2TB Wood’s • 888-829-6637 P-7891-TBW

Lock out / tag out the power

source before proceeding to avoid unexpected

starts. Failure to observe these precautions could

result in bodily injury.

Coupling element may be thrown

from the assembly with substantial force if

subjected to a severe shock load.

Check operating speed against

Maximum RPM value in Table 1.

For a basic installation overview, scan the QR code

below:

Further component information available:

Specification sheets, 3D models

ecatalog.TBWoods.com

Coupling Selection Program

www.TBWoods.com/Select

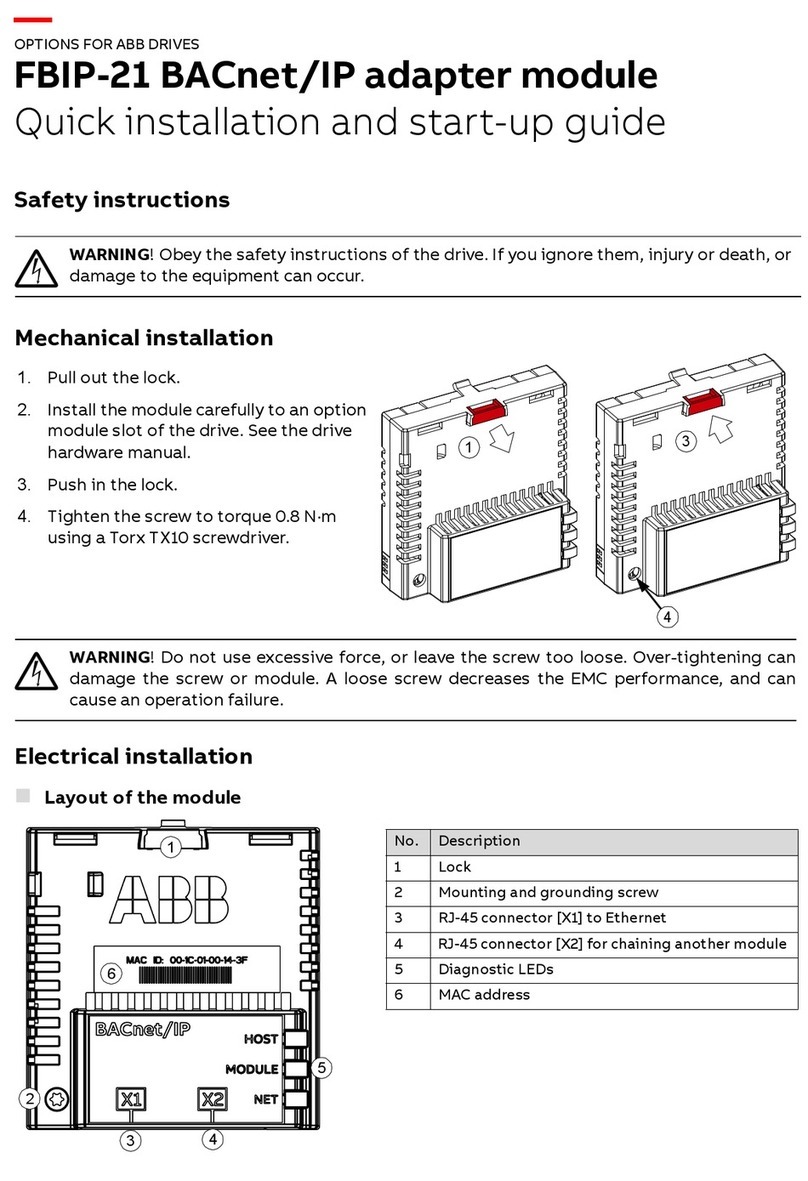

Installation / Alignment

Installation / Alignment Tools

• Hex key set

• Socket set

• Torque wrench

• Straight-edge

• Caliper

• Feeler gauge set

1. Inspect all coupling components and remove

any protective coatings, lubricants, paint or

rust from bores, mating surfaces and fasteners.

Remove any existing burrs, etc. from the shafts.

2. Slide one hub onto each shaft using keys where

required. (When using QD or Taper-Lock hubs,

follow the instructions furnished with the Sure-

Grip or Taper-Lock bushings.)

3. When high speed rings are to be used for

spacer couplings, loosely install one ring on

each half element.

4. Hold one half element on the hubs to determine

the appropriate hub spacing. If using spacer

elements with high speed rings, hold both half

elements on hubs to make sure that the hubs

do not interfere with the rings. The hub may be

installed with the hub extension facing in or out.

Make sure that the shaft extends into the hubs

at least .8 times the shaft diameter.

5. Lightly fasten hubs to shafts to prevent them

from moving during alignment.

6. Angular Alignment: Without rotating the

coupling, run a caliper around the hub and

set the caliper to the widest point. Find the

narrowest point with the caliper and feeler

gauges. Reposition equipment until this value

is as small as possible; reference Table 2 for

maximum value/degree.

7. Parallel Alignment: Using the misalignment

value from the previous step, look up the

maximum allowable parallel misalignment using

Table 2 and Figure 1. Without rotating the

shafts, run a straight-edge around the hub and

find the maximum offset with feeler gauges. If

necessary, realign the shafts. Recheck parallel

alignment.

Parallel Alignment

Angular Alignment

Scan to Watch Installation Video

or visit our Dura-Flex product page

at www.TBWoods.com