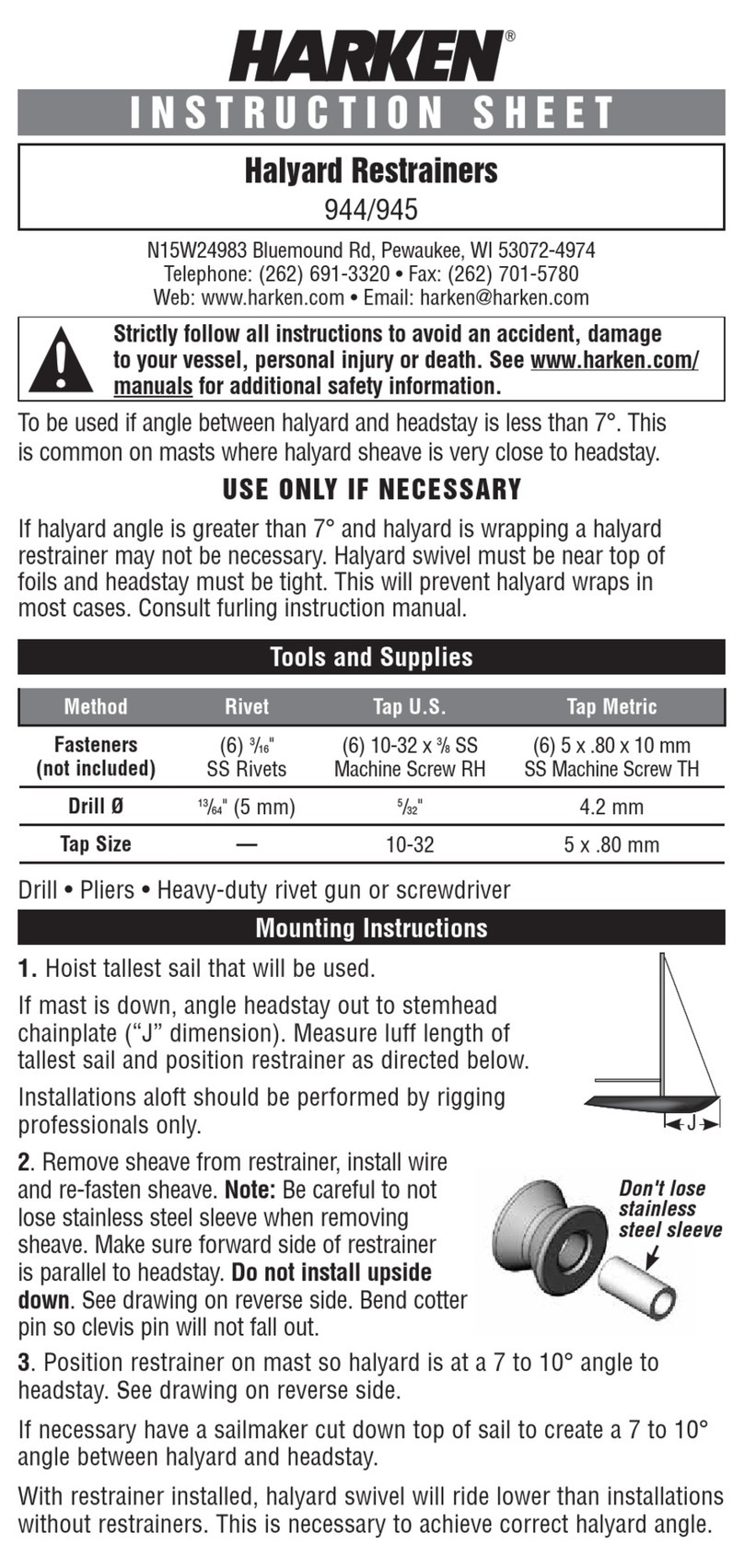

INSTRUCTIONS

Ti-Lite Carbo AirBlock®

351 (29mm), 2651 (40mm), 2607 (57mm)

1251 E. Wisconsin Avenue • Pewaukee, WI 53072 USA

Tel: 262-691-3320, Fax: 262-691-3008

A2 Repeat A1 two times.

See: E Finish—Dead-End

Line.

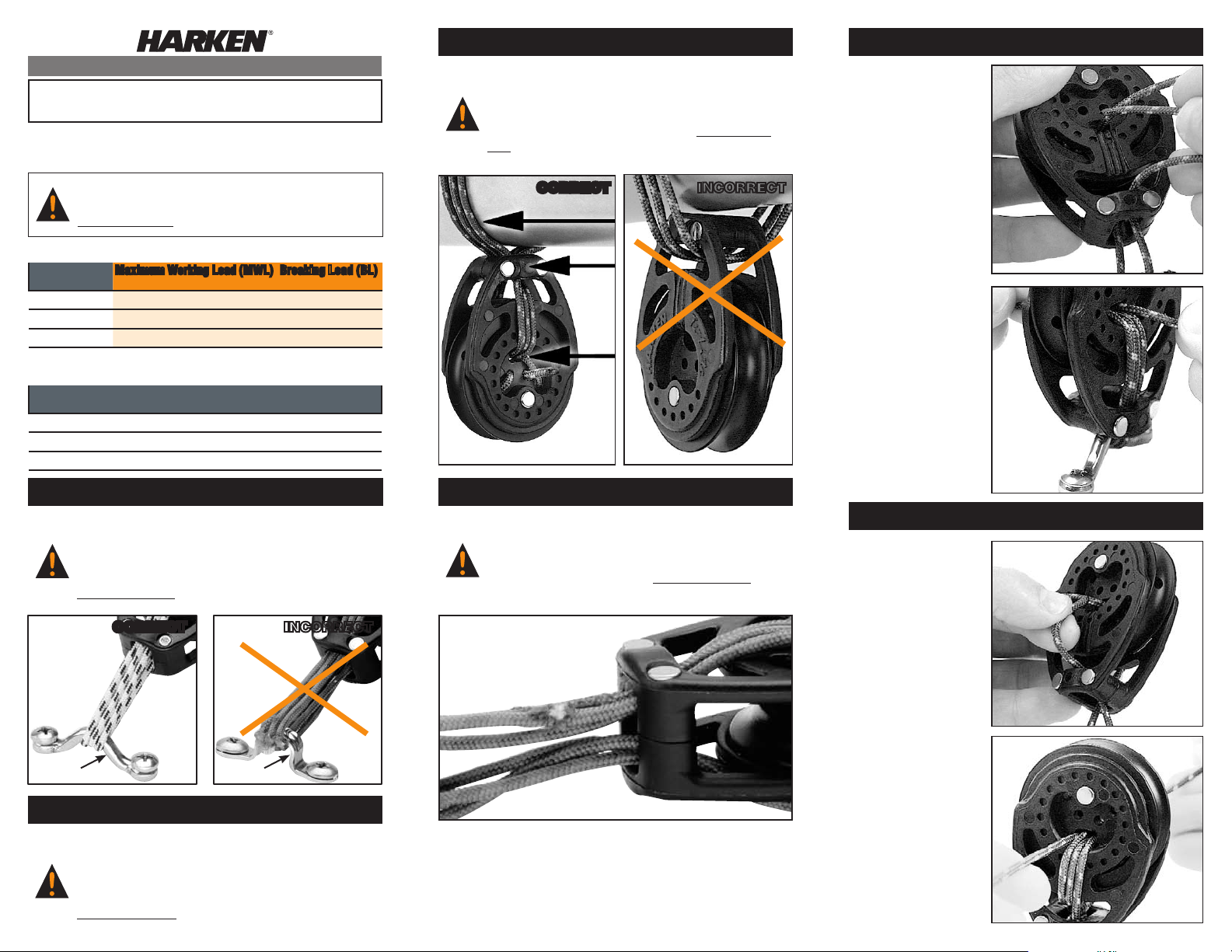

A1

A2

A1 Pass line through

mouth, through head,

around bail, through

head and through mouth

in opposite

direction.

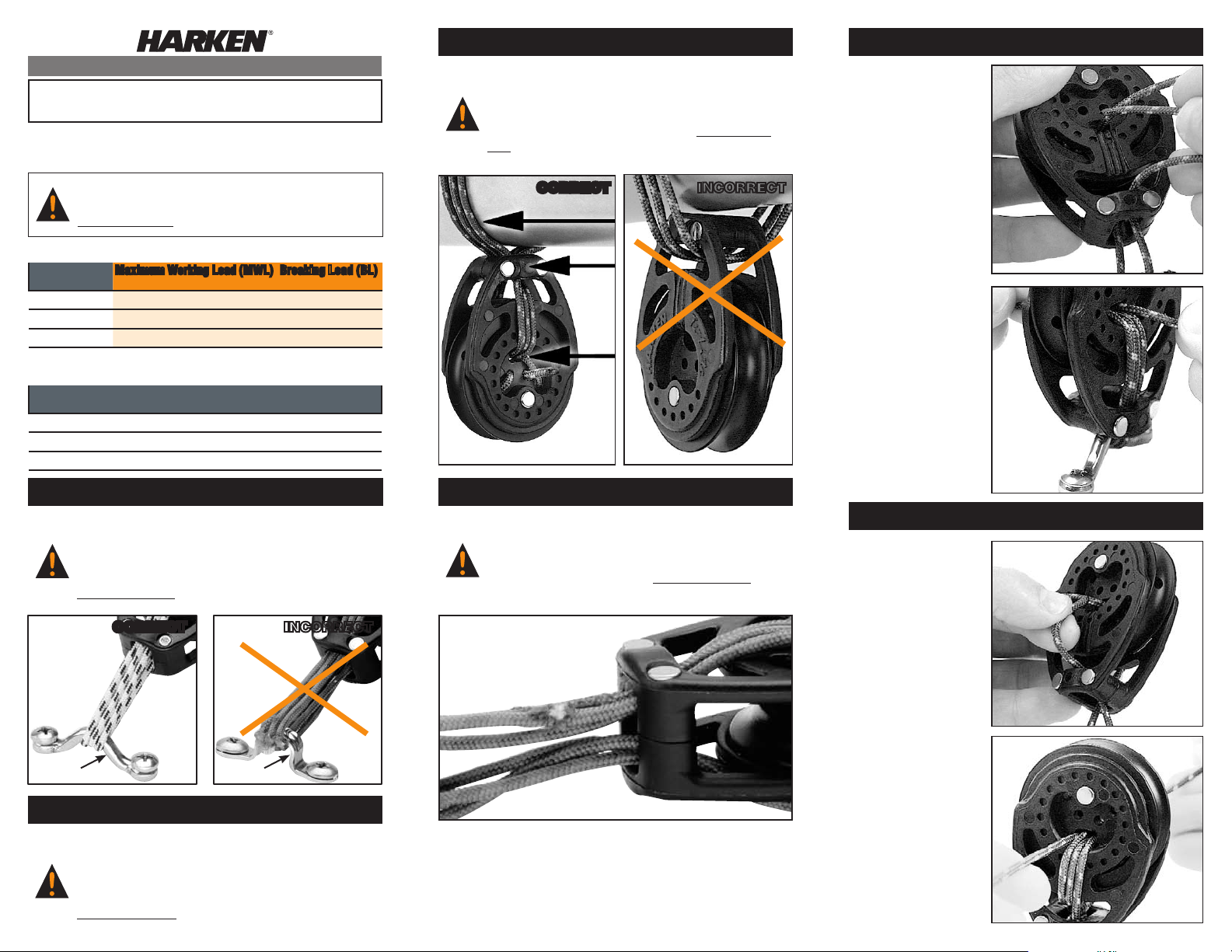

B1 Pass line through

mouth, through head,

around bail so line

crosses.Go through

head and through

mouth in opposite

direction.

B1

B2

B Tie to Bail/Eyestrap—Perpendicular

B2 Repeat B1 two

times, crossing line each

time.

See: C Tie to Boom.

for complete

instructions.

See: E Finish—Dead-End

Line.

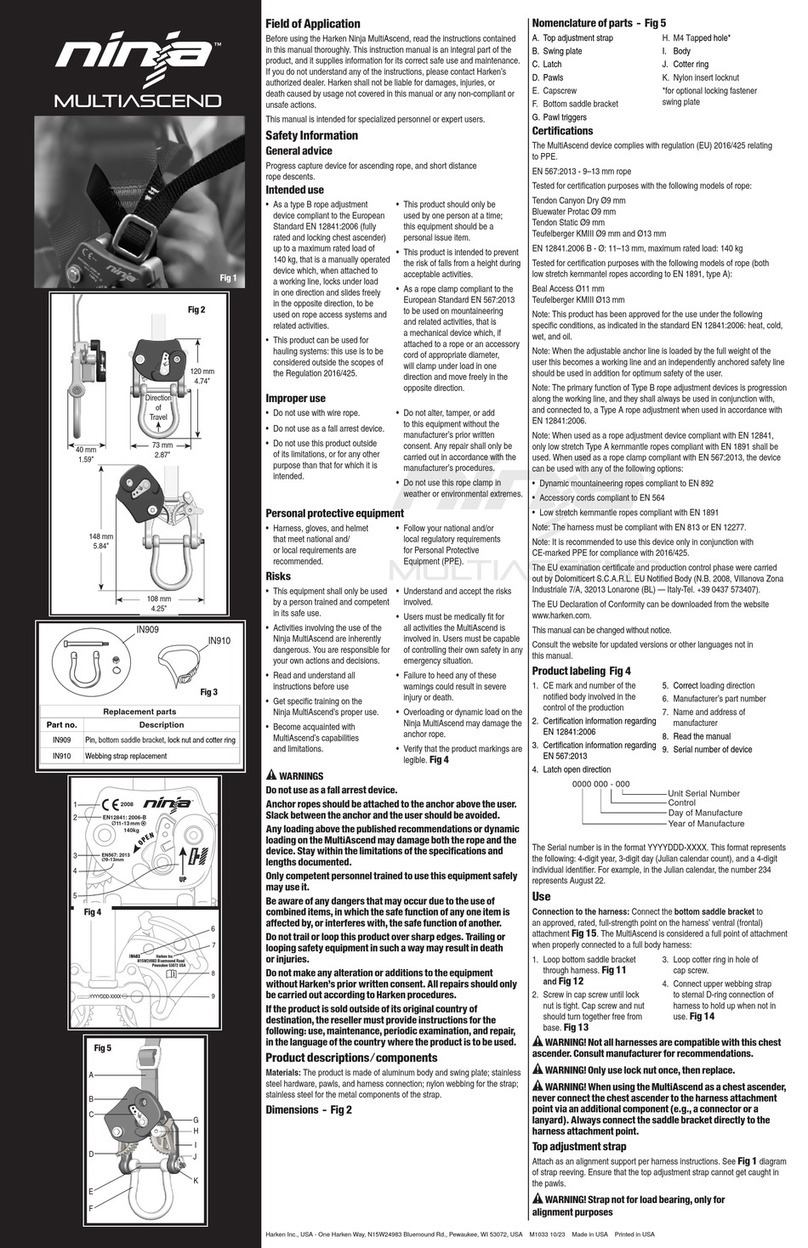

A Tie to Bail/Eyestrap—Parallel

WARNING!: Use three loops of the line supplied.

Using fewer loops will weaken the block causing it to

break suddenly causing an accident, damage to your

vessel, personal injury or death. See www.harken.

com for additional safety information.

Inspect Line Every Time You Sail

Inspect line for chafe or UV-damage every time you sail. Replace

damaged line immediately. Replace line with no visible damage after

no more than two-years use. Consult Chart B (left) for replacement

line or use block breaking strength, Chart A (left) to select the

correct line.

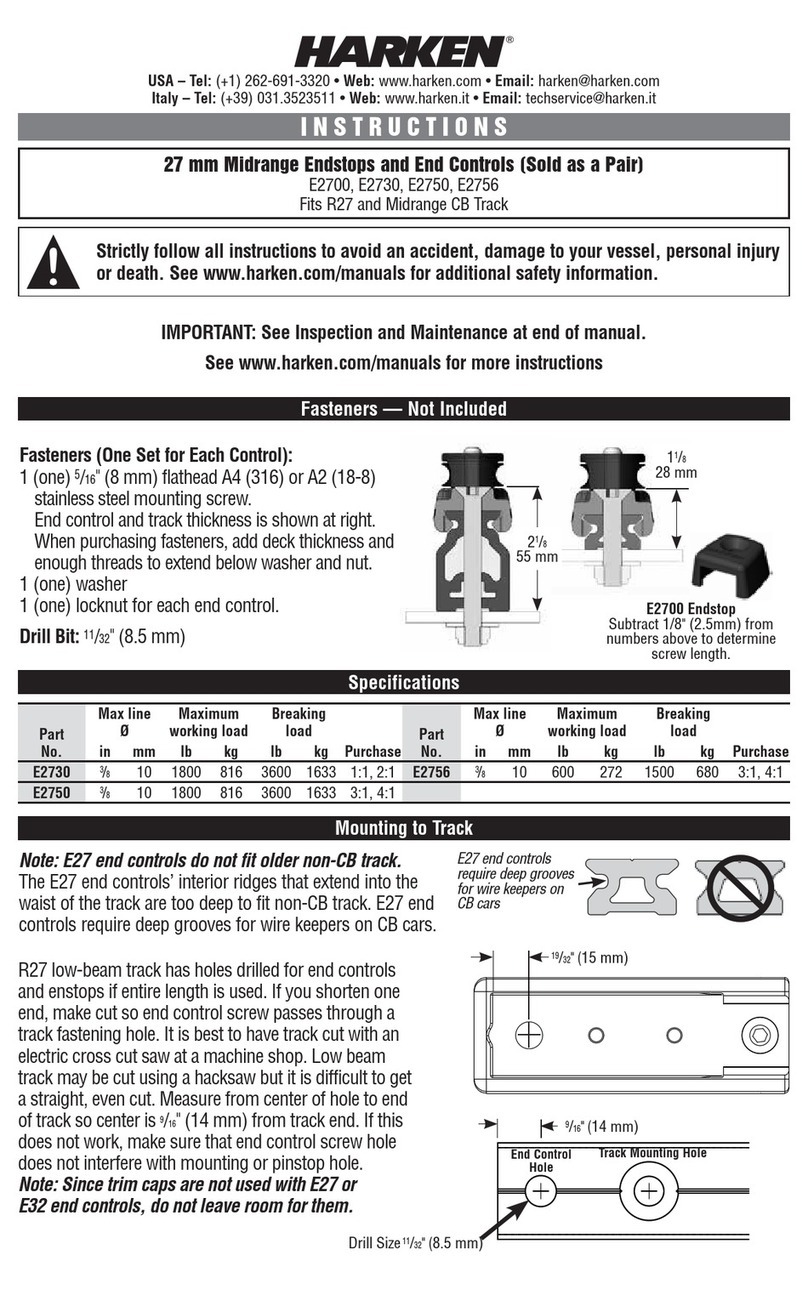

Tie to Mouth of Block

Use Three (3) Loops of Supplied Line

Tie Only to Objects with Rounded Edges

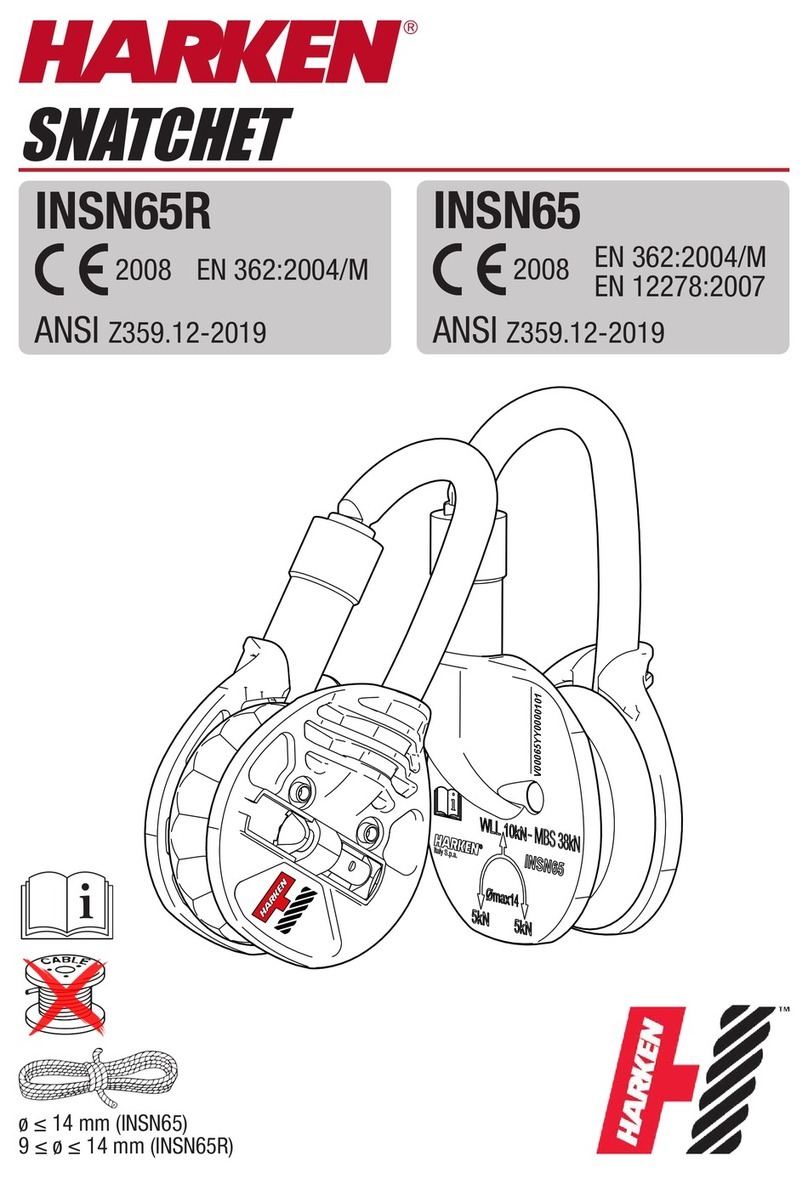

Part

No.

Reorder

Part No.

Line Ø Line Type

in mm

351 HCP1438 1/16 2 Maxibraid

2651 HCP1419 3/32 2.5 Maxibraid

2607 HCP392 1/8 3 Maxibraid

Chart B—Line Replacement

*Includes 4' (1.2m) line

Part

No.

Size

(mm)

Maximum Working Load (MWL) Breaking Load (BL)

lb kg lb kg

351* 29 330 150 1000 454

2651* 40 485 220 1200 544

2607* 57 792 360 2380 1080

Chart A—Block Specifications

3 LOOPS

HEAD

MOUTH

CORRECT INCORRECT

CORRECT INCORRECT

Strictly follow all instructions to avoid an accident,

damage to your vessel, personal injury or death. See

www.harken.com for additional safety information.

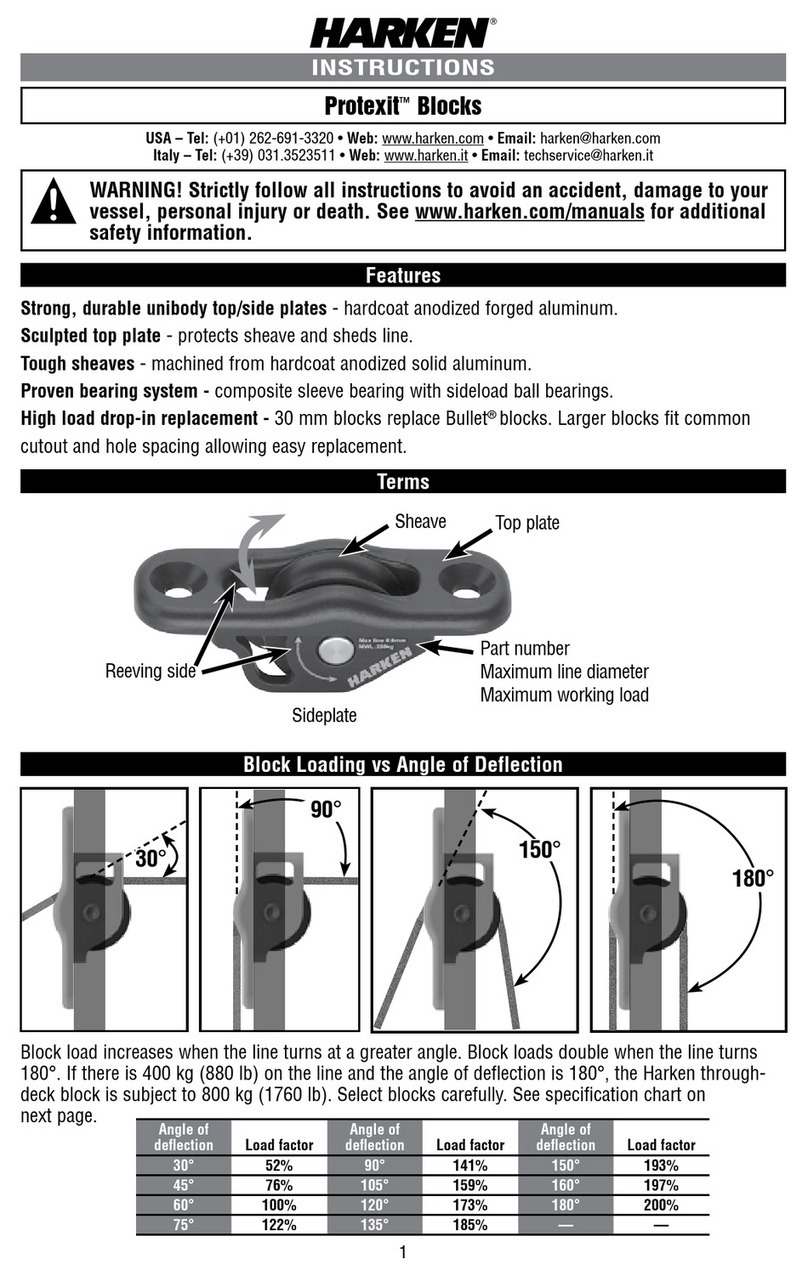

WARNING!: Attach only to objects with rounded edges.

Do not tie block to stamped eyestrap. This will cause

line to chafe and break suddenly causing an accident,

damage to your vessel, personal injury or death. See

www.harken.com for additional safety information.

WARNING!: Tie only to the mouth of the block as

shown. Do not tie to head of block. This will cause

the block to break suddenly causing an accident,

damage to your vessel, personal injury or death. See

www.harken.com for additional safety information.

WARNING!: Failure to inspect and replace UV-dam-

aged, worn or frayed line can cause the line to break

suddenly causing an accident, damage to your vessel,

personal injury or death. See www.harken.com for

additional safety information.

Rounded Sharp