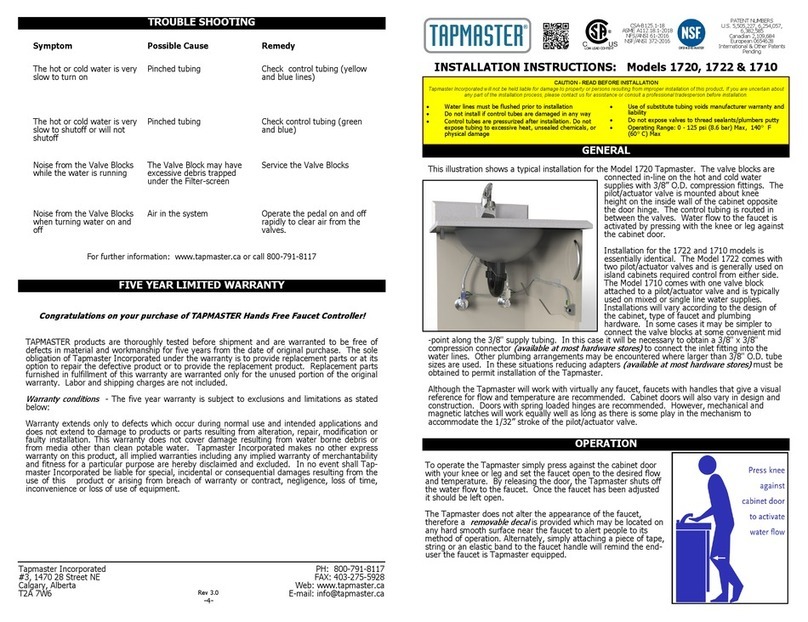

Start by determining whether the control tubing will

be routed through the base of the kick plate as in

Figure 1, or through the kick plate end cap as in

Figure 2. It is recommended the kick plate be posi-

tioned as to be aligned with the center of the faucet/

sink.

CONTROL TUBING ROUTED THROUGH KICK

PLATE BASE (Figure 1)

STEP #1 - Drill a 1/2” to 2” hole in the cabinet toe

kick and similar size hole in the back of the inside of

the cabinet floor. Using a “fish tape”, wire or other means, pull the control tubing through the

holes. Be sure not to kink the tubing

.

Before drilling the holes, make sure there are no utilities in

behind the cabinet panels which may be damaged.

STEP #2 - Remove the end cap by removing the two screws on the end cap and slide off the

cover

(They may require tapping or prying to remove)

.

STEP #3 - Momentarily reassemble the end cap back on the aluminum base. Temporarily re-

move the control tube bundle and the snap pushing from its hole in the base. Place the assembly

against the toe kick. With the end caps resting on the floor and the center of the kick plate

assembly aligned with the center of the sink/faucet, mount the kick plate with the two #8 x 3/4”

pan head Phillips screws provided.

STEP #4 - Remove the end cap. Slide the cover back on the kick plate base, by pressing down

on each spring in succession while the cover is slid on. Remount the end cap.

CONTROL TUBING ROUTED THROUGH PEDAL END CAP (Figure 2)

It is recommended that the control tubing be routed

on the inside of the hinge side of the cabinet door.

STEP #1 - Remove the end cap

which the tubing is to be routed

through by removing the two

screws on the end cap and slide

off the cover

(They may require

tapping or prying to remove)

.

STEP #2 - Drill a 5/16” hole

through the end cap using the

upper of the two cone shaped

recesses on the inside of the end

cap as a guide (see Figure 3).

Repeat STEP #3 and STEP #4 as above.

Drill

5/16”

Hole

Figure 3

INSTALLING THE VALVE BLOCKS

INSTALLING THE KICK PLATE

The Tapmaster valve blocks are connected in-line between the

hot and cold shut off valves and the faucet tubes as shown in

Figure 4. The valve blocks are identical in function and may be

used on either hot or cold water lines. Position them according

to how the control tubing will be routed.

STEP #1 - Connect the control tubes from the kick plate to the

valve block with the plastic sleeves provided as per the color-

coded arrangement in Figure 4. To ease installation, dip the

ends of the tubing into hot soapy water and, using needle nose

pliers, push the tubing on to the barb fittings. An adjustable

wrench opened to the diameter of the tubing will assist in pushing on the sleeves. Take care not

to damage the barb fittings or crush the tubes

.

If a tube must be removed from a barb fitting, split

the tube with a sharp knife

(Do not pull as this may damage barbs).

Figure 4

-2-

Figure 1

End Cap

Control Tube Bundle Bushing

Figure 2

Base

Actuator Valve

Springs

The kick plate assembly may require adjustment from time to

time to compensate for wear in the latching mechanism or

simply adjusted to suit personal preference. The latch may

be set to operate heavy or sensitive depending upon the

position of the pilot/actuator valve in the kick plate base.

STEP # 1 - Remove the kick plate assembly from cabinet

toe kick and then remove the end cap

(To adjust the kick

plate properly one should be able to see through the

assembly as per Figure 6).

STEP # 2 - Proceed to adjust the mounting height of the

pilot/actuator valve by adjusting the valve body mounting

nuts until there is approximately a 0.02” air gap between the

black button of the pilot/actuator valve and the inside of the

cover. Be sure to hold the hook of the cover against the

catch of the base to take up any play

(Note: Repositioning

the nuts by as little as half a turn is often adequate)

STEP # 3 - Test the assembly for proper operation using

your hands only. In momentary mode (

pressing the vertical

face

) the cover should move freely and the black button

should bottom out before the hook of the cover bottoms

against the base. In continuous mode (

pressing the angled

face)

the top of the cover should return to its unlatched

position by a firm tap against the bottom vertical face of the

cover. If the cover unlatches with difficulty, the gap will

need to be increased. If the cover does not latch at all or is

too sensitive, decrease the gap. Remount the kick plate to

the cabinet toe kick as per instructions above.

ADJUSTING THE KICK PLATE

-3-

STEP #2 - Turn off the water supplies and place a bucket

underneath the shut off valves to catch water that may run out of

the plumbing.

(Closing the faucet handles will minimize leakage)

.

Loosen the compression nuts on the connecting 3/8” O.D. supply

tubes, at the shut off valves. If the faucet utilizes copper tube risers,

bend and reposition the tubes in such a manner as to create a 1-

1/2" gap

(DO NOT KINK).

To simplify the installation, replace the

copper risers with flex risers

(available at hardware stores)

. If this

cannot be readily accomplished the tubes will have to be shortened

approximately 1-1/2”. Cut the tubes with a tube cutter. If a tube

cutter is unavailable a hacksaw may be used, however be sure to de

-bur and square the ends. Extra compression nuts and sleeves are

provided should the tubes need to be cut.

STEP #3 - Prior to installing the valve blocks, open the shut-off

valves momentarily to flush out any debris in the water lines. Large

pieces of water borne debris will be trapped by the filter/screen in

the valve blocks and may reduce water flow or cause noisy

operation. As shown in Figure 5 connect the valve block(s) with the

integrated nut (input) to the shutoff fitting and the faucet riser to

the compression thread (output). Finger tighten only until both valve

blocks are in position. Be sure the plastic control tubing and fittings

are not damaged.

STEP #4 - Proceed to tighten the compression nuts using a 5/8”

wrench on the nut and a 7/8” wrench on the valve block body . Do

not over tighten 3/8” compression fittings with O-ring seals such as

the valve block input fitting. Hand tighten plus 1/2 turn with

wrench.

STEP #5 - Verify that all connections are tight. Turn on the water

supply(s) and inspect all connections for leaks. Set the faucet, both

hot and cold, completely open and push the kick place to activate

the water flow. Operate the kick plate on and off rapidly to clear air

from the valves. The valves may exhibit noise until the air is cleared.

Figure 5

FAUCET

RISER

OUTPUT

INPUT

SHUTOFF

LOCK

Figure 6

HOOK

CATCH

0.02”

MOMENTARY

& UNLOCK