TATAREK RT-08K User manual

Zakład elektroniczny TATAREK Jerzy Tatarek

USER MANUAL

1

RT-08K

REGULATOR

OF

HEATING SYSTEM WITH FIREPLACE

12

RT08K/2008/TITANIUM/ANG

The regulator controls heating system based on a water jacket fireplace which is a heat source. The

heat receivers are: applicable warm water accumulator (CWU) and central heating system (CO).

1.Basic technical parameters:

Power 230V/50Hz

Power consumption without load 5W

Max connection power 750W

Operation conditions 0 50 C, humidity 10 90%

(No condensation)

Housing protection class IP41

Fuse 6,3A/250V

Number of outputs to control pumps 3 * 250W/230V/50Hz

Number of nonvoltage outputs 1

Number of water temperature sensors 3 * KTY81 (0...+100 C )

Temp. measurement precision 2 C

Temp. measurement resolution 0,5 C

Number of time zones 4

÷ ÷

o

o

o

o

Zakład elektroniczny TATAREK Jerzy Tatarek

50-559 Wroclaw, wieradowska st,

ph. (071) 367-21-67, 373-14-88, fax 373-14-58;

Bank account: BZ WBK S.A. WROCŁAW 6910901522-0000-0000-5201-9335

75 S

Admission date Realization date Signature REMARKS

211

2. Principle of operation

T1

T3

T2

P3

P1

Fig.1a Basic configuration of regulator operation

T1

T3

T2

P3

P3

P1

Fig.1b Configuratio of regulator operation with heat exchanger for the CO central heating system

(pump of the heat exchanger and CO connected to the output P3)

T1

T3

T2

P2

P3

P1

Fig.1c Configuration of regulator operation with heat exchanger for the CO and CWU systems

The regulator RT-08K controls the pump that supplies the applicable water accumulator

(P1). The pump P1 operates if both a fireplace temperature exceeds the value and is higher

than the temperature of the accumulator (T2) by the value (see

PARAMETERS OF LEVEL1).

The second function is the control of the circulating pump of the central heating system(P3).

The pump works if a fireplace temperature exceeds the value. It’s possible to turn on the

CWU priority function (see the description of the operation modes of the pump CO.

The regulator is equipped with the clock to control the CWU priority over the selected times of

the day.

warm

CWU

central heating

ZAŁ CWU

DeltaCWU

ZAŁ CO

CE CONFORMITY DECLARATION

Ref. No. 58.RT.01.2007/1/B

We, ZAKŁAD ELEKTRONICZNY TATAREK Jerzy Tatarek

75 Swieradowska St. , 50-559 Wroclaw

declare under our sole responsibility that

the product: Regulator of heating system with solar collector

model: RT-08, RT-08K, RT-08P

PN-EN 55022: 2000 - (EMC)- IT devices

Characteristics of radioelectric noises. Acceptable levels and measurement methods

:

Laboratory IASE 51-618 Wroclaw, 1 Wystawowa st.

Test report No. 39/DL/I/07 of 22.06.2007

41/DL/I/07 of 03.07.2007

Place of issue: Manufacturer representative:

Wroclaw Mirosław Zasępa

Date of issue: Position:

08.2007 Konstruktor

is in conformity with the basic requirements included in Directive EMC 2004/108/WE of 15.12.2004 (the

electromagnetic compatibility law of 13.04.07) and Directive LVD 2006/95/WE of 21.08.07 (Laws Journal

of 2007 No. 155 pos. 1098) regarding the requirements for electric devices.

To the conformity evaluation the following harmonized standards were used:

PN-EN 60730-2-1: 2002 - Automatic electric regulators for house usage and the like. Part 2-1:

Specific requirements regarding electric regulators for electric house

devices

PN-EN 60730-1: 2002 - Automatic electric regulators for house usage and the like.

Part 1: General requirements.

Electromagnetic compatibility

Complementary information

Electronic Engineering Plant TATAREK

has initiated management system and complies with the following standard :

ISO9001: 2000 CERTIFICATE No. 133/2004 of 01.2004

Polish Foreign Trade Chamber

The last two digits of the year in which the CE marking was affixed: 07

10 3

CWU Applicable Warm Water Accumulator (boiler)

KOM Water jacket fireplace

CO Central heating system

T1 Upper temperature sensor of solar collector

T2 Lower temperature sensor of CWU

T3 Temperature sensor of fireplace water jacket

P1 Pump supplying CWU from fireplace

P2 Pump of the primary side of heat exchanger (it operates if P1 and P3 are activated)

P3 Circulating pump CO

2.1 Pump CO operation

2.2 Pump CWU operation

2.3 CWU priority and summer mode

In the regulator one can set “TrybCWU”parameter achieving different strategies of operation.

Possible modes are:

The pump CWU turned off

Turning off the heating system in summer time (the pump CO doesn’t operate). Fireplace

only works in the preparation function CWU.

Standard operation (parallel operation of pumps) without favouring the CWU circuit

WYŁ -

LATO-

ZAŁ -

If fireplace temperature exceeds a set value of 45 C (”T.załCO”parameter) the pump CO turns on.

The switch-off of the pump below the value causes a faster heating of the water jacket above the dew

point and by that a longer life-time of the fireplace.

During supplying the applicable warm water accumulator CWU, the pump can operate cyclically if

the CWU priority is set (Limitation of the heat amount flowing into the system CO).

The cyclical operation is based on turning on the pump for 45 secs and then turning off for 4min

(”t.stopCO”parameter).

The regulator realizes the after season rundown of the pump by switching it on for 1 min if it doesn’t

operate for a week.

o

The regulator protects the system from freezing, automatically turning on the circulating pump if the

measured temperature is below 4 C.

o

The regulator controls as well the pump supplying the applicable warm water accumulator CWU.

The pump CWU is to turn on if water temperature in fireplace is higher than the threshold of 45 C

(”T.załCWU”parameter) and higher than in the accumulator CWU by 5 C (”DeltaCWU”

parameter). If CWU temperature exceeds 65 C (”T.maxCWU”parameter) the pump CWU turns off.

There are 2 ways of supplying the accumulator CWU:

65 C

(„TmaxCWU”parameter )

Optimal supply (Parameter ”SterCWU”=2) - from partial discharge to max supply. The

supply turns on if the upper temperature sensor of CWU (T1) shows temperature lower than 50 C

(”TminCWU”parameter) and turns off if the lower temperature sensor of CWU (T2) shows

temperature higher than 65 C (”TmaxCWU”parameter)

The regulator realizes the after season rundown of the pump by switching it on for 1 min if it doesn’t

operate for a week.

o

o

o

o

o

o

?

?

Keeping the accumulator CWU at maximal readiness (Parameter ”SterCWU”=1).

The supply starts if the lower temperature sensor of CWU (T2) shows temperature below

Connection cable of regulator may be replaced only

by producer or his authorized service locations

WARRANTY

WARNING !

ANY MODIFICATION OF THE REGULATOR MADE BY USER CAN BE

THE CAUSE OF SAFETY CONDITIONS DETERIORATION AND CAN

EXPOSE THE USER TO ELECTRIC SHOCK OR DAMAGE DEVICES

SUPPLIED.

Date of sale Seller's signature and stamp

Zakład elektroniczny TATAREK Jerzy Tatarek

50-559 Wroclaw, 75 Swieradowska st

ph. (071) 367-21-67, 373-14-88, fax 373-14-58; tax index number 899-020-21-48;

Bank account : BZ WBK S.A. O/WROCŁAW 6910901522-0000-0000-5201-9335

1.Warranty is valid [24] months from the date of sale.

2.Producer does not take responsibility for any mechanical damages made by user.

3.MAKING REPAIRS OR MODYFYING THE DEVICE BY USER IS

FORBIDDEN AND CAUSES WARRANTY CANCELATION

4.Warranty card is valid only with date of sale, seller's signature and stamp

5.Warranty and after-warranty repairs should be done only by producer, damaged

regulators should be sent to producer in order to make all repairs needed.

6.Warranty protection involves the EU

7.Warranty does not exclude, not restrict and not suspend buyer’s rights coming from

the incompatibility of the article with the agreement (Laws Journal No. 141 Pos. 1176)

WARNING!

1. Producer does not take the responsibility for damage

caused by atmospheric discharge

2. and overvoltage in the mains

3. Burnt fuses are not subject to warranty replacement

Register No.. GIOS: E 0002240WZ

Worn out electronic

and electric devices must be transfered to

the utilization collection place, where will

be accepted for free

ARGO-FILM

Recycling Plant No. 6

180 Krakowska st., 52-015 Wroclaw

ph.: 071 794 43 01,

0 515 122 142

49

PRIO-

ZEGAR-

Faster reaching the readiness of CWU accumulator by limiting heat obtain by heating

system. The pump CO works cyclically. Turning off the pump CWU after supplying the accumulator

causes the comeback of normal operation of the pump CO

beyond time zones the pump operates like in the ZAŁmode and in time zone like PRIO

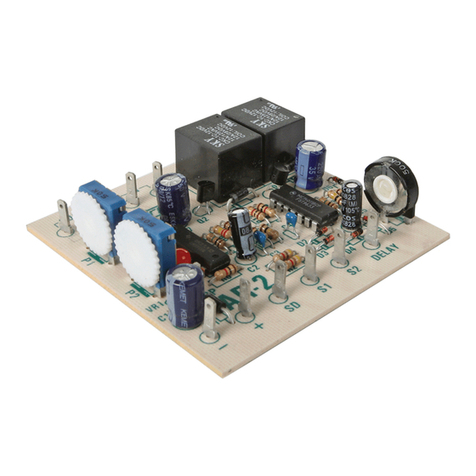

Fig.3 Electrical scheme

T1 Upper temperature sensor of solar collector (option)

T2 Lower temperature sensor of CWU accumulator

T3 Temperature sensor of fireplace water jacket

P1 Pump supplying CWU accumulator from a fireplace

P2 Pump of the primary side of heat exchanger (it operates if P1 or P3 is activated)

P3 Circulating pump CO

Pump P1

230V/50Hz

Pump P3

230V/50Hz

MAINS

230V/50Hz

Pump P2

230V/50Hz

+

+

+

Temperature

sensors

T1

T2

T3

CONTROL

2.4 Output „CONTROL”

The regulator is equipped with the relay CONTROL whose contacts can be used e.g. to switch

off another heat source when a fireplace works. The “PrzekSTR”parameter defines the function of

the relay more precisely

3 Service of the regulator

There are elements on the control panel (fig. 2).

The state is presented on the text display (1). The screens inform about the operation of devices,

temperature of sensors; they make it possible to change the parameters etc..The change of screen is

done by pressing the WYBIERZ button (3). If this is the screen that is able to change a parameter,

press the USTAW button, which causes blinking of the parameter field to be changed. By pressing

“+”(2) or “-”(4) one can alter its value.

If there are more parameter fields on the screen (e.g. setting the clock) then one will go among them

by pressing the WYBIERZ button (3).

Fig.2 Control panel view

1. Text display

2. Increase button

3. Choice button of parameter

4. Decrease button

5. Confirm button

By clicking the USTAW button (5) one confirms the changes - the parameter field stops blinking.

The changed parameter not confirmed for 10 secs is not accepted by the regulator and it recalls a

previous value of the parameter.

123

4 5

5

Załączony przekaźnik STEROWANIE

Wskazanie górnego czujnika CWU

Wskazanie dolnego czujnika CWU

Wskazanie czujnika kominka

CO *

KOM ?CWU

80 o

73 o68 o

8

3.1 Time zones

The regulator is equipped with the clock, which enables the automatic change of the regulator

operation at different times of day. 24 hrs are divided into 3 time zones ( ) and the single time

when no zone is active that is ZONE 0 or BAZA (BASE). Each zone has a start time (OD)/FROM

and an end time (DO)/TILL.

For the regulator factory settings are as it follows:

ZONE 1 FROM 6.00 TILL 8.00

ZONE 2 FROM 14.00 TILL 17.30

ZONE 3 FROM 20.00 TILL 22.30

$1, $2, $3

3.2 Screens

Alarm screens is not seen till the following emergency situation takes place:

1. Damage of sensor T1 (upper one of CWU). “T1”shows up. The alarm doesn’t work if the sensor

is not installed.

2. Damage of sensor T2 (lower one of CWU). “T2”shows up.

3. Damage of sensor T3 (of fireplace). “T3”shows up.

4. The exceeding of the acceptable temperature of fireplace /”TEMP KOM”/ defined by

the “T.ALARMU”parameter

ALARM !!

T1

ALARM !!

TEMP KOM

Emergency situation is accompanied by a broken sound alarm that can be turned off by pressing the

USTAW button.

In emergency of temperature exceeding the pump CO turns on to cool off fireplace.

shows the actual temperature of

fireplace

Screen of fireplace water jacket temperature measurement

It’s a stable state that is in order to change it one needs to press the WYBIERZ button

shows the actual temperature in the upper and lower part of the CWU

accumulator.

Screen of CWU temperature

KOMINEK

73.50

1...30mins 4mins

1...2 1

1

2

75...89 oC 85 oC

1...6 1

1

2

3

4

5

6

t StopCO

Ster CWU

T ALARMU

PrzekSTR

4 Installing the regulator

!

!

!

!

THE REGULATOR SHOULD NOT BE EXPOSED TO WATERAFFECTING.

ITS ENVIRONS OUGHTTO BE CLEAN.

THE PRODUCER DOESN'TTAKEANY RESPONSIBILITYFOR

DAMAGES CAUSED BYWRONG USAGE OF THE REGULATOR.

Connection diagram of the elements of the regulator is presented on fig. 3

THE REGULATOR IS SUPPLIED BY230V/50HZ .

THE REGULATOR HAS TO BE CONNECTED TO THE MAINS WITH THE

ANY MOVES REGARDING INSTALLATION SHOULD BE MADE AT

THE DISCONNECTED MAINS.

ZERO-PIN.

FUNCTION

PARAMETERS OF LEVEL 3

NAME RANGE

FACTORY

SETTING

Pause time of CO pump in cyclical mode. After the time the pump

turns on for 45 secs.

Kind of supply for the CWU accumulator

Temperature sensor T2 (down) controls the supply of CWU

Temperature sensors T1 (up) and T2 (down) control

the supply of CWU accumulator

Fireplace temperature at which alarm turns on.

Switch-on of the relay CONTROL if

fireplace temperature is higher than „T.załCO”

„T.załCWU”fireplace temperature is higher than

fireplace temperature is higher than

CWU temperature measured by T2 sensor is higher

than “TminCWU”

CWU temperature measured by T1 sensor is higher than

CWU temperature measured by T2 sensor is higher than

6

7

CWU 80o

68o

Upper temperature sensor T1 (if available)

Lower temperature sensor T2

It’s a stable state that is in order to change it one needs to press the WYBIERZ button

Screen of whole system operation

On the screen are the symbols of devices:

KOM- fireplace

CO - central heating system

CWU - applicable warm water accumulator

$ - if the relay CONTROL is switched on

The symbols (every few seconds or after pressing USTAW button) are replaced with numbers

presenting the temperatures of those devices.

The blinking arrows mean the actual heat flow as an effect of pumps operation:

KOM->CWU the pump P1supplying the CWU accumulator is turned on.

KOM->CO the pump P3 is turned on.

fireplace sensor

80 o

73 o68 o

If the summer mode is active (only CWU), LATO replaces CO.

It’s a stable screen that is in order to change it one needs to press the WYBIERZ button

CO $

KOM->CWU

Screen of CWU operation mode

TrybCWU

LATO

In the regulator one can set “TrybCWU”parameter achieving different strategies of operation.

Possible modes are:

The pump CWU turned off

Turning off the heating system in summer time (the pump CO doesn’t operate). Fireplace

only works in the preparation function CWU.

Standard operation (parallel operation of pumps) without favouring the CWU circuit

Faster reaching the readiness of CWU accumulator by limiting heat obtain by heating

system. The pump CO works cyclically. Turning off the pump CWU after supplying the accumulator

causes the comeback of normal operation of the pump CO

beyond time zones the pump operates like in the ZAŁmode and in the time zone like PRIO

WYŁ-

LATO-

ZAŁ-

PRIO-

ZEGAR-

Screen of clock

The screen shows the actual time and the number of active time zone.

Time correction is possible after pressing the USTAW button (5) and the minutes field begins

blinking. The blinking value can be altered with the buttons “+”or “-”. Pressing the WYBIERZ

button (3) one comes to the hours field that can be set with the buttons “+”or “-”.

Pressing the USTAW button confirms the changes (the clock field will stop blinking).

ZEGAR $1

17:15

PoziomUS

0

Screen of setting the parameters

Normally the parameters setting level equals to “0”namely the parameters aren’t available.

After changing the level to “1”,“2”or “3”successive screens show the values of parameters.

The last screen contains “****”after which it comes back to the above mentioned screens.

30...60 oC 50 oC

20...85 oC 50 oC

30...100

oC

65 oC

30...100

oC

50 oC

1...10 oC 2 oC

T zaŁCO

TzaŁCWU

Tmax CWU

Tmin CWU

DeltaCWU

0:00...23:45 6:00

0:00...23:45 8:00

:00...23:45 14:00

0:00...23:45 17:30

0:00...23:45 20:00

0:00...23:45 22:30

0

CONTROL relay is turned on.

upper sensor of CWU

lower sensor of CWU

PARAMETERS OF LEVEL 1

FUNCTION

NAME RANGE

FACTORY

SETTING

Minimal temperature of fireplace at which the pump P3(CO)

is activated.

Minimal temperature of fireplace at which the pump P1(CWU)

turns on.

Maximal temperature of CWU accumulator. The exceeding

turns off the supply pump

Minimal temperature of CWU accumulator. The exceeding

turns on the supply pump

Minimal difference between fireplace and CWU accumulator

temperature needed for the pump operation P1 (CWU)

PARAMETERS OF LEVEL 2

FUNCTION

NAME RANGE

FACTORY

SETTING

STRF1 from

STRF1 till

STRF2 from

STRF2 till

STRF3 from

STRF3 till

Start of 1st time zone

End of 1st time zone

Start of 2nd time zone

End of 2nd time zone

Start of 3rd time zone

End of 3rd time zone

Table of contents

Other TATAREK Controllers manuals

Popular Controllers manuals by other brands

SMC Networks

SMC Networks PSE200 Series instruction manual

Galcon

Galcon Gal Pro DC operating manual

Weka

Weka HC 10 D operating instructions

Nice

Nice ROX600 Instructions and warnings for installation and use

EuroLite

EuroLite SPX-405 DMX user manual

Energy Master

Energy Master HHPM SERIES Installation, Operation, Maintenance, Service Manuals

Conoflow

Conoflow HP300 Instruction and maintenance manual

Auber Instruments

Auber Instruments TH220A instruction manual

Omron

Omron E5 K Series manual

Chamberlain

Chamberlain 945C Owner's instructions

Manson Engineering Industrial

Manson Engineering Industrial SBC-7208 user manual

Cooper

Cooper IBS-8431 installation instructions