Tapmaster 1780 User manual

Rev. 1.1

-4-

PH: 800-791-8117

FAX: 403-275-5928

Web: www.tapmaster.ca

E-mail: info@tapmaster.ca

Tapmaster Incorporated

3-1470 28th Street NE

Calgary, AB Canada

T2A 7W6

TROUBLE SHOOTING

FIVE YEAR LIMITED WARRANTY

Congratulations on your purchase of a TAPMASTER Hands Free Faucet Controller.

TAPMASTER products are thoroughly tested before shipment and are warranted to be free of de-

fects in material and workmanship for five years from the date of original purchase. The sole obli-

gation of Tapmaster Incorporated under the warranty is to provide replacement parts or at its op-

tion to repair the defective product or to provide the replacement product. Replacement parts

furnished in fulfillment of this warranty are warranted only for the unused portion of the original

warranty. Labor and shipping charges are not included.

Warranty conditions

- The five year warranty is subject to exclusions and limitations as stated be-

low:

Warranty extends only to defects which occur during normal use and intended applications and

does not extend to damage to products or parts resulting from alteration, repair, modification or

faulty installation. This warranty does not cover damage resulting from water borne debris or from

media other than clean potable water. Tapmaster

Incorporated makes no other express warranty on this product, all implied warranties including any

implied warranty of merchantability and fitness for a particular purpose are hereby disclaimed and

excluded. In no event shall

Tapmaster Incorporated be liable for special, incidental or consequential damages resulting from

the use of this

product or arising from breach of warranty or contract, negligence, loss of time, inconvenience or

loss of use of equipment.

OPERATION

To operate the Tapmaster simply step on the activator disk and open the faucet to the desired flow

and temperature. By stepping off the activator disk or releasing pressure shuts off the water flow

to the faucet. Once the faucet has been adjusted it should be left open. As in other foot operated

devices all operators should allow themselves some time to get accustomed to this unique method

of operation.

The use of short bursts of water as required will maximize water savings.

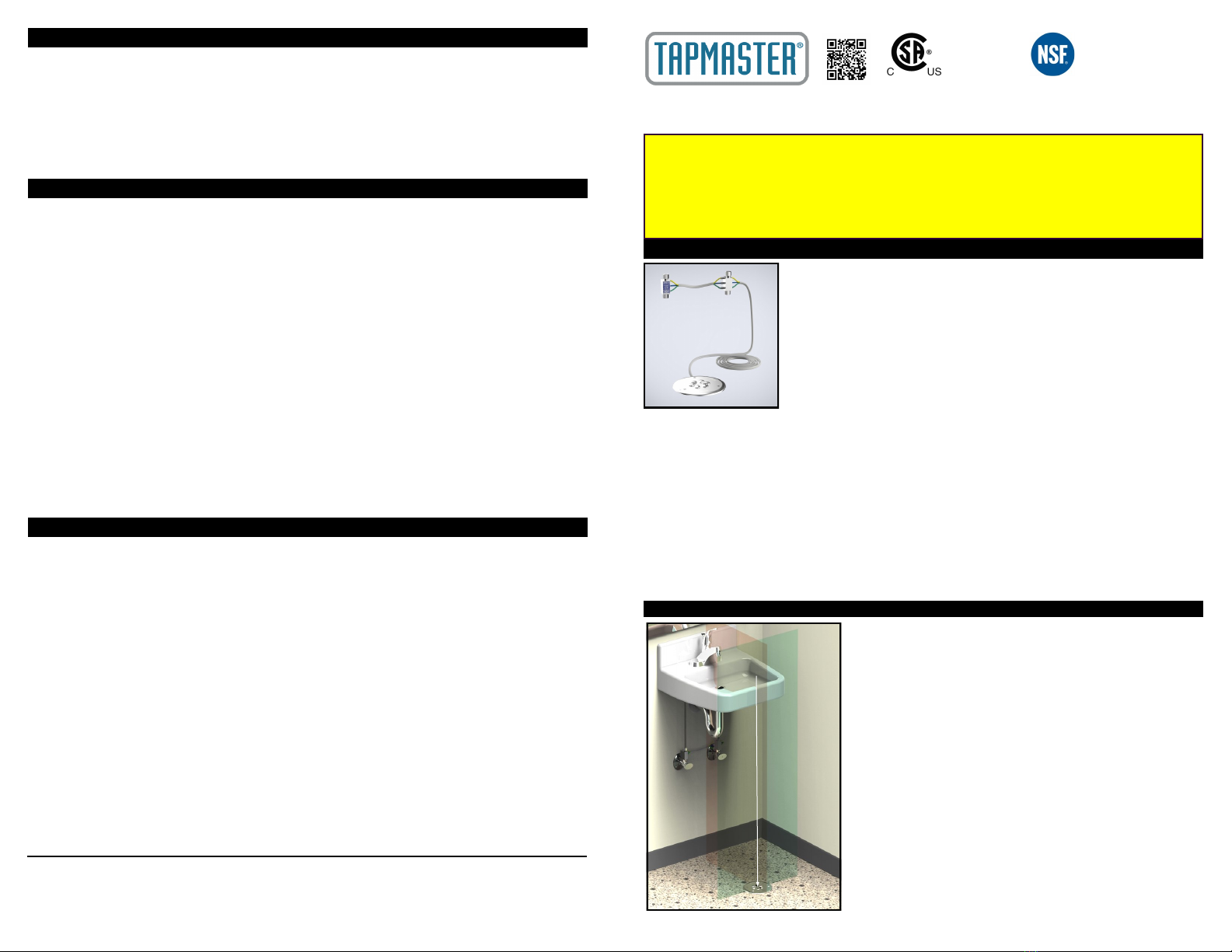

Figur

GENERAL

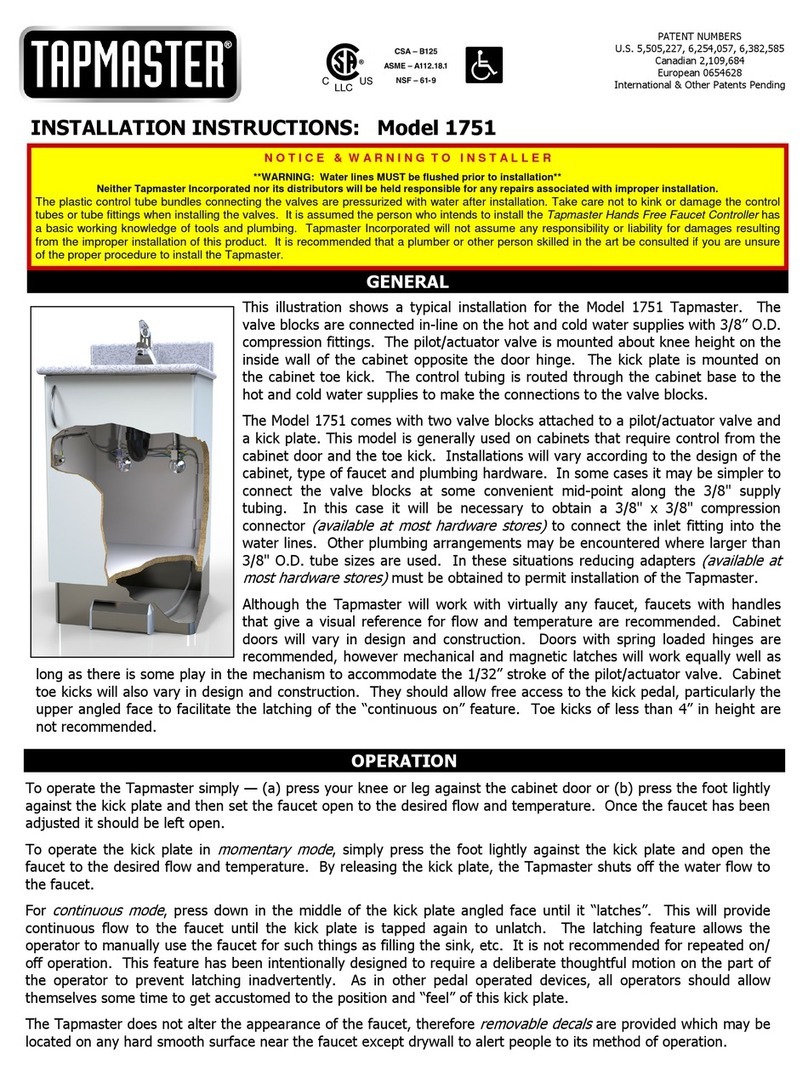

This illustration shows a typical Model 1780 Tapmaster. The valve blocks

connect in-line on the hot and cold water supplies with 3/8” O. D.

compression fittings. The pilot/actuator valve is mounted to the underside

of the activator disk which is mounted to the floor with the three #8 coun-

tersunk screws provided.

Model 1780, shown at left, features two in-line valve blocks, one each for

the hot and cold water lines and one step on activator disk. Model 1781

features one in-line valve block with one step on activator disk and is used

in situations where only one water line (typically tepid or recirculating

warm water systems) is required. Model 1782 is identical to Model 1781

with an additional activator disk added to permit water flow activation from

two separate locations as would be found in an island sink. Model 1784 is identical to Model 1780

with two in-line valve blocks and a second activator disk. Model 1786 features Hot/Warm/Cold

(HWC) temperature selection. Model 1788 is identical to Model 1786 except there are two HWC

disks.

Installation of the valve blocks will vary according to the application. In some cases it may be

simpler to connect the valve blocks at some mid-point along the 3/8" supply tubes. It will be

necessary to obtain a 3/8" x 3/8" compression connector

(available at most hardware stores)

to

connect the inlet fitting to the water lines. Other plumbing arrangements may be encountered

where larger than 3/8" O.D. tube size is used. In these situations reducing adapters

(available at

hardware stores)

must be obtained to permit installation of the Tapmaster.

Although Tapmaster will work with virtually any faucet, faucets that have handles which give a

visual reference for flow and temperature are recommended.

INSTALLATION INSTRUCTIONS: Models 1780, 1781, 1782,

1784,1786 & 1788

INSTALLING THE IN-FLOOR ACTIVATOR

GENERAL: The following instructions for installing the in-floor

activator are for a typical installation and only a guideline.

Whether it is a retrofit situation or a new facility install, sink

arrangements, floor coverings and construction materials will

vary greatly.

LOCATION: As per Figure 1, locate the center of the faucet/

sink and mark this location on the floor. Locate the leading

edge of the sink or counter and extend this line to the floor to

intersect the previously drawn center line. With the template

provided locate the activator disk in the center of this

position.

For new concrete floor installations, the in-floor activator

is design to fit into a standard round PVC "concrete pour type"

in-floor electrical box. These type of electrical boxes are

available from manufacturers such as Hubbel, LEW, Carlon

and Kraloy to name a few. PVC conduit is run from the in-

floor electrical box and out of the wall just underneath the

sink and above the water supply shutoff valves (see Figure 2

next page). After the PVC box is cut as per the manufacturers

instructions and the flooring placed, the Tapmaster activator

disk is ready to be installed.

Figure 1

Symptom Possible Cause Remedy

The hot or cold water is very slow

to turn on

Pinched tubing Check control tubing (yellow

and blue lines)

The hot or cold water is very slow

to shutoff or will not shutoff

Pinched tubing Check control tubing (green

and blue)

Noise from the Valve Blocks while

the water is running

The Valve Block may have

excessive debris trapped under

the Filter-screen

Service the Valve Blocks

Noise from the Valve Blocks when

turning water on and off

Air in the system Operate the pedal on and off

rapidly to clear air from the

valves.

PATENT NUMBERS

U.S. 5,505,227, 6,254,057,

6,382,585

Canadian 2,109,684

European 0654628

International & Other Patents

Pending

CSA-B125.1-18

ASME A112.18.1-2018

NFS/ANSI 61-2016

NSF/ANSI 372-2016

LOW LEAD CONTENT DRINKING WATER

For further information: www.tapmaster.ca or call 800-791-8117

CAUTION - READ BEFORE INSTALLATION

Tapmaster Incorporated will not be held liable for damage to property or persons resulting from improper installation of this product. If you are uncertain about

any part of the installation process, please contact us for assistance or consult a professional tradesperson before installation.

• Water lines must be flushed prior to installation

• Do not install if control tubes are damaged in any way

• Control tubes are pressurized after installation. Do not

expose tubing to excessive heat, unsealed chemicals, or

physical damage

• Use of substitute tubing voids manufacturer warranty and

liability

• Do not expose valves to thread sealants/plumbers putty

• Operating Range: 0 - 125 psi (8.6 bar) Max, 140° F

(60° C) Max

INSTALLING THE VALVE BLOCKS

STEP #2 - Apply a quality silicone caulking compound to the floor

side of the rubber gasket away from the activator disk.

(Warning;

Do not use excessive amount of caulking as this may glue the acti-

vator disk in place and make removal difficult should future service

be required)

With the #8 x 1” stainless steel countersunk screws

provided mount the activator disk to the finished floor. Use the

concrete anchors provided if required

(Model 1780 in-floor activators

are provided with regular #2 Phillips head screws or tamper-

resistant 5/32" center to center hole type screws upon request).

CAUTION DO NOT OVER TIGHTEN SCREWS particularly on

uneven floor coverings such as ceramic or porcelain tile. This may

damage the disk, cause it to warp and become unusable. Extra

caulking or mortar may be required to "bridge" uneven sections. If

the mounting service is exceptionally uneven use 3/16” ID washers

on the screws between the activator disk and floor to bridge the

gaps. The activator disk must be installed completely level and sta-

ble. If there are any questions or concerns in this or any other re-

gard please do not hesitate to contact us at 1-800-791-8117 and

ask for tech support.

Tapmaster valve blocks are connected in-line between the hot and cold

shut off valves and the faucet tubes as shown in Figure 2.

(Note:

The valve blocks are identical in function and may be used on either

hot or cold water lines. Position them according to how the control

tubing will be routed).

STEP #1 - Hook up the control tubes from the floor activator to the

valve block with the plastic sleeves provided as per the color-coded

arrangement in Figure 7.

(Note: To facilitate the installation of the

tubing and sleeves, dip the ends of the tubing into hot soapy water

and, using a pair of needle nose pliers, push the tubing on to the barb fittings. An adjustable

wrench opened to the diameter of the tubing will assist in pushing on the sleeves. Take care not

to damage the barb fittings or crush the tubes).

If a tube must be removed from a barb fitting,

split the tube along its length with a sharp knife

(Do not pull as this may damage the barb).

STEP #2 - Turn off the water supplies and place a bucket underneath the shut off valves to

catch water that may run out of the plumbing.

(Hint: Closing the faucet handles will minimize

leakage)

. Loosen the compression nuts on the riser tubes from the faucet at the shut-off valves. If

the faucet utilizes copper tube risers, bend and reposition the tubes in such a manner as to create

a 1-1/2" gap

(Do not kink).

To simplify the installation, replace the copper risers with flex risers

(available at most hardware stores)

. If this cannot be readily accomplished

the tubes will have to be shortened approximately 1-1/2”. Cut the tubes with

a tube cutter. If a tube cutter is not available a hacksaw may be used,

however be sure to de-bur and square the ends. Extra compression nuts and

sleeves are provided should the tubes need to be cut.

STEP #3 - Prior to installing the valve blocks, open the shut-off valves

momentarily to flush out any debris in the water lines. Large pieces of water

borne debris will be trapped by the filter/screen in the valve blocks and may

reduce water flow or cause noisy operation. As shown in Figure 8 connect

the valve block(s) with the integrated nut (input) to the shutoff fitting and the

faucet riser to the compression thread (output). Finger tighten only until both

valve blocks are in position. Be sure the plastic control tubing and fittings are

not damaged in any manner.

STEP #4 - Proceed to tighten the compression nuts using a 5/8” wrench on

the nut and a 7/8” wrench on the valve block body . Do not over tighten 3/8”

compression fittings with O-ring seals such as the valve block input

fitting. Hand tighten plus 1/2 turn with wrench.

STEP #5 - Verify that all connections are tight. Turn on the water supply

(s) and inspect all connections for leaks. Set the faucet, both hot and cold,

completely open and push the bar activator to start the water flow. Operate

the bar activator on and off rapidly to clear air from the valves. The valves

may experience some noise during on or off operation until the air is cleared.

Allow significant time to pass and then re-inspect all connections for leaks

(Small leaks may take several minutes to show up).

Figure 8

RISER

OUTPUT

INPUT

SHUTOFF

TUBE BUNDLES

MODEL 1786

SHOWN

The activator disk is

momentarily attached to

the optional PVC box

adapter ring (see Figure 3)

with the #8 x 1” stainless

steel countersunk screws .

PVC cement is applied to

the adapter ring, glued in

place and the activator disk

removed.

Retrofit installations will

vary according to the type

of floor, the availability, and

if any access underneath

the floor and the extent of

other renovations that may

be done in conjunction with

the Tapmaster install. For

example, for an "on-

slab" (concrete floor - no

under floor access) with a

floor covering replacement,

it would involve cutting a small trench to accommodate a

small diameter plastic or metal tube (eg:1/2" PEX, soft or rigid copper) routed up into the wall

underneath the sink through which the control tube bundle may be routed (see Figure 4). A

small pocket would also be cut into the concrete to accommodate the actuator valve on the

underside of the activator disk. The trench may be filled in , the floor covering installed and

finally the control tube bundle fished through the tube and the activator disk mounted to the floor

with concrete anchors.

In a situation where the floor covering, such as ceramic or porcelain tile is to be left in place, a

slot may be cut into the tile to accommodate the control tube bundle, routed into surface mount

plastic conduit for the wall, and the control tube bundle grouted into the floor (see Figure 5).

Another example of a retrofit installation would be a wood floor with access underneath (see

Figure 6). This situation would involve drilling a 2" (50mm) hole in the floor. Another hole

drilled through the floor to allow access into the wall and other to allow access through the wall

underneath the sink. (

Note: model 1786 HWC requires a 4" [100mm] hole to accommodate 2

actuator valves).

The control tube bundle is fished through these holes and the activator disk

mounted onto the floor with the template and screws provided.

Another example would be a concrete floor with access underneath. In this situation a may be

simpler to drill or core one

hole at the activator disk

location and another to

permit access into the wall

behind you and the sink. A

"U" shaped piece of conduit

or plastic pipe (depending on

local codes) could be

installed to allow the control

tube bundle to be fished

through underneath the sink.

This example is only one of

many possible solutions to

route the control tube

bundle.

STEP #1 Route the control

tube bundle through the

rubber gasket supplied and

route the control tube

bundle through the floor/wall

to the water line shutoff(s).

(see Figure 2 & 3 for PVC

box install and figure 4, 5 &

6 for retrofit install)

The control tube bundle may

be shortened . Be sure not to kink or damage the control

tubes in any way.

Figure 5

CONCRETE

ANCHORS (3)

SCREWS (3)

#8 x 1-1/4

CS

CONTROL

TUBE BUN-

DLE

THROUGH

SLOT CUT TILE

AND REGROUT

SCREWS (3)

#8 x 1-1/4 CS

INSTALLER SUPPLIED CAULKING

IN-FLOOR

ELECTRICAL

BOX

TUBE BUNDLE

ACTIVATOR DISK

Figure 2

PVC ELECTRICAL

BOX

PVC CONDUIT

Figure 4

POCKET CUT

INTO TILE/

CONCRETE

PIPE CUT INTO FLOOR

-2- -3-

Figure 7

Figure 3

Figure 6

This manual suits for next models

5

Other Tapmaster Bathroom Aid manuals