Gal Pro Instruction 1.0

1. Preface ................................................................................................................................. 5

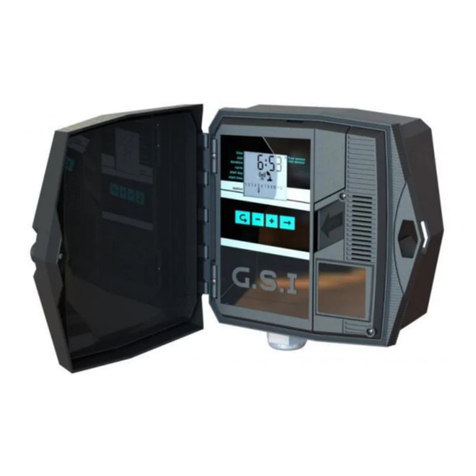

2. Controller Description ........................................................................................................... 6

3. Installation ............................................................................................................................ 8

a. Physical connection .................................................................................................. 8

b. Output connection ..................................................................................................... 9

c. Input Connection ..................................................................................................... 11

d. Power Supply .......................................................................................................... 11

4. First Operation .................................................................................................................... 14

5. Controller Definition ............................................................................................................ 16

a. Service Menu .......................................................................................................... 16

b. System Setup Menu ................................................................................................ 17

c. Water Meter Menu .................................................................................................. 19

d. Fertilizer System Menu ........................................................................................... 20

e. Filter Flush System Menu ....................................................................................... 21

f. Alarm Menu ............................................................................................................. 22

g. Log Books Menu ..................................................................................................... 22

6. Programming ...................................................................................................................... 23

a. Valves - Water and Fertilizer Programs .................................................................. 24

b. Sequence Setup ..................................................................................................... 26

c. Sequence Timings .................................................................................................. 27

7. Information and Programming ............................................................................................ 28

a. System Status ......................................................................................................... 28

b. Valve Status ............................................................................................................ 29

c. Valve Information .................................................................................................... 30

d. Sequence Status ..................................................................................................... 31

e. Sequence Information ............................................................................................ 32

8. Manual Overriding .............................................................................................................. 36

9. Alarm Menu ........................................................................................................................ 37

10. Data Loggers ...................................................................................................................... 38

11. Advance operation guide .................................................................................................... 39

a. Flow Control Mechanism ........................................................................................ 39

b. Condition Input Operation ....................................................................................... 40

12. Maintenance ....................................................................................................................... 42

a. Output Checkup ...................................................................................................... 42

13. Technical Specification ....................................................................................................... 43

Index