1/5

I'D EVAC 2019

RIG 2018

I'D S 2019

I'D L 2019

PPE INSPECTION - Inspection procedure - I’D S, I’D L I’D EVAC and RIG (160519)

I’D S, I’D L, I’D EVAC and RIG

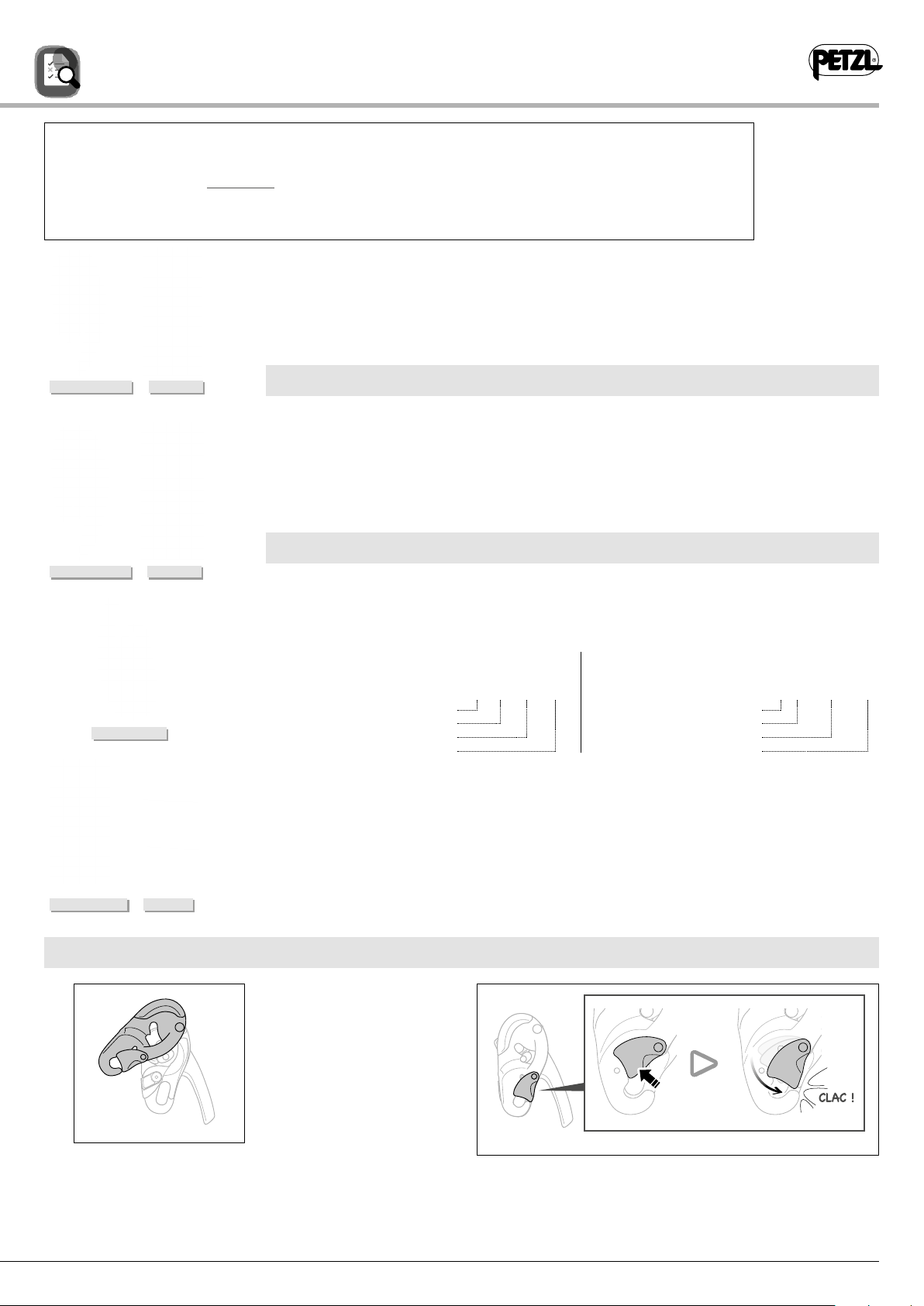

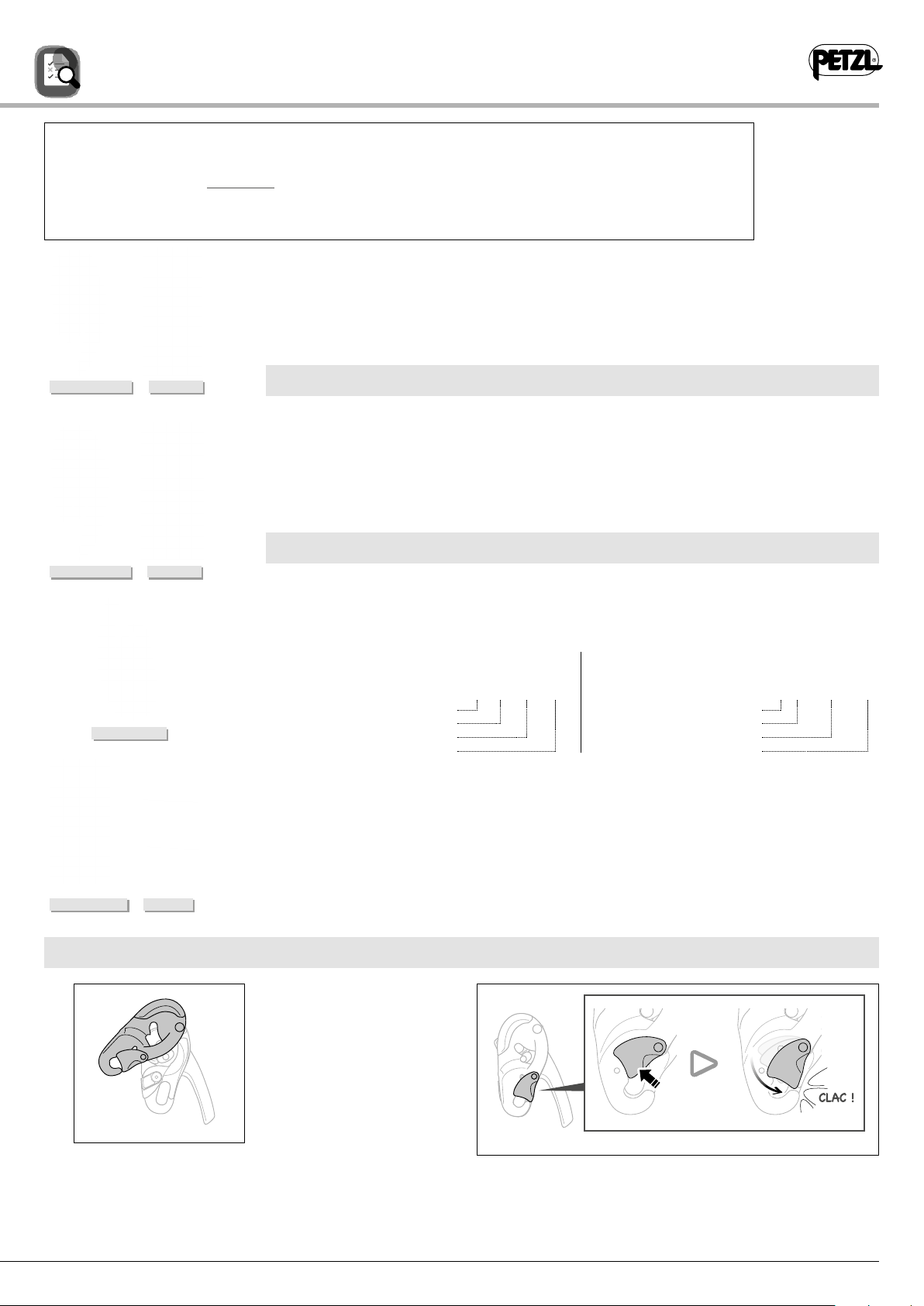

• Check the condition of the safety gate and the effectiveness of the spring.

• Check the condition

of the moving side plate

(marks, deformation, dirt,

cracks, wear...).

3. Checking the moving side plate

1. Known product history

Any PPE showing unexpected degradation should be quarantined, pending a detailed inspection.

The user should:

- Provide precise information on the usage conditions.

- Report any exceptional event regarding his/her PPE.

(Examples: fall or fall arrest, use or storage at extreme temperatures, modification outside manufacturer's

facilities...)

2. Preliminary observations

Verify the presence and legibility of the serial number and the CE mark.

Note: the serial number code on our products is evolving. Two types of code will coexist.

See below for details on each serial number code.

Code A: Code B:

00 000 AA 0000 00 A 0000000 000

Year of manufacture Year of manufacture

Day of manufacture Month of manufacture

Name of Inspector Batch number

Incrementation Incrementation

Verify that the product lifetime has not been exceeded.

Compare with a new product to verify there are no modifications or missing parts.

• In addition to routine checks for each use, PPE should regularly undergo a detailed inspection by a competent

person. Petzl recommends an inspection every 12 months and after any exceptional event in the life of the product.

• PPE inspection should be conducted with the manufacturer's Instructions for Use.

Download the instructions at PETZL.COM.

PPE Inspection

Inspection procedure

I’D S, I’D L, I’D EVAC and RIG

• Check the condition of the safety gate and the effectiveness of the spring.

• Check the condition

of the moving side plate

(marks, deformation, dirt,

cracks, wear...).

3. Checking the moving side plate

1. Known product history

Any PPE showing unexpected degradation should be quarantined, pending a detailed inspection.

The user should:

- Provide precise information on the usage conditions.

- Report any exceptional event regarding his/her PPE.

(Examples: fall or fall arrest, use or storage at extreme temperatures, modification outside manufacturer's

facilities...)

2. Preliminary observations

Verify the presence and legibility of the serial number and the CE mark.

Note: the serial number code on our products is evolving. Two types of code will coexist.

See below for details on each serial number code.

Code A: Code B:

00 000 AA 0000 00 A 0000000 000

Year of manufacture Year of manufacture

Day of manufacture Month of manufacture

Name of Inspector Batch number

Incrementation Incrementation

Verify that the product lifetime has not been exceeded.

Compare with a new product to verify there are no modifications or missing parts.

• In addition to routine checks for each use, PPE should regularly undergo a detailed inspection by a competent

person. Petzl recommends an inspection every 12 months and after any exceptional event in the life of the product.

• PPE inspection should be conducted with the manufacturer's Instructions for Use.

Download the instructions at PETZL.COM.

PPE Inspection

Inspection procedure

Pre-2019 I’D S

Pre-2019 I’D L

Pre-2018 RIG