©Copyright Task Force Tips, Inc. 2003 - 2010 LIH-020 September 25, 2010 Rev06

2

BOLT-ON PISTOL GRIP REMOVAL: PISTOLGRIP[19v]isheld on by a SOCKET

HEAD CAP SCREW [21v]. Remove screw with a 5/16” Ball DriverAllen wrench. To

reinstall, clean thread and apply Loctite® #271. Tighten screw to 95 in-lbs.

VALVE PLUG REPLACEMENT: Afterremoving back end, VALVE PLUG [17v,10b,

or 24b] is removed by pulling straight back. New valve plug can be installed using

a mallet.

VALVE SHUTOFF ADJUSTMENT: Shutoff valve is adjusted by the threads be-

tween the valve body and the front end of the nozzle. While holding the VALVE

HANDLE [3v]against stops intheOFF position, screwfrontendinto thevalvebody

until contact is made with the VALVE PLUG [17v]. Open handle to ON position to

remove contact. Screw the front end in 1/12 turn further to give the valve shutoff

compression. Thread in both SET SCREWS [12v] until they bottom out, without

applyingpressure.Inanalternatingfashioncontinueturninginsetscrewsuntil tight.

VALVE ADJUSTMENT FOR SEVERE COLD: To help prevent hose line freezing

in cold climates, the valve may be adjusted for intentional leakage by unscrewing

the front end slightly. The valve may then be returned to normal adjustment for

complete shut off during warm weather as stated above.

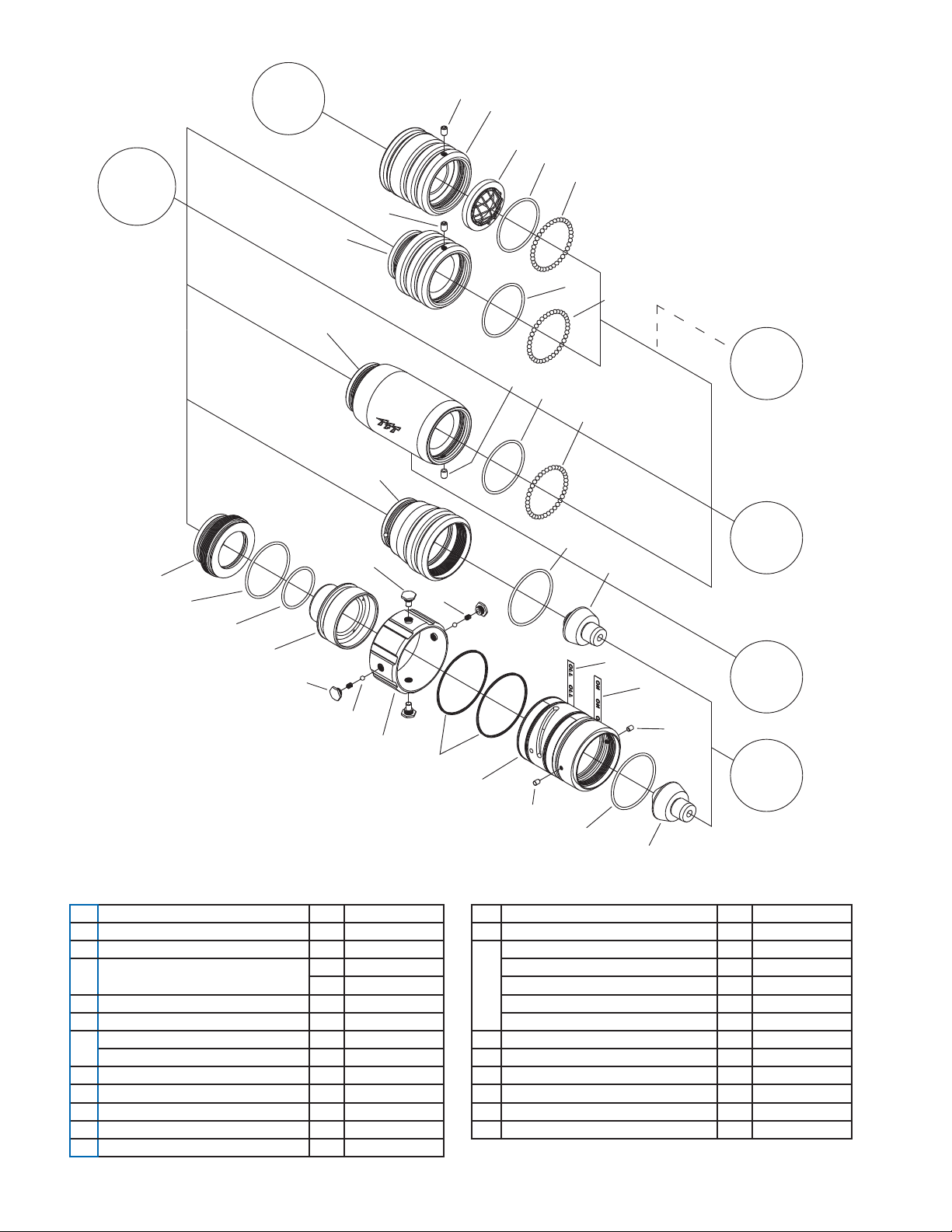

SLIDE VALVE DISASSEMBLY SEQUENCE

HANDLE REMOVAL: Remove both BUTTON HEAD CAP SCREWS [6v] from

VALVE HANDLE [3v] using a 7/32” Allen wrench. Slide CAM and SAFETY PINS

[4v and 5v] out of handle by gently prying about 3/8” apart the handle and the valve

body using a flat screw driver. To remove the handle, pull upwards while containing

theDETENTBALLS [7v] and SPRINGS [8v] toprevent their loss. Service to interior

valve parts should be done prior to reinstalling handle.

SLIDER AND SEAL REMOVAL: Remove #10-32 x ¼” SOCKET SET SCREWS

[12v] from the VALVE ASSEMBLY [11v] using a 3/32” Allen wrench. Unscrew front

portion of nozzle from valve. SLIDER [15v] can now be pulled out from the front of

valve. Remove and inspect O-RINGS [13v, 14v and 16v]. Replace O-Rings if they

are damaged.

SLIDE VALVE ASSEMBLY SEQUENCE

SLIDER AND SEAL INSTALLATION: Insert O-RINGS [13v, 14v and 16v] into

the proper grooves in the valve body. Check SLIDER [15v] for any raised metal at

groove area. Replace if necessary. Lubricate O-Rings and slider with DOW #112

Lube. Push slider into the valve body.

HANDLE INSTALLATION: Insert DETENT SPRINGS [8v] and DETENT BALLS

[7v] into the handle lugs. While holding balls in place, snap the HANDLE [3v] into

placewithoffsetholes FORWARD.Carefully align thegrooveonSLIDER[15v]with

offset hole in VALVE DISCS [9v] and with offset hole in handle. Slide SAFETYPIN

[5v] into offset hole in handle. Push down into engagement with groove in slider,

until head of pin is flush with handle. Repeat procedure for CAM PIN [4v]. Insert

BUTTON HEAD SCREWS [6v] through the lower handle holes. Thread each into

corresponding center trunnion hole. Tighten HANDLE SCREWS [6v] securely with

atorquevalueof100in-lbs(11.3N m). Handle should click firmlyand smoothly into

all detent positions and the slider should move back and forth smoothly. The force

to move handle should be between 5 lbs and 13 lbs applied at top center of handle.

FRONT END

SHELL SERVICE PROCEDURE

SHAPER REMOVAL: The rubber bumper is permanently bonded onto the stream

shaper as a single unit referred to as the SHAPER [10f]. The shaper is attached

to the SHAPER GUIDE [4f, or 5f] by a threaded joint that is retained by Loctite®

#271. Grip rear portion of the nozzle in a vise with padded jaws, or clamp SHAPER

GUIDE [4f, or 5f] using TFT special tool TH502 held in a vise. Direct a hot narrow

flamearound the rear portion ofthe shaper and heatfor approximately 20seconds.

Damage to BUMPER [10f] and LABELS [1f, 2f, or 6f] can be reduced by protecting

them with a wet cloth. Use a strap wrench to unscrew the shaper from the shaper

guide. Remove the shaper. Inside the shaper are (48) 13/16”ACETALBALLS [8f],

some of which may fall free as the Shaper is removed. If Shaper is to be reused,

clean ball track and replace 336 O-RING [9f] if damaged.

SERVICE TO CAM GROOVES AND BALLS: When Shaper is removed, check

to see if the stream shaping GUIDE BALLS [3f] and CAM GROOVES [7f - part of

BARRELCONE ASSEMBLY] are damaged. Replace Balls if sheared or missing. If

the CAM GROOVES are badly damaged, the BARREL CONE ASSEMBLY should

also be replaced.

BARREL CONE ASSEMBLY SERVICE: This assembly is permanent and cannot

be taken apart. Check to ensure that the flush spring is not damaged by pushing

down on the Barrel Cone with both hands (about 50 lbs force). The Barrel Cone

AssemblyshouldbereplacediftheBarrel Cone does not push down or spring back

up by itself. Lightly grease the CAM GROOVES before re-installing the SHAPER

GUIDE.

SHAPER INSTALLATION: Install 336 O-RING [9f] in front groove of SHAPER

[10f]. Grease the seal and ball groove heavily. Place (48) 13/16” ACETAL BALLS

[8f] into greased ball groove. Apply Loctite® #271 to male thread on SHAPER

GUIDE[4f, or5f].StartshaperontoSHAPERGUIDEthreads. PlacethreeSHAPER

GUIDE BALLS [3f] into the grooves on barrel and screw down shaper until threads

bottom out.

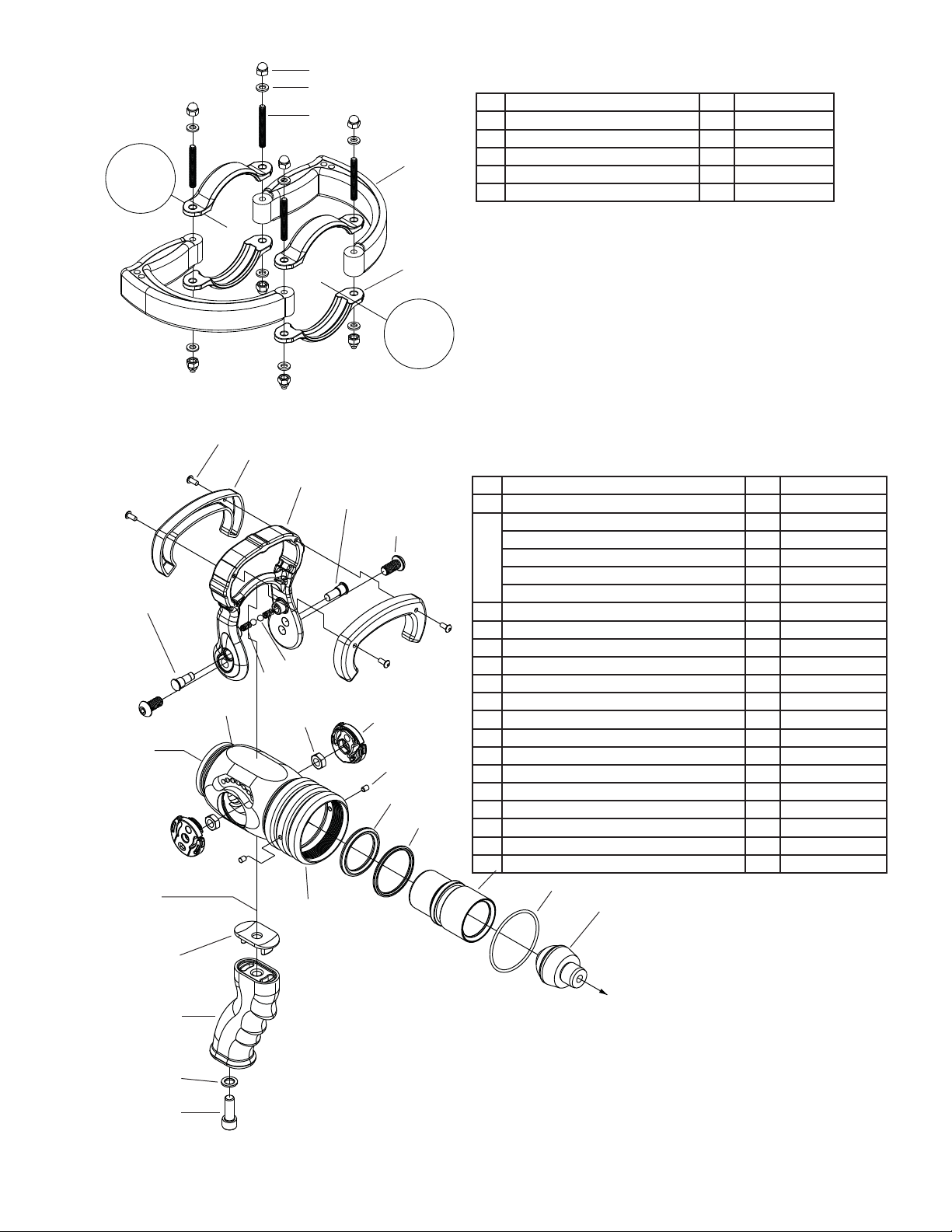

PRESSURE CONTROL SERVICE PROCEDURE

Tools Required:

1/4Allen wrench (10” Long)

1/4Allen wrench (regular length)

Mallet

PRESSURE CONTROL REPLACEMENT: The pressure control may be removed

and replaced as a unit by following the procedure in the PRESSURE CONTROL

REMOVALand INSTALLATION AND INITIALOPENINGADJUSTMENT sections.

NOTICE: The Pressure Control Unit is part of the BARREL ASSEMBLY [7f]. This

unitisfactorycalibratedandsealed.Serviceonthisunitisbestperformedatthefac-

tory using special tooling and equipment. In the unlikely event that this unit should

need service, it is highly recommended that you return the complete nozzle to the

factory for repairs OR replace the entire PRESSURE CONTROL UNIT. DO NOT

ATTEMPTTODISASSEMBLETHEPRESSURECONTROLUNIT!TaskForceTips

willassume NO liability for damage orinjury resulting fromattempts to disassemble

or repair the Pressure Control Unit.

PRESSURE CONTROL REMOVAL: To remove the CONTROLUNIT first separate

the front end from the nozzle, then remove the VALVE PLUG (106, 24b or 17v).

Loosen and remove the shaft locking SCREW (1p) with a 3/16 allen wrench. Insert

a 7/32Allen wrench into the front of the shaft and screw the shaft out of the barrel

assembly. LOCKING SLEEVE (2p) is removed by pushing it forward and out of

BARRELASSEMBLY (7f) with a punch. Note: LOCKING SLEEVE may require light

tapping with a hammer to remove.

PRESSURE CONTROL INSTALLATIONAND INITIAL OPENING ADJUSTMENT:

To install the CONTROL UNIT, lightly grease I.D. and O.D. of locking sleeve and

also threads of the screw. Place LOCKING SLEEVE (2p) with hollow end forward

onto back of shaft, thread finger tight. Note: If old LOCKING SLEEVE is reused it

may require light tapping with a hammer and punch to install. Screw CONTROL

UNIT (with pressure control parts installed) into barrel assembly. Insert a 7/32 Allen

wrench into front of shaft and turn in until baffle just touches BARREL CONE (7f)

then turn back between ½ and 3/4 of a turn (opening gap of .026/.036 inches or

.66/.91mm).KeepAllenwrench in shaft to assure that shaft doesn’t turn and tighten

screw against locking sleeve, to approximately 180 in-lbs.

IMPORTANT: Always flow test after adjusting. Nozzle pressure and flow require-

ments are shown on the following table:

INITIAL OPENING at 40 PSI (2.8 BAR)

FLOW (MIN) FLOW (MAX) Opening Gap (REF)

38 GPM 58 GPM .026/.036in

(144L/MIN) (204 L/MIN) (.66/.91mm)

NOZZLE PRESSURE NOZZLE PRESSURE

AT 95 GPM AT 250 GPM

100 PSI MODEL 85 PSI +/- 6 99 PSI +/- 6

75 PSI MODEL 60 PSI +/- 6 80 PSI +/- 6

DUAL-FORCE KNOB REMOVAL: To remove the DUAL-FORCE KNOB [8p] from

the BAFFLE [4p]:

1) Turn knob to standard setting.

2) Turn the SHAPER [10f] back to full flush.

3) Insert a small probe (such as a 1/16” drill bit) into the smaller of the two holes on

top of the knob.

4) Simultaneously push down with probe while turning knob clockwise (when

viewed from the front). Once knob turns a little, the probe may be removed.

5) Turn knob clockwise until it hits a stop. (about 25 degrees).

6) Pull knob to remove from baffle.