TBEI CRYSTEEL'S User manual

1309630B 2013-12-101

TAILGATE

SPREADER

CRYSTEEL’S

Web Site E-Mail Phone (507) 726-2728

Website: www.TBEI.com

E-mail: [email protected]

this manual must be included with the vehicle

after completing the installation.

1309630B 2013-12-102

DATE PURCHASED __________________________________________________________________

SPREADER SERIAL NUMBER ______________________________________________________

DEALER __________________________________________________________________

ADDRESS __________________________________________________________________

PHONE __________________________________________________________________

FOREWORD

This tailgate spreader is designed to fit 96 inch wide dump bodies. It is available in six configurations to

match the desired sand or salt delivery rate and the body design.

This manual contains information for mounting the tailgate spreader on a dump body. Study it carefully

before attempting to mount the tailgate spreader. With proper installation, use, and regular maintenance,

the tailgate spreader will give many years of trouble free service.

When ordering parts, be sure to give the serial number of the tailgate spreader. The seri-

al number of the spreader is stamped into the right end (passenger side) panel near the au-

ger drive motor. For future reference, record this number NOW in the space provid-

ed above. Order parts by number and description as given in the parts listing in this manual.

1309630B 2013-12-103

TABLE OF CONTENTS

FOREWORD 2

SAFETY PRECAUTIONS 4

SPECIFICATIONS 4

SAFETY DECAL LOCATIONS 5

ASSEMBLE SPREADER MOUNTS 7

LOCATE SPREADER 7

LOCATE SPREADER MOUNTS 8

ASSEMBLE SUPPORT STRAPS 9

1309630B 2013-12-104

1. Improper use or maintenance of this equipment can cause serious injury. To reduce this

possiblity, know how this equipment works, how to maintain it and, when using it, give it

complete and undivided attention.

saFEty pREcautiOns

2. Learn the controls, know how to control this equipment quickly in an emergency.

3. Operate this equipment safely. Keep all individuals not involved in the operation of this

equipment a safe distance away.

4. Allow only trained personnel to operate this equipment.

5. Always wear relatively tight fitting and belted clothing when operating or maintaining

this equipment. Loose fitting jackets, shirts or other baggy clothing can become caught in

moving parts or on controls.

6. Shut off all controls for this equipment before starting the engine so equipment will not

start when the engine is started.

7. Shut off all controls for this equipment and the truck engine before performing any clean-

ing, maintenance or when storing the equipment.

8. Always check the area around the truck to make sure it is clear before operating this equip-

ment.

9. When leaving the truck unattended, take steps to secure the truck from untrained operators

or unintended movement. Shut off all hydraulic controls, the engine, set the parking brake

and remove the key.

10. Before storing this equipment, be sure to release any trapped hydraulic pressure.

11. Replace any damaged or unreadable safety decals. Place them as shown in Fig. 1 on page

5.

spEciFicatiOns

1. Operating Pressure 1500 PSI Maximum

2. Auger Flow Rate 0-14 GPM

3. Spinner Flow Rate 0-7 GPM

5. Auger

6” 6” Diameter, 4” Pitch, 3/8” AR Flighting

9” 9” Diameter, 6” Pitch, 3/8” AR Flighting

6. Materials Trough - 201 Stainless Steel

Spinner Mount - 201 Stainless Steel

Auger - Steel

4. Hydraulics Fluid - ISO 32 Hydraulic Fluid or Dexron III

Filtration - 10 micron Return Line

1309630B 2013-12-105

saFEty DEcal lOcatiOns

One on each end

of the spreader.

P/N 1309633

P/N 1309633

!! !!

CAUTION

1. OPERATE THIS EQUIPMENT

ONLY FROM A SAFE

LOCATION.

2. KEEP HANDS, FEET AND

CLOTHING AWAY FROM

MOVING PARTS.

3. SET PARKING BRAKE ON

VEHICLE AND SHUT OFF ALL

POWER TO THIS EQUIPMENT

BEFORE SERVICING OR

CLEANING.

4. SECURELY SUPPORT THIS

EQUIPMENT WHEN MOUNTING,

DIS-MOUNTING OR STORING.

On spreader

clean-out door,

above spinner.

P/N 1309632

P/N 1309632

!! !!

DANGER

BEWARE

OF

FLYING

OBJECTS

On rear frame of spreader,

one on each side.

P/N 1309631

DANGER

SHUT OFF ALL POWER

BEFORE CLEANING OR

SERVICING

P/N 1309631

Fig. 1

1309630B 2013-12-106

installatiOn instRuctiOns

GEnERal inFORMatiOn

It is a good idea to look through these installation instructions before beginning to mount the hoist and

hydraulic system.

When welding, protect the truck’s electrical, air and brake systems by disconnecting, removing or cover-

ing. Tighten all nuts and bolts to a consistent level. Use the following table for torque values.

Size Grade 2 Torque Grade 5 Torque Grade 8 Torque

1/4-20 3-4 lb-ft 6-7 lb-ft 10-11 lb-ft

1/4-28 4-5 lb-ft 8-9 lb-ft 11-12 lb-ft

5/16-18 8-9 lb-ft 14-15 lb-ft 21-22 lb-ft

5/16-24 9-10 lb-ft 15-16 lb-ft 21-22 lb-ft

3/8-16 17-18 lb-ft 24-26 lb-ft 37-40 lb-ft

3/8-24 19-20 lb-ft 28-30 lb-ft 40-43 lb-ft

1/2-13 38-42 lb-ft 60-65 lb-ft 90-100 lb-ft

1/2-20 43-47 lb-ft 70-75 lb-ft 95-105 lb-ft

5/8-11 75-80 lb-ft 122-130 lb-ft 180-190 lb-ft

5/8-18 85-90 lb-ft 145-150 lb-ft 200-210 lb-ft

3/4-10 132-140 lb-ft 220-230 lb-ft 315-330 lb-ft

3/4-16 152-160 lb-ft 250-260 lb-ft 355-370 lb-ft

The following abbreviations are used in describing hydraulic fittings.

ORBM O-Ring Boss - Male Thread

NPTM Pipe - Male Thread

NPTF Pipe - Female Thread

JICM JIC 37° - Male Thread

JICF JIC 37° - Female Thread

1309630B 2013-12-107

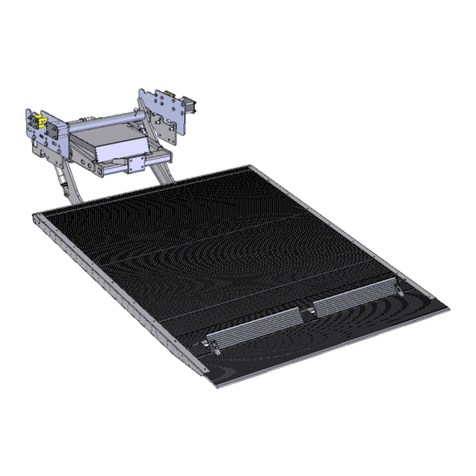

lOcatE spREaDER

The front of the spreader is designed to fit against the rear crossmember of the body, under the floor. Using

a spreader chain connected at the lift points of the spreader and an overhead hoist, position the spreader

against the back of the dump body under the tailgate as shown in Fig. 3.

Assemble the spreader mounts as shown in Fig. 2. These will be used to attach the spreader to the

body.

assEMblE spREaDER MOunts

Fig. 2

USE ON DRIVER’S SIDE USE ON PASSENGER’S SIDE

LIFT POINT

Fig. 3

1/4” BELOW

TAILGATE

1309630B 2013-12-108

lOcatE spREaDER MOunts

Locate the spreader mounting brackets to the outside of the spreader and to the outside of the rear corner

posts of the dump body as shown in Fig. 4. Clamp them in place.

Fig. 4

Depending on the overall widths of the body and spreader, it might be necessary to put shims under the

spreader mounts. If needed, install these shims before welding the spreader mounts to the body and to the

spreader. Weld the mounts to the body and to the spreader as shown in Fig. 5.

WELDWELD

Fig. 5

1309630B 2013-12-109

assEMblE suppORt stRaps

Assemble the two studs, two hairpins to each support strap as shown in Fig. 5.

Fig. 5

Place one assembled strap on each side of the dump body approximately as shown in Fig. 6A. Tack weld

the studs to the body and to the spreader. Remove the hairpins and straps and fully weld the studs to the

body and to the spreader. (See Fig. 6B.) Reinstall the straps and hairpins. Remove the spreader chains.

Fig. 6A Fig. 6B

Weld

Strap

Stud

Hairpin

1309630B 2013-12-1010

ITEM DESCRIPTION MODEL NUMBER QTY

1. SHIELD AUGER - 6” 6” 1283137 1

SHIELD AUGER - 9” 9” 1283155 1

2. HEX HD SCREW 5/16-18 X 3/4 SS ALL 1644455 2

3. HEX NUT 5/16-18 SS ALL 1620499 2

6

31

32

1

2

345

6

7

9

10

11

21

28

27

30

26 25

22

24

23

8

14

15

20

19

18

16

17

20

5A

12

13

29

1309630B 2013-12-1011

ITEM DESCRIPTION MODEL NUMBER QTY

4. AUGER - 6” 6” 1385860 1

AUGER - 9” 9” 1361368 1

5. ASSY TROUGH - SPREADER 6” STD 6” STD 1362531 1

ASSY TROUGH - SPREADER 9” 9” STD 1361365 1

5A. ASSY TROUGH - SPREADER 6” SLDR 6” HIGH 1385863 1

ASSY TROUGH - SPREADER 9” SLDR 9 ” HIGH 1362528 1

6. HEX NUT 1/2-13 SS ALL 1644893 6

7. HYDRAULIC MOTOR - 23.8 CID FORCE FH 6” STD 1294382 1

HYDRAULIC MOTOR - 45.6 CID WHITE RE 6” SALT & 9” 1294381 1

8. PLATE AUGER MOTOR MOUNT - 23.8 CID MOTOR ALL 1265580 1

9. PAD AUGER MOTOR MOUNT ALL 1645207 1

10. HEX HD SCREW 1/2-13 X 2 1/2 SS ALL 1644891 4

11. ASSY TROUGH BOTTOM - SPREADER - 6” 6” 1362533 1

ASSY TROUGH BOTTOM - SPREADER - 9” 9” 1361372 1

12. CLEVIS PIN 5/8 X 1 1/2 SS ALL 1645064 2

13. COTTER PIN 5/32 X 1 1/4 SS ALL 1361369 2

14. STUD SPREADER SUPPORT STD 1258144 4

STUD SPREADER SUPPORT - LONG HIGH 1260744 2

15. STRAP SPREADER SUPPORT STD 1258154 2

16. ASSY SPREADER MOUNT - SPREADER ALL 1283157 2

17. HAIR PIN #11 ALL 1620139 2

18. ASSY SPREADER MOUNT - BODY ALL 1258152 2

19. PULL PIN - SPREADER MOUNT ALL 1258156 2

20. HAIR PIN #11 ALL 1620139 8

21. SHAFT SPINNER HANGER ALL 1234297 1

22. ASSY SPINNER MOUNT ALL 1361375 1

23. HYDRAULIC MOTOR - 2.8 CID EATON H ALL 1361371 1

24. LOCK WASHER 3/8 SS ALL 1644119 4

25. HEX HEAD SCREW 3/8-16 X 3/4 SS ALL 1361373 4

26. HEX NUT 3/8-16 SS ALL 1643589 4

27. FLAT WASHER 3/8 SS ALL 1644118 4

28. HEX HEAD SCREW 3/8-13 X 1 1/2 SS ALL 1645094 4

29. SPINNER HUB ALL 1645157 1

30. SPINNER - 18” POLY ALL 1645158 1

31. HEX HEAD SCREW 1/2-13 X 1 1/2 SS ALL 1645009 2

32. BEARING 2-BOLT 1.250 ALL 1645153 1

1309630B 2013-12-1012

CRYSTEEL MANUFACTURING, INC.

P/N 1309633

!! !!

CAUTION

1. OPERATE THIS EQUIPMENT

ONLY FROM A SAFE

LOCATION.

2. KEEP HANDS, FEET AND

CLOTHING AWAY FROM

MOVING PARTS.

3. SET PARKING BRAKE ON

VEHICLE AND SHUT OFF ALL

POWER TO THIS EQUIPMENT

BEFORE SERVICING OR

CLEANING.

4. SECURELY SUPPORT THIS

EQUIPMENT WHEN MOUNTING,

DIS-MOUNTING OR STORING.

cRystEEl ManuFactuRinG’s

5 yEaR custOMER satisFactiOn plEDGE

& WaRRanty

Crysteel offers the most comprehensive warranty in the truck equip-

ment industry. Crysteel warrants each product against defects in mate-

rial and workmanship for 60 months from the in-service date.

For the full Customer Satisfaction Pledge and Warranty information,

please visit our website.

http://www.crysteel.com

Table of contents

Other TBEI Lifting System manuals

Popular Lifting System manuals by other brands

Jacka Industries

Jacka Industries JackaJay user guide

Christie

Christie WCLW18TE Operator's instruction manual

Tommy Gate

Tommy Gate G2 dual drive G-330 Mounting instructions

TESA

TESA Auto lift system Installation & operation manual

Nussbaum

Nussbaum 4.55 SL Operating Instruction and Documentation

Hailo

Hailo 1-2-3 500 Assembly instructions