©Copyright Task Force Tips, Inc. 2004 - 2017 LIU-330 November 16, 2017 Rev08

4

1.0 MEANING OF SAFETY SIGNAL WORDS

A safety related message is identifi ed by a safety alert symbol and a signal word to indicate the level of risk involved with a particular

hazard. Per ANSI standard Z535.6-2006, the defi nitions of the four signal words are as follows:

DANGER DANGER indicates a hazardous situation which, if not avoided, will result in death or serious

injury.

WARNING WARNING indicates a hazardous situation which, if not avoided, could result in death or serious

injury.

CAUTION CAUTION indicates a potentially hazardous situation which, if not avoided, could result in minor

or moderate injury.

NOTICE NOTICE is used to address practices not related to personal injury.

2.0 SAFETY

The eductor is designed for Class A and Class B foam concentrates. If you intend to use the eductor for liquids other than Class A

and Class B concentrates and water, we urge you to contact the Task Force Tips Engineering Department. The use of other liquids

may void the warranty and subject the user to hazards not addressed in this manual. The user assumes all risks for non-intended

uses.

• Make sure there is enough foam concentrate prepared before fi ghting fi re. TFT’s eductors are calibrated 15% more than the

nominal rate, or half percent point, which ever is less. Per FOAM EQUIPMENT AND LIQUID CONCENTRATES – UL 162,

the liquid concentrate induction rate of a proportioner, expressed as a percentage of the fl ow rate of the mixed water plus

concentrate solution, shall be minus zero (0) percent, plus thirty (30) percent of the manufacturer’s specifi ed induction rate or

one percent point, whichever is less.

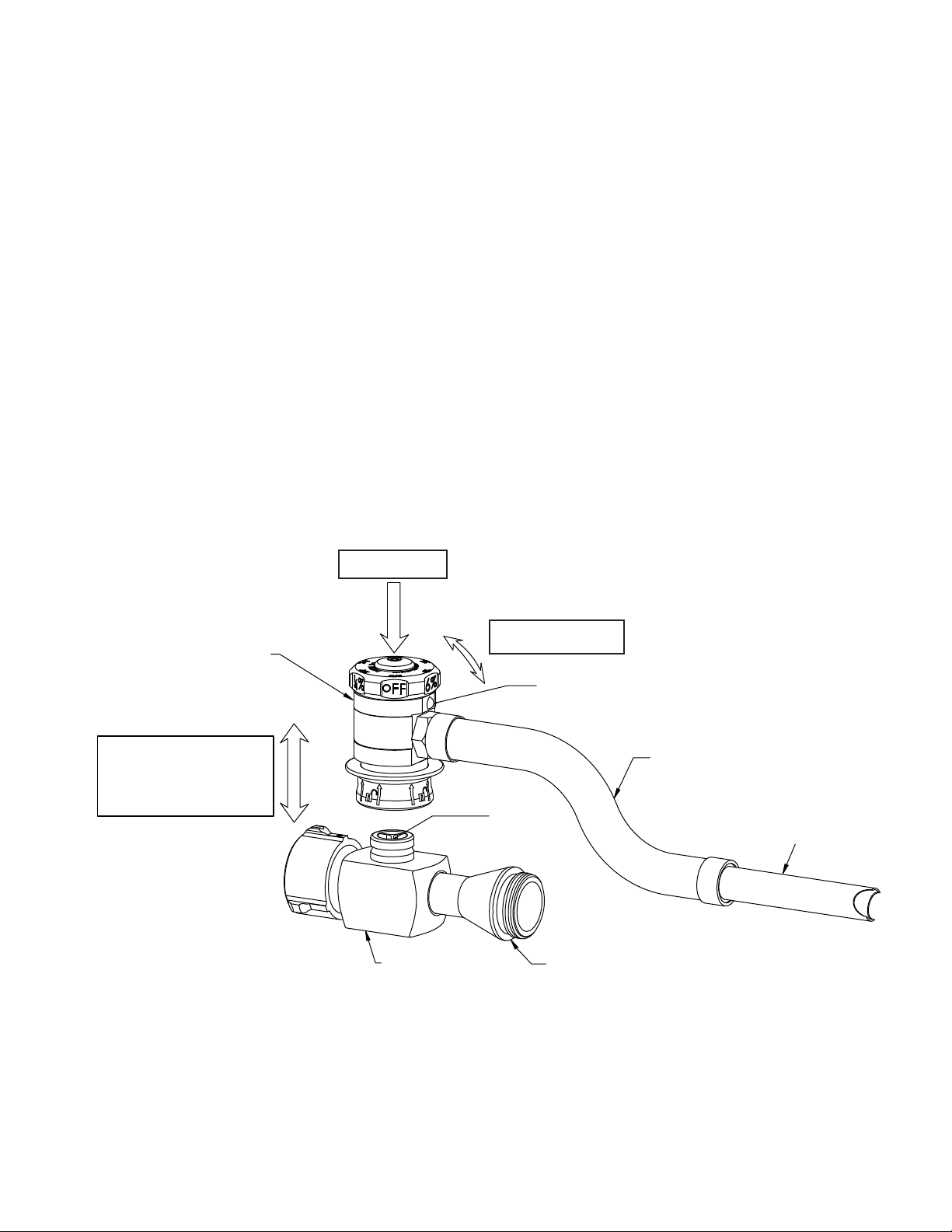

• Make sure the meter head set to OFF position and the correct nozzle and hose lay are securely attached to the eductor before

the hose line is charged.

• Make sure the nozzle gallonage matches eductor’s gallonage.

• Make sure the hose lay does not exceed the maximum listed in the operating instruction.

• Make sure that the meter head is set to the correct concentration for the type of foam being used. Foam concentrates can be

ineff ective if not used at the correct percentage.

DANGER Lack of foam can place operator at risk of injury or death. Establish foam fl ow before advancing

into hazardous situations. Make sure you do not run out of foam concentrate before the task is

complete. Check concentrate level periodically and keep an adequate supply on hand.

WARNING Do not use Class A foam on Class B fi res or Class B foam on Class A fi res. Note: Some foam

concentrates are universal and can be used on Class B fi res and spills and as a wetting agent

on Class A fi res. (Refer to foam concentrate manufacturer’s recommendations for proper foam

choice.)

WARNING Improper use of foam can result in injury or damage to the environment. Follow the foam

concentrate manufacturer’s instructions and fi re service training to avoid the following:

• Using the wrong type of foam on a fi re, i.e. Class A foam on Class B fl ammable liquid fi re

• Mishandling of concentrates

• Plunging foam into pools of liquid fuels

• Directing foam onto yourself or other personnel

WARNING There is a wide variety of foam concentrates. Each user is responsible for verifying that any foam

concentrate chosen to be used with this unit has been tested to assure that the foam obtained is

suitable for the purpose intended.