆNSEDE RETSMIDLER: Ved skriftlig henvendelse til 3M vil 3M reparere eller erstatte ethvert

produkt, der af 3M vurderes at have en fabriksdefekt i den håndværksmæssige udførelse eller

materialer. 3M forbeholder sig ret til at kræve produktet returneret til dets anlæg for at vurdere krav

om garanti. Denne garanti dækker ikke skade på produktet slid, misbrug, forkert brug, transportskade,

manglende vedligeholdelse af produktet eller anden skade uden for 3M’s kontrol. 3M vil alene fastslå

produktets tilstand og mulighederne for garanti.

Denne garanti gælder kun for den oprindelige køber og er den eneste garanti gældende for 3M’s

produkter til faldsikring. Kontakt venligst 3M’s kundeserviceafdeling i dit område for at få hjælp.

BEGRÆNSNING AF GARANTIFORPLIGTELSER: I DEN UDSTRÆKNING DET TILLADES AF LOKALE

LOVE ER 3M IKKE ANSVARLIG FOR NOGEN INDIREKTE, TILFÆLDIGE, SPECIELLE ELLER PÅFØLGENDE

SKADER, HERUNDER MEN IKKE BEGRÆNSET TIL TAB AF FORTJENESTE, DER PÅ NOGEN MÅDE ER

RELATERET TIL PRODUKTERNE UANSET DEN UDLAGTE JURIDISKE TEORI.

GLOBALE PRODUKTGARANTIE, BESCHRÄNKTES RECHTSMITTEL

UND HAFTUNGSBESCHRÄNKUNG

GARANTIE: FOLGENDES GILT STELLVERTRETEND FÜR ALLE GARANTIEN ODER BEDINGUNGEN,

EINSCHLIESSLICH STILLSCHWEIGEND ANGENOMMENER GARANTIEN ODER BEDINGUNGEN

HINSICHTLICH DER TAUGLICHKEIT ODER EIGNUNG FÜR EINEN BESTIMMTEN ZWECK.

Soweit gesetzlich nicht anders vorgeschrieben, werden bei 3M-Produkten für die Absturzsicherung

werksseitige Mängel bei Verarbeitung und Material für einen Zeitraum von einem Jahr ab dem Datum

der Installation oder der erstmaligen Benutzung durch den ursprünglichen Eigentümer garantiert.

BESCHRÄNKTES RECHTSMITTEL: Nach schriftlicher Mitteilung an 3M wird 3M jedes Produkt ersetzen

oder austauschen, bei dem durch 3M ein werkseitiger Material- oder Verarbeitungsfehler festgestellt

wird. 3M behält sich das Recht vor, die Rücksendung des Produkts an das Werk zur Beurteilung der

Garantieansprüche zu verlangen. Unter dieser Garantie sind keine Schäden am Produkt gedeckt, die auf

Verschleiß, Missbrauch, Transportschäden, Versäumnis der Instandhaltung des Produkts oder sonstige

außerhalb der Kontrolle von 3M liegende Schäden zurückzuführen sind. 3M triff t allein die Entscheidung

über Produktzustand und Garantieoptionen.

Diese Garantie gilt ausschließlich für den ursprünglichen Käufer und ist die einzige, die für

Absturzsicherungsprodukte von 3M maßgeblich ist. Kontaktieren Sie bitte die Kunden-Service-Abteilung,

um Unterstützung zu erhalten.

HAFTUNGSBESCHRÄNKUNG: SOWEIT NACH GELTENDEM RECHT ZULÄSSIG, IST 3M NICHT

HAFTBAR FÜR UNMITTELBARE, MITTELBARE, BESONDERE SCHÄDEN ODER FOLGESCHÄDEN JEDER

ART, EINSCHLIESSLICH VON VERLUST VON GEWINN, DER IM ZUSAMMENHANG MIT DEN PRODUKTEN

ENTSTEHT, UNGEACHTET DER ANGEFÜHRTEN RECHTSTHEORIE.

GARANTÍA GLOBAL DE PRODUCTO, COMPENSACIÓN LIMITADA

Y LIMITACIÓN DE RESPONSABILIDAD

GARANTÍA: LAS SIGUIENTES DISPOSICIONES PREVALECERÁN SOBRE CUALQUIER GARANTÍA O

CONDICIÓN, EXPRESA O IMPLÍCITA, INCLUIDAS LAS CONDICIONES O GARANTÍAS IMPLÍCITAS DE

COMERCIABILIDAD O IDONEIDAD PARA UN FIN ESPECÍFICO.

Salvo que la legislación local estipule lo contrario, los productos de protección contra caídas de 3M están

garantizados contra defectos de fabricación de mano de obra y materiales durante un periodo de un año

a partir de la fecha de instalación o del primer uso por parte del propietario original.

COMPENSACIÓN LIMITADA: Tras recibir comunicación por escrito, 3M reparará o sustituirá los

productos que considere que tienen un defecto de fabricación de mano de obra o materiales. 3M se reserva

el derecho a solicitar la devolución del producto a sus instalaciones para evaluar las reclamaciones de

garantía. Esta garantía no cubre los daños en el producto resultantes de desgaste, mal uso, uso indebido,

daños durante el tránsito, mantenimiento inapropiado del producto o daños que escapen al control de

3M. 3M será el único con derecho a determinar el estado del producto y las opciones de garantía.

Esta garantía puede ser utilizada únicamente por el comprador original y es la única que cubre

los productos de protección contra caídas de 3M. Si necesita ayuda, póngase en contacto con el

departamento de servicios de atención al cliente de 3M.

LIMITACIÓN DE RESPONSABILIDAD: EN LA MEDIDA QUE LO PERMITA LA LEGISLACIÓN LOCAL,

3M NO SE RESPONSABILIZARÁ DE LOS DAÑOS INDIRECTOS, FORTUITOS, ESPECIALES O

RESULTANTES, INCLUIDA LA PÉRDIDA DE GANANCIA, RELACIONADOS DE MANERA ALGUNA CON

LOS PRODUCTOS, INDEPENDIENTEMENTE DE LOS FUNDAMENTOS LEGALES QUE SE ALEGUEN.

GLOBAALI TUOTETAKUU, RAJATTU KORVAUS

JA VASTUUNRAJOITUS

TAKUU: SEURAAVA ON LAADITTU KAIKKIEN SUORIEN TAI EPÄSUORIEN TAKUIDEN TAI EHTOJEN

SIJAAN, MUKAAN LUKIEN EPÄSUORAT TAKUUT MYYNTIKELPOISUUDESTA TAI SOPIVUUDESTA TIETTYYN

TARKOITUKSEEN.

Ellei muutoin paikallisissa laeissa säädetä, 3M-putoamisenestotuotteilla on yhden vuoden takuu

valmistusvirheitä ja materiaalivirheitä koskien asennuspäivästä tai alkuperäisen käyttäjän

ensimmäisestä käyttöpäivästä alkaen.

RAJATTU KORVAUS: Kirjallisella 3M:lle lähetetyllä ilmoituksella 3M korjaa tai vaihtaa kaikki tuotteet,

joissa on 3M:n määrittelemä valmistus- tai materiaalivirhe. 3M pidättää oikeuden vaatia tuotetta

palautettavaksi tehtaalle takuuvaatimusten arvioimiseksi. Tämä takuu ei kata kulumisesta, tuotteen

väärinkäytöstä, kuljetusvahingoista tai tuotteen epäonnistuneesta huollosta aiheutunutta vauriota tai

muuta vauriota, johon 3M ei pysty vaikuttamaan. Tuotteen kunnosta ja takuuvaihtoehdoista päätöksen

tekee ainoastaan 3M.

Tämä takuu koskee vain alkuperäistä ostajaa, ja sitä sovelletaan ainoastaan 3M:n putoamisenestotuotteisiin.

Ota yhteyttä paikalliseen 3M:n asiakaspalveluun saadaksesi apua.

VASTUUNRAJOITUS: PAIKALLISTEN LAKIEN SALLIMISSA MÄÄRIN 3M EI OLE VASTUUSSA MISTÄÄN

EPÄSUORASTA, SATTUMANVARAISESTA, ERITYISESTÄ TAI AIHEUTUNEESTA VAHINGOSTA, MUKAAN

LUKIEN, MUTTA SIIHEN KUITENKAAN RAJOITTUMATTA, TUOTTOJEN MENETTÄMINEN, MILLÄÄN TAVALLA

TUOTTEISIIN LIITTYEN OIKEUSTEORIASTA HUOLIMATTA.

GARANTIE PRODUIT INTERNATIONALE, RECOURS LIMITÉ

ET LIMITATION DE LA RESPONSABILITÉ

GARANTIE : LES DISPOSITIONS SUIVANTES SONT PRISES EN LIEU ET PLACE DE TOUTES LES GARANTIES

OU CONDITIONS, EXPRESSES OU IMPLICITES, Y COMPRIS LES GARANTIES OU CONDITIONS IMPLICITES

DE QUALITÉ MARCHANDE OU D'ADAPTATION À UN USAGE SPÉCIFIQUE.

À moins d’un confl it avec une législation locale, les produits antichute de 3M sont garantis contre les défauts

de fabrication en usine et de matériaux pendant une période d'un an à compter de la date d'installation ou

de la première utilisation par le propriétaire initial.

RECOURS LIMITÉ : Sur demande écrite à 3M, 3M s’engage à réparer ou remplacer tout produit considéré

par 3M comme souff rant d’un défaut de fabrication en usine ou de matériaux. 3M se réserve le droit d’exiger

que le produit lui soit retourné pour une évaluation de la réclamation au titre de la garantie. Cette garantie

ne couvre pas les dommages du produit liés à l’usure, aux abus, à la mauvaise utilisation, aux dommages

liés aux transports, au manque d’entretien du produit ou tout autre dommage indépendant du contrôle

de 3M. 3M sera l’unique juge de la condition du produit et des options de la garantie.

Cette garantie ne s’applique qu’au propriétaire initial et elle constitue l’unique garantie s’appliquant aux

produits antichute de 3M. Veuillez contacter le service à la clientèle 3M de votre région pour obtenir de

l’assistance.

LIMITATION DE LA RESPONSABILITÉ : DANS LES MESURES PERMISES PAR LA LÉGISLATION

LOCALE, 3M N’EST PAS RESPONSABLE POUR TOUT DOMMAGE INDIRECT, ACCESSOIRE, SPÉCIFIQUE OU

CONSÉCUTIF, Y COMPRIS, MAIS SANS S'Y LIMITER, LA PERTE DE PROFITS, LIÉE DE QUELQUE MANIÈRE

QUE CE SOIT AUX PRODUITS, MALGRÉ LA THÉORIE JURIDIQUE REVENDIQUÉE.

GARANZIA GLOBALE SUL PRODOTTO, RIMEDIO LIMITATO

E LIMITAZIONE DI RESPONSABILITÀ

GARANZIA: LA SEGUENTE GARANZIA SOSTITUISCE TUTTE LE GARANZIE O CONDIZIONI, ESPRESSE O

IMPLICITE, COMPRESE LE GARANZIE O CONDIZIONI IMPLICITE DI COMMERCIABILITÀ O IDONEITÀ PER

UN PARTICOLARE SCOPO.

Salvo ove diversamente specifi cato dalle leggi locali, i prodotti di protezione anticaduta 3M sono

garantiti da difetti di fabbricazione e dei materiali per un periodo di un anno dalla data di installazione o

di primo utilizzo da parte del proprietario originale.

RIMEDIO LIMITATO: previa comunicazione scritta a 3M, 3M riparerà o sostituirà qualsiasi prodotto

in cui 3M avrà individuato un difetto di fabbricazione o dei materiali. 3M si riserva il diritto di richiedere

la restituzione del prodotto all'impianto per la valutazione della richiesta di risarcimento in garanzia.

La presente garanzia non copre i danni al prodotto causati da usura, abuso, utilizzo errato, trasporto

o mancata manutenzione del prodotto o altri danni avvenuti fuori dal controllo di 3M. 3M è la sola che

potrà giudicare le condizioni del prodotto e le opzioni di garanzia.

La presente garanzia è valida solo per l’acquirente originale ed è l’unica applicabile ai prodotti di

protezione anticaduta 3M. Per assistenza, contattare il Servizio Clienti di 3M della propria area.

LIMITAZIONE DI RESPONSABILITÀ: NELLA MISURA CONSENTITA DALLE LEGGI LOCALI, 3M NON

RISPONDE DI EVENTUALI DANNI INDIRETTI, INCIDENTALI, SPECIALI O CONSEQUENZIALI COMPRESI,

SENZA LIMITAZIONE, DANNI PER PERDITA DI PROFITTO, IN QUALSIASI MODO COLLEGATI AI

PRODOTTI INDIPENDENTEMENTE DALLA TEORIA LEGALE ASSERITA.

WERELDWIJDE PRODUCTGARANTIE, BEPERKTE VERHAALSMOGELIJKHEID

EN BEPERKING VAN AANSPRAKELIJKHEID

GARANTIE: DE VOLGENDE BEPALING VERVANGT ALLE GARANTIES OF VOORWAARDEN, EXPLICIET

OF IMPLICIET, INCLUSIEF DE IMPLICIETE GARANTIES OF VOORWAARDEN VAN VERKOOPBAARHEID OF

GESCHIKTHEID VOOR EEN BEPAALD DOEL.

Tenzij anders is bepaald door lokale wetgeving, zijn valbeschermingsproducten van 3M voorzien van een

garantie op fabrieksfouten door fabricage- en materiaalgebreken gedurende een periode van één jaar

na de datum van installatie of het eerste gebruik door de oorspronkelijke eigenaar.

BEPERKTE VERHAALSMOGELIJKHEID: Na schriftelijke kennisgeving aan 3M zal 3M eender welk

product repareren of vervangen waarvan 3M heeft vastgesteld dat het een fabrieksfout heeft door

een fabricage- of materiaalgebrek. 3M behoudt zich het recht voor om te eisen dat het product naar

zijn vestiging wordt geretourneerd om garantieaanspraken te beoordelen. Deze garantie is niet van

toepassing op productschade door slijtage, oneigenlijk gebruik, misbruik, transportschade, nalatigheid

bij onderhoud van het product of andere schade waarover 3M geen controle heeft. 3M zal als enige

oordelen over de toestand van het product en garantieopties.

Deze garantie is alleen van toepassing op de oorspronkelijke koper en is de enige garantie die van

toepassing is op valbeschermingsproducten van 3M. Neem contact op met de klantendienst van 3M voor

uw regio als u assistentie wenst.

BEPERKING VAN AANSPRAKELIJKHEID: VOOR ZOVER TOEGESTAAN DOOR LOKALE WETGEVING,

IS 3M NIET AANSPRAKELIJK VOOR ENIGE INDIRECTE, INCIDENTELE, SPECIALE OF GEVOLGSCHADE,

INCLUSIEF, MAAR NIET BEPERKT TOT, WINSTVERLIES, DIE OP ENIGE WIJZE VERBAND HOUDT MET DE

PRODUCTEN, ONGEACHT DE RECHTSLEER DIE WORDT AANGEHAALD.

GLOBAL PRODUKTGARANTI, BEGRENSET AVHJELP

OG BEGRENSNING AV ERSTATNINGSANSVAR

GARANTI: DET FØLGENDE KOMMER I STEDET FOR ALLE GARANTIER ELLER VILKÅR, UTTRYKKELIGE

ELLER UNDERFORSTÅTTE, INKLUDERT DE UNDERFORSTÅTTE GARANTIENE ELLER VILKÅRENE OM

SALGBARHET ELLER EGNETHET FOR ET BESTEMT FORMÅL.

Med mindre annet er bestemt av lokale lover, er 3Ms fallsikringsprodukter garantert mot fabrikasjonsfeil

i håndverksmessig utførelse og materialer for en periode på ett år fra installasjonsdatoen eller første

bruk av den opprinnelige eieren.

BEGRENSET AVHJELP: Ved skriftlig melding til 3M, vil 3M reparere eller erstatte ethvert produkt som

av 3M fastslås å ha en fabrikasjonsfeil i håndverksmessig utførelse eller materialer. 3M forbeholder

seg retten til å kreve at produktet blir levert tilbake til fabrikken for evaluering av garantikrav. Denne

garantien dekker ikke produktskade grunnet slitasje, misbruk, skade i transitt, unnlatelse av å

vedlikeholde produktet eller annen skade utenfor 3Ms kontroll. 3M vil være den eneste til å bedømme

produktvilkår og garantialternativer.

Denne garantien gjelder kun den opprinnelige kjøperen og er den eneste garantien som er anvendelig

for 3Ms fallsikringsprodukter. Vennligst kontakt 3Ms kundeserviceavdeling i ditt område for hjelp.

BEGRENSNING AV ERSTATNINGSANSVAR: I DEN UTSTREKNING DET ER TILLATT AV LOKALE

LOVER, ER IKKE 3M ERSTATNINGSANSVARLIG FOR NOEN SOM HELST INDIREKTE, HENDELIGE,

SPESIELLE ELLER FØLGEMESSIGE SKADER INKLUDERT, MEN IKKE BEGRENSET TIL TAP AV

FORTJENESTE, PÅ NOEN SOM HELST MÅTE FORBUNDET MED PRODUKTENE, UAVHENGIG AV HVILKEN

JURIDISK TEORI SOM PÅBEROPES.

GLOBAL PRODUKTGARANTI, BEGRÄNSAD KOMPENSATION

OCH BEGRÄNSAD ANSVARSSKYLDIGHET

GARANTI: FÖLJANDE GÄLLER SOM ERSÄTTNING FÖR ALLA GARANTIER ELLER VILLKOR, UTTRYCKLIGA

ELLER UNDERFÖRSTÅDDA, INKLUSIVE UNDERFÖRSTÅDDA GARANTIER ELLER VILLKOR FÖR

SÄLJBARHET ELLER LÄMPLIGHET FÖR ETT VISST ÄNDAMÅL.

Såvida inte annat stipuleras i lokala lagar, garanteras 3M:s fallskyddsprodukter mot fabrikationsfel

avseende tillverkning och material under en period av ett år från datum för ursprunglig ägares

installation eller första användning.

BEGRÄNSAD KOMPENSATION: Efter skriftlig avisering till 3M, kommer 3M att reparera eller byta

ut varje produkt, som av 3M fastställts vara behäftad med fabrikationsfel vad gäller tillverkning eller

material. 3M förbehåller sig rätten att kräva att produkt returneras till företagets anläggning för

utvärdering av garantianspråk. Denna garanti omfattar inte produktskada till följd av slitage, felaktig

användning, missbruk, skada under transport, underlåtenhet att sköta produkten eller annan skada

utom 3M:s kontroll. 3M är ensam bedömare av produktskick och garantialternativ.

Denna garanti avser enbart den ursprunglige köparen och är den enda garanti som gäller för

3M:s fallskyddsprodukter. Kontakta 3M:s kundtjänstavdelning i din region för assistans.

BEGRÄNSNING AV ANSVARSSKYLDIGHET: I DEN OMFATTNING SOM TILLÅTS AV LOKALA LAGAR,

ANSVARAR 3M INTE FÖR NÅGRA INDIREKTA, OFÖRUTSEDDA, SPECIELLA ELLER FÖLJDSKADOR,

INKLUSIVE MEN INTE BEGRÄNSAT TILL FÖRLUST AV VINSTER, VILKA PÅ NÅGOT SÄTT HÄNFÖRTS TILL

PRODUKTERNA, OAVSETT HÄVDAD RÄTTSLIG GRUND.

USA

3833 SALA Way

Red Wing, MN 55066-5005

Distributed by Engineered Fall Protection

www.EngineeredFallProtection.com

Tel: (314) 492-4422

ISO

9001

FM534873

EU DECLARATION OF CONFORMITY:

3M

Table of contents

Other DBI SALA Protection Device manuals

Popular Protection Device manuals by other brands

nxt

nxt BIA-nXt-DPC 1-22 Installation and operation manual

TFortis

TFortis SG-Switch operating manual

BERNINI DESIGN

BERNINI DESIGN Be172 instruction manual

Rayleigh Instruments

Rayleigh Instruments RI-ENERGYSET-3P-ESS-50-100 manual

E.K.T.

E.K.T. ke-DP01 quick start guide

Sola HD

Sola HD STV100K Series instruction manual