TBEI CRYSTEEL LB520 User manual

1643725H (404416) 2020-09-281

LO-BOY

TRUCK HOIST

CRYSTEEL’S

LB520

Web Site E-Mail Phone (507) 726-2728

Website: www.TBEI.com

E-mail: [email protected]

THIS MANUAL MUST BE INCLUDED WITH THE VEHICLE

AFTER COMPLETING THE INSTALLATION.

1643725H (404416) 2020-09-2821643725H (404416) 2020-09-283

DATE PURCHASED __________________________________________________________________

HOIST SERIAL NUMBER ____________________________________________________________

CYLINDER SERIAL NUMBER ______________________________________________________

DEALER __________________________________________________________________

ADDRESS __________________________________________________________________

PHONE __________________________________________________________________

FOREWORD

Crysteel’s LB520 Hoist has been designed and intended for use on single-axle trucks with cab-to-axle

dimensions of 72 to 132 inches and body lengths of 9 to 16 feet.

This manual contains information necessary for the proper installation and operation of Crysteel’s Model

LB520 Hoist. Study it carefully before attempting to mount or use the hoist. With proper installation and

maintenance, the Crysteel Model LB520 Hoist will give many years of trouble-free service.

When ordering parts, be sure to give serial number of hoist and cylinder. The serial number of the hoist

is stamped into the hoist frame near the base end of the cylinder. The serial number of the cylinder is

stamped on the barrel of the cylinder near the base. For future reference, copy these numbers NOW in the

space provided above. Order parts by number and description as given in the parts listing in this manual.

1. Engage PTO from cab and adjust engine speed to fast idle.

OPERATIONANDUSE

SOMEDO’SANDDON’TSFORSAFEANDLONGSERVICE

1. Usetheproperhydraulicuid.KEEPITCLEAN.Remembertochangeitregularly.

2. ALWAYS operate the hoist from inside the cab of the truck.

3. If the hydraulic hose connections are correct, the hoist should raise when the hoist control

lever is pulled back, hold when the lever is in the center detent, and lower when the lever

is pushed forward.

4. To raise the hoist, pull the control lever back. To hold the body in a raised position, place

the control lever in its center detent position. To lower the hoist, push the control lever

forward.

5. ALWAYS return the hoist control lever to its center detent position after each use.

6. Whenthehoistcylinderreachestheendofthestroke,oilwillowthroughtheautomatic

bypass valve built into the piston inside the cylinder and return to the reservoir.

7. It is advisable to run the PTO to “power down” or lower the hoist because this will act as

an hydraulic lock to hold the hoist in the lowered position. It is not necessary to do this,

however,becausethereservoirhassucientcapacitywhetherornotthehoistispowered

down.Youwillbenetfromtheadvantagesofthedoubleactinghoistonlyifyoupower

down.

8. To make use of the hydraulic lock feature, place the hoist control lever in the center hold

position after the hoist is powered down. This places the pressure on the valve, where it

belongs, not on the pump.

9. DO NOT LEAVE THE PTO IN GEAR WHILE TRANSPORTING. THIS CAN CAUSE

SEVERE DAMAGE TO THE PTO OR HYDRAULIC PUMP.

10.Thehydraulicsystemshouldbedrained,ushedandrelledwithproperhydraulicuid

atregularintervals.CAUTION:NEVERusehydraulicBRAKEFLUIDinthehydraulic

system.

11.Afteraddingorreplacingthehydraulicuid,cyclethehoistseveraltimestoremoveair

from the cylinders and hydraulic hoses.

2. Lubricateallgreasettingsevery100cyclesoreverytwomonths.Infrequentorinsu-

cient lubrication will cause hoist failure and possibly injury or death.

3. ALWAYS carefully block up the body, using the body prop, before working under it.

4. Do not “race” the engine when unloading.

5. Do not load the hoist beyond its capacity.

6. DO NOT tamper with the hydraulic relief valve. This will void the warranty. It can cause

severe damage to the hoist and cylinder.

7. Never leave the PTO in gear while transporting. It could ruin the hydraulic pump, the PTO

or the transmission.

8. Checkallboltsandttingsregularly.Keepthemtight.Seetableonpage4fortorqueval-

ues.

9. Alwaysoperatehoistonarmandlevelsurface.

10. Always make sure area around truck is clear and safe for hoist operation and dumping.

1643725H (404416) 2020-09-2841643725H (404416) 2020-09-285

TABLE OF CONTENTS

FOREWORD 2

SOME DO’S AND DON’TS FOR SAFE AND LONG SERVICE 3

OPERATION AND USE 3

INSTALLATION INSTRUCTIONS 6

LOCATEHOIST-SUBFRAMEASSEMBLYONTRUCK 6

LOCATEBODY/HOISTASSEMBLYONTRUCK 7

LOCATE MOUNTING PLATES 7

DRILLTRUCKFRAME 7

WELD REAR HINGE AND SUBFRAME 8

SUPPORT FUEL FILL TUBE 8

HYDRAULIC PUMPS 8

MOUNT GEAR PUMP 8

MOUNT RESERVOIR/VALVE ASSEMBLY 9

INSTALL REMOTE VALVE CONTROL 9

INSTALL PUMP HOSES - 4 GPM 10

INSTALL PUMP HOSES - 6 GPM 10

INSTALL CYLINDER HOSES - GEAR PUMP SYSTEMS 11

ELECTRIC PUMP MOUNTING - GENERAL 12

ELECTRIC PUMP INSTALLATION - DOUBLE-ACTING 13

ADD HYDRAULIC OIL 13

POWER HOIST DOWN 14

INSTALLTIPPERBODYONTRUCK 14

INSTALLOTHERBODYONTRUCK 15

INSTALLBODYPROPBRACKETONBODYLONGBEAM 16

INSTALL BODY GUIDES 16

INSTALLGREASEZERKSANDLUBRICATEHOIST 17

INSTALL DECALS 17

LB520 CYLINDER PARTS 19

HYDRAULIC SYSTEM PARTS 20

FRAME & CYLINDER AND SUBFRAME PARTS 22

INSTALLATION INSTRUCTIONS

GENERAL INFORMATION

It is a good idea to look through these installation instructions before beginning to mount the hoist and

hydraulic system.

When welding, protect the truck’s electrical, air and brake systems by disconnecting, removing or cover-

ing.Tightenallnutsandboltstoaconsistentlevel.Usethefollowingtablefortorquevalues.

Size Grade2Torque Grade5Torque Grade8Torque

1/4-20 3-4 lb-ft 6-7 lb-ft 10-11 lb-ft

1/4-28 4-5 lb-ft 8-9 lb-ft 11-12 lb-ft

5/16-18 8-9 lb-ft 14-15 lb-ft 21-22 lb-ft

5/16-24 9-10 lb-ft 15-16 lb-ft 21-22 lb-ft

3/8-16 17-18 lb-ft 24-26 lb-ft 37-40 lb-ft

3/8-24 19-20 lb-ft 28-30 lb-ft 40-43 lb-ft

1/2-13 38-42 lb-ft 60-65 lb-ft 90-100 lb-ft

1/2-20 43-47 lb-ft 70-75 lb-ft 95-105 lb-ft

5/8-11 75-80 lb-ft 122-130 lb-ft 180-190 lb-ft

5/8-18 85-90 lb-ft 145-150 lb-ft 200-210 lb-ft

3/4-10 132-140 lb-ft 220-230 lb-ft 315-330 lb-ft

3/4-16 152-160 lb-ft 250-260 lb-ft 355-370 lb-ft

Thefollowingabbreviationsareusedindescribinghydraulicttings.

ORBM O-Ring Boss - Male Thread

NPTM Pipe - Male Thread

NPTF Pipe - Female Thread

JICM JIC 37° - Male Thread

JICF JIC 37° - Female Thread

1643725H (404416) 2020-09-2861643725H (404416) 2020-09-287

INSTALLATION INSTRUCTIONS

LOCATE HOIST-SUBFRAME ASSEMBLY ON TRUCK

The hoist-subframe assembly is normally mounted to the truck before attaching it to the body.

For Ford trucks, with a 40 gallon rear fuel tank, place the end of the subframe even with the end of the

truck frame, 47 1/2 inches behind the center of the rear axle.

For Ram trucks with a 52 gallon rear fuel tank, and GM trucks with a 40 gallon rear fuel tank, place the

end of the subframe 3 inches ahead of the end of the truck frame.

For trucks where the rear fuel tank does not extend behind the rear spring hanger, and for trucks with fuel

tanks mounted under the cab or outside the frame just behind the cab, mark the truck frame 36 inches be-

hind the center of the rear axle. This should be a minimum of 2 inches behind the rear spring hanger. The

truckframewillbecutoatthismark.

LOCATEBODY/HOISTASSEMBLYONTRUCK

Makesurethemarksforcuttingthetruckframeareaccurateandevenfromsidetoside.Cutothetruck

frame and grind the ends smooth. Place the subframe on the truck making sure it is even with the end of

thetruckframe,centeredsidetosideandsquarewiththetruckframe.Thereshouldbe3or31/2inches

clearance between the back of the cab and the front end of the subframe.

NOTE:Ifthetruckframehasrivetsinthetopange,addspacersbetweenthetruckframeandsubframe,

or counter sink the rivet heads into the subframe by drilling holes in the subframe. Do not remove the rivet

heads!

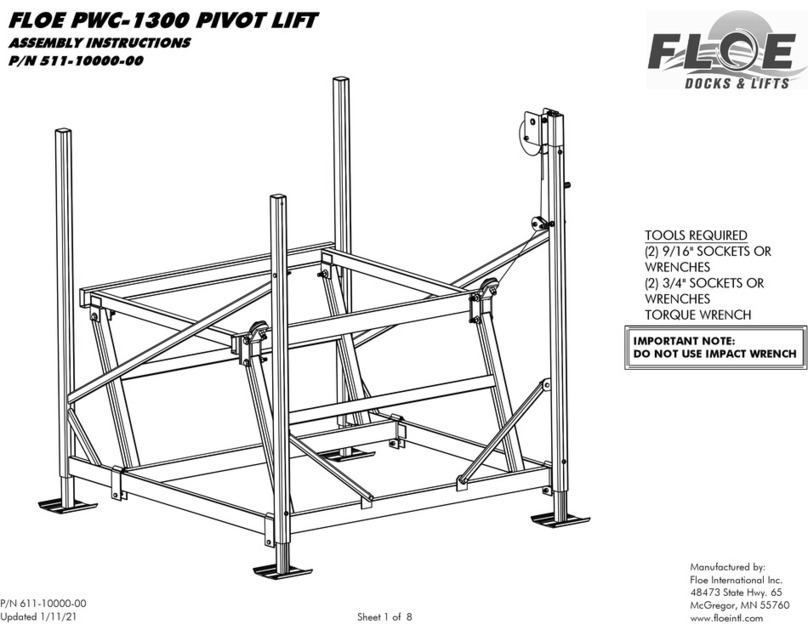

Fig. 1

MODEL LB520

Cab Clearance 3-5"

30"-36"

CAUTION: BE CAREFUL OF BRAKELINES, WIRING, ETC. INSIDE THE

TRUCK FRAME WHEN DRILLING THE TRUCK FRAME.

Use the following installation procedures when the body and hoist have been assembled at the factory.

Place the body and hoist assembly on the truck frame so there is 3 to 5 inches of cab clearance. Now,

check the location of the back end of the subframe. It should be a minimum of 2 inches behind the rear

springhanger.Thetruckframewillneedtobecutoevenwiththebackendofthesubframerails,as

shown in Fig. 3.

IfthetruckisaFordF450orF550,thebackedgeoftherearhingeshouldbeushwiththeendofthe

truck frame. If the truck is a Ram 4500 or 5500, then the end of the subframe should be 3 inches ahead of

the end of the truck frame.

Block up the back end of the body/hoist assembly and cut the truck frame as marked.

NOTE:Ifthetruckframehasrivetsinthetopange,addspacersbetweenthetruckframeandsubframe,

or counter sink the rivet heads into the subframe by drilling holes in the subframe. Do not remove the rivet

heads!

LOCATEMOUNTINGPLATES

There are six mounting plates, three for each side

- one at the front of the subframe, one at the hoist

mount and one between the hoist mount and the

rear hinge. Clamp the mounting plates to the truck

frame and to the subrame as shown in Figures 1

and 2. If desired, locate the plates to use existing

holes in the frame. Mark the mounting plates for

drilling. Repeat this for the other side.

For Dodge trucks, where the subframe is oset

foward from the end of the truck frame, be sure to

locate the rear mounting plate within 2 inches of

the rear hinge.

Drill 21/32” holes in the mounting plates and the truck frame. Bolt the mounting plates in place using 5/8

x 2 cap screws (grade 8) and hex lock nuts, tightening to 180-190 lb-ft.

DRILLTRUCKFRAME

1643725H (404416) 2020-09-2881643725H (404416) 2020-09-289

WELD REAR HINGE AND SUB-

FRAME

Make sure the body/hoist assembly or hoist/

subframe assembly is correctly located, cen-

teredonandsquarewiththetruckframe.Se-

curely weld the mounting plates to the sub-

frame. Add a plate (not supplied) to the end

of the truck frame rail. (See Fig. 3.) Securely

weld the plates to the end of the truck frame

rails and to the back end of the subframe. Do

this on both sides.

HYDRAULIC PUMPS

CrysteeloerstwodierenthydraulicsystemsforusewiththeModelLB520Hoist.Mountinginstruc-

tions can be found on the pages shown:

MOUNT GEAR PUMP

ThegearpumphasanSAE`A’mountingconguration,an11-toothsplinedshaftandatwo-boltmounting

ange,andisassembledforcounterclockwiserotation.Note:ThispumpwillmountdirectlytoChelsea’s

output type `AD’ or Muncie’s output type `T’. Crysteel Manufacturing recommends a PTO ratio of 100-

120%.Thisassuresaminimumpumpoperatingspeedof600RPM.CHECKTHEROTATIONOFTHE

PTO! If it is opposite of the engine, then the pump can be used as it is. If the PTO rotation is the same as

the engine, then the pump will need to be reversed. (See instructions included with the pump.) Bolt the

gearpumptothePTOoutputangeusing3/8x1”capscrewsandlockwashers.

Theoptional6GPMgearpumphasanSAE`B’mountingconguration,a13toothsplinedshaftanda

four-boltmountingange,andisassembledforrotationineitherdirection.NOTE:Thispumpwillmount

directlytoChelsea’soutputtype`XK’orMuncie’soutputtype`D’.CrysteelManufacturingrecommends

a PTO ratio of 100-120%. This assures a minimum pump operating speed of 600 RPM. Bolt the gear pump

tothePTOoutputangeusing1/2x11/4capscrewsandlockwashers.

PTO driven Gear Pump with Remote Reservoir/Valve Page 8

Electric Pumps - General Page 12

Electric Pumps - Double-Acting Page 13

SUPPORTFUELFILLTUBE

Ifnecessary,constructsupportsforthefueltanklltubes.Constructthesupportsothatitdoesnotinter-

fere with any portion of the body or hoist operation.

MOUNT RESERVOIR/VALVE ASSEMBLY

The reservoir/valve assembly should be mounted on the same side of the truck as the pump and as high as

possible for reliable pump performance. The slotted end of the valve spool should be towards the front of

the truck so the valve control cable can be easily connected. The mounting brackets for the reservoir/valve

assembly can be used to mount the reservoir/valve assembly outside the truck frame or inside between

the truck frame rail and the driveshaft. Determine where to mount the reservoir/valve assembly and bolt

themountingbracketstothereservoir/valveassemblyusing3/8x1capscrews,atwashersandhexlock

nuts. Locate the reservoir/valve assembly and clamp the mounting brackets to the truck frame. See Fig.

4. If inside the truck frame, make sure there is enough clearance for the drive line and hot exhaust pipes.

THE ENGINE EXHAUST MUST NEVER BLOW DIRECTLY ONTO THE RESERVOIR/VALVE AS-

SEMBLY. Insert the spacers in the mounting brackets and mark the truck frame for drilling using the pump

mounting brackets as guides

CAUTION: BE CAREFUL OF BRAKELINES, WIRING, ETC. INSIDE THE

TRUCK FRAME WHEN DRILLING THE TRUCK FRAME.

INSTALL REMOTE VALVE CONTROL

Temporarily assemble the valve control head to the pedestal using 5/16 x 2 1/4” machine screws and hex

nuts.Placethisassemblyontheoorofthecab.Makesurethereisenoughroomtooperatethevalvecon-

trolandthegearshiftleverandtoadjusttheseat.Checkbelowtheoorforobstructionsandcablerouting.

Relocatethevalvecontrolifnecessary.Marktheoorusingthepedestalasatemplateanddrill1/4”holes

for the mounting screws and a 3/4” hole for the control cable. Assemble the control cable to the valve

control head and assemble the valve control head and cover to the pedestal using 5/16 x 2 1/4” cap screws

andhexlocknuts.Insertthecontrolcablethroughtheholeintheoorandmountthepedestaltotheoor

using 5/16 x 1/2 machine screws and hex lock nuts. Make sure the valve control lever is in its center detent

position.Keepthecontrolcableawayfromhotexhaustpipesandrotatingdriveshafts.Thecontrolcable

should not have any sharp bends or kinks in it (these will make the control harder to operate).

Install the 3/4” hex jam nut onto the valve end of the control cable and turn it past the threads. Insert the

1643725H (404416) 2020-09-2810 1643725H (404416) 2020-09-2811

Fig. 5

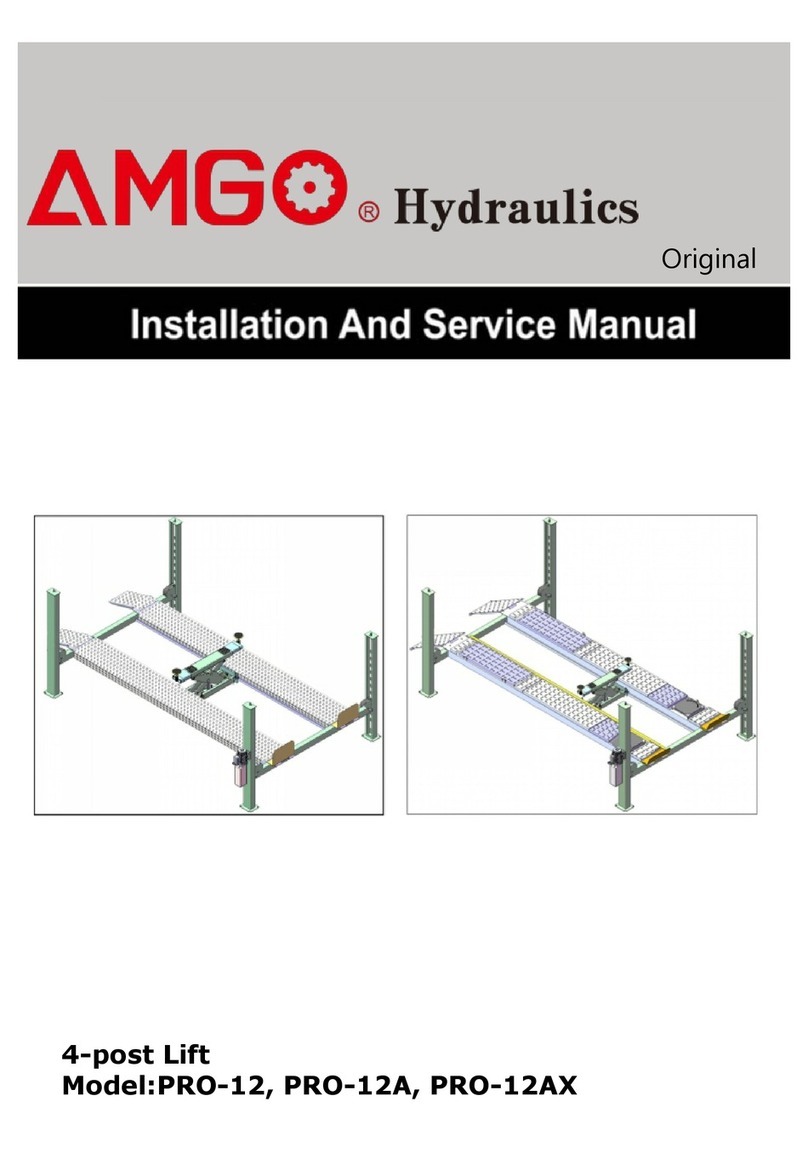

INSTALL PUMP HOSES - 4 GPM

Study Fig. 6 very carefully before connecting the hoses. Install a 3/4” 90° street elbow and a 3/4” hose

barb in the suction port on the bottom of the reservoir. Install a 1 1/16 ORB x 3/4” hose barb in the suction

port of the pump and install a 3/4” ID suction hose. Secure the suction hose in place using hose clamps.

Install a 1 1/16 ORB x 1/2 NPT 90° swivel adapter in the `IN’ port of the control valve and a 7/8 ORB x

1/2 NPT adapter in the pressure port of the pump. Connect a 72” long 1/2” ID hose between the pump and

the valve.

end of the cable through the bonnet clamp. Install the bonnet onto the control cable and turn it past the

threads also. Install the 1/4” hex jam nut and terminal eye on the core rod of the cable. Lock the terminal

eye to the core rod of the cable using the hex jam nut. Place the terminal eye in the slot of the valve spool;

insert the short pin through the valve spool and terminal eye and secure it in place with the `E’ ring.

Threadthebonnetontotheendofthecablesoitrmlytouchestheendofthevalve.(Donotover-or

under -tighten the bonnet as either would move the valve spool out of its neutral position.) Remove two

cap screws from opposite corners of the seal retainer plate. Slide the bonnet clamp onto the bonnet and

secureittothevalveusingthe1/4x11/4”capscrews,lockwashersandatwashers.Lockthebonnetto

the cable using the 3/4” hex jam nut. See Fig. 5.

INSTALLPUMPHOSES-6 GPM

Study Fig. 6 very carefully before connecting the hoses. Install a 3/4” 90° street elbow and a 3/4” hose

barb in the suction port on the bottom of the reservoir. Install a 1 1/16 ORBM x 3/4’’ hose barb in the

suction port of the pump and install the suction hose. Secure the suction hose in place using hose clamps.

Install a 1 1/16 ORB x 1/2 NPT 90° swivel adapter in the `IN’ port of the control valve and install a 1 1/16

ORBM x 1/2 adapter in the pressure port of the pump. Install a 72” long 1/2” ID hose from the pump to

the valve.

INSTALLCYLINDERHOSES-GEARPUMPSYSTEMS

Install 90° swivel adapters in the work ports of the control valve and in the ports on the cylinder. Connect

the36”long1/2”IDhosewith7/8JICttings,fromthe`B’portonthecontrolvalvetothebaseendport

onthecylinder.Connectthe60”long1/2”IDhosewith7/8JICttings,fromthe`A’portonthecontrol

valve to the rod end port on the cylinder. This will raise the hoist when the control lever is pulled back and

lower it when pushed forward.

NOTE: The `A’ port is the `power-down’ port and has a pressure of only 500-1000 PSI at engine idle; the

`B’ port has full system pressure.

Fig. 6

1643725H (404416) 2020-09-2812 1643725H (404416) 2020-09-2813

CAUTION: BE CAREFUL OF BRAKELINES, WIRING, ETC. INSIDE THE

TRUCK FRAME WHEN DRILLING THE TRUCK FRAME.

Drill 17/32” holes in the truck frame and bolt the reservoir/valve assembly in place using 1/2 x 2 3/4 cap

screws and hex lock nuts, tightening to 90 to 100 lb-ft.

For rated performance, the voltage at the power unit must be a minimum of 12VDC. This should be

measured between the large terminal of the start solenoid (where the battery cable is connected) and the

power unit base, where it is bolted to the mounting bracket. NOTE: Grounding of the power unit is just

as important as the installation of the positive battery cable. It is easier to get a good ground by using a

second battery cable.

Connect the large terminal on the motor start solenoid to the positive terminal on the battery with a #0

gauge battery cable. Connect the negative terminal on the battery to the grounding hole on the power unit

with a #0 gauge battery cable. See Figure 8. Check the voltage between the large terminal on the start

solenoid and the power unit base.

ELECTRICPUMPINSTALLATION-DOUBLE-ACTING

Install 9/16 ORB x 3/4 JIC 90° swivel adapters in both work ports on the electric pump. If needed, for

good hose routing, install 3/4 JIC x 3/4 JIC 90° swivel adapters to both of these adapters. Connect the

shorter3/8IDhosewith3/4JICttingsfromthe‘C1’portonthepumptothebaseendportonthecylin-

der.Connectthelonger3/8”IDhosewith3/4JICttingsfromthe‘C2’porttotherodendport.

NOTE: The ‘C2’ port is the power down port and has only 500 PSI maximum pressure.

ADDHYDRAULICOIL

Useaqualityhydraulicuidof150SSU@100°Fwhichcontainscorrosionandoxidationinhibitors

andafoamdepressant.ThisisapproximatelytheequivalentofSAE10Worlighterweightoil.Dexron

automatictransmissionuidshouldbeusedintheelectricpumps.Fillthehydraulicreservoirusingthe

following table.

KEEP THE OIL CLEAN. USE CLEAN CONTAINERS, FUNNELS AND

OTHER EQUIPMENT!

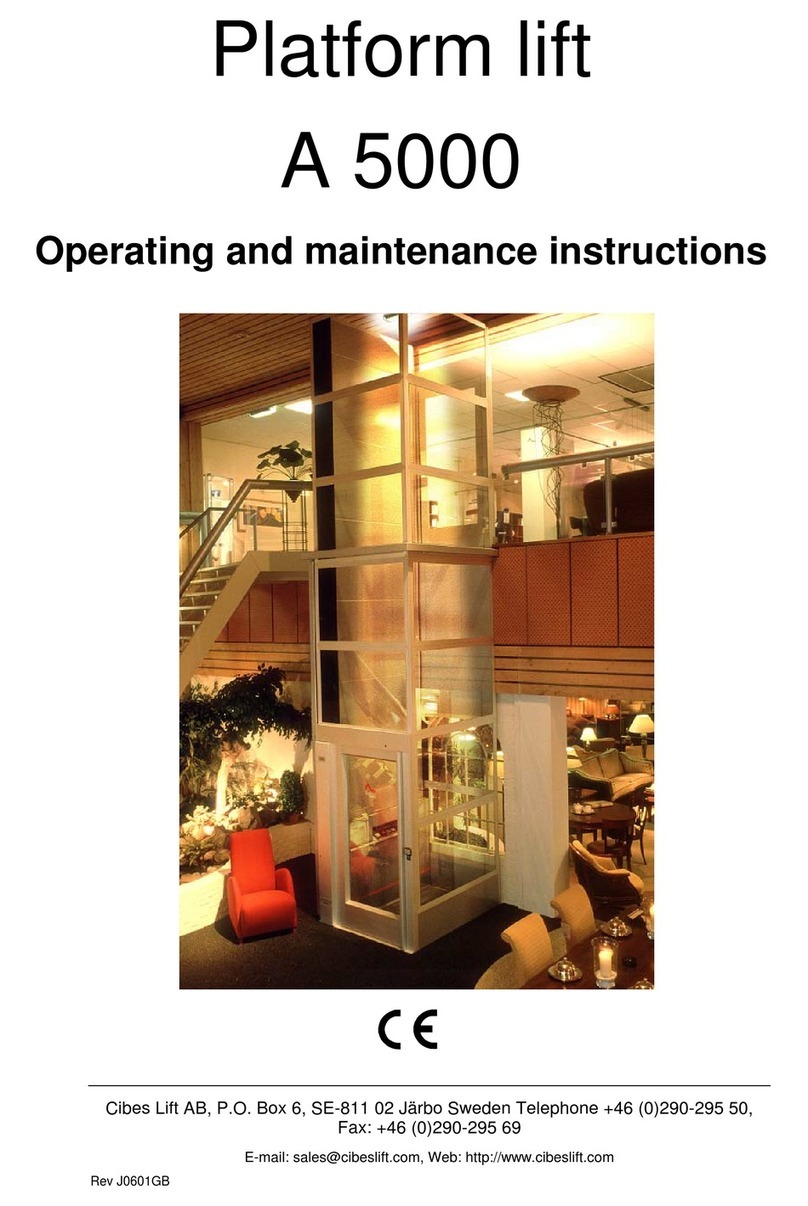

ELECTRICPUMPMOUNTING-GENERAL

The electric power unit should be mounted behind the cab, either to a mounting bracket in the subframe

or to mounting brackets bolted to the truck frame as shown in Fig. 7. If using the bracket in the subframe,

bolt the double-acting power unit with the motor towards the passenger’s side to the bracket provided

using3/8x1capscrewsandatwashers,tighteningto24to26lb-ft.Boltthesingle-actingpowerunit

withthemotortowardsthedriver’ssidetothebracketprovidedusing3/8x1capscrewsandatwashers.

, tightening to 24 to 26 lb-ft Insert the 3 x 5 rubber pad under the end of the tank and clamp the tank to the

mounting bracket with the 33” long cable tie.

If separate mounting brackets are used, chose the location for mounting the power unit, bolt one mount-

ing angle to the power unit using the 3/8 x 1 hex head cap screws, tightening to 24 to 26 lb-ft. Clamp the

mounting bracket to the truck frame. Clamp the second mounting angle to the truck frame so it supports

the far end of the reservoir. Insert a rubber pad between the mounting angle and the reservoir; and secure

it in place with a tie strap. Mark the truck frame for drilling using the pump mounting angles as guides.

Fig. 7

ELECTRIC POWER UNIT

MOUNTING

ANGLE

RUBBER PAD

TIE STRAP

Fig. 8

Locate the control in the cab and route the cable out of the cab through a hole in the back of the cab. Con-

nect the control to the electric power unit using the 4-pin connector set.

After completing the wiring, install the motor start switch cover over the start switch and secure with a

tie strap.

Start Switch

Cover

Fig. 9

Connect Ground Cable

Double-Acting

Power Unit

Connect Power Cable

Hyd System Reservoir Size FluidRequired Initial Fill

Gear Pump w/ Valve/Tank 6 Gal 5.5 Gallons 4 Gallons

Electric Double-Acting 7.5 Quarts 13.5 Quarts 7.5 Quarts

1643725H (404416) 2020-09-2814 1643725H (404416) 2020-09-2815

POWER HOIST DOWN

Before mounting the body, the hoist must be completely closed to make certain that the hoist gives full lift

height and performance. Make sure the lift angles are straight up and down.

For hydraulic systems with the direct mount gear pump, start the truck engine, engage the PTO and power

down the hoist to “bottom-out” the hydraulic cylinder and the hoist frame. Place the hoist valve control in

the “hold” position. Both the hoist frame and the hydraulic cylinder are now completely closed.

For hydraulic systems with the double-acting electric pump, press and hold the `DOWN’ push-button on

the control to “bottom-out” the hydraulic cylinder and the hoist frame. Release the `DOWN’ push-button.

Both the hoist frame and the hydraulic cylinder are now completely closed.

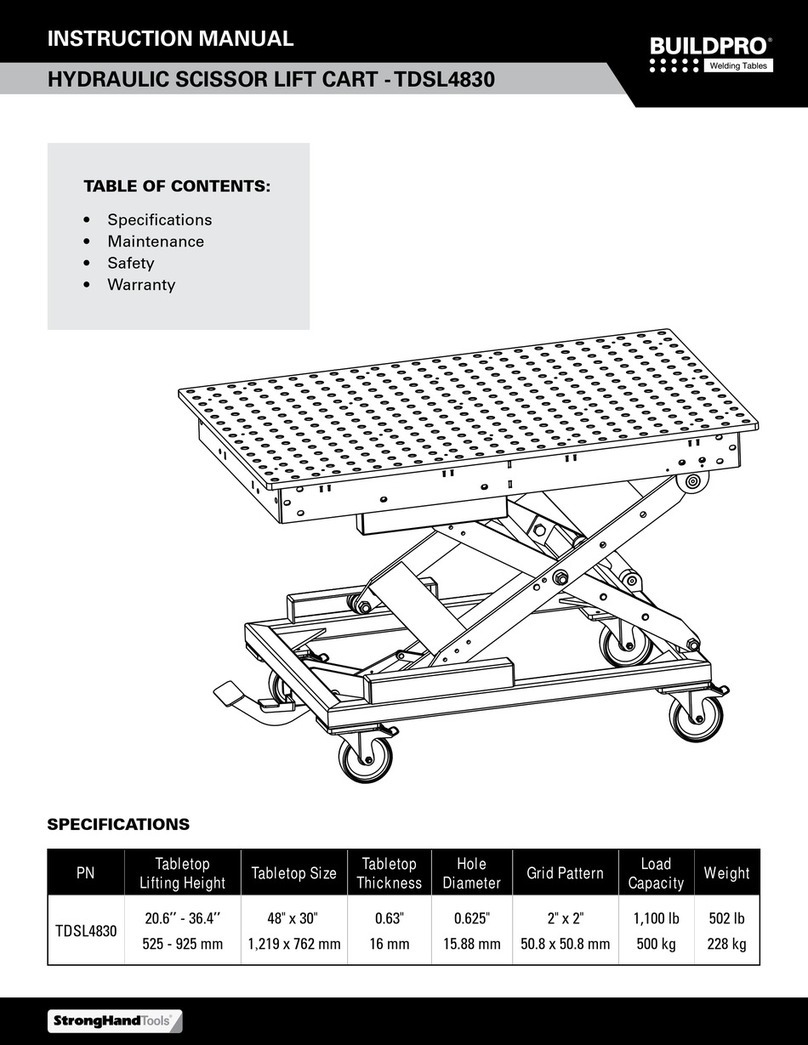

INSTALL OTHER BODY ON TRUCK

Study the diagram in Fig. 10 before installing the body. Make sure there is enough clearance under the

bodyforthehoisttot.Theinsideofthelongbeamsshouldbeboxedintoprovideaatsurfaceforweld-

ing the body and hoist together. Carefully measure the location of the hoist lift plate and mark this location

on the inside of the longbeams and box in the inside of the longbeams. Place the body on the truck with

3to5inchesofclearancebehindthecab.Makesurethereissucientclearancebetweenthebodyand

the reservoir/valve assembly. Relocate the reservoir/valve assembly if necessary. Carefully align the body

longbeams to the subframe rails. Securely weld the rear hinge bracket to the longbeams. Securely weld the

hoist lift plates to the boxed-in sections of the longbeams.

DO NOT WORK UNDER A RAISED BODY UNLESS THE BODY IS

SECURELY BLOCKED OR PROPPED IN THE RAISED POSITION.

Ifthebodyandsubframehavebeenassembledatthefactory,nishweldingthehoistliftbracketstothe

llplatesontheinsideofthelongbeams.

93.00 FOR 45INSTALLATIONS

84.00 FOR 50INSTALLATIONS

Fig. 10

INSTALL TIPPER BODY ON TRUCK

Place the Tipper body on the subframe so the front of the body and the front end of the subframe are even.

Makesurethereissucientclearancebetweenthebodyandthereservoir/valveassembly.Relocatethe

reservoir/valve assembly if necessary. Carefully align the body longbeams to the subframe rails. Securely

weld the rear hinge bracket to the longbeams. Securely weld the hoist lift plates to the boxed-in sections

of the longbeams.

DO NOT WORK UNDER A RAISED BODY UNLESS THE BODY IS

SECURELY BLOCKED OR PROPPED IN THE RAISED POSITION.

1643725H (404416) 2020-09-2816 1643725H (404416) 2020-09-2817

INSTALL BODY GUIDES

Two body guides have been included and should be mounted near the front of the subframe. Clamp the

body guides to the outside of the subframe as shown in Fig. 12. The body guide should be tight against the

outside of the longbeams of the body. Securely weld the body guides to the subframe.

2. Raise the prop arm to a free standing position by allowing the prop arm to rest against the

rearangeoftheproppivot.Thetopoftheproparmwillswinginunderthelongbeam.

4. Tooperatethebodyprop,raisethebodytothedesiredheight,shutoallpower,raisethe

prop arm to a free standing position. Lower the body slowly until the longbeam bracket

contacts the prop arm saddle. DO NOT POWER HOIST DOWN!

5. To place the body prop in the storage position, raise the body to clear the body prop sad-

dle, lower the body prop to the storage position and lower the body.

3. Slowly lower the body until the bottom of the longbeam rests on the body prop saddle.

Place the longbeam bracket against the outside of the longbeam so the legs straddle the

prop arm saddle. Securely weld this bracket to the body. (See Fig. 11.)

INSTALL BODY PROP BRACKET ON BODY LONGBEAM

The body prop is designed and intended to support an EMPTY truck body in the raised position. Using the

body prop permits service work to be performed safely beneath a raised body. It is mounted on the outside

of the subframe on the driver’s side.

BODY PROP

SUBFRAME

Fig. 12

LONGBEAM BRACKET

PROP

PIVOT

Fig. 13

TRUCK FRAME

SUBFRAME

LONGBEAM

BODY

GUIDE

BODY

LONGBEAM

LONGBEAM BRACKET

Fig. 11 Fig. 12

1. Raise the body more than half way up.

INSTALLGREASEZERKSANDLUBRICATEHOIST

Install grease zerks on the hoist and lubricate the hoist in the following locations:

Upper Crosstube.............................................................2 Fittings

Lower Crosstube ............................................................2 Fittings

Cylinder Base Pivot .......................................................1 Fitting

Rear Hinge ......................................(already installed) 2 Fittings

Body Prop ........................................(already installed) 1 Fitting

Lubricateallttingsatregularintervals,atleasteachtimethetruckchassisislubricated.Thereareex-

tremely high forces on the bearings surfaces within the hoist frame. It pays to be generous in lubricating

the hoist to insure proper operation and long life.

Thecenterhingeandthecylindercrossheaddonotneedtobegreased.Thesepivotpointsareequipped

with self lubricating composite bearings that do not need lubrication.

ONE OF THE MOST COMMON REASONS FOR HOIST PROBLEMS IS FAILURE BY THE OPERA-

TOR TO LUBRICATE THE HOIST.

INSTALLDECALS

After the body and hoist have been installed and painted, install the decals in the following locations:

1. Decal 1642842 Mount in the cab above the valve control.

(400640)

2. Decal 1642848 Mount on the body longbeam near the body prop. (one on each side)

(400719)

3. Decal 1642846 Mount on the body prop arm.

(400661)

4. Decal 1643067 Mount on the outside of the body longbeams near the front of the body.

(401576) (one on each side).

5. Decal 1642844 Mount on the body longbeam on the drivers side.

(400643)

6. Decal 1643068 Mount in the cab in a prominent location.

(401577)

7. Decal 1642843 Mount in the cab in a prominent location.

(400642)

Seetheillustrationsonthefollowingpagefordecalidentication.(SeeFig.11.)

1643725H (404416) 2020-09-2818 1643725H (404416) 2020-09-2819

Fig. 13

1642848 (400719)

1643067 (401576) 1642844 (400643)

1643068 (401577) 1642843 (400642)

1642842 (400640) 1642846 (400661)

2

13

18 17 16 15

14

12

11

10

9

8

6

5

4

3

1

7

19

LB520 CYLINDER PARTS

20

ITEM DESCRIPTION LB520 QTY

1. Cylinder Shaft Assy 1621556 1

2. Cap Ring 1635171 1

3. Set Screw 1/4 x 3/16 1642724 1

4. Wiper 1642878 1

5. Cylinder Head 1637938 1

6. Shaft Seal 1642765 1

7. O-Ring 1642766 2

8. O-Ring 1642767 1

9. Cylinder Piston 1629601 1

10. Piston Seal 1642764 1

11. Hex Jam Nut 1642995 1

12. Cylinder Tube Assy 1621554 1

13. Plug 7/8-14 ORB 1642807 1

14. Plug 3/4-16 ORB 1642805 1

15. Ball 3/8 1642679 1

16. Bypass Valve Pin 1642894 1

17. O-Ring 1642907 1

18. Bypass Valve Body 1642893 1

19. BypassValveKit 1621569 1

20. CylinderSealKit 1621640 1

21. Cylinder Assy 1621532

1643725H (404416) 2020-09-2820 1643725H (404416) 2020-09-2821

ITEM DESCRIPTION PART NO. QTY.

1. Reservoir/Valve Carton 6 Ga 3250 PSI (includes items 2 through 10) 1621943 1

2. Reservoir Weldment 6 Ga 1621925 1

3. Hex Jam Nut 7/8-14 1643196 1

4. Cone Washer 7/8 1643197 1

5. O-Ring .755 ID x .097 CS 1643198 1

6. Cap Screw, Soc Hd 5/16-18 x 2 1643205 1

7. Lock Washer 5/16 1642733 1

8. Control Valve 30 GPM 3250 PSI -10 Port 1643185 1

9. Breather Cap 1644723 1

10. Pipe Plug 3/4 Magnetic 1642794 1

11. Adapter 7/8 ORBM x 7/8 JICF 90° 1643724 2

12. Adapter 7/8 ORBM x 1/2 NPTF 90° 1642969 1

13. Hose 1/2 NPT x 72” RM/RM 3500 PSI 1643015 1

14. Pipe Elbow 3/4 Street 1643226 1

15. Hose Barb 3/4 NPTM x 3/4 1643017 1

16. Hose Clamp #24 1643011 2

17. Suction Hose 3/4 ID x 72” 1643805 1

18. Hose Barb 1 1/16 ORBM x 3/4 1643228 1

19. Adapter 1 1/16 ORBM x 1/2 NPTF 1283139 1

19A. Adapter 7/8 ORM x 3/8 NPTF 1642813 1

20. Cap Screw 1/2-13 x 1 1/4 Gr 8 1642726 4

20A. Cap Screw 3/8-16 x 1 Gr 5 1642714 2

21. Gear Pump 6 GPM B 4-Bolt 1644773 1

21A. Gear Pump 4 GPM A 2-Bolt 11 Tooth 1645052 1

22. Cable, Valve Control - 96” 1643210 1

Cable, Valve Control - 72” 1643209 1

Cable, Valve Control - 84” 1643332 1

Cable, Valve Control - 120” 1643211 1

Cable, Valve Control - 144” 1643212 1

Cable, Valve Control - 180” 1643213 1

23. Hex Lock Nut 5/16-18 1642962 5

24. Clamp Plate, Pedestal 1631026 1

25. Machine Screw 5/16-18 x 1/2 1643329 2

26. Pedestal Channel, Short - RVC 1630851 1

27. Machine Screw 5/16-18 x 2 1/2 1643233 3

28. Remove Valve Control w/ Center Detent (RVC) 1643208 1

29. Pedestal Bracket, Short - RVC 1630850 1

30. ValveConnectionKit-Prince5100 1643215 1

31. Hex Lock Nut 3/8-16 1643177 4

32. Flat Washer 3/8 1642732 4

33. Cap Screw, Hex Hd 3/8-16 x 1 Gr 5 1642714 4

34. Cap Screw 1/2-13 x 2 3/4 Gr 8 1643730 4

35. Flat Washer 1/2 1642739 8

36. Spacer VT Mounting 1632739 4

37. Assy VT Mounting 1622700 2

38. Hex Lock Nut 1/2-13 1642984 4

HYDRAULIC SYSTEM PARTS

46

45

44

41

39

42

40

43

34

36

35

37

38

47

48

49

51

21A

20A

19A

1643725H (404416) 2020-09-2822 1643725H (404416) 2020-09-2823

ITEM DESCRIPTION PART NO. QTY.

39. Cable Tie - 33” 1643817 1

40. Rubber Pad 1/4 x 3 x 5 1643881 1

41. Breather Cap, Splash Resistant 1644498 1

42. Electric Power Unit - DA 2219241 1

43. Cover Solenoid Service 1644330 1

44. Adapter 9/16 ORBM x 3/4 JICM 1643375 2

45. Control Station W/Cord, 4 Wire DA Pistol 2296414 1

46. Keeper,PistolGrip 2296415 1

47. Hose 7/8 JIC x 48” SF/SF 4000 PSI 1643360 1

Hose 7/8 JIC x 84” SF/SF 4000 PSI 1644009 1

48. Hose 7/8 JIC x 72” SF/SF 4000 PSI 1643804 1

Hose 7/8 JIC x 108” SF/SF 4000 PSI 1644010 1

49. Adapter 7/8 ORBM x 7/8 JICM 90° 1643724 1

50. Decal - Hoist Control 1643216 1

51. Adapter 3/4 ORBM x 7/8 JICM 90° 1643723 1

ITEM DESCRIPTION LB520 QTY

1. Hoist Frame Assy 1622670 1

2. Cylinder Assy 1621532 1

3. Cap Screw 1/2-13 x 3 3/4 Gr 8 1642721 2

4. Hex Lock Nut 1/2-13 1642984 14

5. Cap Screw 3/4-10 x 4 1/2 Gr 8 1642956 1

6. Hex Lock Nut 3/4-10 1642957 1

7. Cap Screw 1/2-13 x 1 1/4 Gr 8 1642726 8

8. Grease Zerk 1/8 NPT 1642699 7

9. Frame & Cylinder Assy 1622669 1

ITEM DESCRIPTION LB520 QTY

1. Subframe Assy - 9’ 50° 1289363 1

Subframe Assy - 10’ 50° 1289636 1

Subframe Assy - 11’ 50° 1289616 1

Subframe Assy - 12’ 50° 1289624 1

Subframe Assy - 14’ 50° 1289620 1

Subframe Assy - 10’ 45° 1289640 1

Subframe Assy - 14’ 45° 1289628 1

2. Body Guide 1630827 2

3. Mounting Plate 1631206 2

4. Cap Screw 5/8-11 x 2 Gr 8 1643313 12

5. Hex Lock Nut 5/8-11 1643070 12

6. Body Prop Longbeam Bracket 1634760 1

7. Body Prop Arm Assy - Left 1623886 1

8. Spring Pin 1/4 x 3 1642757 1

9. Grease Zerk 1/8 NPT 1642699 2

10. Grease Zerk 1/8 NPT 90° 1642713 1

FRAME&CYLINDERANDSUBFRAMEPARTS

1643725H (404416) 2020-09-2824

CRYSTEEL MANUFACTURING, INC.

CRYSTEEL MANUFACTURING’S

5YEARCUSTOMERSATISFACTIONPLEDGE

& WARRANTY

Crysteel oers the most comprehensive warranty in the truck equip-

ment industry. Crysteel warrants each product against defects in mate-

rial and workmanship for 60 months from the in-service date.

For the full Customer Satisfaction Pledge and Warranty information,

please visit our website.

http://www.crysteel.com

Table of contents

Other TBEI Lifting System manuals

Popular Lifting System manuals by other brands

WilTec

WilTec 50789 Operation manual

AMGO

AMGO PRO-12 Installation and service manual

global lift corp

global lift corp Legend L-325 owner's manual

ShoreStation

ShoreStation WATERFRONT SYSTEMS manual

SmarterHome

SmarterHome Multi-Bike XL installation manual

Ranger

Ranger RFJ-3TQP Installation and operation owner's manual

DoorHan

DoorHan MT Series Installation and operation instruction

StrongHandTool

StrongHandTool BUILDPRO TDSL4830 instruction manual

GYS

GYS AIRFIX DRAW ALIGNER G manual

Extreme Max

Extreme Max Boat Lift Buddy Installation & use instructions

Globaljig

Globaljig Quick Pull Instructions for installation, use and maintenance manual

Terex

Terex Genie GR -15 Operator's manual