©Copyright Task Force Tips, Inc. 2003 - 2011 LIZ-030 September 27, 2011 Rev07

8

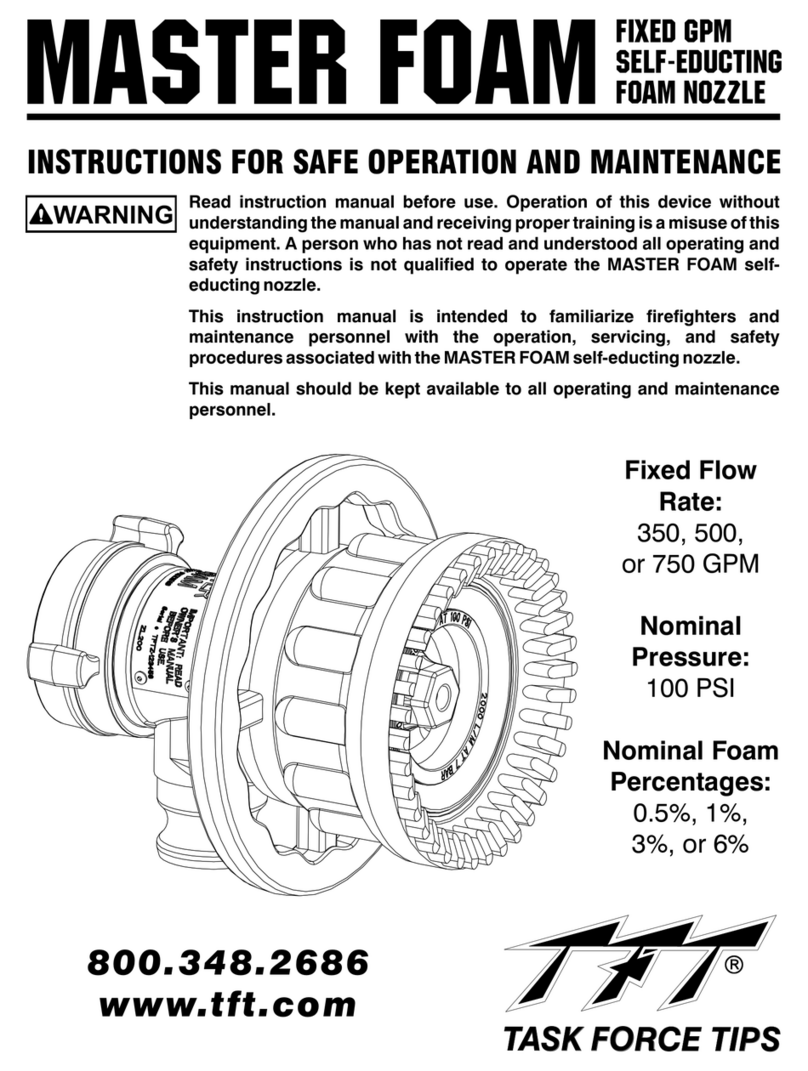

3.5.4 USE OF FOAMJET LX

Check For

Desired Percentage

Insert into Inlet

Push On

To L o c k

Fold Levers

To Hose

To increase the expansion ratio, Task Force Tips’ “Foamjet

LX” (model FJ-LX-M) may be used. This low expansion

foam tube attaches and removes quickly from the nozzle.

Note:Asexpansionratioisincreasedthereachofthenozzle

will be decreased due to the greater amount of bubbles in

the stream and their inability to penetrate the air. Figure

2.5.4 gives approximate stream trajectory information with

and without Foamjet LX. Actual results will vary based on

brand of foam, hardness of water, temperature, etc.

3.5.5 CLEANING AFTER USE

After educting foam it is recommended that water be

educted in through the concentrate hose and inlet. This will

washoutfoamconcentrateresidueinthehose,orificeplate,

and nozzle passages. If not removed, any residue may dry

and adversely affect the accuracy of proportioning.

3.5.6 USE WITH SALT WATER

Use with salt water is permissible provided nozzle is

thoroughly cleaned with fresh water after each use. The

service life of the nozzle may be shortened due to the

effects of corrosion and is not covered under warranty.

For saltwater compatibility with foam, refer to supplier’s

technical data

Fig 2.5.3a Orifice Plate and Concentrate

Hose Connection

4.0 MAINTENANCE AND INSPECTION

WARNING The nozzle may be damaged if frozen while containing sufficient amounts of water. Such

damage may be difficult to detect visually and can lead to possible injury or death. Any time

the nozzle is subject to possible damage from freezing, it must be hydrostatically tested by

qualified personnel before being considered safe for use.

The MASTER FOAM self-educting nozzle requires no routine maintenance. The shaper seal slides on a plastic surface and requires

no grease. The nozzle should be inspected regularly to assure proper operation. In particular, check that:

• Coupling and gasket are tight and leak free.

• The desired orifice plate (flow and percentage) is installed.

• Concentrate inlet hose and gasket are damage and leak free.

• Flow passages are unobstructed.

• Baffle is in place and tightened securely.

• Shaper moves freely.