Tascam 122MKII User manual

Other Tascam Cassette Player manuals

Tascam

Tascam 130 Guide

Tascam

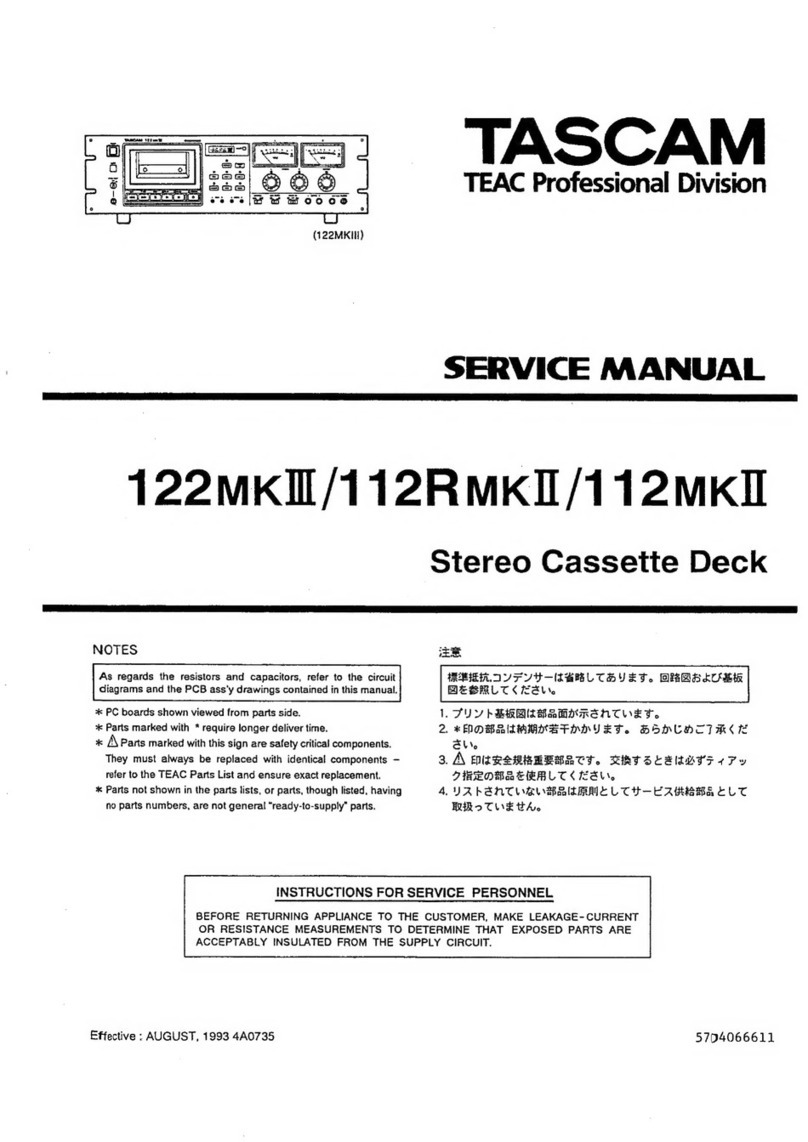

Tascam 122MKmIII User manual

Tascam

Tascam 130 User manual

Tascam

Tascam PortaStudio 424 User manual

Tascam

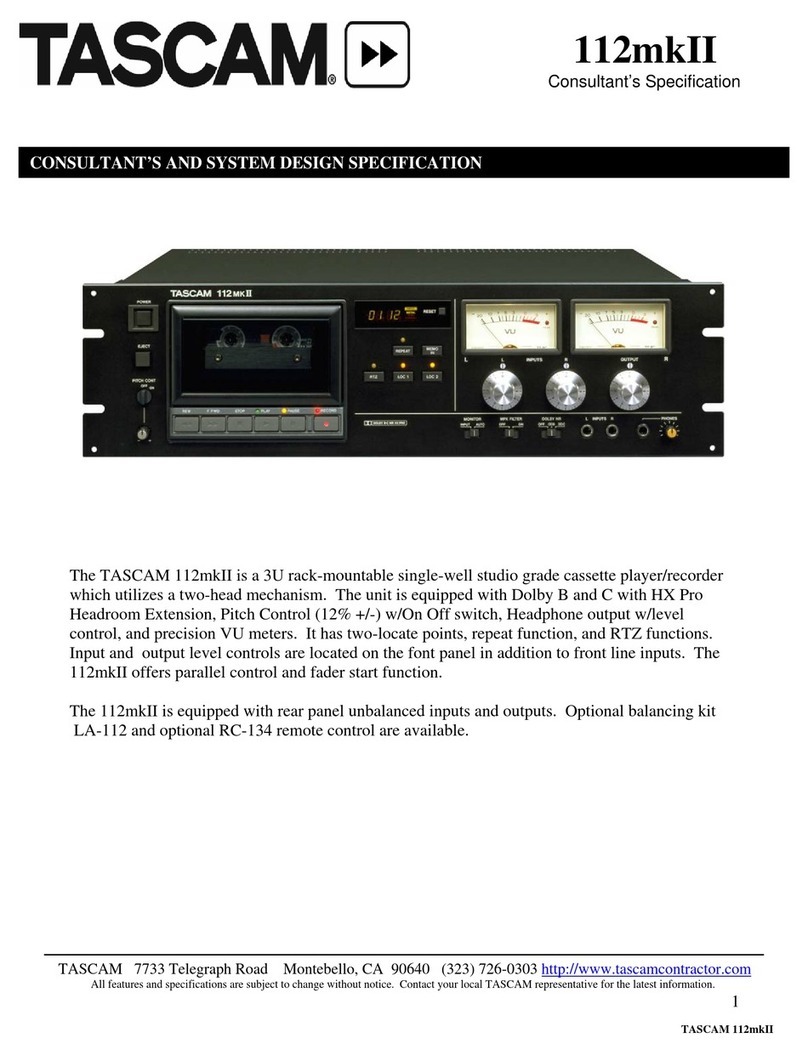

Tascam 112mkII User manual

Tascam

Tascam 122MKIII User manual

Tascam

Tascam 122MKIII User manual

Tascam

Tascam 302 User manual

Tascam

Tascam 688 Midistudio User manual

Tascam

Tascam 202MKVI User manual

Tascam

Tascam 202 MK III User manual

Tascam

Tascam 122MKIII Guide

Tascam

Tascam 102MKII Guide

Tascam

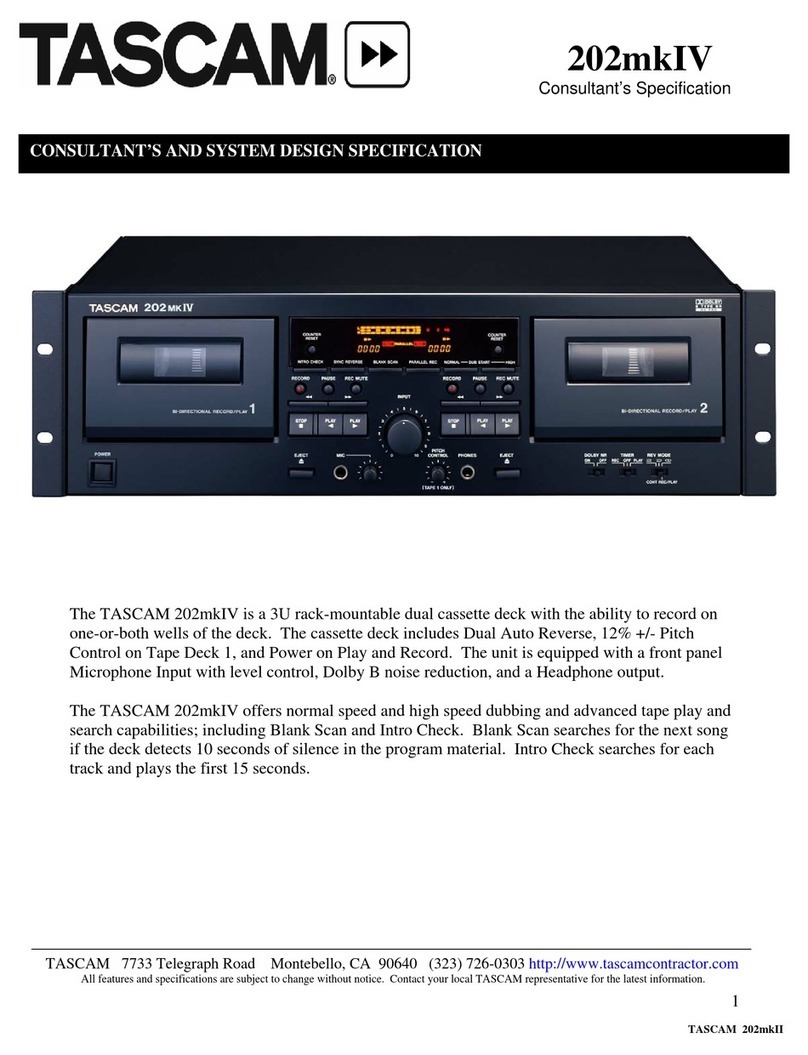

Tascam 202mkIV User manual

Tascam

Tascam 112mkII User manual

Tascam

Tascam 122MKIII User manual

Tascam

Tascam 322 User manual

Tascam

Tascam 302mkII User manual

Tascam

Tascam 202mkV User manual

Tascam

Tascam PortaStudio 424 MKII User manual

Popular Cassette Player manuals by other brands

Sony

Sony CFS-B15 - Am/fm Stereo Cassette Recorder operating instructions

Sony

Sony WMFS220 - Portable Sports AM/FM Cassette... operating instructions

Aiwa

Aiwa HS-TA21 operating instructions

Sanyo

Sanyo MCD-ZX700F Service manual

Aiwa

Aiwa CS-P77 Service manual

Sony

Sony Pressman TCM-465V operating instructions