AUBER INSTRUMENTS WWW.AUBERINS.COM

2019-05 P3/5

HoS2HOS Humidity Operating

Setpoint -40°F ~ 176°F 36 10

Hob2HOB Humidity Operating

Band 0°F ~ 200°F 2 10

System setting (SYS)1

PSD1PSD Device Access

Password 100 ~ 999 666 11

RST2RST Factory Reset N, Y N 12

Note 1: The TH220 model doesn’t have SYS menu and the parameter PSD. Only the

TH220-W and TH220A-W have the password parameter PSD.

Note 2: These parameters, HDM, HDT, HOS, HOD, and RST are only available in

TH220A and TH220A-W.

Details About Each Parameter

Note 1. tSP and HSP are the setpoints for temperature-control and humidity-

control respectively. tdF and HdF are the control-differential (i.e., control

hysteresis band) to prevent the load being turned on and off frequently. These

hysteresis bands are one-sided. tCM is the temperature control mode, which

can be set to heating (HT) or cooling (CL). HCM is humidity control mode,

which can be set to humidifying (H) or dehumidifying (dEH).

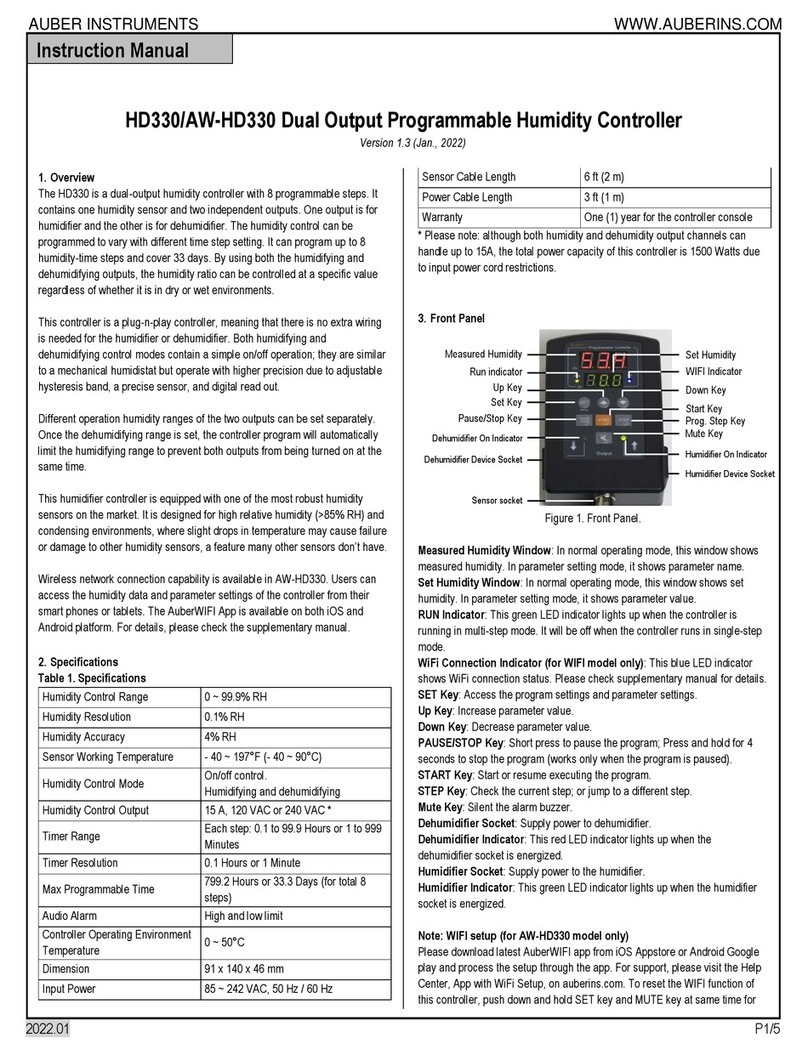

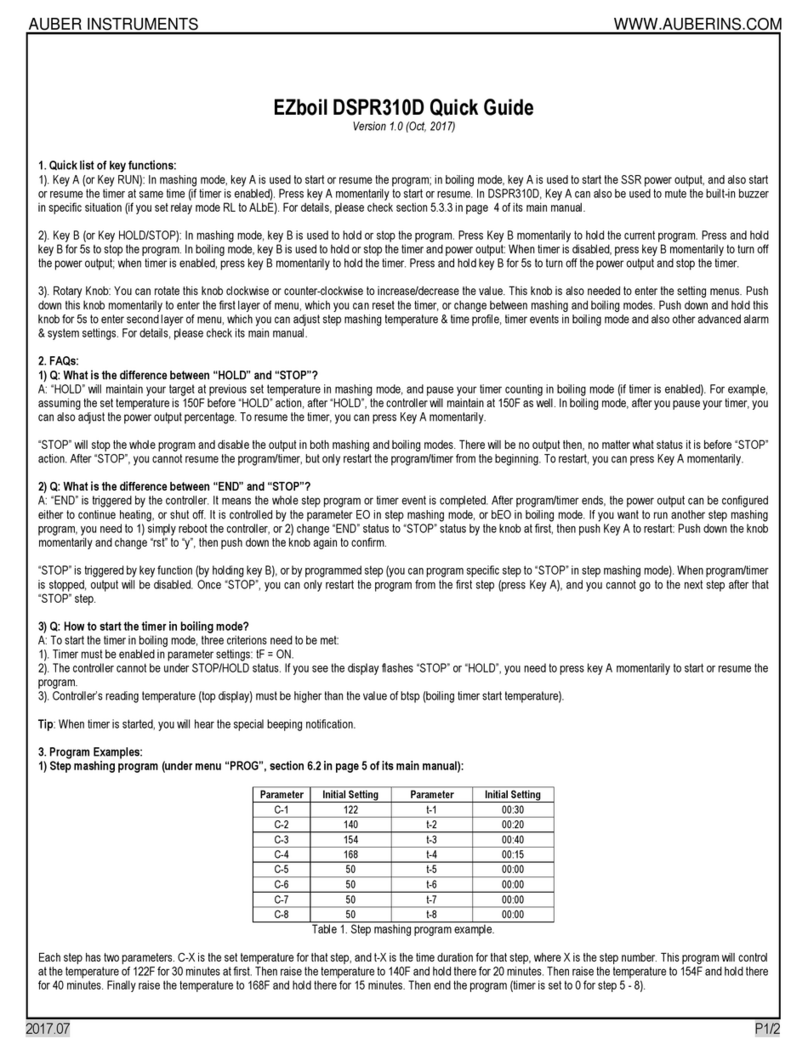

In the heating mode of the temperature-control channel, the controller will

energize the output socket till the temperature rise to the setpoint tSP; the

output socket will be energized again when the temperature drops below (tSP -

tDF). In contrast, in the cooling mode of the temperature-control channel, the

controller will energize the output socket till the temperature drops to the

setpoint tSP; the output socket will be energized again when the temperature

rises above (tSP + tDF). Please refer to the Figure 4 below when the output

relay will be turned on.

(TSP + TDF)

TSP

Temperature

Time

C oolin g Mo de

Relay ON

(TSP – TDF)

TSP

Temperature

Time

Relay ON

Heating Mode

Figure 4. Temperature output is decided by tSP and tDF.

Similarly, in the humidifying mode of the humidity-control channel, the

controller will energize the output socket till the temperature rise to the setpoint

HSP; the output socket will be energized again when the temperature drops

below (HSP - HDF). In contrast, in the dehumidifying mode of the humidity-

control channel, the controller will energize the output socket till the humidity

drops to the setpoint HSP; the output socket will be energized again when the

humidity rises above (HSP + HDF). Please refer to the Figure 5 below when

the output relay will be turned on.

(HSP + HDF)

(HSP – HDF)

HSP

Humidity

Time

Relay ON

Humidifying

Mode

HSP

Humidity

Time

Dehumidifying

Mo de

Relay ON

Figure 5. Humidity output is decided by HSP and HDF.

Small differential gives tight control. Large differential reduces the frequency of

cycle on and off, and it will extend the life of relay and compressor.

Note 2. toF and HoF are the sensor calibration offset for temperature and

humidity readings respectively. The offset is used to set an input offset to

compensate the error produced by the sensor or input signal itself.

For example, for temperature reading, if the unit displays 37ºF when the actual

temperature is 32ºF, setting parameter toF = - 5 will make the controller display

32ºF.

Note 3. The low limit alarm should be always lower than the high limit alarm.

When the measured temperature is higher than tAH, the temperature high limit

alarm will be on; when the measured temperature is lower than tAL, the

temperature low limit alarm will be on.

Similarly, for humidity readings, when the measured humidity is higher than

HAH, the humidity high limit alarm will be on; when the measured humidity is

lower than HAL, the humidity low limit alarm will be on.

When an alarm is on, the display will be flashing between the measured value

and the alarm type. To mute the alarm, press the DOWN key momentarily.

When the alarm is muted, the alarm indicator (see Figure 1, the small dot on

the last digit) will be lit. If the measured value gets out of the alarm zone then

gets back to the alarm zone again, the alarm will be on again. To resume the

alarm, press the UP key, the alarm indicator should turn off.

To disable the alarm, set High Limit Alarm = Low Limit Alarm. For example,

you can set both tAH and tAL to 32°F, so the temperature alarm will be

disabled.

Note 4. The parameter tAS and HAS are Anti-Short Cycle Delay for cooling

and dehumidifying respectively. The controller is used for cooling or

dehumidifying control, and the load is a compressor, use the parameter tAS or

HAS to prevent the compressor being turned on again when it is at high

pressure (i.e., just after it is turned off). Otherwise, it may shorten the life of

compressor. The Anti-Short Cycle Delay function is used to prevent the rapid

cycling of the compressor. It establishes the minimum time that the output

contact remains open (after reaching cutout) before closing again. The delay

overrides any load demand and does not allow the output contact to close until

the set time-delay value has elapsed. It gives time to release the refrigerant

pressure through evaporator. It is typically set to 4 - 6 minutes.

Note 5. Parameter tSF and HSF are the Sensor Failure Operation for

temperature and humidity control respective, they can be set to ON or OFF.