Tapmaster 1751 User manual

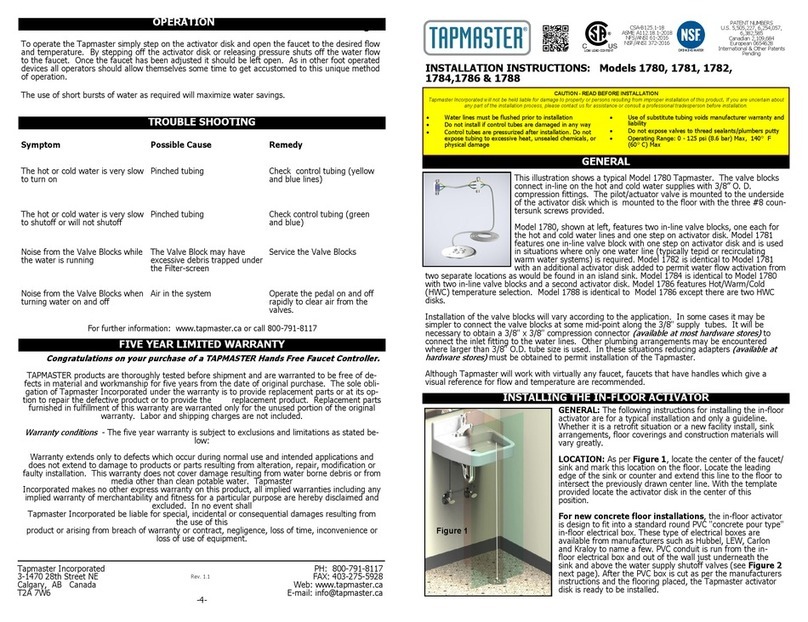

GENERAL

This illustration shows a typical installation for the Model 1751 Tapmaster. The

valve blocks are connected in-line on the hot and cold water supplies with 3/ ” O.D.

compression fittings. The pilot/actuator valve is mounted about knee height on the

inside wall of the cabinet opposite the door hinge. The kick plate is mounted on

the cabinet toe kick. The control tubing is routed through the cabinet base to the

hot and cold water supplies to make the connections to the valve blocks.

The Model 1751 comes with two valve blocks attached to a pilot/actuator valve and

a kick plate. This model is generally used on cabinets that require control from the

cabinet door and the toe kick. Installations will vary according to the design of the

cabinet, type of faucet and plumbing hardware. In some cases it may be simpler to

connect the valve blocks at some convenient mid-point along the 3/ " supply

tubing. In this case it will be necessary to obtain a 3/ " x 3/ " compression

connector

(available at most hardware stores)

to connect the inlet fitting into the

water lines. Other plumbing arrangements may be encountered where larger than

3/ " O.D. tube sizes are used. In these situations reducing adapters

(available at

most hardware stores)

must be obtained to permit installation of the Tapmaster.

Although the Tapmaster will work with virtually any faucet, faucets with handles

that give a visual reference for flow and temperature are recommended. Cabinet

doors will vary in design and construction. Doors with spring loaded hinges are

recommended, however mechanical and magnetic latches will work equally well as

long as there is some play in the mechanism to accommodate the 1/32” stroke of the pilot/actuator valve. Cabinet

toe kicks will also vary in design and construction. They should allow free access to the kick pedal, particularly the

upper angled face to facilitate the latching of the “continuous on” feature. Toe kicks of less than 4” in height are

not recommended.

OPERATION

To operate the Tapmaster simply — (a) press your knee or leg against the cabinet door or (b) press the foot lightly

against the kick plate and then set the faucet open to the desired flow and temperature. Once the faucet has been

adjusted it should be left open.

To operate the kick plate in

momentary mode

, simply press the foot lightly against the kick plate and open the

faucet to the desired flow and temperature. By releasing the kick plate, the Tapmaster shuts off the water flow to

the faucet.

For

continuous mode

, press down in the middle of the kick plate angled face until it “latches”. This will provide

continuous flow to the faucet until the kick plate is tapped again to unlatch. The latching feature allows the

operator to manually use the faucet for such things as filling the sink, etc. It is not recommended for repeated on/

off operation. This feature has been intentionally designed to require a deliberate thoughtful motion on the part of

the operator to prevent latching inadvertently. As in other pedal operated devices, all operators should allow

themselves some time to get accustomed to the position and “feel” of this kick plate.

The Tapmaster does not alter the appearance of the faucet, therefore

removable decals

are provided which may be

located on any hard smooth surface near the faucet except drywall to alert people to its method of operation.

INSTALLATION INSTRUCTIONS: Model 1751

PATENT NUMBERS

U.S. 5,505,227, 6,254,057, 6,3 2,5 5

Canadian 2,109,6 4

European 065462

International & Other Patents Pending

LLC

N O T I C E & W A R N I N G T O I N S T A L L E R

**WARNING: Water lines MUST be flushed prior to installation**

Neither Tapmaster Incorporated nor its distributors will be held responsible for any repairs associated with improper installation.

The plastic control tube bundles connecting the valves are pressurized with water after installation. Take care not to kink or damage the control

tubes or tube fittings when installing the valves. It is assumed the person who intends to install the Tapmaster Hands Free Faucet Controller has

a basic working knowledge of tools and plumbing. Tapmaster Incorporated will not assume any responsibility or liability for damages resulting

from the improper installation of this product. It is recommended that a plumber or other person skilled in the art be consulted if you are unsure

of the proper procedure to install the Tapmaster.

-2-

These cutaway views of various cabinet styles provide illustrations for some of the many

possibilities of positioning the pilot/actuator valve using the door as an activator. The

activator does not necessarily have to be a door. The possibilities are only limited by the

hardware available and the imagination of the installer. Any surface or panel where a

slight movement

(approximately 1/32”)

can be created which can be pressed by the knee,

leg or hip has the potential to be a hands free activator.

INSTALLING THE PILOT/ACTUATOR VALVE

First determine a height location where the pilot/

actuator valve is to be mounted on the inside of the

cabinet opposite the door hinge, preferably about

knee height or higher. The objective is to mount

the pilot/actuator valve so that the inside face of

the cabinet rests against the button of the pilot/

actuator valve. This will set the door ajar very

slightly, about 1/32".

STEP #1 - Fasten the mounting bracket with the

wood screws and washers provided, ensuring that

there is approximately 1/4" gap between the inside

of the door and the face of the mounting bracket

(see illustration).

STEP #2 - Mount the pilot/actuator valve onto

the mounting bracket ensuring the inside of the

door rests against the button of the pilot/actuator valve. To adjust the position of the pilot/actuator valve relative to

the door, use the screw slots on the mounting bracket as a coarse adjustment and the 15/32-32 hex nuts on the pilot/

actuator valve body as a fine adjustment. The pilot/actuator should be positioned to assure full travel of the button of

the pilot/actuator valve while minimizing how far the door is set ajar or offset

(Hint: Set the first nut on the pilot/

actuator valve all the way down on the stem and adjust second nut until the valve is properly adjusted then tighten the

first nut to secure the valve).

STEP #3 - Route the control tubing with the self-adhesive plastic clips provided. The control tubing is pressurized, be

sure it is properly secured to prevent accidental damage by cabinet doors, hinges or objects being transferred in and

out of the cabinet.

INSTALLING THE PILOT/ACTUATOR VALVE IN VARIOUS CABINETS

1/4” Gap

Use bracket mounting screws

for coarse adjustment.

Use valve

mounting

nuts for fine

adjustment.

Ca inet Door

The kick plate assembly may require adjustment from time to time to compensate for wear in the

latching mechanism or simply adjusted to suit personal preference. The latch may be set to operate

heavy or sensitive as a “hair trigger” depending upon the position of the pilot/actuator valve in the kick

plate base.

STEP # 1 - Remove the kick plate assembly from cabinet toe kick and then remove the end cap.

(Note:

To adjust the kick plate properly one should be able to see through the assembly as per Figure 6)

STEP # 2 - Proceed to adjust the mounting height of the pilot/actuator valve by adjusting the valve

body mounting nuts until there is approximately a 0.02” air gap between the black button of the pilot/

actuator valve and the inside of the cover. Be sure to hold the hook of the cover against the catch of

the base to take up any play

(Note: Repositioning the nuts by as little as half a turn is often adequate)

STEP # 3 - Test the assembly for proper operation using your hands only. In momentary mode (

pressing the vertical

face

) the cover should move freely and the black button should bottom out before the hook of the cover bottoms

against the base. In continuous mode (

pressing the angled face)

the top of the cover should return to its unlatched

position by a firm tap against the bottom vertical face of the cover. If the cover unlatches with difficulty, the gap will

need to be increased. If the cover does not latch at all or is on a “hair trigger”, decrease the gap. Remount the kick

plate to the cabinet toe kick as per instructions above.

Start by determining whether the control tubing will be routed through the

base of the kick plate as in Figure 1, or through the kick plate end cap as

in Figure 2. It is recommended the kick plate be positioned as to be

aligned with the center of the faucet/sink. Alternately, it may be posi-

tioned to best suit the needs of the end user.

CONTROL TUBING ROUTED THROUGH KICK PLATE BASE (Figure 1)

STEP #1 - Drill a 1/2” to 2” hole in the cabinet toe kick and similar size

hole in the back of the inside of the cabinet floor. Using a “fish tape”, wire

or other means, pull the control tubing through the holes. Be sure not to kink the tubing

(Note: The kick plate will

cover the hole in the toe kick and the hole size will determine how easily the control tubing will be fished through. Hint:

Drilling a hole large enough in the back of the cabinet to accommodate a finger will allow one to” feel” for the wire)

Before drilling the holes, make sure there are no utilities in behind the cabinet

panels which may be damaged.

STEP #2 - Remove the end cap by removing the two screws on the end cap and

slide off the cover

(Note: The end caps fit snug to prevent them from coming

loose over time. They may require tapping or prying to remove)

.

STEP #3 - Momentarily reassemble the end cap back on the aluminum base.

Temporarily remove the control tube bundle and the snap pushing from its hole in

the base. Place the assembly against the toe kick. With the end caps resting on

the floor and the center of the kick plate assembly aligned with the center of the

sink/faucet, mount the kick plate with the two # x 3/4” pan head Phillips screws

provided.

STEP #4 - Remove the end cap. Slide the cover back on the kick plate base, by pressing down on each spring in suc-

cession while the cover is slid on. Remount the end cap.

CONTROL TUBING ROUTED THROUGH PEDAL END CAP (Figure 2)

It is recommended that the control tubing be routed on the inside of the hinge side of the cabinet door.

STEP #1 - Remove the end cap which the tubing is to be routed through by removing the two screws

on the end cap and slide off the cover

(Note: The end caps fit snug to prevent them from coming loose

over time. They may require tapping or prying to remove)

.

STEP #2 - Drill a 5/16” hole through the end cap using the upper of the two cone shaped recesses on

the inside of the end cap as a guide (see Figure 3).

Repeat STEP #3 and STEP #4 as above.

Drill

5/16”

Hole

Figure 3

INSTALLING THE KICK PLATE

-3-

Figure 1

End Cap

Control Tube Bundle Bushing

ADJUSTING THE KICK PLATE

Base

Actuator Valve

Figure 2

Springs

-4-

INSTALLING THE VALVE BLOCKS

The Tapmaster valve blocks are connected in-line between the hot and cold shut off valves and the faucet tubes as

shown in Figure 2.

(Note: The valve blocks are identical in function and may be used on either hot or cold water

lines. Position them according to how the control tubing will be routed). (Small leaks may take several minutes to

show up).

STEP #1 - Hook up the control tubing from the pilot/actuator to the valve

block with the plastic sleeves provided as per Figure 1. (Note: To facilitate

the installation of the tubing and sleeves, dip the ends of the tubing into hot

soapy water and using a pair of needle nose pliers push the tubing on to the

barb fittings. An adjustable wrench opened to the diameter of the tubing will

assist in pushing on the sleeves.

Take care not to damage the barb fittings or

crush the tubes.

If a tube must be removed from a barb fitting, split the tube

along its length with a sharp knife

(Do not pull as this may damage the barb).

STEP #2 - Turn off the water supplies

and place a bucket underneath the shut

off valves to catch water that may run out of the plumbing.

(Hint: Closing the

faucet handles will minimize leakage)

. Loosen the compression nuts on the con-

necting 3/ ” O.D. supply tubes, at the shut off valves. If the faucet utilizes cop-

per tube risers, bend and reposition the tubes in such a manner as to create a 1-

1/2" gap

(Do not kink).

To simplify the installation, replace the copper risers with

flex risers

(available at most hardware stores)

. If this cannot be readily

accomplished the tubes will have to be shortened approximately 1-1/2”. Cut the

tubes with a tube cutter. If a tube cutter is not available a hacksaw may be used,

however be sure to de-bur and square the ends. Extra compression nuts and

sleeves are provided should the tubes need to be cut.

STEP #3 - Prior to installing the valve blocks, open the shut-off valves

momentarily to flush out any debris in the water lines. Large pieces of water

borne debris will be trapped by the filter/screen in the valve blocks and may

reduce water flow or cause noisy operation. As shown in Figure 2 connect the

valve block(s) with the integrated nut (input) to the shutoff fitting and the faucet

riser to the compression thread (output). Finger tighten only until both valve

blocks are in position. Be sure the plastic control tubing and fittings are not

damaged in any manner.

STEP #4 - Proceed to tighten the compression nuts using a 5/ ” wrench on the

nut and a 7/ ” wrench on the valve block body . Do not over tighten 3/ ” com-

pression fittings with O-ring seals such as the valve block input fitting. Hand

tighten plus 1/2 turn with wrench.

STEP #5 - Verify that all connections are tight. Turn on the water supply(s)

and inspect all connections for leaks. Set the faucet, both hot and cold,

completely open and push the cabinet door to activate the water flow. Operate

the Tapmaster on and off rapidly to clear air from the valves. The valves may

experience some noise during on or off operation until the air is cleared. Allow

significant time to pass and then re-inspect all connections for leaks

(Small leaks

may take several minutes to show up).

Figure 1

Figure 2

FAUCET

RISER

OUTPUT

INPUT

SHUTOFF

TROUBLE SHOOTING

FIVE YEAR LIMITED WARRANTY

Congratulations on your purchase of TAPMASTER Hands Free Faucet Controller.

TAPMASTER products are thoroughly tested before shipment and are warranted to be free of defects in material and

workmanship for five years from the date of original purchase. The sole obligation of Tapmaster Incorporated under

the warranty is to provide replacement parts or at its option to repair the defective product or to provide the

replacement product. Replacement parts furnished in fulfillment of this warranty are warranted only for the unused

portion of the original warranty. Labor and shipping charges are not included.

Warranty conditions

- The five year warranty is subject to exclusions and limitations as stated below:

Warranty extends only to defects which occur during normal use and intended applications and does not extend to

damage to products or parts resulting from alteration, repair, modification or faulty installation. This warranty does

not cover damage resulting from water borne debris or from media other than clean potable water. Tapmaster

Incorporated makes no other express warranty on this product, all implied warranties including any implied warranty

of merchantability and fitness for a particular purpose are hereby disclaimed and excluded. In no event shall

Tapmaster Incorporated be liable for special, incidental or consequential damages resulting from the use of this

product or arising from breach of warranty or contract, negligence, loss of time, inconvenience or loss of use of

equipment.

Symptom Possi le Cause Remedy

The hot or cold water Pinched tubing Check control tubing

is very slow to turn on (yellow and blue)

or will not turn on

The hot or cold water Pinched tubing Check control tubing

is very slow to shutoff (green and blue)

or will not shutoff

Noise from the Valve Blocks The Valve Block may have Service the Valve Blocks

while the water is running excessive debris trapped under

its Filter-screen

Noise from the Valve Blocks Air in the system Operate the pedal on and off

when turning water on and off rapidly to clear air from the

valves.

Further information: www.tapmaster.ca or call 00-791- 117

Rev. 2.2

-5-

PH: 00-791- 117

FAX: 403-275-592

Web: www.tapmaster.ca

E-mail: [email protected]

Tapmaster Incorporated

20175 Township Rd 262

Calgary, AB Canada

T3P 1A3

Table of contents

Other Tapmaster Bathroom Aid manuals

Popular Bathroom Aid manuals by other brands

Cobi Rehab

Cobi Rehab XXL-Rehab Rise N Tilt user manual

Invacare

Invacare 9630E Styxo Assembly, installation and operating instructions

Leckey

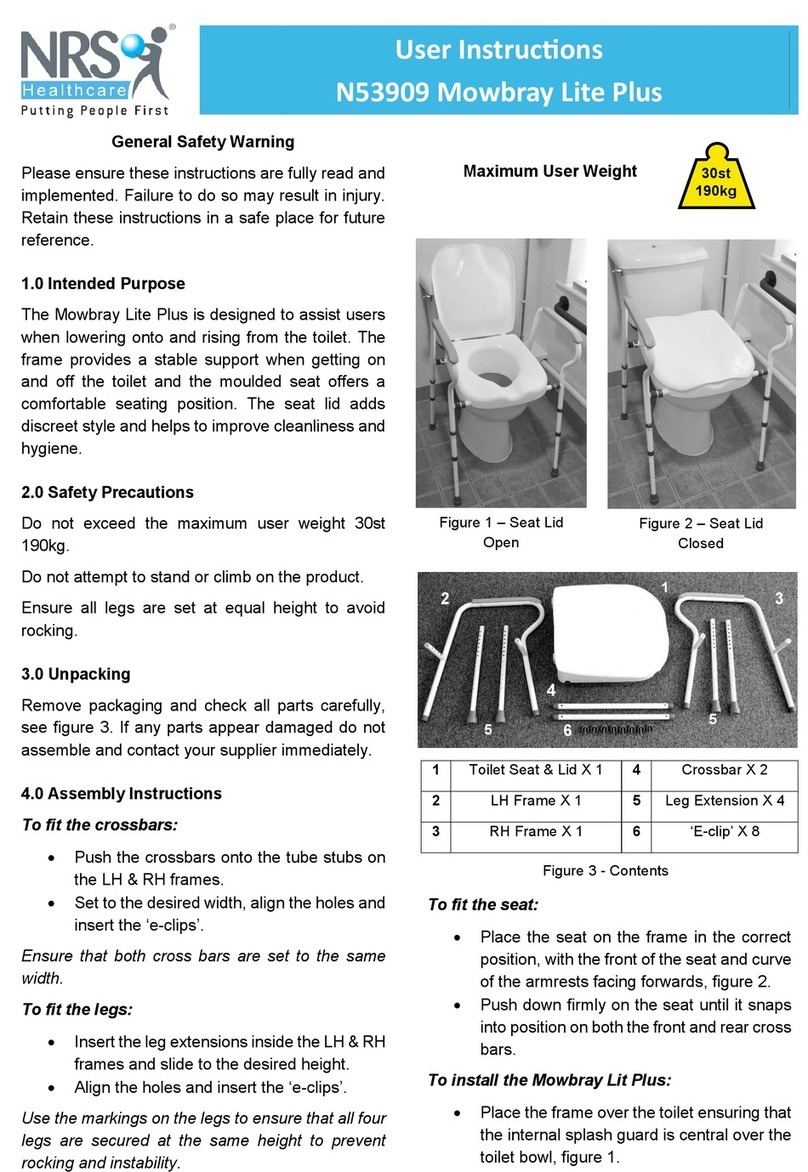

Leckey firefly splashy BIG user manual

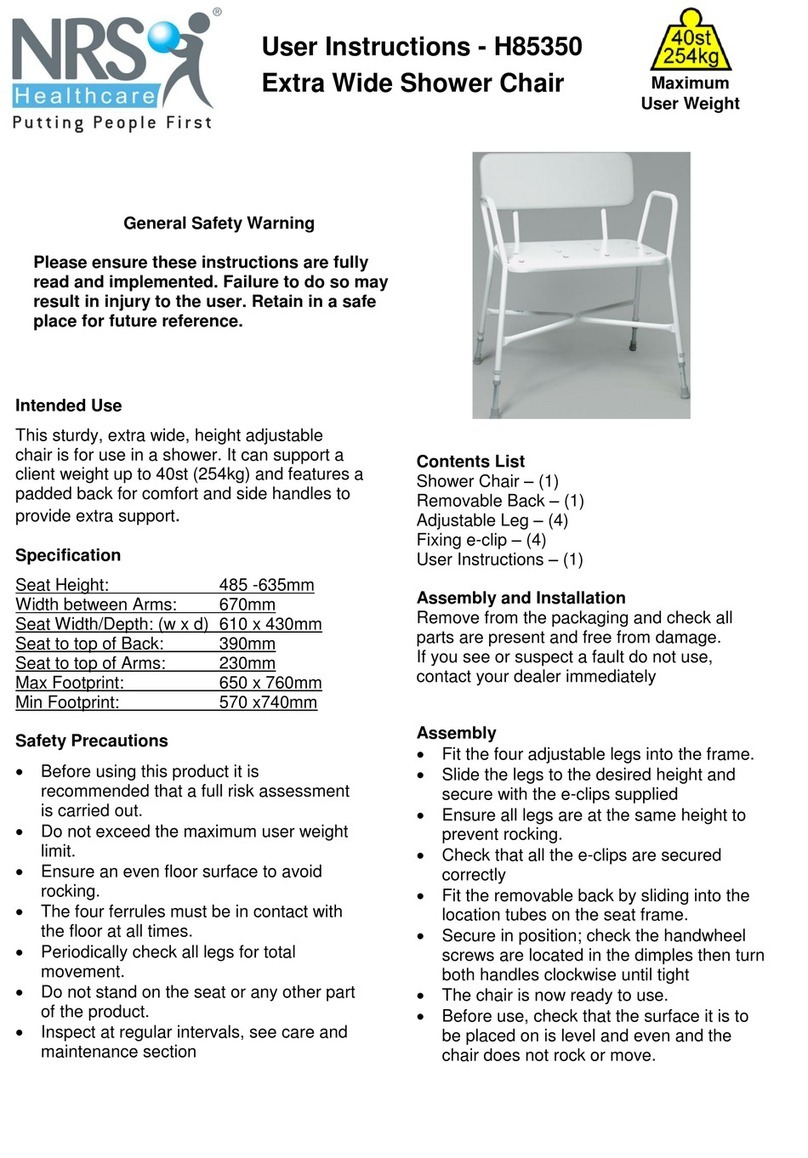

NRS Healthcare

NRS Healthcare H85350 User instructions

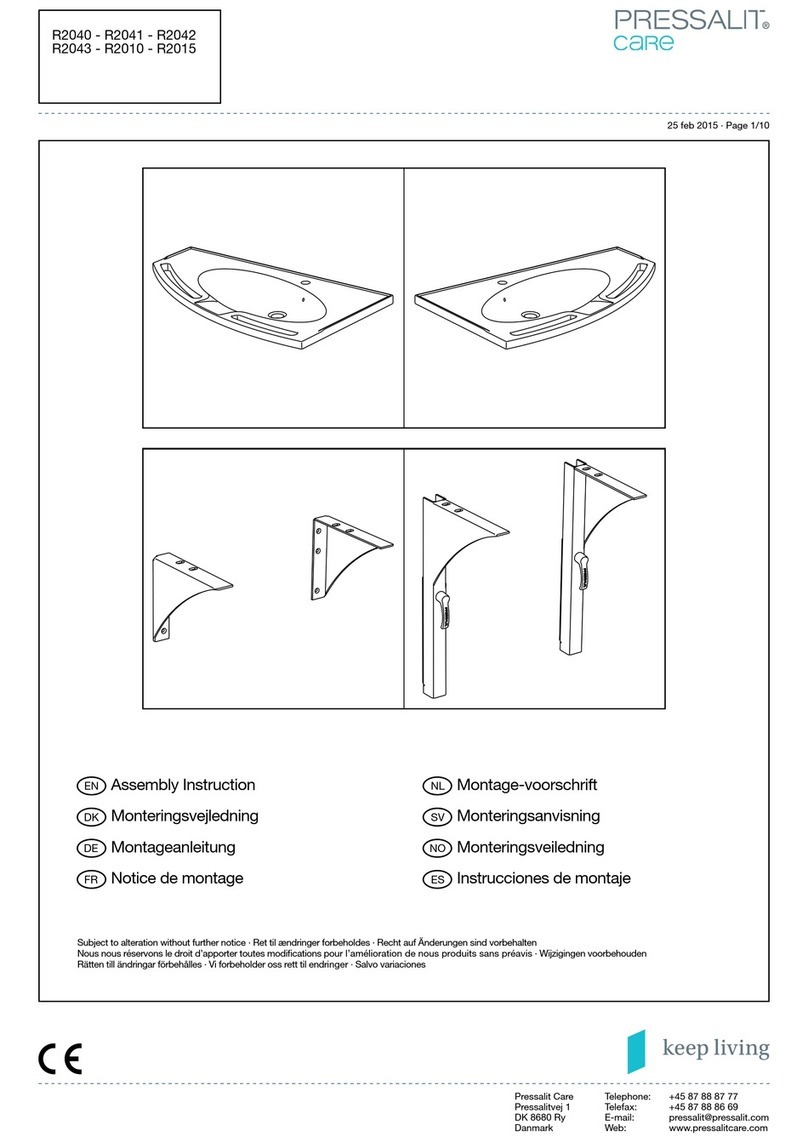

Pressalit Care

Pressalit Care R2040 Assembly instruction

WENKO

WENKO 23285100 Assembly instructions