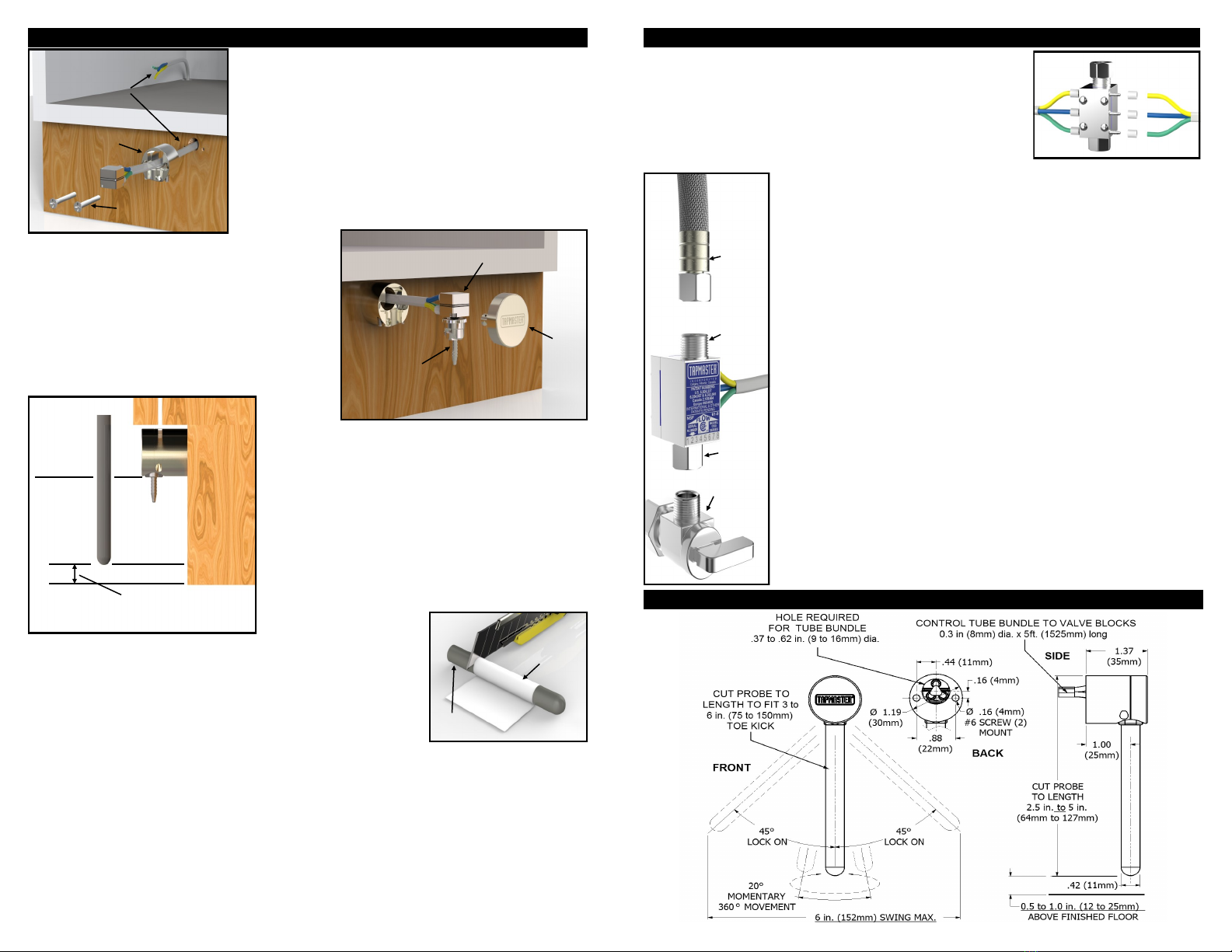

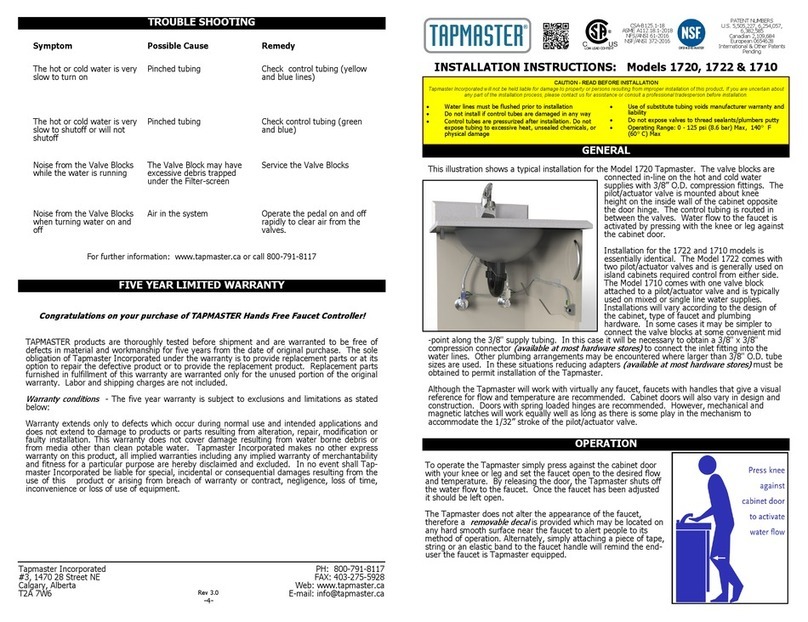

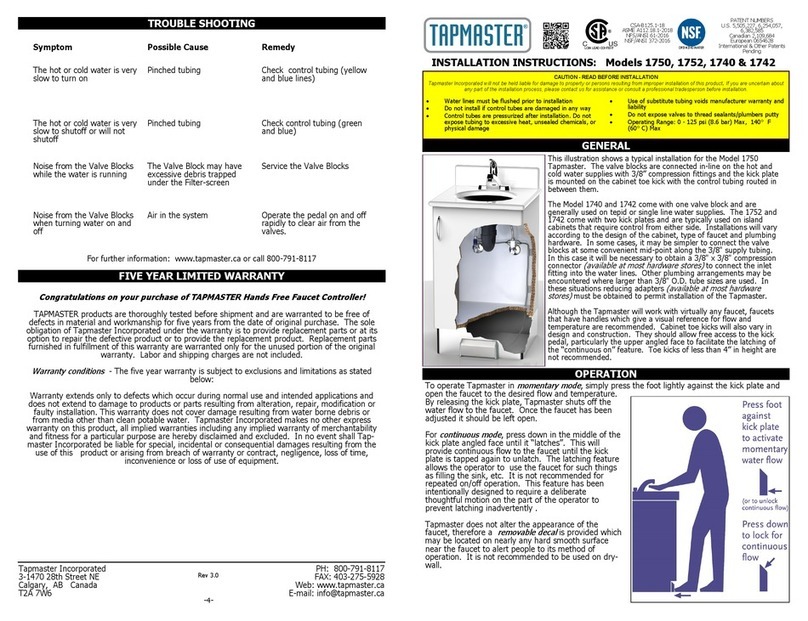

This illustration shows a typical installation for the Euro Model 1770 series

Tapmaster. The valve blocks are connected in-line on the hot and cold water

supplies with 3/8” compression fittings. The Euro foot activator is mounted on

the cabinet toe kick with the control tubing routed from the foot activator

through the cabinet base to the hot and cold water supplies to make the con-

nections to the valve blocks.

Models 1771 and 1776 come with one valve block and are generally used on

tepid or single line water supplies. Models 1770 and 1775 come with two

valve blocks for standard hot and cold water lines. Installations will vary

according to the design of the cabinet, type of faucet and plumbing hardware.

In some cases, it may be simpler to connect the valve blocks at a mid-point

along the 3/8" supply tubing. In this case it will be necessary to obtain a 3/8"

x 3/8" compression connector

(available at most hardware stores)

to connect

the inlet fitting into the water lines. Other plumbing arrangements may be

encountered where larger than 3/8" O.D. tube sizes are used. In these

situations reducing adapters

(available at hardware stores)

must be obtained

to install the Tapmaster.

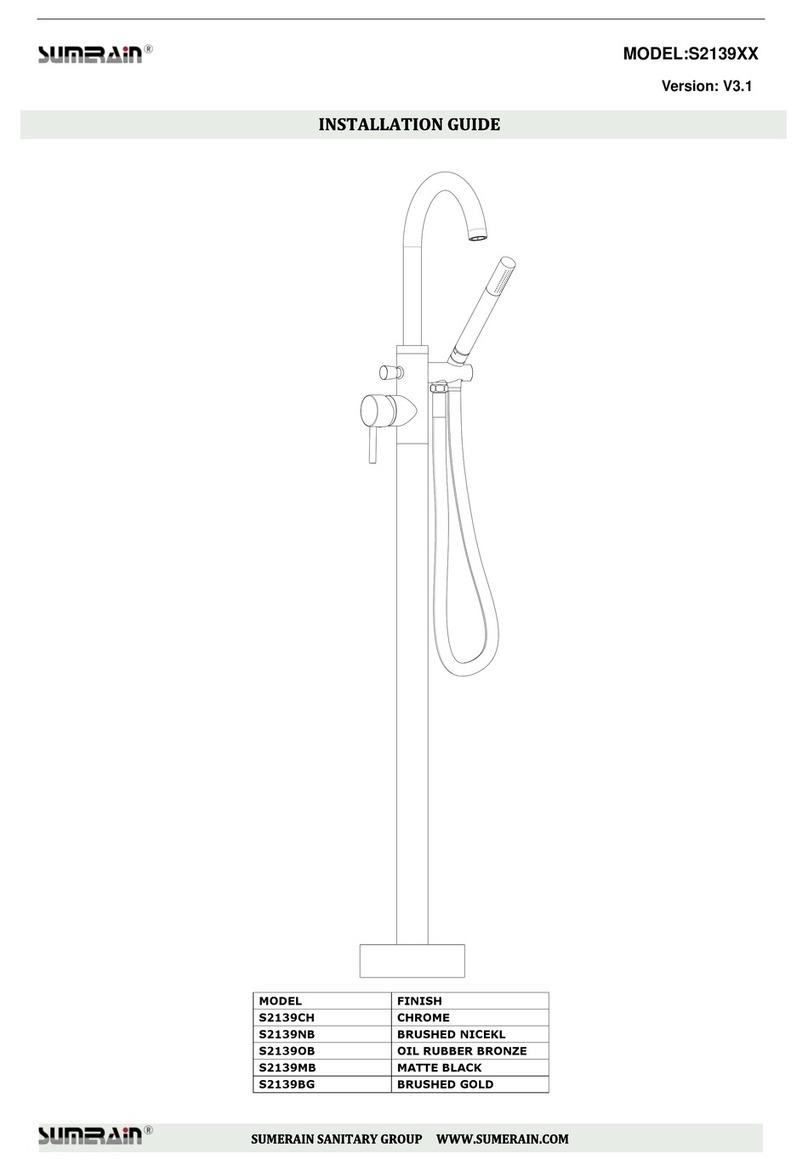

Although Tapmaster will work with any faucet, faucets that have handles which give a reference

for flow and temperature are recommended. The Euro foot activator will fit cabinets with toe kicks

ranging in height from 3” (75mm) to 6” (150mm) and it is recommended to be vertically aligned

with the center of the faucet. The plastic probe part of the foot activator is cut to length to keep

the bottom of the probe approximately 1/2” to 1” above the floor.

GENERAL

Models 1770 and 1771 feature momentary operation only,

while Models 1775 and 1776 incorporate a lock on feature in

addition to momentary operation.

To operate the Tapmaster Euro in

momentary mode

, leave

the faucet open at the flow and temperature desired, push

the Euro probe foot activator in any direction for momentary

water flow, release to turn off.

For

continuous mode

, push the Euro probe foot activator

sideways to 45 degrees in either direction to lock on; push

activator back to vertical rest position to turn off. The locking

feature allows the operator to manually use the faucet for

such things as filling the sink, etc. It is not recommended for

repeated on/off operation. This feature has been

intentionally designed to require a deliberate thoughtful

motion on the part of the operator to prevent locking inad-

vertently.

Tapmaster does not alter the appearance of the faucet,

therefore a

removable decal

is provided which may be

located on any hard smooth surface near the faucet to alert

people to its method of operation.

CAUTION: it is possible for pets or small children to inadvert-

ently lock on the Tapmaster—simply leave the faucet closed. Never leave the drain stopper in the

closed position in any sink.

INSTALLATION INSTRUCTIONS: EURO Models 1770, 1771, 1775 & 1776

TROUBLE SHOOTING

FIVE YEAR LIMITED WARRANTY

Congratulations on your purchase of TAPMASTER Hands Free Faucet Controller!

TAPMASTER products are thoroughly tested before shipment and are warranted to be free of

defects in material and workmanship for five years from the date of original purchase. The sole

obligation of Tapmaster Incorporated under the warranty is to provide replacement parts or at its

option to repair the defective product or to provide the replacement product. Replacement parts

furnished in fulfillment of this warranty are warranted only for the unused portion of the original

warranty. Labor and shipping charges are not included.

Warranty conditions

- The five year warranty is subject to exclusions and limitations as stated

below:

Warranty extends only to defects which occur during normal use and intended applications and

does not extend to damage to products or parts resulting from alteration, repair, modification or

faulty installation. This warranty does not cover damage resulting from water borne debris or

from media other than clean potable water. Tapmaster Incorporated makes no other express

warranty on this product, all implied warranties including any implied warranty of merchantability

and fitness for a particular purpose are hereby disclaimed and excluded. In no event shall Tap-

master Incorporated be liable for special, incidental or consequential damages resulting from the

use of this product or arising from breach of warranty or contract, negligence, loss of time,

inconvenience or loss of use of equipment.

Rev 3.0

-4-

PH: 800-791-8117

FAX: 403-275-5928

Web: www.tapmaster.ca

E-mail: info@tapmaster.ca

Tapmaster Incorporated

3-1470 28th Street NE

Calgary, AB Canada

T2A 7W6

Symptom Possible Cause Remedy

The hot or cold water is very

slow to turn on

Pinched tubing Check control tubing (yellow

and blue lines)

The hot or cold water is very

slow to shutoff or will not

shutoff

Pinched tubing Check control tubing (green

and blue)

Noise from the Valve Blocks

while the water is running

The Valve Block may have

excessive debris trapped

under the Filter-screen

Service the Valve Blocks

Noise from the Valve Blocks

when turning water on and

off

Air in the system Operate the pedal on and off

rapidly to clear air from the

valves.

For further information: www.tapmaster.ca or call 800-791-8117

PATENT NUMBERS

U.S. 5,505,227, 6,254,057,

6,382,585

Canadian 2,109,684

European 0654628

International & Other Patents

Pending

CSA-B125.1-18

ASME A112.18.1-2018

NFS/ANSI 61-2016

NSF/ANSI 372-2016

LOW LEAD CONTENT DRINKING WATER

OPERATION

CAUTION - READ BEFORE INSTALLATION

Tapmaster Incorporated will not be held liable for damage to property or persons resulting from improper installation of this product. If you are uncertain about

any part of the installation process, please contact us for assistance or consult a professional tradesperson before installation.

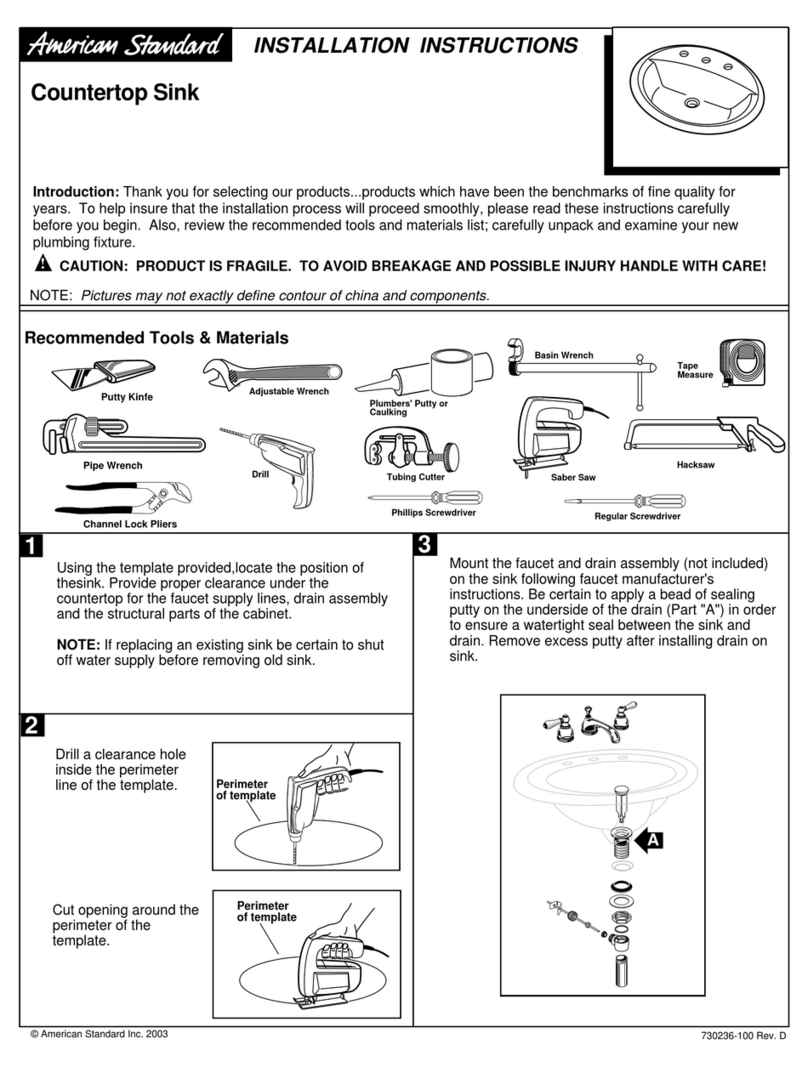

• Water lines must be flushed prior to installation

• Do not install if control tubes are damaged in any way

• Control tubes are pressurized after installation. Do not

expose tubing to excessive heat, unsealed chemicals, or

physical damage

• Use of substitute tubing voids manufacturer warranty and

liability

• Do not expose valves to thread sealants/plumbers putty

• Operating Range: 0 - 125 psi (8.6 bar) Max, 140° F

(60° C) Max