©Copyright Task Force Tips LLC 2003-2020 3 LIU-030 August 24, 2020 Rev10

1.0 MEANING OF SAFETY SIGNAL WORDS

A safety related message is identified by a safety alert symbol and a signal word to indicate the level of risk involved with a particular

hazard. Per ANSI Z535.6, the definitions of the four signal words are as follows:

2.0 SAFETY

This portable decontamination system can be used in potentially dangerous situations. The following must be observed at all times:

3.0 GENERAL INFORMATION

The PRO/pak Portable Foam System is a very versatile eductor-type foam application appliance. It can be used with 0.1%-1% Class A

foam concentrates for wildland, rural and urban fire suppression on Class A fuels (wood, paper, combustible materials). On Class A

materials the PRO/pak is intended to be used for direct extinguishment, overhaul, and wetting of fuels. Some foam concentrates are

corrosive, we recommend using only Class A concentrates that have received USDA and USFS approval.

On Class B materials, the PRO/pak is primarily intended to be used for vapor suppression. It can be used with 1% and 3% AFFF Class

B concentrates on flammable liquids that do not contain alcohol. It can be used with 3% and 6% Alcohol Resistant AFFF Class B

concentrates on flammable liquids containing polar solvents. It can also be used with 3% X 6% or 6% Class B foam concentrates.

Whenever possible, back up the PRO/pak with additional water/foam capabilities for added safety.

The Pro/pak can be used on ignited liquid fuels, but its foam application rate is very limited. Based on NFPA 11 this unit should not be

used on ignited Class B fuels with an area greater than 120 square feet (10 x 12 feet) or 11 square meters. The PRO/pak should not be

used on burning Polar Solvents with an area greater than 60 square feet (6 x 10 feet) or 5.5 square meters.

The PRO/pak is designed for Class A and Class B foam concentrates, but it has been used with other concentrates for other uses. If you

intend to use the PRO/pak for liquids other than Class A and Class B concentrates and water, we urge you to contact the Task Force

Tips Engineering Department. The use of other liquids may void the warranty and subject the user to hazards not addressed in this

manual. The user assumes all risks for non-intended uses.

3.1 SPECIFICATIONS

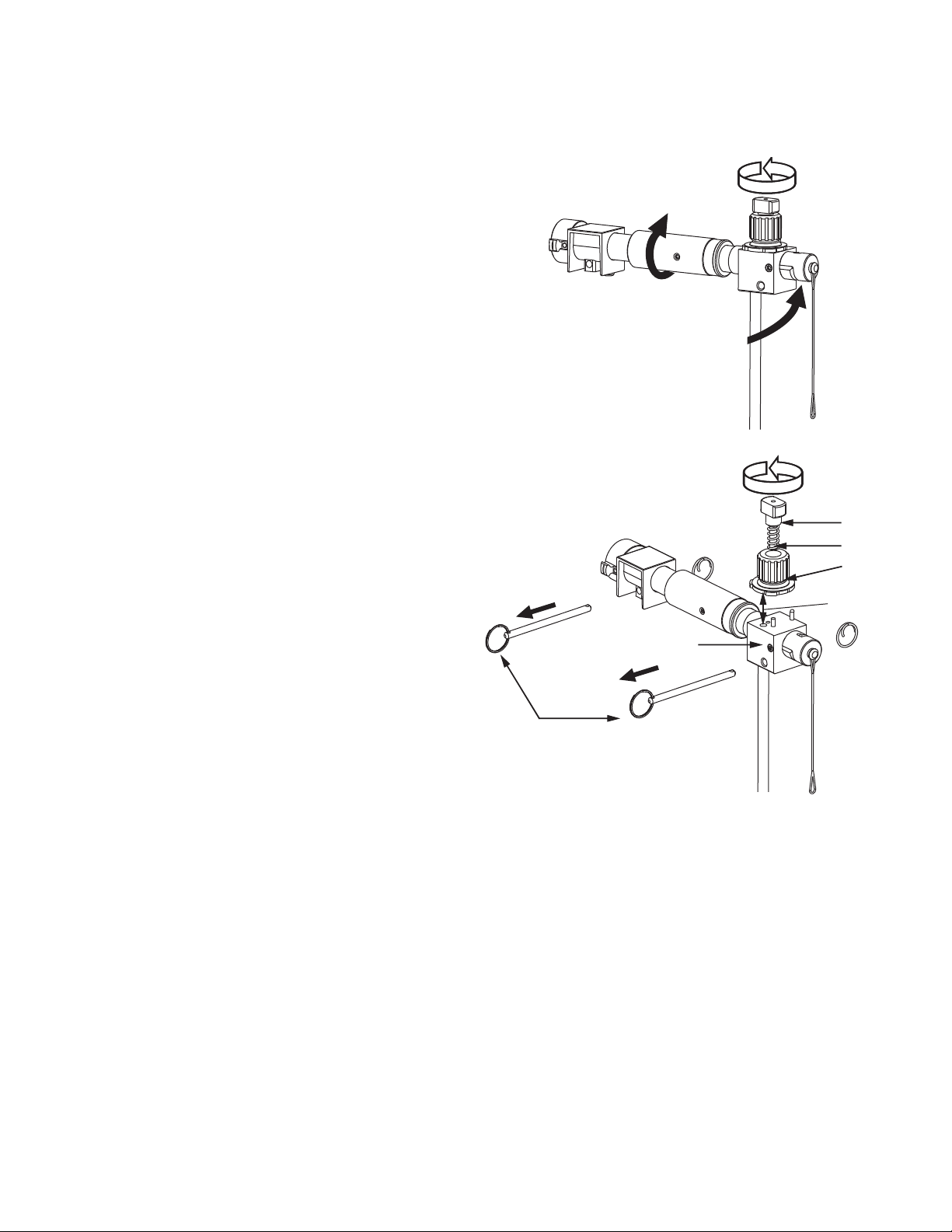

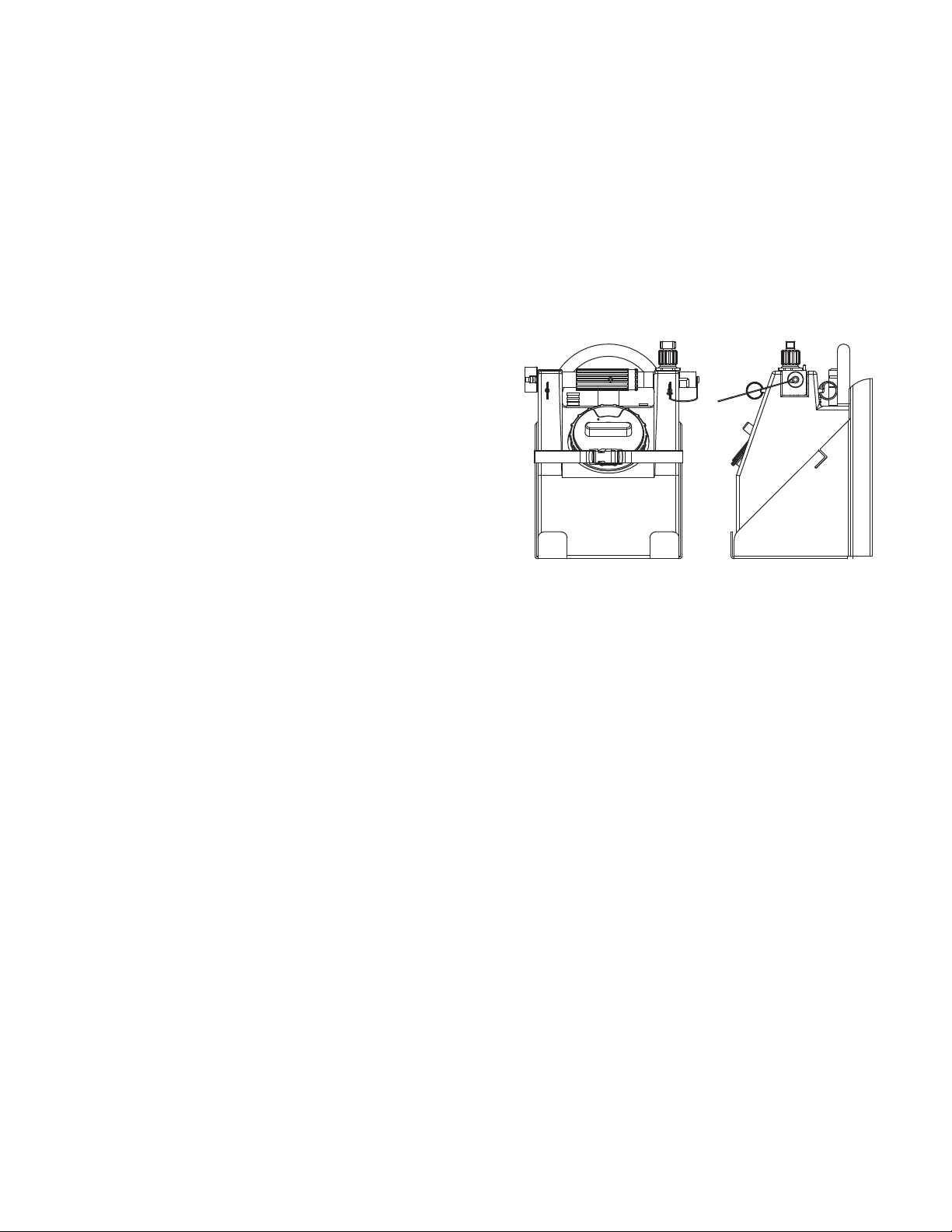

Figure 3.1

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious

injury.

CAUTION CAUTION indicates a potentially hazardous situation which, if not avoided, could result in minor

or moderate injury.

NOTICE is used to address practices not related to physical injury.

Lack of foam can place operator at risk of injury or death. Establish foam flow and adequate supply

of concentrate for the task before advancing into hazardous situations.

Improper use of agent could result in death or serious injury, including damage to the eyes. To

reduce the risk of injury, avoid directing agent onto the faces of yourself and other personnel.

Always wear PPE, including eye protection, as directed by the AHJ.

Improper use of foam or using the wrong type of foam can result in illness, injury, or damage to the

environment. Follow foam manufacturer’s instructions and fire service training as directed by the

AHJ.

US Units Metric Units

Tank Capacity (to bottom of fill port) 2.5 gal 9.5 liters

Nominal Flow (all nozzles) 12 gpm @ 100 psi 45 l/min @ 7.0 bar

Weight Empty 11.5 lb 5.2 kg

Weight Full 30.1 lb 13.6 kg

Length x Width x Height 13.5” x 10.75” x 17” 345mm x 275mm x 430mm

Operating Pressure Max/Min 500/40 psi 40/3 bar

Straight Stream Nozzle Reach 50 feet @ 100 psi 15 meters @ 7.0 bar

Low Expansion Nozzle Reach 37 feet @ 100 psi 11 meters @ 7.0 bar

Medium Expansion Nozzle Reach 9 feet @ 100 psi 3 meters @ 7.0 bar