2

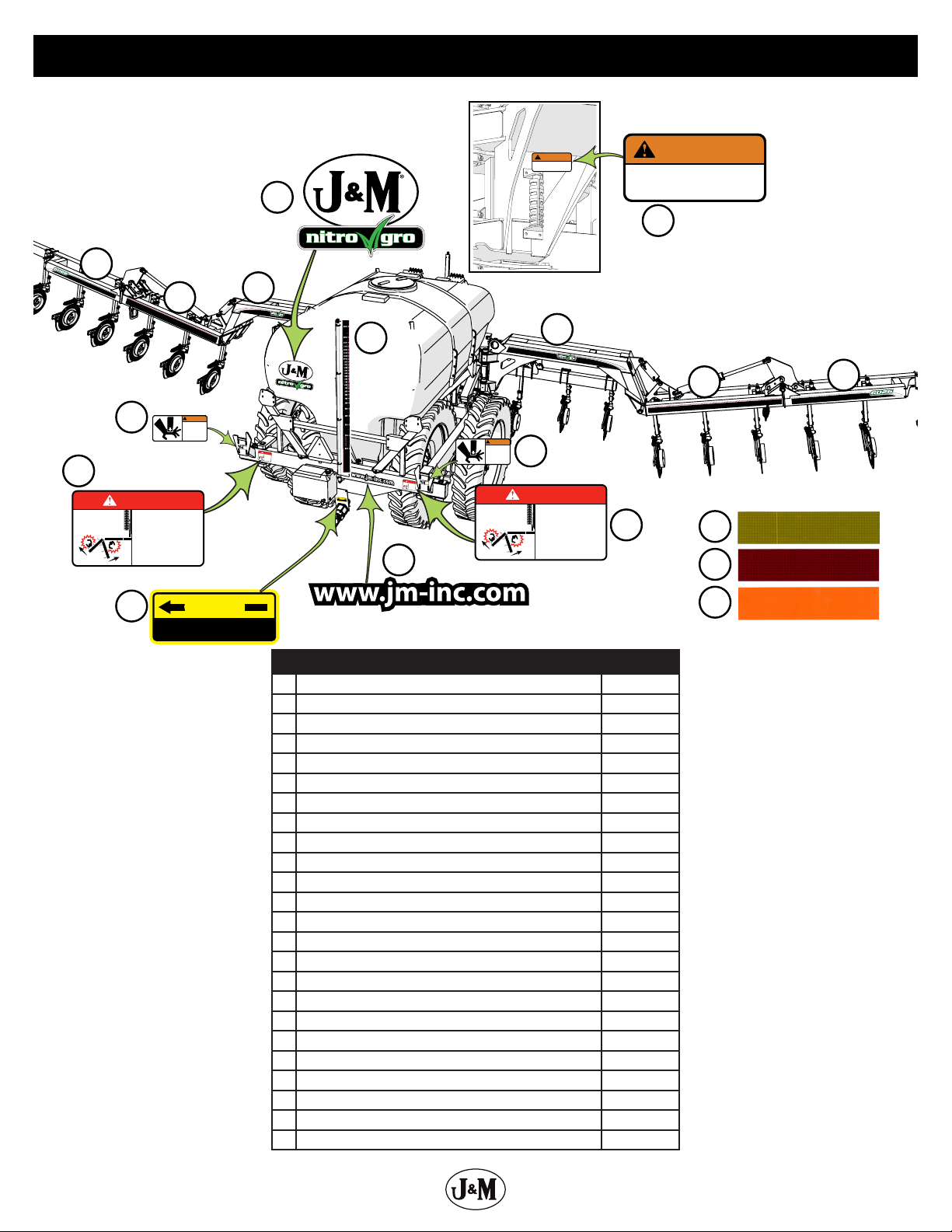

Decals

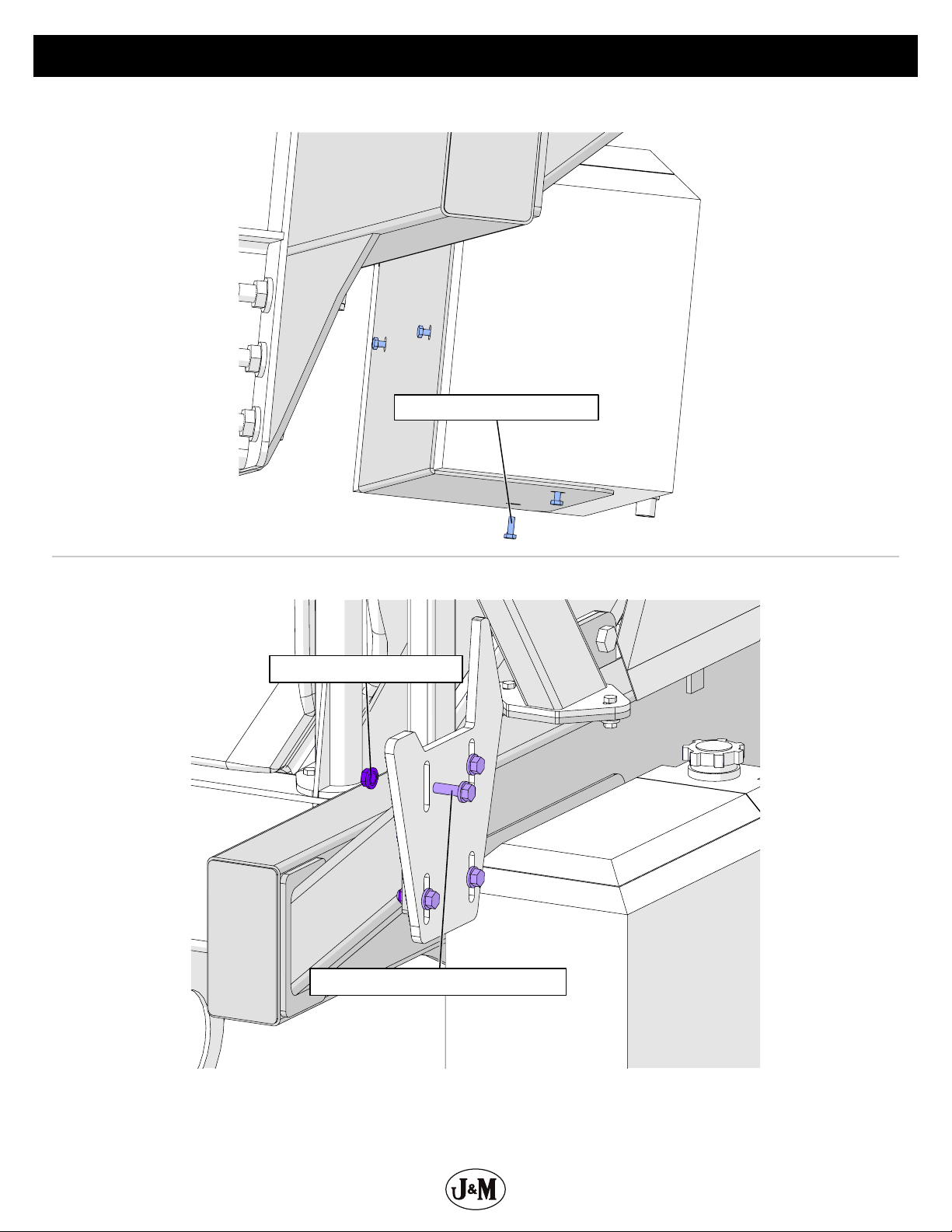

WARNING

JM0035880

HIGH PRESSURE FLUID

HAZARD

Toavoid serious injury or Death:

• Relievepressure on system before repairing

or adjusting or disconnecting

• Wear proper hand and eye protection

when searchingfor leaks. Use wood or

cardboardinstead of hands.

• Keepall componets in good repair.

DOWN PRESSURE

Turn clockwise to increase pressure

+ PSI

DO NOT EXCEED 1350 PSIJM0035892

DANGER

JM0035887

ELECTROCUTION

HAZARD

Toavoid serious injury or

death, DO NOT come into

contact with overhead

power-lines.

Maintain awareness at all

times during transport,

folding and unfolding process

CAUTION

JM0035881

Failure to observe instructions and safety practices

can result in serious bodily injury!

Toavoid injury :

• Read and understand your Operators Manual before

Servicing or operating this machine.

• Learn to operate and adjust the machine safely.

• Do not allow any passengers on the machine or tractor.

• Be certain that everyone is clear before moving the nitrogen applicator,

hydraulics or starting the folding and/or unfolding process.

JM0035882

TOWING STABILITY

HAZARD

Toavoid serious injury or Death:

• Always tow nitrogen applicator with

agricultural tractor.

• Never tow in excess of 20 MPH.

• Nitrogen applicator should never exceed

1.5 times the weight of the towing tractor.

and road transport instructions.

WARNING

MAKESURE

LOCKS

AREFULLY

ENGAGED

ANDAPPLY CONSTANT

PRESSUREDURING USE

MAKESURE

LOCKS

AREFULLY

ENGAGED

ANDAPPLYCONSTANT

PRESSUREDURING USE

WARNING

PINCHPOINT

KEEPHANDSCLEAR

JM0014994

COULTERBEARINGLUBRICATION

JM0038099

2pumpsof good quailty LS EP2 severe duty,

highshockload, lithium based grease every

50hrsof operation to every coulter bearing.

DONOTOVER GREASE

DAMAGETOSEALSWILL OCCUR!

DANGER

JM0035887

ELECTROCUTION

HAZARD

Toavoidseriousinjuryor

death,DONOTcomeinto

contactwithoverhead

power-lines.

Maintainawarenessatall

timesduringtransport,

foldingandunfoldingprocess

CAUTION

JM0035881

Failuretoobserveinstruc tions and safetyprac tices

canresultin serious bodily injury!

Toavoidinjury:

•Readandunderstand your Operators Manual before

Ser vicing or operatingthis mach ine.

•Learntooperate and adjust the machine safely.

•Donotallow any passengers on the machine or tractor.

•Becertain thatever yoneis clear before moving the nitrogen applicator,

hydraulics or starting the folding and/or unfolding process.

JM0035882

TOWINGSTABILITY

HAZARD

Toavoidseriousinjuryor Death:

•Alwaystownitrogen applicator with

agriculturaltractor.

•Nevertowin excess of 20 MPH.

•Nitrogenapplicatorshould never exceed

1.5times the weight of the towing tractor.

androad transpor t instructions.

WARNING

DOWNPRESSURE

Turnclockwiseto increase pressure

+PSI

DONOT EXCEED 1350 PSI

JM0035892

R

E

A

D

O

W

N

E

R

S

M

A

N

U

A

L

F

O

R

P

S

I

R

A

T

I

N

G

C

H

E

C

K

T

I

R

E

P

R

E

S

S

U

R

E

D

O

N

O

T

E

X

C

E

E

D

M

A

X

P

S

I

JM0038097

R

E

A

D

O

W

N

E

R

S

M

A

N

U

A

L

F

O

R

P

S

I

R

A

T

I

N

G

C

H

E

C

K

T

I

R

E

P

R

E

S

S

U

R

E

D

O

N

O

T

E

X

C

E

E

D

M

A

X

P

S

I

JM0038097

COULTER BEARING LUBRICATION

JM0038099

2 pumps of good quailty LS EP2 severe duty,

high shock load, lithium based grease every

50 hrs of operation to every coulter bearing.

DO NOT OVER GREASE

DAMAGETO SEALS WILL OCCUR!

WARNING

JM0035880

HIGHPRESSUREFLUID

HAZARD

ToavoidseriousinjuryorDeath:

•Relievepressureonsystem before repairing

oradjustingor disconnecting

•Wearproperhandandeye protection

whensearchingfor leaks. Use wood or

cardboardinsteadof hands.

•Keepallcomponetsin good repair.

MAKE SURE

LOCKS

ARE FULLY

ENGAGED

AND APPLY CONSTANT

PRESSURE DURING USE

MAKE SURE

LOCKS

ARE FULLY

ENGAGED

AND APPLY CONSTANT

PRESSURE DURING USE

WARNING

PINCHPOINT

KEEPHANDSCLEAR

JM0014994

R

E

A

D

O

W

N

E

R

S

M

A

N

U

A

L

F

O

R

P

S

I

R

A

T

I

N

G

C

H

E

C

K

T

I

R

E

P

R

E

S

S

U

R

E

D

O

N

O

T

E

X

C

E

E

D

M

A

X

P

S

I

JM0038097

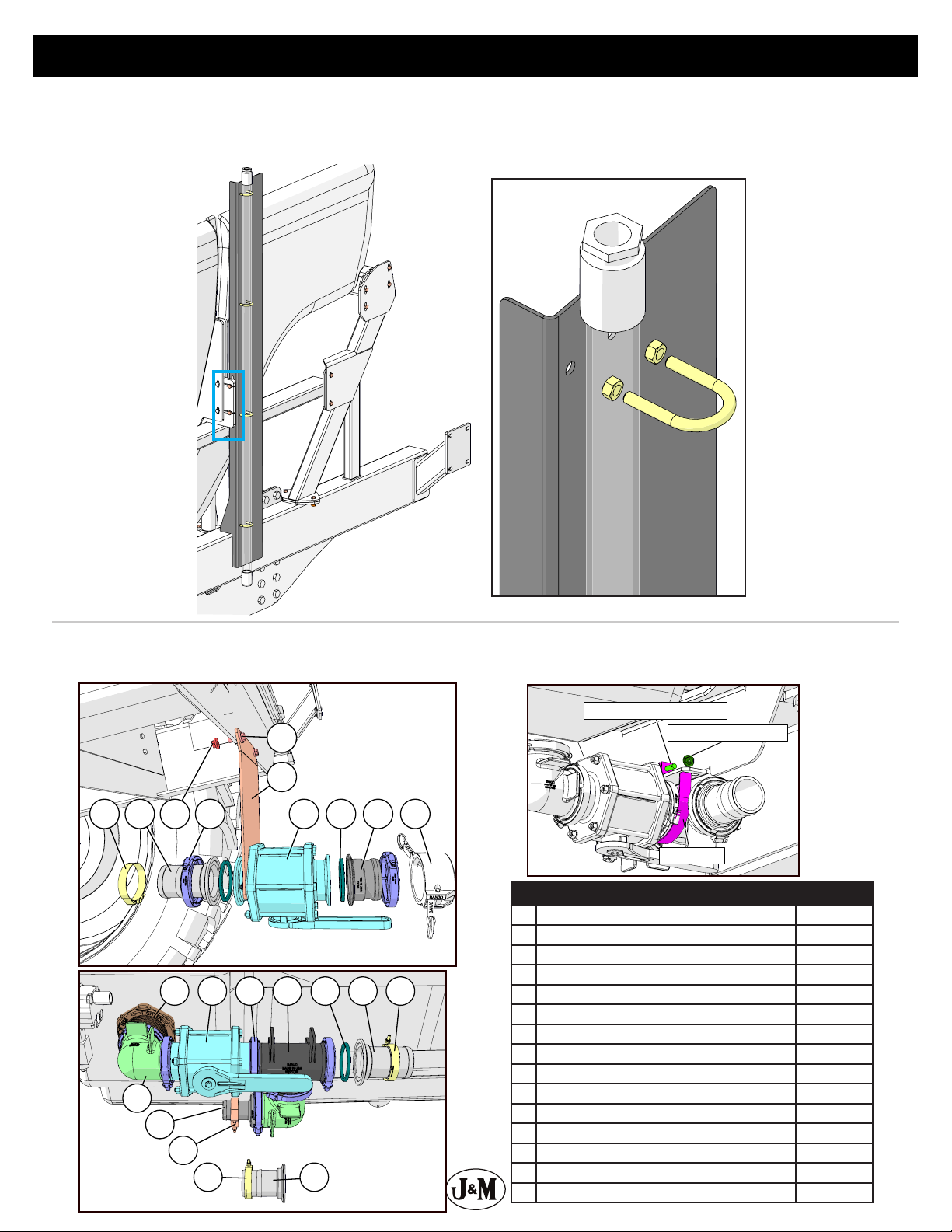

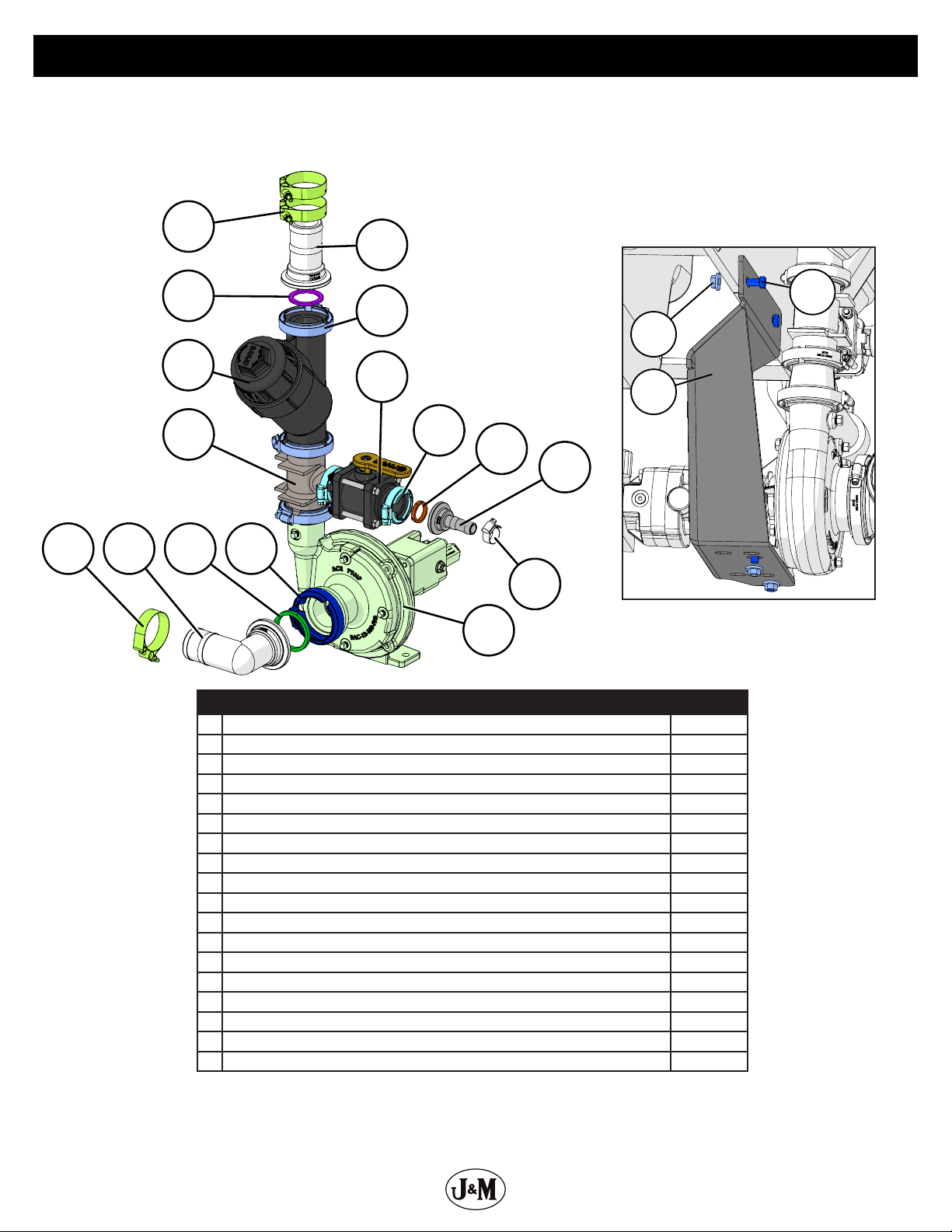

CHECK FILTER

DAILY

REMOVEALL DEBRIS

JM0035884

OPEN

OPEN

KEEPTANK AGITATION

VALVEOPEN

DURINGFIELD OPERATIONS

KEEPTANK MAINTENANCE

VALVEOPEN

DURINGFIELD OPERATIONS

OPEN

OPEN

CHECK FILTER

DAILY

REMOVE ALL DEBRIS

JM0035884

OPEN

OPEN

KEEP TANK AGITATION

VALVE OPEN

DURING FIELD OPERATIONS

KEEP TANK MAINTENANCE

VALVE OPEN

DURING FIELD OPERATIONS

OPEN

OPEN

WARNING

JM0014994

PINCH POINT

KEEP HANDS CLEAR

18

11 12

13

8

19

20

21

7

6

5

4

3

2

1

10

17

16

15

14

9

JM0035885

K

E

E

P

L

U

G

N

U

T

S

T

I

G

H

T

C

H

E

C

K

F

R

E

Q

U

E

N

T

L

Y

R

E

A

D

O

W

N

E

R

S

M

A

N

U

A

L

F

O

R

T

O

R

Q

U

E

S

P

E

C

S

Description Part No.

1 NitroGro Wing Decal (Front Right, Rear Left) JM0055012

2 Make Sure Locks are Fully Engaged Decal (Right) JM0055013

3 Coulter Bearing Lubrication Decal JM0038099

4 Make Sure Locks are Fully Engaged Decal (Left) JM0055018

5 6018 Tank Stripes Red (Left) JM0055208

5 6018 Tank Stripes Green (Left) JM0055209

5 6018 Tank Stripes Red (Right) JM0055210

5 6018 Tank Stripes Green (Right) JM0055211

6 NitroGro Wing Decal (Front Left, Rear Right) JM0055023

7 Check Tire Pressure NitroGro Decal JM0038097

8 Tighten All Wheel Nuts NitroGro Decal JM0035885

9 Tongue 6018 Stripe Red (Right) JM0055212

9 Tongue 6018 Stripe Green (Right) JM0055213

10 Tongue NitroGro Top Red Decal JM0055027

10 Tongue NitroGro Top Green Decal JM0055028